1-Port VNA Series

R54

R140

R60

R180/RP180

Operating Manual

Software version 18.3.0

July 2018

T A B L E O F C O N T E N T S

INTRODUCTION ....................................................................................................................... 8

SAFETY INSTRUCTIONS .......................................................................................................... 9

1. GENERAL OVERVIEW ....................................................................................................... 11

1.1 Description ........................................................................................................................................ 11

1.2 Specifications ................................................................................................................................... 11

1.3 Measurement Capabilities ........................................................................................................... 11

1.4 Principle of Operation .................................................................................................................. 16

2. PREPARATION FOR USE .................................................................................................. 18

2.1 General Information ...................................................................................................................... 18

2.2 Software Installation ..................................................................................................................... 20

2.3 Top Panel ........................................................................................................................................... 20

2.4 Test Port ............................................................................................................................................. 23

2.5 Mini B USB Port ............................................................................................................................... 23

2.6 External Trigger Signal Input Connector (R140 model only) ........................................ 24

2.7 External Reference Frequency Input Connector (R140 model only) .......................... 24

2.8 Reference Frequency Input/Output Connector (R60 and R180 model

only) 24

2.9 External Trigger Signal Input/Output Connector (R60 and R180 model

only) 25

3. GETTING STARTED .......................................................................................................... 26

3.1 Analyzer Preparation for Reflection Measurement ........................................................... 27

3.2 Analyzer Presetting ........................................................................................................................ 27

3.3 Stimulus Setting .............................................................................................................................. 28

3.4 IF Bandwidth Setting .................................................................................................................... 29

3.5 Number of Traces, Measured Parameter and Display Format Setting ...................... 30

3.6 Trace Scale Setting ........................................................................................................................ 31

3.7 Analyzer Calibration for Reflection Coefficient Measurement ..................................... 31

3.8 SWR and Reflection Coefficient Phase Analysis Using Markers .................................. 34

4. MEASUREMENT CONDITIONS SETTING ......................................................................... 36

4.1 Screen Layout and Functions ..................................................................................................... 36

4.1.1 Left and Right Softkey Menu Bars .................................................................................... 36

4.1.2 Top Menu Bar ........................................................................................................................... 37

4.1.3 Instrument Status Bar ........................................................................................................... 40

4.2 Channel Window Layout and Functions ................................................................................ 42

4.2.1 Channel Title Bar .................................................................................................................... 43

4.2.2 Trace Status Field ................................................................................................................... 43

4.2.3 Graph Area ................................................................................................................................. 46

4.2.4 Markers ........................................................................................................................................ 47

4.2.5 Channel Status Bar ................................................................................................................. 48

4.3 Quick Channel Setting Using Mouse....................................................................................... 49

4.3.1 Active Channel Selection ..................................................................................................... 49

2

4.3.2 Active Trace Selection .......................................................................................................... 50

4.3.3 Display Format Setting ......................................................................................................... 50

4.3.4 Trace Scale Setting................................................................................................................. 50

4.3.5 Reference Level Setting ....................................................................................................... 51

4.3.6 Marker Stimulus Value Setting .......................................................................................... 52

4.3.7 Switching between Start/Center and Stop/Span Modes ......................................... 52

4.3.8 Start/Center Value Setting .................................................................................................. 53

4.3.9 Stop/Span Value Setting ...................................................................................................... 53

4.3.10 Sweep Points Number Setting ........................................................................................ 54

4.3.11 IF Bandwidth Setting .......................................................................................................... 54

4.3.12 Power Level Setting ............................................................................................................ 55

4.4 Channel and Trace Display Setting ......................................................................................... 55

4.4.1 Setting the Number of Channel Windows ..................................................................... 55

4.4.2 Channel Activating ................................................................................................................. 56

4.4.3 Active Channel Window Maximizing ............................................................................... 57

4.4.4 Number of Traces Setting .................................................................................................... 58

4.4.5 Active Trace Selection .......................................................................................................... 59

4.5 Measurement Parameters Setting ............................................................................................ 62

4.5.1 S-Parameters............................................................................................................................. 62

4.5.2 Trace Format ............................................................................................................................. 62

4.5.3 Rectangular Format ............................................................................................................... 63

4.5.4 Polar Format ............................................................................................................................. 65

4.5.5 Smith Chart Format ................................................................................................................ 66

4.5.6 Data Format Setting ............................................................................................................... 68

4.6 Trigger Setting ................................................................................................................................. 69

4.6.1 External Trigger (except R54) ............................................................................................ 71

4.6.1.1 Point Feature ..................................................................................................................... 71

4.6.1.2 External Trigger Polarity .............................................................................................. 71

4.6.1.3 External Trigger Position ............................................................................................. 72

4.6.1.4 External Trigger Delay .................................................................................................. 73

4.6.2 Trigger Output (except R54/R140) .................................................................................. 76

4.6.2.1 Switching ON/OFF Trigger Output ........................................................................... 77

4.6.2.2 Trigger Output Polarity ................................................................................................. 78

4.6.2.3 Trigger Output Function ............................................................................................... 79

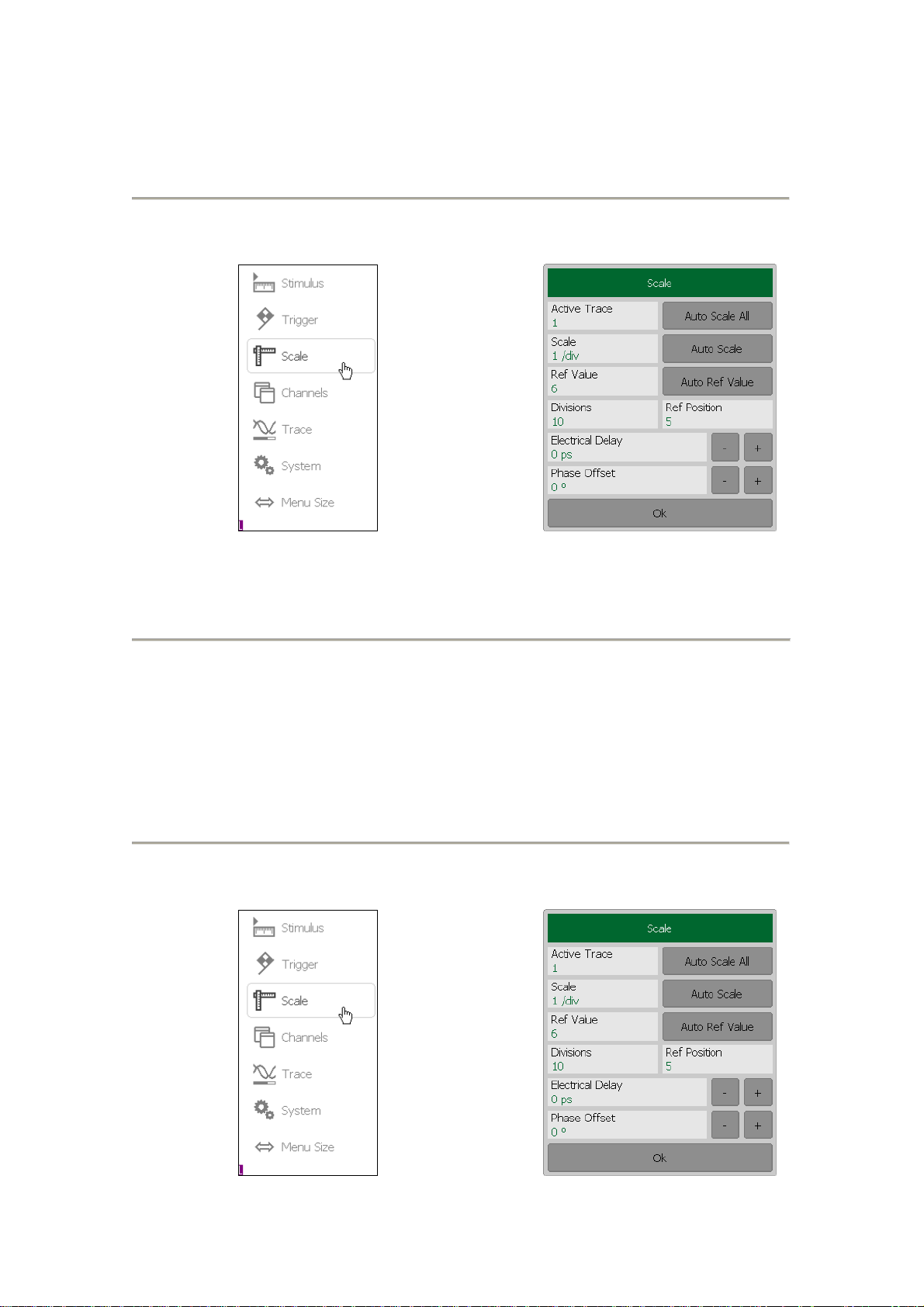

4.7 Scale Setting ..................................................................................................................................... 80

