A.N.T.S.

A l w a y s N o r m a l T a r g e t S i g h t

Technical

Manual

Copper John Corp

1 7 3 S t a t e S t .

A u b u r n , N Y 1 3 0 2 1

3 1 5 - 2 5 8 - 9 2 6 9

sales @copperjohn .com

www.copperjohn.com

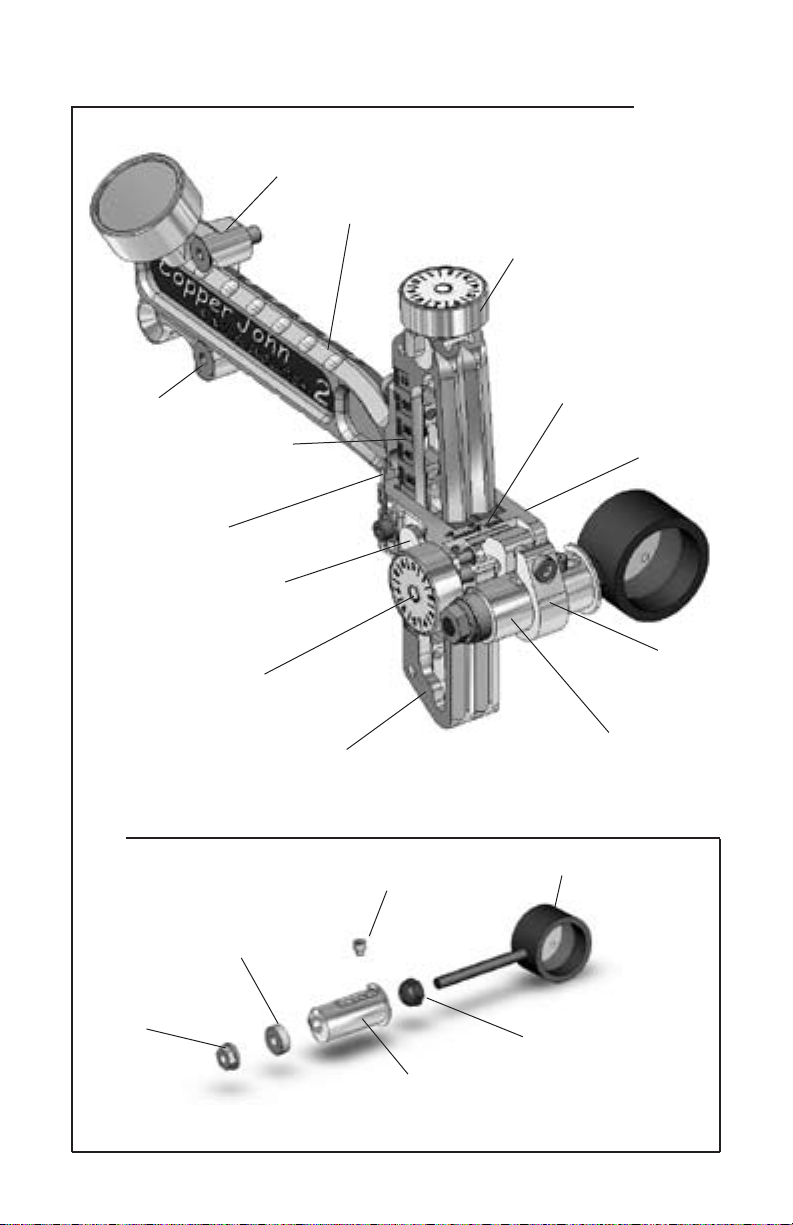

Parts of the A.N.T.S System

Extension block

Extension

Elevation Knob

Mounting Screws

Elevation Scale

Elevation

Indicator Needle

Elevation Block

Quick Release

Windage Knob

Frame

Windage Scale

Elevation Block

Windage Block

Scope Mounting Block

Parts of the Double Axis Adjustment

Horizontal Stop

Screw

Radiused Washer

Scope

Flange nut

Pivot Nut

Scope Mounting

Barrel

A.N.T.S Assembly

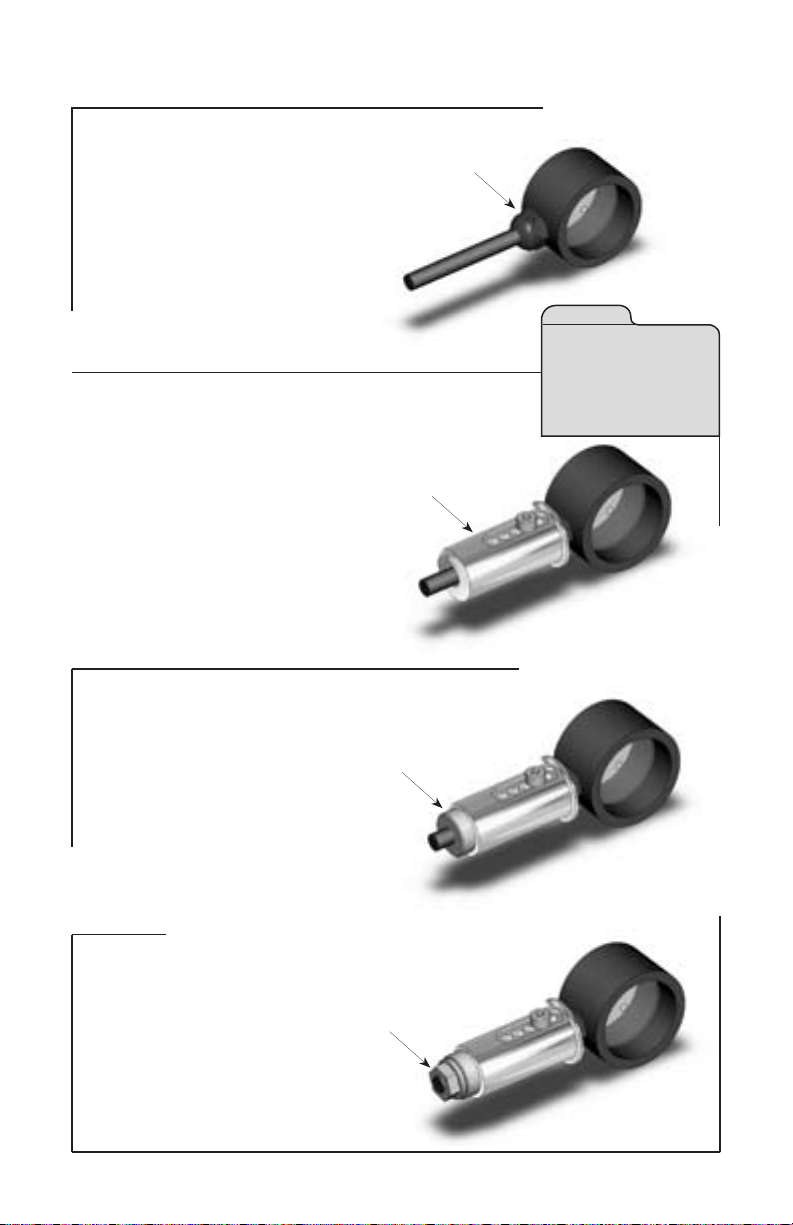

Step 1

Screw the Pivot Nut on to

your scope’s threaded rod.

Using a 7/16 wrench, securely

snug the nut against the

scope housing.

Step 2

Slide on the scope mounting barrel. Make sure that

the pivot nut seats fully in its

socket. Test that the sight rotates properly by moving the

scope thread back and forth.

Make sure it glides smoothly.

Step 3

H i n t

Always use a open end

wrench that is the proper size

when making adjustments in

this area. Pliers or adjustable

wrenches can damage the nut

and ruin your sight.

Slip the Radiused Washer into

place. Orient the “cave” side

of the washer to the Scope

Barrel. Test it and make sure

it glides over the end of the

Scope Barrel properly.

Step 4

Screw on the ange nut

and snug it in place with a

3/8 wrench. Initially, you will

want to leave this just nger

tight. You will need to adjust

your scope level later during

set up.

A.N.T.S Assembly cont.

Step 5

Insert the Double Axis assembly into the Windage Block.

