Page 1

Xenus XTL™ User Guide

P/N 95-00875-000

Revision 3

June 2008

Page 2

Xenus XTL User Guide

This page for notes.

Page 3

TABLE OF CONTENTS

About This Manual ................................................................................................................................................................................5

1: Introduction ................................................................................................................................................................................. 9

1.1: Amplifier ............................................................................................................................................................................... 10

1.2: CME 2 .................................................................................................................................................................................. 11

1.3: CMO/CML ............................................................................................................................................................................11

2: Operational Theory....................................................................................................................................................................13

2.1: Amplifier Internal Power........................................................................................................................................................ 14

2.2: Synchronizing PWM Switching Frequency............................................................................................................................ 16

2.3: Commutation Modes ............................................................................................................................................................ 16

2.4: Feedback.............................................................................................................................................................................. 16

2.5: Operating Modes.................................................................................................................................................................. 17

2.6: CANopen Operation .............................................................................................................................................................28

2.7: Limit Switches ...................................................................................................................................................................... 30

2.8: Brake Operation ................................................................................................................................................................... 31

2.9: Status Indicators................................................................................................................................................................... 32

2.10: Protection...........................................................................................................................................................................34

2.11: Position and Velocity Errors................................................................................................................................................ 36

2.12: Communication ..................................................................................................................................................................39

2.13: Inputs .................................................................................................................................................................................40

2.14: Outputs............................................................................................................................................................................... 41

2.15: Regen Resistor Theory....................................................................................................................................................... 42

3: Specifications............................................................................................................................................................................ 43

3.1: Agency Approvals.................................................................................................................................................................44

3.2: Power Input ..........................................................................................................................................................................44

3.3: Power Output........................................................................................................................................................................ 44

3.4: Control Loops ....................................................................................................................................................................... 45

3.5: Regen Circuit Output ............................................................................................................................................................ 45

3.6: Digital Command Input ......................................................................................................................................................... 45

3.7: Analog Command Input........................................................................................................................................................46

3.8: Digital Inputs.........................................................................................................................................................................46

3.9: Digital Outputs......................................................................................................................................................................46

3.10: Brake Output ...................................................................................................................................................................... 47

3.11: Encoder Power Supply Output............................................................................................................................................ 47

3.12: Primary Encoder Inputs ...................................................................................................................................................... 47

3.13: Analog Encoder Inputs .......................................................................................................................................................47

3.14: Hall Switch Inputs...............................................................................................................................................................48

3.15: Resolver Interface .............................................................................................................................................................. 48

3.16: Multi-Mode Port .................................................................................................................................................................. 48

3.17: Serial Interface ................................................................................................................................................................... 49

3.18: CAN Interface.....................................................................................................................................................................49

3.19: Status Indicators................................................................................................................................................................. 49

3.20: Fault Levels ........................................................................................................................................................................ 49

3.21: Power Dissipation............................................................................................................................................................... 50

3.22: Thermal Impedance............................................................................................................................................................50

3.23: Mechanical and Environmental...........................................................................................................................................50

3.24: Dimensions......................................................................................................................................................................... 51

4: Wiring......................................................................................................................................................................................... 53

4.1: General Wiring Instructions ..................................................................................................................................................54

4.2: AC Mains (J1)....................................................................................................................................................................... 56

4.3: Motor (J2) ............................................................................................................................................................................. 57

4.4: Regen Resistor (J3) (Optional) .............................................................................................................................................59

4.5: Logic Supply / Brake (J4)...................................................................................................................................................... 60

4.6: RS-232 Serial Communications (J5)..................................................................................................................................... 61

4.7: CAN Bus (J6) ....................................................................................................................................................................... 62

4.8: Control (J7)........................................................................................................................................................................... 63

4.9: Motor Feedback (J8)............................................................................................................................................................. 67

5: Quick Setup with CME 2 ........................................................................................................................................................... 73

5.1: Warnings..............................................................................................................................................................................74

5.2: CME 2 Installation and Serial Port Setup.............................................................................................................................. 75

5.3: Prerequisites ........................................................................................................................................................................ 79

5.4: Basic Setup..........................................................................................................................................................................81

5.5: Motor/Feedback Setup .........................................................................................................................................................84

5.6: Amplifier Configuration .........................................................................................................................................................93

5.7: Command Input.................................................................................................................................................................. 103

5.8: Auto Phase.........................................................................................................................................................................110

5.9: Current Loop....................................................................................................................................................................... 116

5.10: Velocity Loop....................................................................................................................................................................120

5.11: Position Loop.................................................................................................................................................................... 122

5.12: Completion Steps .............................................................................................................................................................126

6: Using CME 2 ............................................................................................................................................................................ 127

Copley Controls Corp. 3

Page 4

Table of Contents Xenus XTL User Guide

6.1: CME 2 Overview.................................................................................................................................................................128

6.2: Manage Amplifier and Motor Data ...................................................................................................................................... 133

6.3: Downloading Firmware .......................................................................................................................................................136

6.4: Control Panel...................................................................................................................................................................... 138

6.5: Manual Phasing.................................................................................................................................................................. 142

6.6: Home Function................................................................................................................................................................... 144

A: Regen Resistor Sizing and Configuration ............................................................................................................................. 145

A.1: Sizing a Regen Resistor..................................................................................................................................................... 146