4.7.1 Rectangular Scale ................................................................................................................... 80

4.7.2 Rectangular Scale Setting ................................................................................................... 80

4.7.3 Circular Scale ............................................................................................................................ 81

4.7.4 Circular Scale Setting ............................................................................................................ 81

4.7.5 Automatic Scaling ................................................................................................................... 82

4.7.6 Reference Level Automatic Selection ............................................................................. 83

4.7.7 Electrical Delay Setting ........................................................................................................ 83

4.7.8 Phase Offset Setting .............................................................................................................. 84

4.8 Stimulus Setting .............................................................................................................................. 86

4.8.1 Sweep Type Setting ............................................................................................................... 86

4.8.2 Sweep Span Setting ............................................................................................................... 86

3

4.8.3 Sweep Points Setting ............................................................................................................ 87

4.8.4 Stimulus Power Setting ........................................................................................................ 88

4.8.5 Segment Table Editing ......................................................................................................... 88

4.9 Trigger Setting ................................................................................................................................. 91

4.10 Measurement Optimizing ......................................................................................................... 92

4.10.1 IF Bandwidth Setting .......................................................................................................... 92

4.10.2 Averaging Setting ................................................................................................................. 92

4.10.3 Smoothing Setting ............................................................................................................... 93

4.10.4 Trace Hold Function ............................................................................................................ 95

4.11 Cable Specifications .................................................................................................................... 96

4.11.1 Selecting the type of cable ............................................................................................... 96

4.11.2 Manually specify Velocity Factor and Cable Loss .................................................... 97

4.11.3 Editing table of cables........................................................................................................ 98

5. CALIBRATION AND CALIBRATION KIT ......................................................................... 100

5.1 General Information .................................................................................................................... 100

5.1.1 Measurement Errors ............................................................................................................. 100

5.1.2 Systematic Errors .................................................................................................................. 100

5.1.2.1 Directivity Error .............................................................................................................. 101

5.1.2.2 Source Match Error ....................................................................................................... 101

5.1.2.3 Reflection Tracking Error ........................................................................................... 101

5.1.3 Error Modeling ....................................................................................................................... 101

5.1.3.1 One-Port Error Model .................................................................................................. 101

5.1.4 Analyzer Test Port Defining .............................................................................................. 102

5.1.5 Calibration Steps ................................................................................................................... 103

5.1.6 Calibration Methods ............................................................................................................. 104

5.1.6.1 Normalization ................................................................................................................. 104

5.1.6.2 Expanded Normalization ............................................................................................ 105

5.1.6.3 Full One-Port Calibration ........................................................................................... 105

5.1.6.4 Waveguide Calibration ................................................................................................ 106

5.1.7 Calibration Standards and Calibration Kits ................................................................ 107

5.1.7.1 Types of Calibration Standards ................................................................................ 107

5.1.7.2 Calibration Standard Model ...................................................................................... 107

5.2 Calibration Procedures ............................................................................................................... 110

5.2.1 Calibration Kit Selection .................................................................................................... 110

5.2.2 Reflection Normalization ................................................................................................... 112

5.2.3 Full One-Port Calibration ................................................................................................... 114

5.2.4 Error Correction Disabling ................................................................................................. 116

5.2.5 Error Correction Status ....................................................................................................... 116

5.2.6 System Impedance Z0 ......................................................................................................... 117

5.2.7 Port Extension ........................................................................................................................ 117

5.2.8 Auto Port Extension ............................................................................................................. 119

5.3 Calibration Kit Management .................................................................................................... 121

5.3.1 Calibration Kit Selection for Editing ............................................................................. 121

5.3.2 Calibration Kit Label Editing ............................................................................................ 121

5.3.3 Predefined Calibration Kit Restoration ........................................................................ 122

4

5.3.4 Calibration Standard Editing ............................................................................................ 124

5.3.5 Calibration Standard Defining by S-Parameter File ................................................ 126

5.4 Automatic Calibration Module ................................................................................................ 128

5.4.1 Automatic Calibration Module Features ...................................................................... 129

5.4.2 Automatic Calibration Procedure ................................................................................... 130

6. MEASUREMENT DATA ANALYSIS ................................................................................. 131

6.1 Markers ............................................................................................................................................. 131

6.1.1 Marker Adding ........................................................................................................................ 132

6.1.2 Marker Deleting ..................................................................................................................... 133

6.1.3 Marker Stimulus Value Setting ........................................................................................ 133

6.1.4 Marker Activating .................................................................................................................. 134

6.1.5 Reference Marker Feature ................................................................................................. 134

6.1.6 Marker Properties .................................................................................................................. 136

6.1.6.1 Marker Coupling Feature ............................................................................................ 136

6.1.6.2 Marker Value Indication Capacity ........................................................................... 138

6.1.6.3 Multi Marker Data Display ......................................................................................... 138

6.1.6.4 Marker Data Alignment ............................................................................................... 139

6.1.6.5 Memory trace value display ...................................................................................... 140

6.1.7 Marker Position Search Functions .................................................................................. 141

6.1.7.1 Search for Maximum and Minimum ....................................................................... 142

6.1.7.2 Search for Peak............................................................................................................... 143

6.1.7.3 Search for Target Level ............................................................................................... 145

6.1.7.4 Search Tracking .............................................................................................................. 147

6.1.7.5 Search Range .................................................................................................................. 147

6.1.8 Marker Math Functions ....................................................................................................... 148

6.1.8.1 Trace Statistics ............................................................................................................... 149

6.1.8.2 Bandwidth Search ......................................................................................................... 151

6.1.8.3 Flatness ............................................................................................................................. 155

6.1.8.4 RF Filter Statistics ......................................................................................................... 157

6.2 Memory Trace Function ............................................................................................................. 160

6.2.1 Saving Trace into Memory ................................................................................................. 161

6.2.2 Memory Trace Deleting ...................................................................................................... 161

6.2.3 Trace Display Setting .......................................................................................................... 162

6.2.4 Memory Trace Math ............................................................................................................. 163

6.3 Fixture Simulation ........................................................................................................................ 164

6.3.1 Port Z Conversion ................................................................................................................. 164

6.3.2 De-embedding ........................................................................................................................ 165

6.3.3 Embedding ............................................................................................................................... 167

6.4 Time Domain Transformation .................................................................................................. 168

6.4.1 Time Domain Transformation Activating .................................................................... 170

6.4.2 Time Domain Transformation Span ............................................................................... 172

6.4.3 Time Domain Transformation Type ............................................................................... 174

6.4.4 Time Domain Transformation Window Shape Setting ........................................... 174

6.4.5 Frequency Harmonic Grid Setting .................................................................................. 175

6.5 Time Domain Gating ................................................................................................................... 177

5

6.5.1 Time Domain Gate Activating .......................................................................................... 178

6.5.2 Time Domain Gate Span..................................................................................................... 178

6.5.3 Time Domain Gate Type ..................................................................................................... 179

6.5.4 Time Domain Gate Shape Setting .................................................................................. 179

6.6 S-Parameter Conversion ............................................................................................................ 180

6.7 Limit Test ......................................................................................................................................... 182

6.7.1 Limit Line Editing ................................................................................................................. 183

6.7.2 Limit Test Enabling/Disabling ......................................................................................... 185

6.7.3 Limit Test Display Management ..................................................................................... 185

6.7.4 Limit Line Offset .................................................................................................................... 186

6.8 Ripple Limit Test........................................................................................................................... 187

6.8.1 Ripple Limit Editing ............................................................................................................. 187

6.8.2 Ripple Limit Enabling/Disabling ..................................................................................... 189

6.8.3 Ripple Limit Test Display Management ....................................................................... 189

7. CABLE LOSS MEASUREMENT ........................................................................................ 191

7.1 Cable Loss Measurement Algorithm ..................................................................................... 191

8. ANALYZER DATA OUTPUT ............................................................................................ 193

8.1 Analyzer State ................................................................................................................................ 193

8.1.1 Analyzer State Saving ......................................................................................................... 193

8.1.2 Analyzer State Recalling .................................................................................................... 195

8.1.3 Autosave and Autorecall State of Analyzer ................................................................ 195

8.2 Channel State ................................................................................................................................. 196

8.2.1 Channel State Saving .......................................................................................................... 196

8.2.2 Channel State Recalling ..................................................................................................... 197

8.3 Trace Data CSV File ..................................................................................................................... 199

8.3.1 CSV File Saving ...................................................................................................................... 199

8.4 Trace Data Touchstone File ...................................................................................................... 201

8.4.1 Touchstone File Saving ...................................................................................................... 202

8.4.2 Touchstone File Recalling ................................................................................................. 203

8.5 Graph Printing ................................................................................................................................ 205

8.5.1 Graph Printing Procedure .................................................................................................. 205

8.5.2 Quick saving program screen shot ................................................................................. 206