Make sure the horizontal stop

screw is all the way against

the Windage Block. Tighten

the Windage Block Locking

screw

Step 6

Mount the sight block to the

bow with the screws provided

and securely tighten the

mounting screws. Slide the

A.N.T.S. bar into the block

and choose your desired distance setting.

Horizontal Block

Stop Screw

H i n t

The horizontal stop screw

will be useful when you are

disassembling your sight

for travel in its case. The

stop screw makes sure your

scope locates perfectly every

time you reassemble your

sight, keeping your windage

dead on.

Windage Block

Locking Screw

H i n t

Once you have chosen your

desired distance, it is helpful

to mark your bar where the

knob contacts it. This will aid

you in setting the sight back

to the your chosen position

after you have removed your

sight for travel.

A.N.T.S Level Setup

It is important when using any range adjustable sight that

your scope is perpendicular with the frame (3rd Axis) and the

scope is level with the earth (2nd Axis). The frame can also be

leveled with the shooting string (1st Axis), but this is not crucial. It is common that shooters will adjust their 1st Axis so that

it matches, or is level, with their natural cant or bow tilt while

at full draw.

Setting the 2nd Axis

You must set the 2nd Axis rst.

Using a line level or similar device against the frame, hold the

frame level and note the level

in the scope. Raise or lower the

ange nut on the end of the

Double Axis Adjustment until

both levels show that they are

perfect. Note, the diagram to

the left is perfect. If your sight

looks like this, You are ready to

move on to the next step.

