Coral Industries 5PJ User Manual

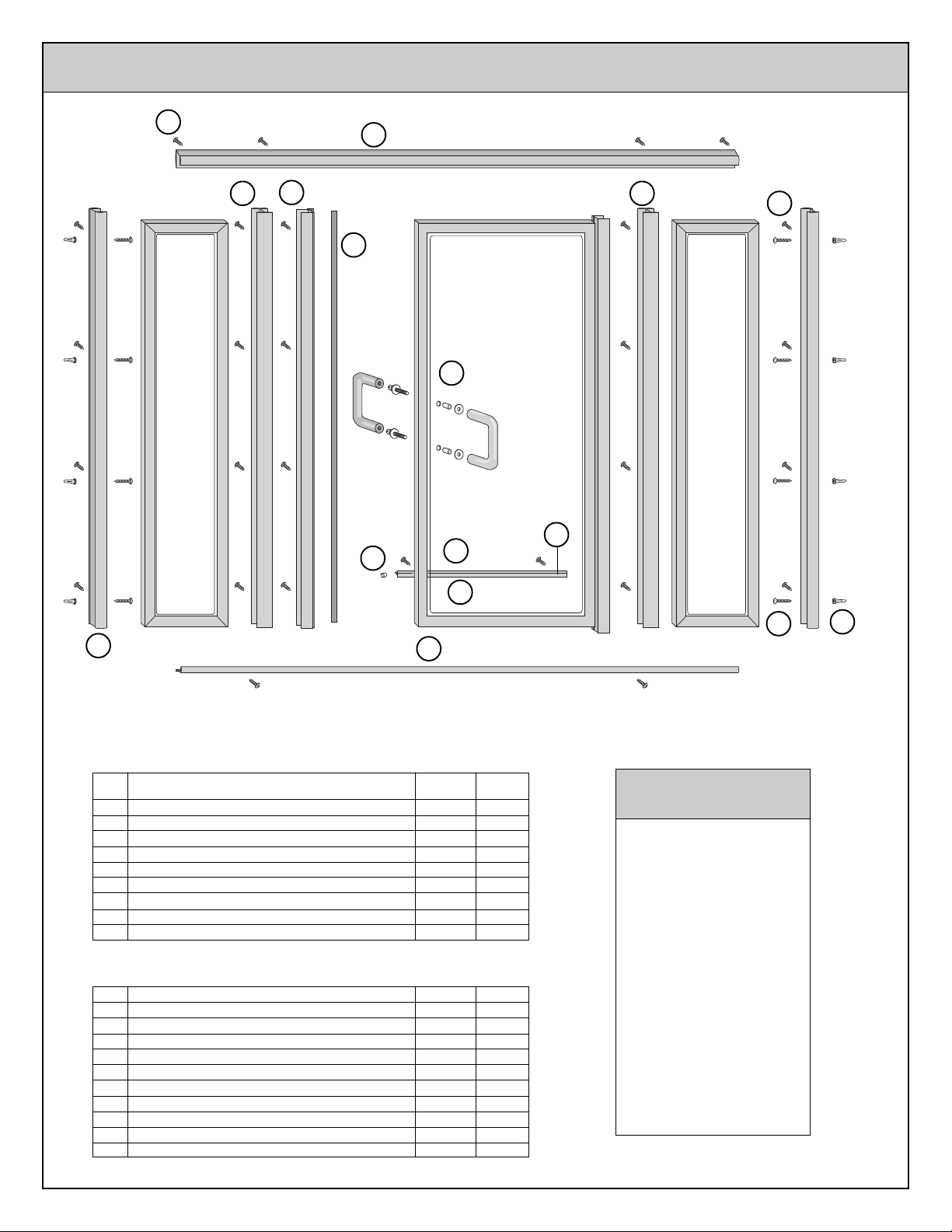

5PJ

H470

TRUSS

HEAD SCREW

DOUBLE CHANNEL

B

A682

JAMB

J

A685

D

A681

E

MAGNETIC DOOR STOP

C

A688

HEADER

DOUBLE CHANNEL

A685

D

TRUSS HEAD

H470

SCREW

J

G

H170

MAGNETIC

STRIP

INTERIOR

HANDLE

HA28

DRIP

RAIL

PLUG

P

OUTSIDE OF SHOWER

A

PULL

L

HANDLE KIT

A710

DRIP

F

RAIL

VS91 DRIP

N

RAIL SWEEP

A689

SILL

EXTERIOR

HANDLE

HT52

DRIP RAIL

TAPE

M

I

H476

PAN HEAD

SCREW

H

H002

ANCHOR

FRAME PACKAGE

KEY DESCRIPTION PART QTY

A SILL A689 1

B JAMB A682 2

C HEADER A688 1

D DOUBLE CHANNEL A685 2

E MAGNETIC DOOR STOP A681 1

F DRIP RAIL A710 1

G MAGNETIC STRIP H170 1

M DRIP RAIL TAPE

N DRIP RAIL SWEEP VS91 1

*

HT52 1

HARDW ARE BAG PARTS

P DRIP RAIL PLUG HA28 1

H ANCHOR H002 8

I 8A X 1 PAN HEAD SCREW H476 8

J 8A X 3/8 TRUSS HEAD SCREW H470 24

K ALLEN WRENCH 1

L PUSH / PULL HANDLE KIT HTG6 1

PLASTIC WASHER 4

EXTERIOR PULL HANDLE 1

INTERIOR PULL HANDLE 1

BUSHING 2

HANDLE CONNECTOR SCREW 2

* Pre-Installed

TOOLS NEEDED

1/8" Drill Bit

3/16" Drill Bit

(3/16" Masonry Bit for

Ceramic Tile)

Scratch Awl

Measuring Tape

Hacksaw

Phillips Screw Driver

Caulking Compound

File

Drill

Level

Masking Tape

5PJ 8/02

INSTALLATION INSTRUCTIONS

Before starting installation of your new enclosure, carefully read all

instructions and lay out parts to become familiar with their identity.

USE OF ANCHORS

Anchors are furnished with every enclosure. However, the use of anchors is not recommended when attaching your enclosure to a fiberglass

unit or wall surrounds with board reinforced mounting areas. Mounting holes in this case should be drilled with a 1/8" drill bit.

Mounting of this unit on tile requires the use of anchors. Special care must be taken not to crack the tile. Before drilling holes in the tile, lightly

chip glazed surface of tile at the desired locations. Drill holes using a 3/16" masonry drill bit. Insert anchors into the holes making certain

that ring on large end of anchor meets the surface of the tile.

CLEANING

Cleaning and care of your enclosure is important to its lasting beauty. We suggest using a nonabrasive liquid cleaner.

Never use scouring powder or pads.

SEALING

The use of a caulking compound can assure a watertight seal when applied along outside edge of the enclosure where metal and bath meet. If

desired, caulk inside of enclosure where jambs meet walls.

Do not try to cut the mirrors or glass used in this enclosure. • Tempered glass and mirrors will disintegrate if cut.

