Coral Industries 8023 User Manual

8023-GP

Swing Door with In-Line Panel and

End Return Step-Up Panel

Technical Assistance is available Monday - Friday, 8:00 a.m. - 5:00 p.m. (Central Time)

1-877-723-7190 (Toll Free)

8023-GP 5/06

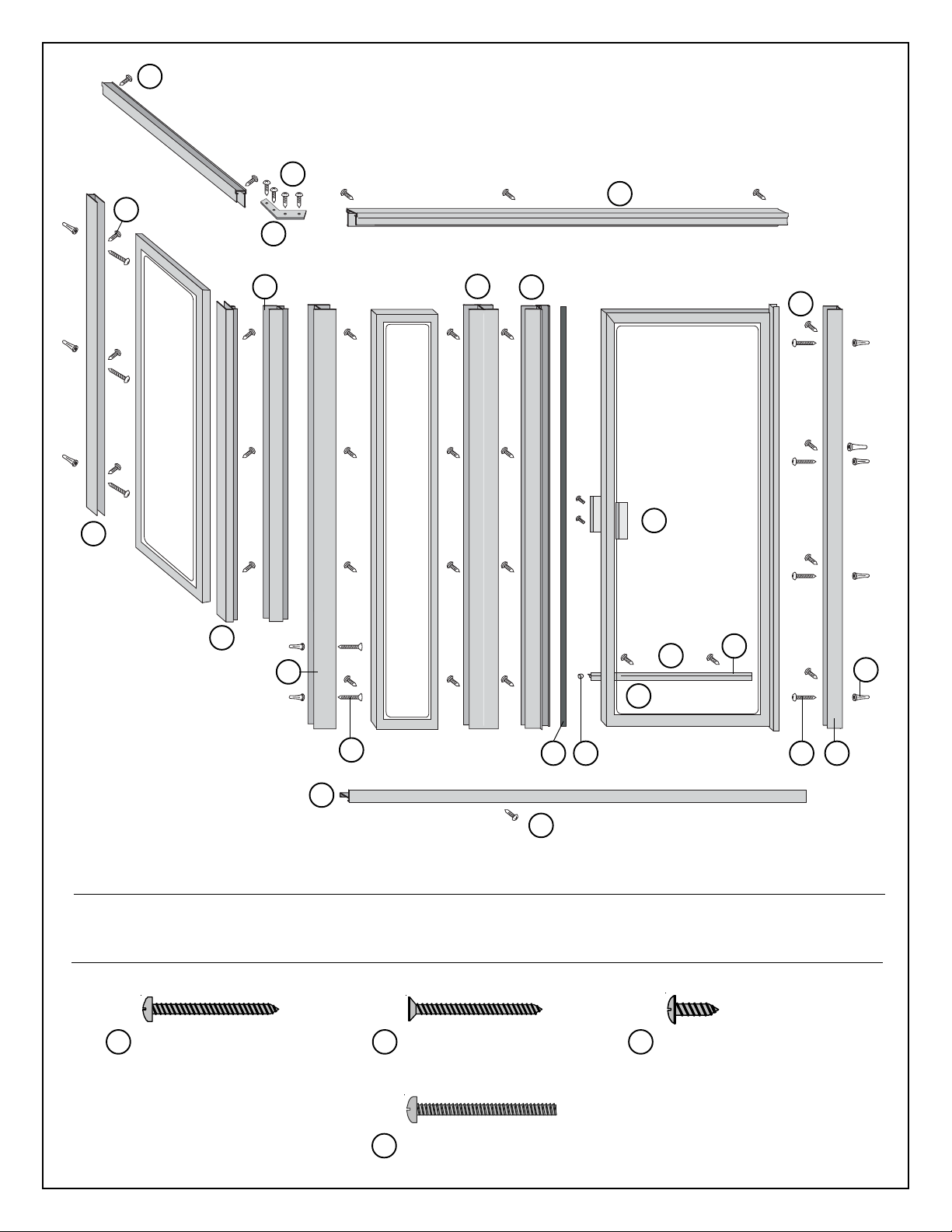

PARTS LIST

FRAME PACKAGE

KEY DESCRIPTION PART QTY

A SILL A855 1

B JAMB A908 2

C BUTTRESS JAMB A942 1

D HEADER A101 2

E DRIP RAIL A710 1

F CORNER POST A929 1

G MAGNETIC DOOR STOP A954 1

H DRIP RAIL TAPE (I) HT52 1

I DRIP RAIL VINYL SWEEP VS91 1

J MAGNETIC STRIP H170 1

K EXPANDER A909 1

L DOUBLE CHANNEL A911 1

HARDWARE BAG

R DRIP RAIL PLUG HA28 1

M ANCHOR H002 10

N 8A X 1 1/4 FLAT HEAD SCREW H810 2

O 8A X 1 1/4 PAN HEAD SCREW H480 8

P 8A X 3/8 TRUSS HEAD SCREW H470 36

Q ALUMINUM GUSSET AG90 1

Z** PULL HANDLE KIT ** HSAD 1

EXTERIOR PULL HANDLE HA31 1

INTERIOR PULL HANDLE HA32 1

6-32 X 1 1/4 PAN HEAD SCREW H485 2

(l) Pre-Installed ** May be Pre-Installed

TOOLS

NEEDED

1/8" Drill Bit

3/16" Drill Bit

(3/16" Masonry Bit for

Ceramic Tile)