9. SYSTEM SETTINGS ......................................................................................................... 207

9.1 Analyzer Presetting ...................................................................................................................... 207

9.2 Program Exit ................................................................................................................................... 207

9.3 Analyzer System Data ................................................................................................................. 208

9.4 System Correction Setting ........................................................................................................ 208

9.5 User Interface Setting ................................................................................................................. 210

10. SPECIFICS OF WORKING WITH TWO OR MORE DEVICES ........................................ 212

10.1 Installation of additional software...................................................................................... 212

10.2 Connecting devices to a USB port ....................................................................................... 212

10.3 Synchronizing the work of analyzers ................................................................................. 212

10.4 Adding / removing devices ..................................................................................................... 214

6

10.5 Frequency adjustment of the internal generators ........................................................ 214

10.5.1 Manual frequency adjustment ....................................................................................... 215

10.5.2 Automatic frequency adjustment ................................................................................. 215

10.6 Features of analyzers calibration ........................................................................................ 216

10.6.1 Calibration Type .................................................................................................................. 217

10.6.2 Scalar Transmission Normalization............................................................................. 218

10.6.3 Expanded Transmission Normalization ..................................................................... 218

10.7 Selection of the measured S-parameters ......................................................................... 221

11. MAINTENANCE AND STORAGE ................................................................................... 222

11.1 Maintenance Procedures ......................................................................................................... 222

11.2 Instrument Cleaning ................................................................................................................. 222

11.3 Factory Calibration .................................................................................................................... 223

11.4 Storage Instructions .................................................................................................................. 223

Appendix 1 .......................................................................................................................... 224

7

INTRODUCTION

This Operating Manual represents design, specifications, overview of functions,

and detailed operation procedure for the Vector Network Analyzer, to ensure

effective and safe use of the technical capabilities of the instrument by the user.

Vector Network Analyzer operation and maintenance should be performed by

qualified engineers with initial experience in operating of microwave circuits and

PC.

The following abbreviations are used in this Manual:

PC – Personal Computer

DUT – Device Under Test

IF – Intermediate Frequency

CW – Continuous Wave

SWR – Standing Wave Ratio

VNA – Vector Network Analyzer

8

SAFETY INSTRUCTIONS

Carefully read through the following safety instructions before putting the

Analyzer into operation. Observe all the precautions and warnings provided in this

Manual for all the phases of operation, service, and repair of the Analyzer.

The VNA must be used only by skilled and specialized staff or thoroughly trained

personnel with the required skills and knowledge of safety precautions.

The Analyzer complies with INSTALLATION CATEGORY I as well as POLLUTION

DEGREE 2 in IEC61010–1.

The Analyzer is a MEASUREMENT CATEGORY I (CAT I) device. Do not use as CAT II,

III, or IV device.

The Analyzer is tested in stand-alone condition or in combination with the

accessories supplied by Copper Mountain Technologies against the requirement of

the standards described in the Declaration of Conformity. If it is used as a system

component, compliance of related regulations and safety requirements are to be

confirmed by the builder of the system.

Never operate the Analyzer in the environment containing inflammable gasses or

fumes.

Operators must not remove the cover or part of the housing. The Analyzer must

not be repaired by the operator. Component replacement or internal adjustment

must be performed by qualified maintenance personnel only.

Electrostatic discharge can damage your Analyzer when connected or

disconnected from the DUT. Static charge can build up on your body and damage

the sensitive circuits of internal components of both the Analyzer and the DUT. To

avoid damage from electric discharge, observe the following:

Always use a desktop anti static mat under the DUT.

Always wear a grounding wrist strap connected to the desktop anti static

mat via daisy-chained 1 MΩ resistor.

Connect the PC and the body of the DUT to protective grounding before

you start operation.

9

SAFETY INSTRUCTIONS

CAUTION

This sign denotes a hazard. It calls attention to a procedure,

practice or condition that, if not correctly performed or adhered

to, could result in damage to or destruction of part or all of the

instrument.

Note

This sign denotes important information. It calls attention to a

procedure, practice, or condition that is essential for the user to

understand.

10

Measured parameters

S

11,

Cable loss.

Number of

measurement

channels

Up to 4 logical channels. Each logical channel is

represented on the screen as an individual channel

window. A logical channel is defined by such stimulus

signal settings as frequency range, number of test points,

etc.

Data traces

Up to 4 data traces can be displayed in each channel

window. A data trace represents one of such parameters

of the DUT as magnitude and phase of S11, DTF, Cable

loss.

Memory traces

Each of the 4 data traces can be saved into memory for

further comparison with the current values.

Data display formats

SWR, Return loss, Cable loss, Phase, Expanded phase,

Smith chart diagram, DTF SWR, DTF Return loss, Group

delay.

Sweep setup features

Sweep type

Linear frequency sweep, logarithmic frequency sweep,

and segment frequency sweep.

Measured points per

sweep

Set by user from 2 to 100,001.

1. GENERAL OVERVIEW

1.1 Description

The VNA is designed for use in the process of development, adjustment and testing of

antenna-feeder devices in industrial and laboratory facilities, as well as in field,

including operation as a component of an automated measurement system. The

Analyzer is designed for operation with external PC, which is not supplied with it.

1.2 Specifications

The specifications of Analyzer model can be found in its corresponding datasheet.

1.3 Measurement Capabilities

11

GENERAL OVERVIEW

Segment sweep

A frequency sweep within several user-defined

segments. Frequency range, number of sweep points, IF

bandwidth and measurement delay should be set for

each segment.

Power settings

Two modes of output power level.

Power levels depending on device.

Sweep trigger

Trigger modes: continuous, single, hold.

Trace display functions

Trace type

Data trace, memory trace.

Trace math

Data trace modification by math operations: addition,

subtraction, multiplication or division of measured

complex values and memory data.

Auto scaling

Automatic selection of scale division and reference level

value to have the trace most effectively displayed.

Electrical delay

Calibration plane moving to compensate for the delay in

the test setup. Compensation for electrical delay in a

DUT during measurements of deviation from linear

phase.

Phase offset

Phase offset defined in degrees.

Accuracy enhancement

Calibration

Calibration of a test setup (which includes the Analyzer

and adapter) significantly increases the accuracy of

measurements. Calibration allows to correct the errors

caused by imperfections in the measurement system:

system directivity, source match, and tracking.

Calibration methods

The following calibration methods are available:

reflection normalization;

full one-port calibration.

Reflection

normalization

The simplest calibration method.

Full one-port

calibration

Method of calibration that ensures high accuracy.

12

GENERAL OVERVIEW

Factory calibration

The factory calibration of the Analyzer allows performing

measurements without additional calibration and

reduces the measurement error after reflection

normalization.

Mechanical

calibration kits

The user can select one of the predefined calibration kits

of various manufacturers or define own calibration kits.

Electronic calibration

modules

Electronic calibration modules manufactured by COPPER

MOUNTAIN TECHNOLOGIES make the Analyzer

calibration faster and easier than traditional mechanical

calibration.

Defining of calibration

standards

Different methods of calibration standard defining are

available:

standard defining by polynomial model;

standard defining by data (S-parameters).

Error correction

interpolation

When the user changes such settings as start/stop

frequencies and number of sweep points, compared to

the settings of calibration, interpolation or extrapolation

of the calibration coefficients will be applied.

Marker functions

Data markers

Up to 16 markers for each trace. A marker indicates

stimulus value and the measured value in a given point

of the trace.

Reference marker

Enables indication of any maker values as relative to the

reference marker.

Marker search

Search for max, min, peak, or target values on a trace.

Marker search

additional features

User-definable search range. Functions of specific

condition tracking or single operation search.

Setting parameters by

markers

Setting of start, stop and center frequencies by the

stimulus value of the marker and setting of reference

level by the response value of the marker.

Marker math functions

Statistics, bandwidth, flatness, RF filter.

13

GENERAL OVERVIEW

Statistics

Calculation and display of mean, standard deviation and

peak-to-peak in a frequency range limited by two

markers on a trace.

Bandwidth

Determines bandwidth between cutoff frequency points

for an active marker or absolute maximum. The

bandwidth value, center frequency, lower frequency,

higher frequency, Q value, and insertion loss are

displayed.

Flatness

Displays gain, slope, and flatness between two markers

on a trace.

RF filter

Displays insertion loss and peak-to-peak ripple of the

passband, and the maximum signal magnitude in the

stopband. The passband and stopband are defined by

two pairs of markers.

Data analysis

Port impedance

conversion

The function of conversion of the S-parameters

measured at 50 Ω port into the values, which could be

determined if measured at a test port with arbitrary

impedance.

De-embedding

The function allows to exclude mathematically the

effect of the fixture circuit connected between the

calibration plane and the DUT from the measurement

result. This circuit should be described by an Sparameter matrix in a Touchstone file.