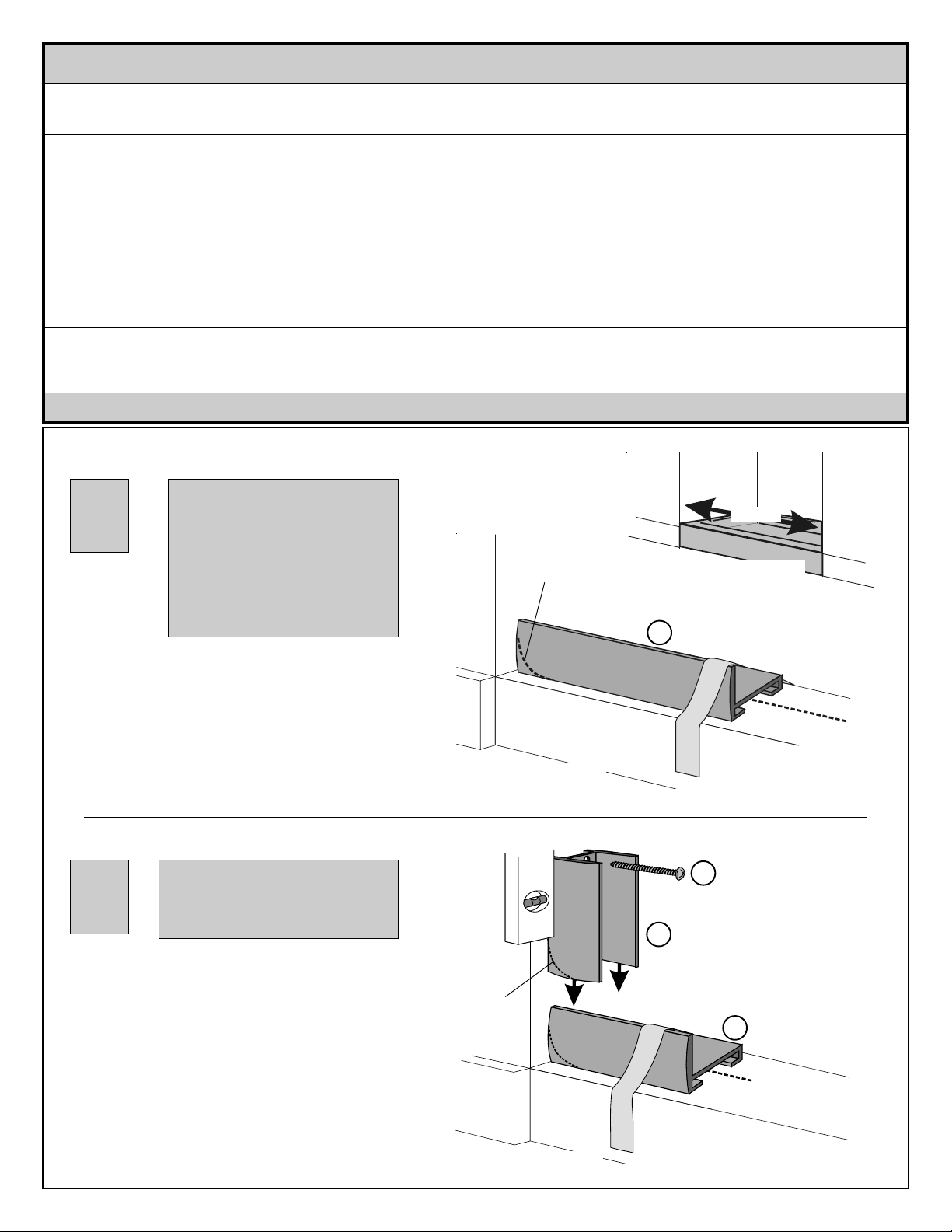

Due to the manufacturing

1

process, there may be rack

marks present at one end of

your sill and header. All sills

and headers must be trimmed

to fit individual openings. When

cutting sill and header, make

certain to trim off end with rack

marks.

File sharp corners of

sill as necessary to fit

contour of your unit

Sill

OUTSIDE OF SHOWER

A

Measure

Measure opening at threshold of shower and cut

sill (A) to that measurement. If necessary, file

sharp corners of sill to fit contour of your unit.

Position sill on center of threshold with tall edge of

sill toward outside of shower. Tape sill to threshold

with masking tape to hold in place while positioning

jambs.

When anchors (H) are used,

holes should be drilled using

2

Place jamb (B) on sill with short legs against wall.

If necessary, file sharp corners on back of jamb to

fit contour of your unit.

Align jamb vertically using a level and mark wall

through prepunched holes. Remove jamb and drill

where marked using 1/8" drill bit. Repeat for

remaining jamb on opposite side.

3/16" drill bit. (Use masonry

bit for tile.)

OUTSIDE OF SHOWER

Contour as

needed

Level

Threshold

B

Jamb

Masking

Tape

I

Pan Head

8A x 1"

Screw

Sill

A

Centerline

Centerline

Reposition jambs on wall and secure using

8A x 1" pan head screws (I).

5PJ 8/02

OUTSIDE OF SHOWER

Loading...

Loading...