Pencil

Measuring Tape

Hacksaw

Phillips Screw Driver

Silicone Caulk

File

Drill

Level

Masking Tape

Before starting installation of your new enclosure, carefully read all instructions

and lay out parts to become familiar with their identity. Installation is a manageable task for an

experienced "Do-It-Yourselfer" and a helper.

USE OF ANCHORS

Anchors are furnished with every enclosure. However, the use of anchors is not recommended when attaching your enclosure

to a fiberglass unit or wall surrounds with board reinforced mounting areas. Mounting holes in this case should be drilled with

an 1/8" drill bit.

Mounting of this unit on tile requires the use of anchors. Special care must be taken not to crack the tile. Before drilling holes

in the tile, lightly chip glazed surface of tile at the desired locations. Drill holes using a 3/16" masonry drill bit. Insert anchors

into the holes making certain that ring on large end of anchor meets the surface of the tile.

CLEANING

Cleaning and care of your enclosure is important to its lasting beauty. We suggest using a nonabrasive liquid cleaner.

Never use scouring powder or pads.

SEALING

The use of a caulking compound can assure a water-tight seal when applied along outside edge of the enclosure where metal

and bath meet. If desired, caulk inside of enclosure where jambs meet walls.

Do not try to cut the mirrors or glass used in this enclosure.

Tempered glass and mirrors will disintegrate if cut.

8023-GP 5/06

H470 TRUSS

HEAD SCREW

P

C

A942

BUTTRESS

JAMB

H470 TRUSS

P

HEAD SCREW

A929

CORNER

POST

AG90

ALUMINUM

GUSSET

F

A908

JAMB

H470 TRUSS

HEAD SCREW

P

Q

A909

K

EXPANDER

B

DOUBLE CHANNEL

A911

A954

MAGNETIC

DOOR STOP

GL

A101

HEADER

D

HSAD

PULL HANDLE

KIT**

Z

A710

DRIP

RAIL

E

VS91

I

DRIP RAIL VINYL

TRUSS HEAD

HT52

DRIP

RAIL

TAPE

H

H470

SCREW

P

H002

ANCHOR

M

A855

SILL

H810

A

FLAT HEAD SCREW

N

MAGNETIC STRIP

H170

OUTSIDE OF SHOWER

J

P

DRIP RAIL PLUG

H470

TRUSS HEAD SCREW

HA28

R

H480

PAN HEAD

SCREW

** May be Pre-Installed

O

B

A908

JAMB

Before beginning installation of this enclosure, make certain that joint between tub and shower along top of threshold

is caulked (under location of sill).

8A x 1 1/4 Pan Head Screw

O

(H480 - Used for Jambs)

8A x 1 1/4 Flat Head Screw

N

(H810 - Used for Jamb)

6-32 x 1 1/4 Pan Head Screw **

Z

(H485 - Used for Pull Handle)

8A x 3/8 Truss Head Screw

P

(H470 - Used for Header, Jambs

to Panels, Door Stops to Panels

and to Attach Drip Rail)