Flange Nut

Compare and

tighten screws.

Leveling Device

Setting the 3rd Axis

The third axis

45° down

adjustment makes

sure the scope is

perpendicular

to the bar, bow,

and plane of the

shooting string.

With your level still

attached to your

scope bar, draw your bow and point your bow

down at around a 45 degree angle. Both bubbles

should match as they do in the diagram to the

right. Move the ange nut to the rear or to the

front to make the bubbles match. Once this is set,

you can tighten the ange nut completely.

Setting the 1st Axis

It is not critical for your rst axis to be set, but some shooters prefer it. Some prefer it to match their natural cant. To

set this, you will draw your bow to full draw with your eyes

closed. Allow it to settle and then open to see if the bubble is

level. Tilt the frame on the bar until this test comes out level.

If you would like to level the frame with the string, put your

bow on a at table and level the string by shimming the bow.

Then put your level on the sight. Tilt the frame into position

and tighten the screws. Once the screws are tight, recheck.

Compare and tighten

Shooting String

Getting the most out of your A.N.T.S

Using the Adjustment Knobs and the Scale

Both the Elevation Knob and the Windage Knob have a

number scale and they are labeled up/down, left/right for

your convenience. The numbers on your knobs are related

to the hash marks on the scale. If you start with the knob on

Zero, and rotate it one full turn, it will move one number or

hash mark on the scale. There are 20 clicks between each

number. When getting

sight marks, note the

number on the scale and

the number on the knob.

This will help you get the

tightest marks possible

and it will get you right

back to the perfect spot

everytime

Adjusting your sight and counting clicks

It is handy to know how much distance a click represents when you are

using your sight. This will help you get

on target faster and stay on target

with a minimum of guesswork. The

distance is expressed in Minute Of

Angle or MOA. The MOA is 5/32 of an

inch at 100 yards on an A.N.T.S. This

means that one click on windage or

elevation equals 5/32 of an inch at

100 yards. Therefore at 20 yards one

click equals 20% of 5/32” or 1/32 of an

inch. 50 yards would be 50% of 5/32”

or 5/64 of an inch.

H i n t

At twenty yards, one click

will move your arrow 1/32”.

It will take 25 clicks to move

your sight from dead center

of the X ring line to the exact

center of the X ring.

General Maintenance

Keep your A.N.T.S. clean and dry. If it gets wet, towel it

off and allow it to dry completely before storing in its case.

Lubrication is normally not necessary, but if you should feel

the need to lube your sight, use only synthetic, non water

soluble grease such as SuperLube®. Lube only the Brass Rear

Bearings by putting a line of lube in their slots and running

the elevation block up and down to distribute the lube, or

you can lube the underside of the adjustment knobs by putting a drop on the knob and spinning the knob to distribute

the lube. No other part of the sight should be lubed. Be very

sparing with the lubrication because excessive amounts of

lube will attract dirt and grime which could hamper the performance of your sight.

Lifetime Warranty

Your A.N.T.S. Sight is warranted against defects in materials or workmanship to the original

owner for the lifetime of the product*.

The warranty is conditioned upon proof of purchase and other conditions listed below. IT

IS IMPORTANT THAT YOUR SALES RECEIPT BE FILED IN A SAFE PLACE FOR FUTURE

REFERENCE, AS REPAIRS WILL NOT BE PERFORMED UNDER WARRANTY WITHOUT A

COPY OF THE DATED SALES RECEIPT. Copper John Corp. warrants that you’re A.N.T.S.

will perform its intended function if used in accordance with the instructions provided.

This Lifetime Warranty covers only the replacement parts, labor, and return ground

transportation costs performed by Copper John Corp. to the customer. Transportation

for the return of the Sight to Copper John Corp. is not covered. No C.O.D. shipments will

be accepted by Copper John Corp. Copper John Corp. makes no other warranty either

expressed or implied, whether of tness or of marketability, except as stated above. Any

such additional warranty is expressly disclaimed. No agent, employee, or representative

of Copper John Corp. or its dealers has the authority to bind Copper John Corp. to any

agreement not herein stated. Buyer agrees that the sole and exclusive remedies for breach

on any warranty concerning Copper John A.N.T.S. Sights shall be repair or replacement of

defective parts. Copper John Corp. shall not be liable for injury or property other than the

A.N.T.S. Sight itself. Copper John Corp. reserves the right to replace defective parts according

to availability with compatible replacement parts.

(*The lifetime of a sight is determined according to the production cycle of the model

and on-hand supply of replacement components. Should a sight model no longer be in

production and supply of components be exhausted, an upgrade fee may be charged in

order to supply the customer with a newer, updated model.)

Loading...

Loading...