Embedding

The function allows to simulate mathematically the DUT

parameters after virtual integration of a fixture circuit

between the calibration plane and the DUT. This circuit

should be described by an S-parameter matrix in a

Touchstone file.

S-parameter

conversion

The function allows conversion of the measured Sparameters to the following parameters: reflection

impedance and admittance, transmission impedance and

admittance, and inverse S-parameters.

14

GENERAL OVERVIEW

Time domain

transformation

The function performs data transformation from

frequency domain into response of the DUT to

radiopulse in time domain. Time domain span is set by

the user arbitrarily from zero to maximum, which is

determined by the frequency step. Windows of various

forms allow better tradeoff between resolution and level

of spurious sidelobes.

Time domain gating

The function mathematically removes unwanted

responses in time domain what allows obtaining

frequency response without influence from the fixture

elements. The function applies reverse transformation

back to frequency domain from the user-defined span in

time domain. Gating filter types are: bandpass or notch.

For better tradeoff between gate resolution and level of

spurious sidelobes the following filter shapes are

available: maximum, wide, normal and minimum.

Other features

Analyzer control

Using external personal computer via USB interface.

Familiar graphical

user interface

Graphical user interface based on Windows operating

system ensures fast and easy Analyzer operation by the

user.

The software interface of Analyzers is compatible with

modern tablet PCs and laptops.

Saving trace data

Saving the traces in graphical format and saving the data

in Touchstone and *.csv (comma separated values)

formats on the hard drive are available.

Remote control

COM/DCOM

Remote control via COM/DCOM. COM automation runs

the user program on an Analyzer PC. DCOM automation

runs the user program on a LAN-networked PC.

Automation of the instrument can be achieved in any

COM/DCOM-compatible language or environment,

including Python, C++, C#, VB.NET, LabVIEW, MATLAB,

Octave, VEE, Visual Basic (Excel) and many others.

Socket

Data transfer between the PC user and the computer

that is connected to the device, can be also performed

via Socket (TCP, port 5025).

15

GENERAL OVERVIEW

1.4 Principle of Operation

The Analyzer consists of the Analyzer Unit, some supplementary accessories, and

personal computer (which is not supplied with the package). The Analyzer Unit is

powered and controlled by PC via USB-interface. The block diagram of the Analyzer is

represented in Figure 1.1.

The Analyzer Unit consists of a source oscillator, a local oscillator, a source power

attenuator, a directional coupler and other components which ensure the Analyzer

operation. The test port is the source of the test signal. The incident and reflected

signals from the directional coupler are supplied into the mixers, where they are

converted into IF, and are transferred further to the 2-channel receiver. The 2-channel

receiver, after filtration, digitally encodes the signals and supplies them for further

processing (filtration, phase difference measurement, magnitude measurement) into the

signal processor. The filters for the IF are digital and have passband from 10 Hz to

30(100) kHz. The combination of the assemblies of directional couplers, mixers, and 2channel receiver forms two similar signal receivers.

An external PC controls the operation of the components of the Analyzer. To fulfill the

S-parameter measurement, the Analyzer supplies the source signal of the assigned

frequency from test port to the DUT, then measures magnitude and phase of the signal

reflected by the DUT, and after that compares these results to the magnitude and phase

of the source signal.

16

Figure 1.1The VNA block diagram

17

2. PREPARATION FOR USE

2.1 General Information

Unpack the VNA and other accessories.

Connect the Analyzer to the PC using the USB Cable supplied in the package.

Install the software (supplied on the flash drive) onto your PC. The software

installation procedure is described below.

Warm-up the Analyzer for the time stated in its specifications.

Assemble the test setup using cables, connectors, fixtures, etc, which allow DUT

connection to the Analyzer.

Perform calibration of the Analyzer. Calibration procedure is described in section

5.

18

PREPARATION FOR USE

Attention!

To avoid motherboard damage you must use USB cables

supplied in the package or similar ones according to the

specifications shown in Figure 2.1 and Figure 2.2 (for

R180/RP180 only)

Figure 2.1 USB TYPE C TO C 2.0, 3A

Figure 2.2 USB TYPE C TO USB 2.0 A MALE, 3A

19

PREPARATION FOR USE

Minimal system

requirements for

the PC

WINDOWS 2000/XP/VISTA/7/8

1.5 GHz Processor

2 GB RAM

USB 2.0 High Speed

Flash drive

contents

Setup_RVNA_vX.X.X.exe installer file

(X.X.X – program version number);

Driver folder contains the driver;

Doc folder contains documentation.

Driver installation

Connect the Analyzer to your PC via the supplied USB

cable.

When you connect the Analyzer to the PC for the first time,

Windows will automatically detect the new USB device and

will open the USB driver installation dialog (Windows

2000/XP/VISTA/7/8).

In the USB driver installation dialog, click on Browse and

specify the path to the driver files, which are contained in

the Driver folder on the USB flash drive.

Program and

related files

installation

Run the Setup_RVNA_vX.X.X.exe installer file from the

supplied USB flash drive. Follow the instructions of the

installation wizard.

2.2 Software Installation

The software is installed to the external PC running under Windows operating

system. The Analyzer is connected to the external PC via USB interface.

The supplied USB flash drive contains the following software:

The procedure of the software installation is performed in two steps. The first one

is the driver installation. The second step comprises installation of the program,

documentation and other related files.

2.3 Top Panel

The top panel view of Analyzers is represented in the figures below. The top panel

is equipped with the READY/STANDBY LED indicator running in the following

modes:

20

PREPARATION FOR USE

green blinking light – standby mode. In this mode the current

consumption of the device from the USB port is minimum;

green glowing light – normal device operation.

Figure 2.3 R140 top panel

Figure 2.4 R54 top panel

Figure 2.5 R60 top panel

21

Figure 2.6 R180 top panel

PREPARATION FOR USE

22

PREPARATION FOR USE

2.4 Test Port

The test port (type-N male 50 Ω) is intended for DUT connection. It is also used as

a source of the stimulus signal and as a receiver of the response signal from the

DUT.

2.5 Mini B USB Port

The mini B USB port view is represented in Figure 2.7, Figure 2.8, Figure 2.9 and

Figure 2.10. It is intended for connection to USB port of the personal computer via

the supplied USB cable.

Figure 2.7 Mini B USB port R54

Figure 2.8 Mini B USB port R140

23

Figure 2.9 Mini B USB port R60

PREPARATION FOR USE

Figure 2.10 Mini B USB port R180

2.6 External Trigger Signal Input Connector (R140 model only)

This connector allows the user to connect an external trigger source. Connector

type is SMA female. TTL compatible inputs of 3 V to 5 V magnitude have up to 1

us pulse width. Input impedance is at least 10 kΩ.

2.7 External Reference Frequency Input Connector (R140 model only)

External reference frequency - see in its specifications, input level is 2 dBm ± 2

dB, input impedance at «Ref In» is 50 Ω. Connector type is SMA female.

2.8 Reference Frequency Input/Output Connector (R60 and R180

model only)

External reference frequency is 10 MHz, input level is 2 dBm ± 2 dB, input

impedance is 50 Ohm. Output reference signal level is 3 dBm ± 2 dB into 50 Ohm

impedance. Connector type is SMA female.

24

PREPARATION FOR USE

2.9 External Trigger Signal Input/Output Connector (R60 and R180

model only)

External Trigger Signal Input allows the user to connect an external trigger

source. Connector type is SMA female. 3.3v CMOS TTL compatible inputs

magnitude have at least 1 μs pulse width. Input impedance is at least 10 kOhm.

The External Trigger Signal Output port can be used to provide trigger to an

external device. The port outputs various waveforms depending on the setting of

the Output Trigger Function: before frequency setup pulse, before sampling pulse,

after sampling pulse, ready for external trigger, end of sweep pulse, measurement

sweep.

25

3. GETTING STARTED

This section represents a sample session of the Analyzer. It describes the main

techniques of measurement of reflection coefficient parameters of the DUT. SWR

and reflection coefficient phase of the DUT will be analyzed.

The instrument sends the stimulus to the input of the DUT and then receives the

reflected wave. Generally in the process of this measurement the output of the

DUT should be terminated with a LOAD standard. The results of these

measurements can be represented in various formats. The given example

represents the measurement of SWR and reflection coefficient phase.

Typical circuit of DUT reflection coefficient measurement is shown in Figure 3.1.

Figure 3.1.

To measure SWR and reflection coefficient phases of the DUT in the given

example you should go through the following steps:

Prepare the Analyzer for reflection measurement;

Set stimulus parameters (frequency range, number of sweep points);

Set IF bandwidth;

Set the number of traces to 2, assign measured parameters and display

format to the traces;

Set the scale of the traces;

Perform calibration of the Analyzer for reflection coefficient measurement;

Analyze SWR and reflection coefficient phase using markers.

26

GETTING STARTED

Ready state

features

The bottom line of the screen displays the instrument status

bar. It should read Ready.