8023-GP 5/06

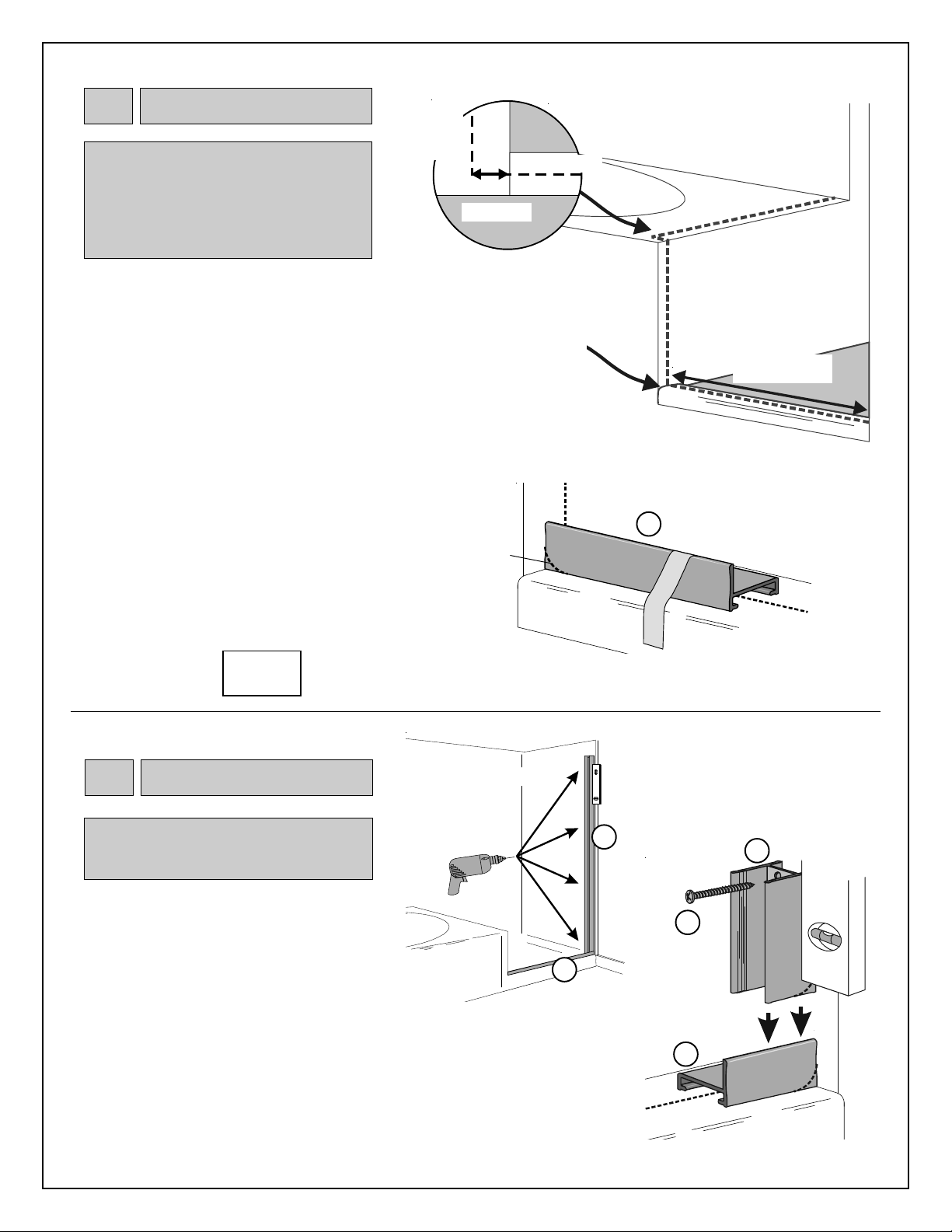

1

Sill (A)

Due to the manufacturing process, there

may be rack marks present at one end of

your sill or header. Sill and header must be

trimmed to fit your individual opening. When

cutting sill and header, make certain to

trim off end with rack marks.

The ideal location for the door sill is

straddling the centerline of the threshold

curb of your base. Locate centerline on

threshold curb and mark using a china

marker. Continue to mark centerline up side

of buttress wall using level to make certain

line is straight and plumb. At top surface of

buttress, continue centerline straight across

(as drawn on threshold curb) for 1 1/16”. At

1 1/16”, turn line to be parallel with buttress

edge as shown.

Measure opening (centerline) on threshold

curb of base and record measurement in

“Sill Cut Length” box below for later use. Cut

sill (A) to that measurement. If necessary,

file sharp corner to fit contour of your unit.

Place sill on threshold straddling centerline,

with tall edge toward outside of shower.

Tape sill to threshold with masking tape to

hold in place while positioning jambs.

Top Surface

of Buttress

If necessary,

corners to fit

OVERHEAD VIEW

Threshold Curb

1 1/16"

Make certain caulk is applied along

joint between top of threshold and

buttress wall (under sill).

Threshold Curb

Buttress Wall

file sharp

contour of

unit.

Threshold Curb

A

Wall

Buttress

Wall

Mark and

Measure Centerline

OUTSIDE OF SHOWER

Sill

Centerline

Sill Cut Length

2

Jamb (B)

When anchors (M) are used holes should

be drilled using 3/16" drill bit. (Use masonry

bit for tile.)

Position one long jamb (B) against wall with

bottom resting on sill.

Align jamb vertically using a level. Holding

jamb securely against wall, drill 4 mounting

holes through jamb into wall using 1/8" drill

bit.

Mount jamb to wall using 8A x 1 1/4” pan

head screws (O).

Drill through

jamb into wall.

OUTSIDE OF SHOWER

OUTSIDE OF SHOWER

Level

Jamb

B

A

Sill

O

8A x 1 1/4”

Pan Head

Screw

Sill

A

Jamb

B

Level

8023-GP 5/06

OUTSIDE OF SHOWER

Loading...

Loading...