Note

You can operate either by the mouse or using a touch screen.

3.1 Analyzer Preparation for Reflection Measurement

Turn on the Analyzer and warm it up for the period of time stated in the

specifications.

Connect the DUT to the test port of the Analyzer. Use the appropriate adapters for

connection of the DUT input to the Analyzer test port. If the DUT input is type-N

(female), you can connect the DUT directly to the port.

3.2 Analyzer Presetting

Before you start the measurement session, it is recommended to reset the

Analyzer into the initial state. The initial condition setting is described in

Appendix 1.

To restore the initial state of the Analyzer use the following softkeys in the right

menu bar System > Preset.

Close the dialog by Ok.

27

GETTING STARTED

3.3 Stimulus Setting

After you have restored the preset state of the Analyzer, the stimulus parameters

will be as follows: full frequency range of the instrument, sweep type is linear,

number of sweep points is 201, power level is high, and IF is 10 kHz.

For the current example, set the frequency range from 100 MHz to 1 GHz.

To set the start frequency of the frequency range to 100 MHz use the following

softkey in the right menu bar Stimulus .

Then select the Start field and enter 100 using the on-screen keypad. Complete

the setting by Ok.

To set the stop frequency of the frequency range to 1 GHz select the Stop field

and enter 1000 using the on-screen keypad. Complete the setting Ok. Close the

Stimulus dialog by Ok.

28

GETTING STARTED

Note

You can also select the IF bandwidth by double clicking on the

required value in the IFBW. The dialog will close automatically.

3.4 IF Bandwidth Setting

For the current example, set the IF bandwidth to 3 kHz.

To set the IF bandwidth to 3 kHz use the following softkey in the left menu bar

Average.

Then select the IFBW field in the Average dialog.

To set the IF bandwidth in the IFBW dialog use the following softkeys 3 kHz > Ok.

29

GETTING STARTED

3.5 Number of Traces, Measured Parameter and Display Format

Setting

In the current example, two traces are used for simultaneous display of the two

parameters (SWR and reflection coefficient phase).

To add the second trace use the following softkeys in the right menu bar Trace >

Add trace.

The added trace automatically becomes active. The active trace is highlighted in

the list and on the graph.

To select the trace display format click on Format.

Set the Phase format by Phase > Ok.

To scroll up and down the formats list click on the list field and drag the mouse

up or down accordingly.

30

GETTING STARTED

Note

To activate a trace use the softkey Active Trace.

To select the first trace display format click on Active Trace and on Format. In the

Format dialog use the following softkeys SWR > Ok.

Close the dialogs by Ok.

3.6 Trace Scale Setting

For a convenience in operation, change the trace scale using automatic scaling

function.

To set the scale of the active trace by the autoscaling function use the following

softkeys in the right menu bar Scale > Auto Scale > Ok.

The program will automatically set the scale for the best display of the active

trace.

If you use the softkeys Scale > Auto Scale All > Ok, the program will automatically

set the scale for all traces.

3.7 Analyzer Calibration for Reflection Coefficient Measurement

Calibration of the whole measurement setup, which includes the Analyzer and

other devices, supporting connection to the DUT, allows to enhance considerably

the accuracy of the measurement.

31

GETTING STARTED

To perform full 1-port calibration, you need to prepare the kit of calibration

standards: OPEN, SHORT and LOAD. Every kit has its description and specifications

of the standards.

To perform proper calibration, you need to select the correct kit type in the

program. In the process of full 1-port calibration, connect calibration standards to

the test port one after another, as shown in Figure 3.2.

Figure 3.2. Full 1-port calibration circuit

In the current example Agilent 85032B/E calibration kit is used.

To select the calibration kit use the following softkeys in the left menu bar

Calibration > Calibration Kit.

32

GETTING STARTED

Then select the required kit from the Calibration Kits list and complete the setting

by Ok.

To perform full 1-port calibration you should execute measurements of the three

standards. After that the table of calibration coefficients will be calculated and

saved into the memory of the Analyzer. Before you start calibration, disconnect

the DUT from the Analyzer.

To perform full 1-port calibration use the following softkey in the left menu bar

Calibration.

33

GETTING STARTED

Connect an OPEN standard and click Open.

Connect a SHORT standard and click Short.

Connect a LOAD standard and click Load.

After clicking any of the Open, Short, or Load softkeys, wait until the calibration

procedure is completed.

To complete the calibration and calculate the table of calibration coefficients click

Apply. Then re-connect the DUT to the Analyzer test port.

3.8 SWR and Reflection Coefficient Phase Analysis Using Markers

This section describes how to determine the measurement values at three

frequency points using markers. The Analyzer screen view is shown in Figure 3.3.

In the current example, a reflection standard of SWR = 1.2 is used as a DUT.

34

GETTING STARTED

Figure 3.3 SWR and reflection coefficient phase measurement example

To enable a new marker use the following softkeys in the left menu bar Marker >

Add Marker.

Double click on the marker in the Marker List to activate the on-screen keypad

and enter the marker frequency value.

Complete the setting by Ok.

35

4. MEASUREMENT CONDITIONS SETTING

4.1 Screen Layout and Functions

The screen layout is represented in Figure 4.1. In this section you will find

detailed description of the softkey menu bars and instrument status bar. The

channel windows will be described in the next section.

Figure 4.1 Analyzer screen layout

4.1.1 Left and Right Softkey Menu Bars

The softkey menu bars in the left and right parts of the screen are the main menu

of the program. Each softkey represents one of the submenus. The menu system is

multilevel and allows to access to all the functions of the Analyzer.

You can manipulate the menu softkeys by the mouse or using a touch screen.

36

MEASUREMENT CONDITIONS SETTING

Note

Type of saving is set by the user in the dialog form Save type (see

section 8.1).

On-screen alphanumeric keypads also support data entering from external PC

keyboard. Besides, you can navigate the menu by «Up Arrow», «Down

Arrow»,«Enter», «Esc» keys on the external keyboard.

To expand the menu bar click on it and drag the cursor to the right or to the left

accordingly. To collapse the menu bar click on it and drag the cursor to the right

or to the left accordingly.

You can also click the softkey Menu Size to expand or to collaps the menu bar.

4.1.2 Top Menu Bar

The menu bar contains the functions of the most frequently used softkeys.

The softkey Recall State allows to recall the state from a file of Analyzer state (see

section 8.1.2).

The softkey Save State allows to save the Analyzer state (see section 8.1.1).

37

MEASUREMENT CONDITIONS SETTING

The softkey Save Data allows to save the trace data in CSV format (see section

8.3.1).

The softkeys Add Marker and Delete Marker add and delete markers on the trace

respectively.

The softkey Reference Marker allows to add the reference marker on the trace. To

delete the reference marker reclick this key.

The softkeys Add Trace and Delete Trace add and delete traces respectively.

The softkey Memory trace enables trace saving into memory (see section 6.2).

38

MEASUREMENT CONDITIONS SETTING

The softkey Data Math pops up the corresponding dialog form for choosing the

math operation type between data traces and memory traces (see section 6.2.4).

The softkey Auto Scale allows to define the trace scale automatically so that the

trace of the measured value could fit into the graph entirely (see section 3.6).

The softkey Auto Ref Value executes the automatic selection of the reference

level (see section 4.7.6).

The softkey Auto Scale All allows to define the trace scale automatically for all

traces (see section 3.6).

39

MEASUREMENT CONDITIONS SETTING

Field

Description

Message

Instrument Status

DSP status

Not Ready

No communication between DSP and PC.

Loading

DSP program is loading.

Ready

DSP is running normally.

Standby

DSP is in energy saving standby mode.

Sweep status

Measure

Continuous sweep.

Hold

A sweep is on hold.

Factory

calibration

error

System Cal

Failure

ROM error of system calibration.

The softkey Inverse Color allows to change the interface color.

4.1.3 Instrument Status Bar

Figure 4.2 Instrument status bar

The instrument status bar is located at the bottom of the screen. It can contain

the following messages (see Table 4.1).

Table 4.1 Messages in the instrument status bar

40

MEASUREMENT CONDITIONS SETTING

Field

Description

Message

Instrument Status

Error

correction

status

Correction Off

Error correction disabled by the user1.

System

correction

status

System

Correction Off

System correction disabled by the user.

1 Disabling of error correction does not affect factory calibration.

41

MEASUREMENT CONDITIONS SETTING

Note

The calibration parameters are applied to the whole Analyzer and

affect all the channel windows.

4.2 Channel Window Layout and Functions

The channel windows display the measurement results in the form of traces and

numerical values. The screen can display up to 4 channel windows

simultaneously. Each window has the following parameters:

Frequency range;

Sweep type;

Number of points;

IF bandwidth.

Physical analyzer processes the logical channels in succession.

In turn each channel window can display up to 4 traces of the measured

parameters. General view of the channel window is represented in Figure 4.3.

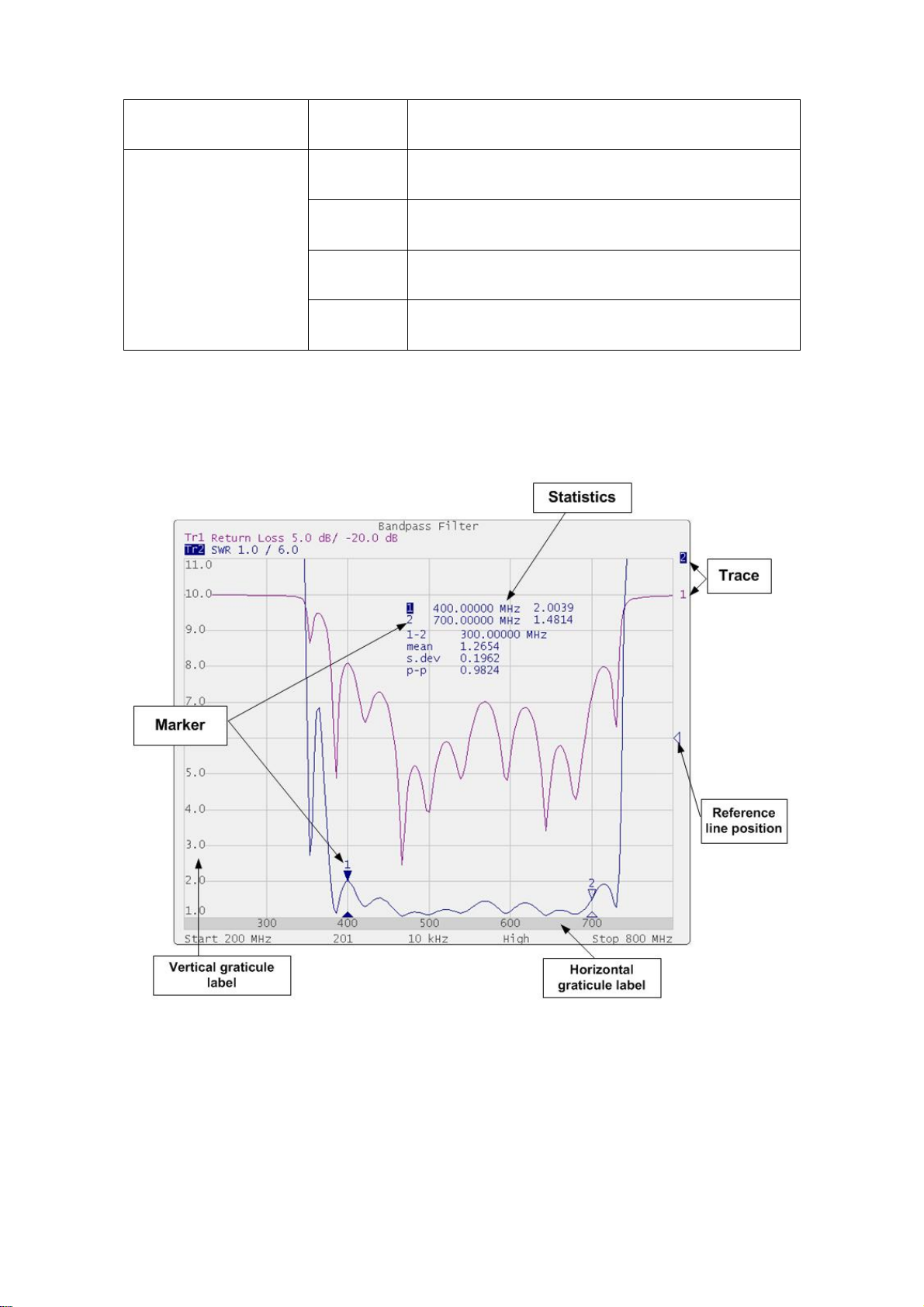

Figure 4.3 Channel window

42

MEASUREMENT CONDITIONS SETTING

Note

To edit the channel title click on the softkey Edit to recall the onscreen keypad.

4.2.1 Channel Title Bar

The channel title feature allows you to enter your comment for each channel

window.

To show/hide the channel title bar use the softkey Display.

Click on Caption field in the opened dialog.

4.2.2 Trace Status Field

Figure 4.4 Trace status field

43

MEASUREMENT CONDITIONS SETTING

Note

Using the trace status field you can easily modify the trace

parameters by the mouse.

The trace status field displays the name and parameters of a trace. The number of

lines in the field depends on the number of traces in the channel.

Each line contains the data on one trace of the channel:

Trace name from Tr1 to Tr4. The active trace name is highlighted in

inverted color;

Display format, e.g. Return Loss;

Trace scale in measurement units per division, e.g. 0.5 dB/;

Reference level value, e.g. -20.0 dB;

Trace status is indicated as symbols in square brackets (see Table 4.2).

44

Table 4.2 Trace status symbols definition

Status

Symbols

Definition

Error Correction

RO

OPEN response calibration

RS

SHORT response calibration

F1

Full 1-port calibration

Data Analysis

Z0

Port impedance conversion

Dmb

De-embedding

Emb

Embedding

Pxt

Port extension

Math Operations

D+M

Data + Memory

D-M

Data - Memory

D*M

Data * Memory

D/M

Data / Memory

Maximum Hold

Max

Hold of the trace maximum between repeated

measurements

Electrical Delay

Del

Electrical delay other than zero

Phase Offset

PhO

Phase offset value other then zero

Smoothing

Smo

Trace smoothing

Gating

Gat

Time domain gating

Conversion

Zr

Reflection impedance

Yr

Reflection admittance

1/S

S-parameter inversion

Conj

Conjugation

MEASUREMENT CONDITIONS SETTING

45

MEASUREMENT CONDITIONS SETTING

Status

Symbols

Definition

Trace display

Dat

Data trace

Mem

Memory trace

D&M

Data and memory traces

Off

Data and memory traces - off

4.2.3 Graph Area

The graph area displays the traces and numeric data (see Figure 4.5).

Figure 4.5 Graph area

46

MEASUREMENT CONDITIONS SETTING

Note

Using the graticule labels, you can easily control all the trace

parameters by the mouse.

The graph area contains the following elements:

Vertical graticule label displays the vertical axis numeric data for the active

trace;

Horizontal graticule label displays stimulus axis numeric data (frequency,

time, or distance);

Reference level position indicates the reference level position of the trace;

Markers indicate the measured values in different points on the active

trace. You can enable display of the markers for all the traces

simultaneously;

Marker functions: statistics, bandwidth, flatness, RF filter;

Trace number allows trace identification in the channel window;

Current stimulus position indication appears when sweep duration exceeds

1 sec.

4.2.4 Markers

The markers indicate the stimulus values and the measured values in selected

points of the trace (see Figure 4.6).

Figure 4.6 Markers

47

MEASUREMENT CONDITIONS SETTING

Symbol

Definition

--

No calibration data. No calibration was performed.

Cor

Error correction is enabled. The stimulus settings are the same for the

measurement and the calibration.

C?

Error correction is enabled. The stimulus settings are not the same for

the measurement and the calibration. Interpolation is applied.

The markers are numbered from 1 to 16. The reference marker is indicated with R

symbol. The active marker is indicated in the following manner: its number is

highlighted in inverse color, the stimulus indicator is fully colored.

4.2.5 Channel Status Bar

The channel status bar is located in the bottom part of the channel window (see

Figure 4.7)

Figure 4.7 Channel status bar

The channel status bar contains the following elements:

Stimulus start field allows to display and enter the start frequency. This

field can be switched to indication of stimulus center frequency, in this

case the word Start will change to Center;

Sweep points field allows to display and enter the number of sweep points.

The number of sweep points can have the following values: 2 - 100001;

IF bandwidth field allows to display and set the IF bandwidth. The values

can be set from 10 Hz to 30 kHz (100 kHz);

Power level field allows to display and enter the port output power;

Stimulus stop field allows to display and enter the stop frequency . This

field can be switched to indication of stimulus span, in this case the word

Stop will change to Span;

Error correction field displays the integrated status of error correction for

S-parameter traces. The values of this field are represented in Table 4.3.

Table 4.3 Error correction field

48

MEASUREMENT CONDITIONS SETTING

Symbol

Definition

C!

Error correction is enabled. The stimulus settings are not the same for

the measurement and the calibration. Extrapolation is applied.

Off

Error correction is turned off.

Note

The manipulations described in this section will help you to

perform the most frequently used settings only. All the channel

functions can be accessed via the softkey menu.

4.3 Quick Channel Setting Using Mouse

This section describes the manipulations, which will enable you to set the channel

parameters of R140 fast and easy. When you move a mouse pointer in the channel

window field where a channel parameter can be changed, the mouse pointer will

change its form and a prompt field will appear.

4.3.1 Active Channel Selection

You can select the active channel window when two or more channel windows

are open. The border line of the active window will be highlighted (see Figure

4.8). To activate a channel click in its window.

Figure 4.8 Active channel window display

49

MEASUREMENT CONDITIONS SETTING

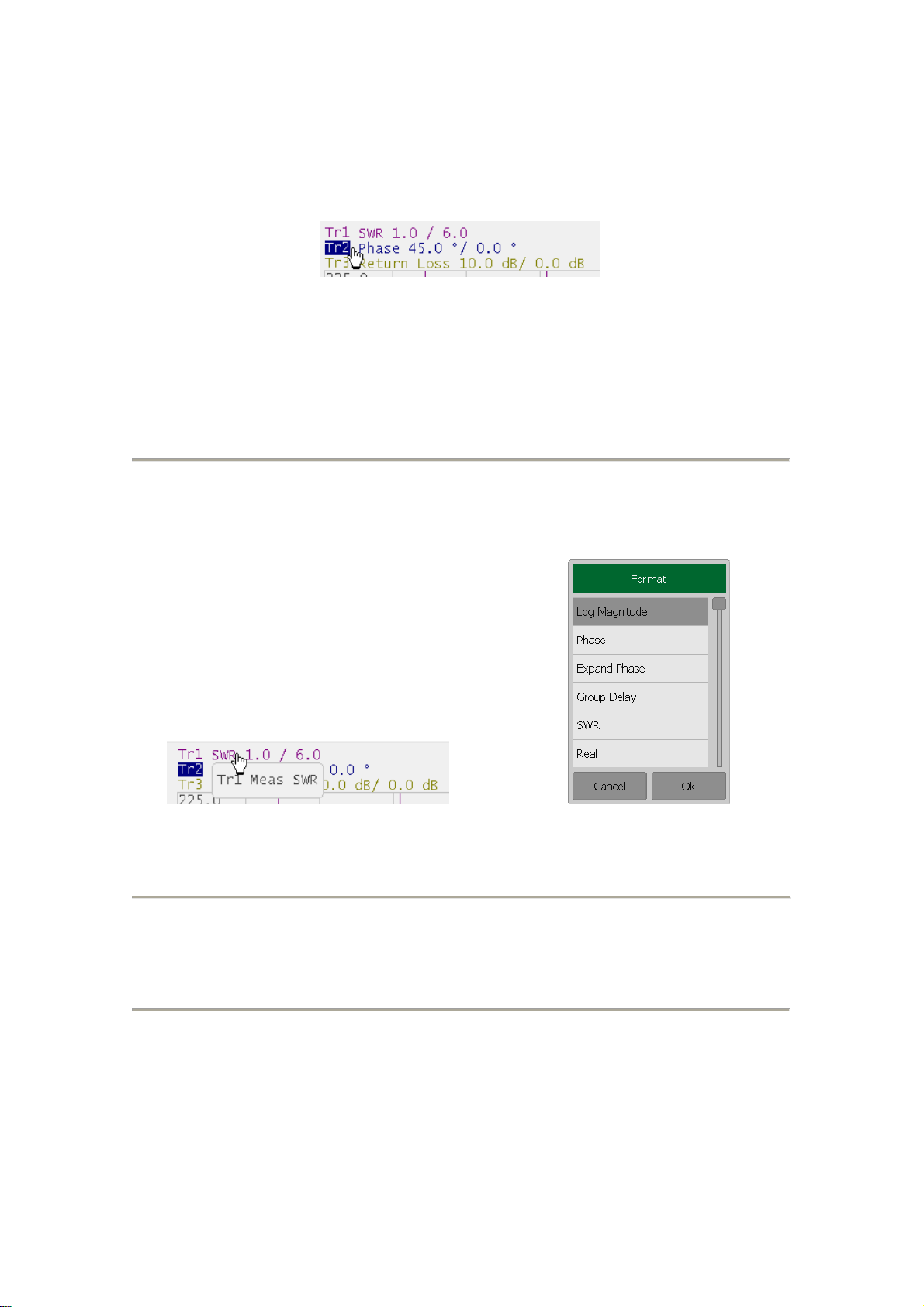

4.3.2 Active Trace Selection

You can select the active trace if the active channel window contains two or more

traces.

The active trace name will be highlighted in inverted color. In the example given

it is Tr2. To activate a trace click on the required trace or its status line.

4.3.3 Display Format Setting

To select the trace display format click on the format name in the trace status

line.

Select the required format in the Format dialog and complete the setting by Ok.

4.3.4 Trace Scale Setting

50

MEASUREMENT CONDITIONS SETTING

To select the trace scale click in the trace scale field of the trace status line.

Enter the required numerical value using the on-screen keypad and complete the

setting by Ok.

4.3.5 Reference Level Setting

To set the value of the reference level click on the reference level field in the

trace status line.

Enter the required numerical value using the on-screen keypad and complete the

setting by Ok.

51

MEASUREMENT CONDITIONS SETTING

4.3.6 Marker Stimulus Value Setting

The marker stimulus value can be set by dragging the marker or by entering the

value from the on-screen keypad.

To drag the marker, move the mouse pointer to one of the marker indicators.

The marker will become active, and a pop-up hint with its name will appear near

the marker. The marker can be moved either by dragging its indicator or its hint

area.

To enter the numerical value of the stimulus in the marker data click on the

stimulus value. Then enter the required value using the on-screen keypad.

4.3.7 Switching between Start/Center and Stop/Span Modes

To switch between the modes Start/Center and Stop/Span click in the respective

field of the channel status bar.

Label Start will be replaced by Center, and label Stop will be replaced by Span.

52

MEASUREMENT CONDITIONS SETTING

4.3.8 Start/Center Value Setting

To enter the Start/Center numerical values click on the respective field in the

channel status bar.

Then enter the required value using the on-screen keypad.

4.3.9 Stop/Span Value Setting

To enter the Stop/Span numerical values click on the respective field in the

channel status bar.

Then enter the required value using the on-screen keypad.

53

MEASUREMENT CONDITIONS SETTING

4.3.10 Sweep Points Number Setting

To enter the number of sweep points click in the respective field of the channel

status bar.

Select the required value in the Points dialog and complete the setting by Ok.

4.3.11 IF Bandwidth Setting

To set the IF bandwidth click in the respective field of the channel status bar.

Select the required value in the IFBW dialog and complete the setting by Ok.

54

MEASUREMENT CONDITIONS SETTING

4.3.12 Power Level Setting

To set the output power level click in the respective field of the channel status

bar.

This way you can switch between high and low power settings.

4.4 Channel and Trace Display Setting

The Analyzer supports 4 channels, which allows measurements with different

stimulus parameter settings. The parameters related to a logical channel are listed

in Table 4.4

4.4.1 Setting the Number of Channel Windows

A channel is represented on the screen as an individual channel window. The

screen can display from 1 to 4 channel windows simultaneously. By default one

channel window is opened.

The program supports three options of the channel window layout: one channel,

two channels, and four channels. The channels are allocated on the screen

according to their numbers from left to right and from top to bottom. If there are

more than one channel window on the screen, one of them is selected as active.

The border line of the active window will be highlighted in inverted color.

55

MEASUREMENT CONDITIONS SETTING

Note

For each open channel window, you should set the stimulus

parameters and make other settings.

Before you start channel parameter setting or calibration, you need

to select this channel as active.

To set the number of channel windows displayed on the screen use the following

softkey in the right menu bar Channels. Then select the softkey with the required

number and layout of the channel windows.

In the Active Channel field, you can select the active channel. The repeated

clicking will switch the numbers of all channels.

The measurements are executed for open channel windows in succession.

4.4.2 Channel Activating

Before setting channel parameters, you need to activate the channel.

56

MEASUREMENT CONDITIONS SETTING

To activate the channel use the following softkeys in the right menu bar Channels

> Active Channel.

Active Channel field allows viewing the numbers of all channels from 1 to 4.

Select the required number of the active channel.

To activate a channel, you can also click on its channel window.

4.4.3 Active Channel Window Maximizing

When there are several channel windows displayed, you can temporarily maximize

the active channel window to full screen size.

The other channel windows will be hidden, and this will interrupt the

measurements in those channels.

57

MEASUREMENT CONDITIONS SETTING

Note

Channel maximizing function can be controlled by a double mouse

click on the channel.

To enable/disable active channel maximizing function use the following softkeys

Channel > Maximize Channel.

4.4.4 Number of Traces Setting

Each channel window can contain up to 4 different traces. Each trace is assigned

the display format, scale and other parameters. The parameters related to a trace

are listed in Table 4.5.

The traces can be displayed in one graph, overlapping each other, or in separate

graphs of a channel window. The trace settings are made in two steps: trace

number setting and trace layout setting in the channel window. By default a

channel window contains one trace. If you need to enable two or more traces, set

the number of traces as described below.

58

MEASUREMENT CONDITIONS SETTING

To add a trace use the following softkeys in the right menu bar Trace > Add Trace.

To delete a trace use the following softkeys in the right menu bar Trace > Delete

Trace.

All the traces are assigned their individual names, which cannot be changed. The

trace name contains its number. The trace names are as follows: Tr1, Tr2 ... Tr4.

Each trace is assigned some initial settings: measured parameter, format, scale

and color, which can be modified by the user.

By default the display format for all the traces is set to Return loss (dB).

By default the scale is set to 10 dB, reference level value is set to 0 dB, reference

level position is in the middle of the graph.

The trace color is determined by its number.

4.4.5 Active Trace Selection

Trace parameters can be entered for the active trace. Active trace belongs to the

active channel, and its name is highlighted in inverted color. You have to select

the active trace before setting the trace parameters.

59

MEASUREMENT CONDITIONS SETTING

Note

A trace can be activated by clicking on the trace status bar in the

graphical area of the program

To select the active trace use the softkeys in the right menu bar Trace.

Click the Active Trace to select the trace you want to assign the active.

60

Table 4.4 Channel parameters

N

Parameter Description

1

Sweep Range

2

Number of Sweep Points

3

IF Bandwidth

N

Parameter Description

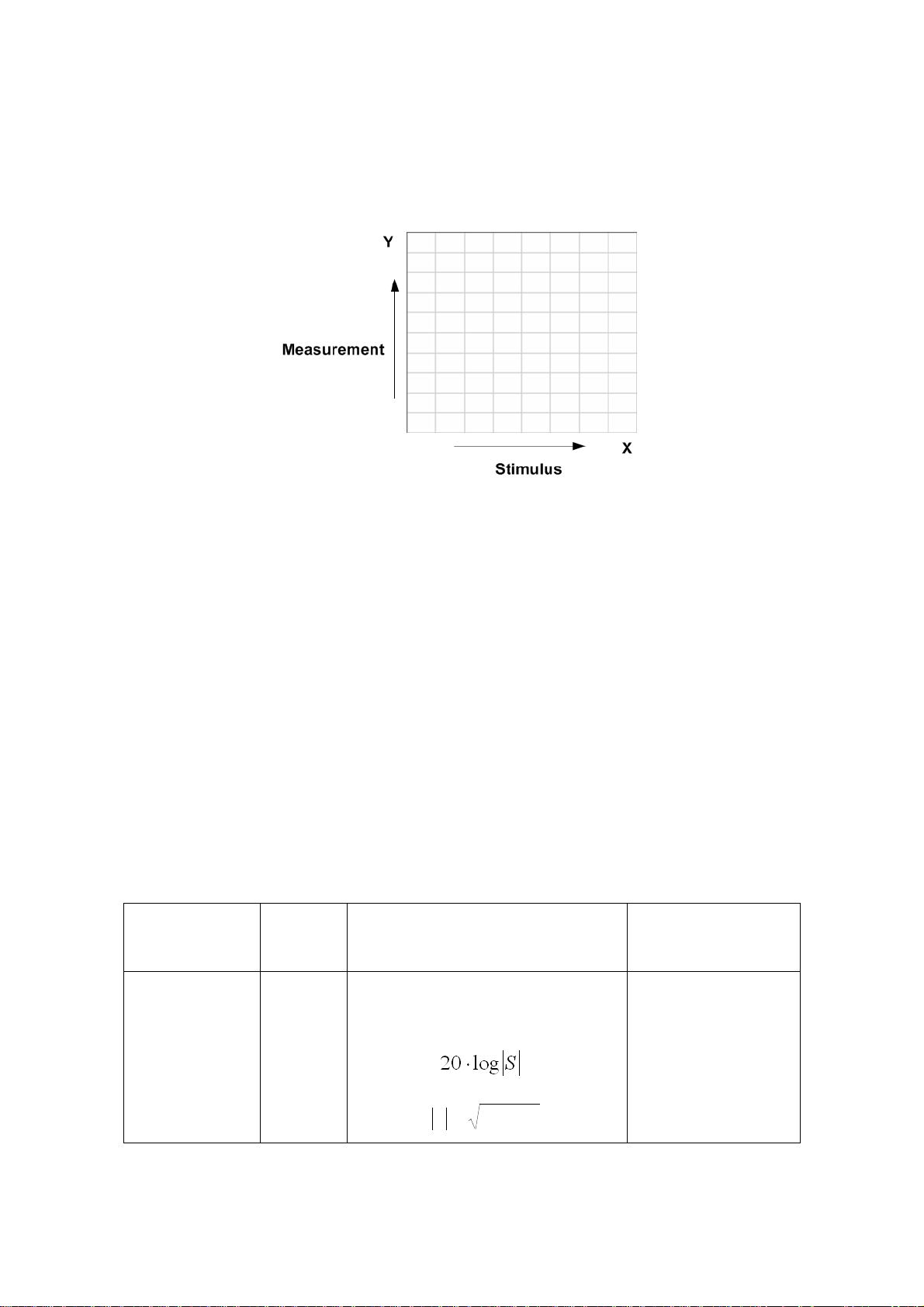

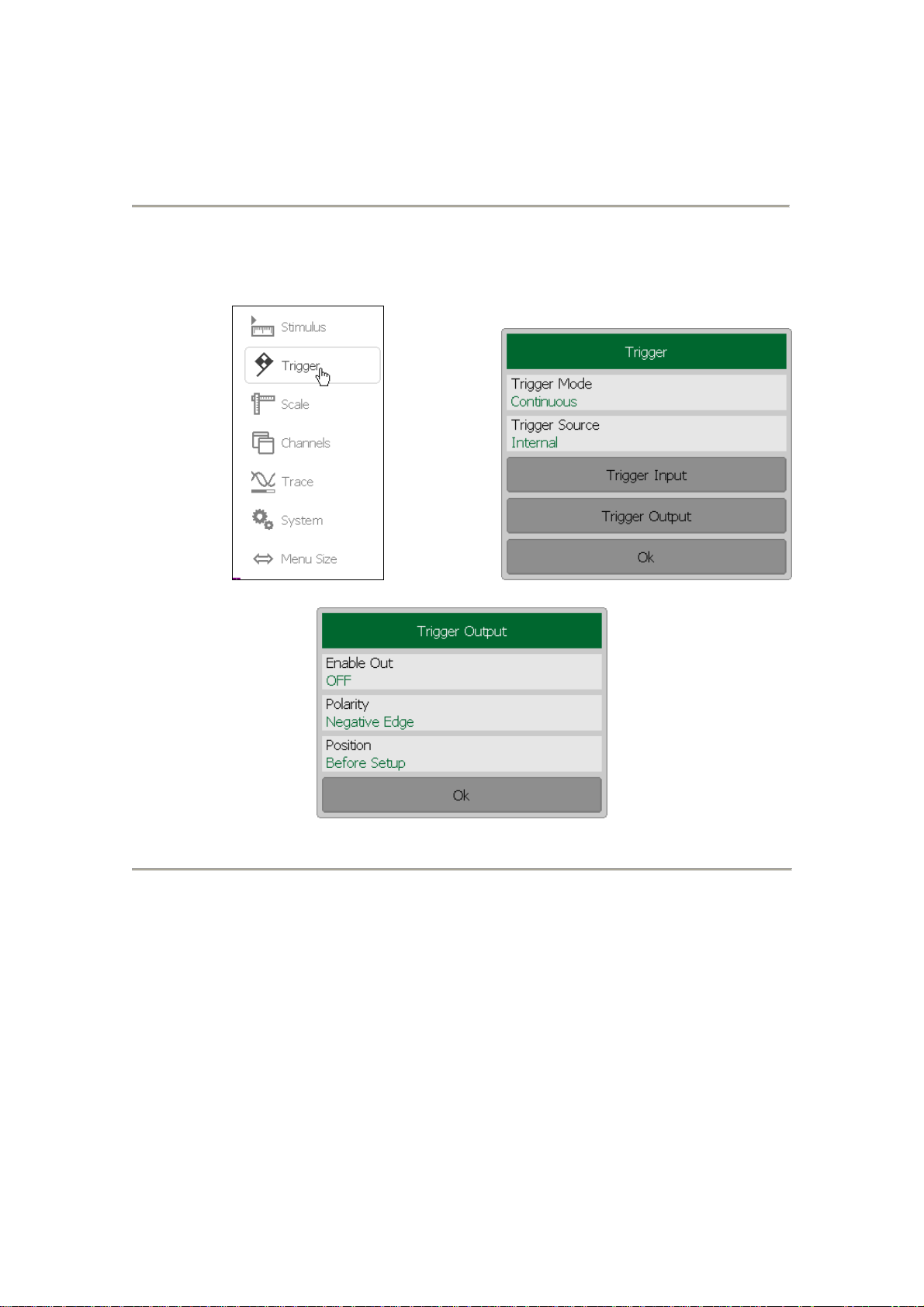

1