A.2: Configuring a Custom Regen Resistor ............................................................................................................................... 150

B: I2T Time Limit Algorithm ......................................................................................................................................................... 153

B.1: I2T Algorithm ...................................................................................................................................................................... 154

C: Thermal Considerations.......................................................................................................................................................... 159

C.1: Operating Temperature and Cooling Configurations .......................................................................................................... 160

C.2: Heatsink Mounting Instructions .......................................................................................................................................... 162

D: Xenus Filter.............................................................................................................................................................................. 163

D.1: Overview............................................................................................................................................................................164

D.2: XTL-FA-01 Edge Filter Specifications ................................................................................................................................ 165

D.3: Thermal Considerations..................................................................................................................................................... 165

D.4: XTL-FA-01 Edge Filter Dimensions.................................................................................................................................... 166

D.5: XTL-FA-01 Edge Filter Wiring............................................................................................................................................ 167

D.6: XTL-FA-01 Edge Filter Ordering.........................................................................................................................................171

E: Connecting for Serial Control................................................................................................................................................. 173

E.1: Single-Axis and Multi-Drop ................................................................................................................................................. 174

F: Ordering Guide and Accessories ........................................................................................................................................... 175

F.1: Amplifier Model Numbers ................................................................................................................................................... 176

F.2: Accessory Model Numbers.................................................................................................................................................177

F.3: Order Example ................................................................................................................................................................... 178

F.5: Copley Standard Regen Resistor Specifications................................................................................................................. 179

4 Copley Controls Corp.

Page 5

ABOUT THIS MANUAL

Overview and Scope

This manual describes the operation and installation of the Xenus XTL amplifier manufactured by

Copley Controls Corporation.

Related Documentation

For important setup and operation information, see the CME 2 User Guide.

Users of the CANopen features should also read these Copley Controls documents:

• CANopen Programmer’s Manual

• CML Reference Manual

• Copley Motion Objects Programmer’s Guide

Also of related interest:

• Copley Indexer 2 Program User’s Guide (describes use of Indexer Program to create motion

control sequences)

• Copley Controls ASCII Interface Programmer’s Guide (describes how to send ASCII format

commands over an amplifier’s serial bus to set up and control one or more amplifiers)

• Copley Amplifier Parameter Dictionary

• Copley Camming User Guide

• Copley DeviceNet Programmer’s Guide

Information on Copley Controls Software can be found at:

http://www.copleycontrols.com/Motion/Products/Software/index.html

Comments

Copley Controls Corporation welcomes your comments on this manual.

For contact information, see http://www.copleycontrols.com

Copyrights

No part of this document may be reproduced in any form or by any means, electronic or

mechanical, including photocopying, without express written permission of Copley Controls

Corporation.

Xenus and XTL are registered trademarks of Copley Controls Corporation.

CME 2 is a registered trademark of Copley Controls Corporation.

Windows NT, ME, 2000, XP, Vista, Visual Basic, Excel, and .NET are trademarks or registered

trademarks of the Microsoft Corporation.

LabVIEW is a registered trademark of National Instruments.

Document Validity

We reserve the right to modify our products. The information in this document is subject to change

without notice and does not represent a commitment by Copley Controls Corporation. Copley

Controls Corporation assumes no responsibility for any errors that may appear in this document.

Copley Controls Corp. 5

Page 6

About this Manual Xenus XTL User Guide

Product Warnings

Observe all relevant state, regional, and local safety regulations when installing and using this

product. For safety and to assure compliance with documented system data, only Copley Controls

Corporation should perform repairs to amplifiers.

DANGER: Hazardous voltages.

Exercise caution when installing and adjusting.

!

DANGER

!

DANGER

!

DANGER

Failure to heed this warning can cause equipment damage, injury, or death.

Risk of electric shock.

High-voltage circuits on J1, J2, and J3 are connected to mains power.

Failure to heed this warning can cause equipment damage, injury, or death.

Risk of unexpected motion with non-latched faults.

After the cause of a non-latched fault is corrected, the amplifier re-enables the PWM

output stage without operator intervention. In this case, motion may re-start

unexpectedly. Configure faults as latched unless a specific situation calls for nonlatched behavior. When using non-latched faults, be sure to safeguard against

unexpected motion.

Failure to heed this warning can cause equipment damage, injury, or death.

Using CME 2 or serial commands may affect or suspend CAN operations.

When operating the amplifier as a CAN node, the use of CME 2 or ASCII serial

!

DANGER

!

DANGER

!

DANGER

commands may affect CAN operations in progress. Using such commands to initiate

motion may cause CAN operations to suspend.

CAN operations may restart unexpectedly when the commanded motion is stopped.

Failure to heed this warning can cause equipment damage, injury, or death.

Latching an output does not eliminate the risk of unexpected motion with nonlatched faults.

Associating a fault with a latched, custom-configured output does not latch the fault

itself. After the cause of a non-latched fault is corrected, the amplifier re-enables

without operator intervention. In this case, motion may re-start unexpectedly.

For more information, see Clearing Non-Latched Faults (p. 34).

Failure to heed this warning can cause equipment damage, injury, or death.

Use equipment as described.

Operate amplifiers within the specifications provided in this manual.

Failure to heed this warning can cause equipment damage, injury, or death.

6 Copley Controls Corp.

Page 7

Xenus XTL User Guide About this Manual

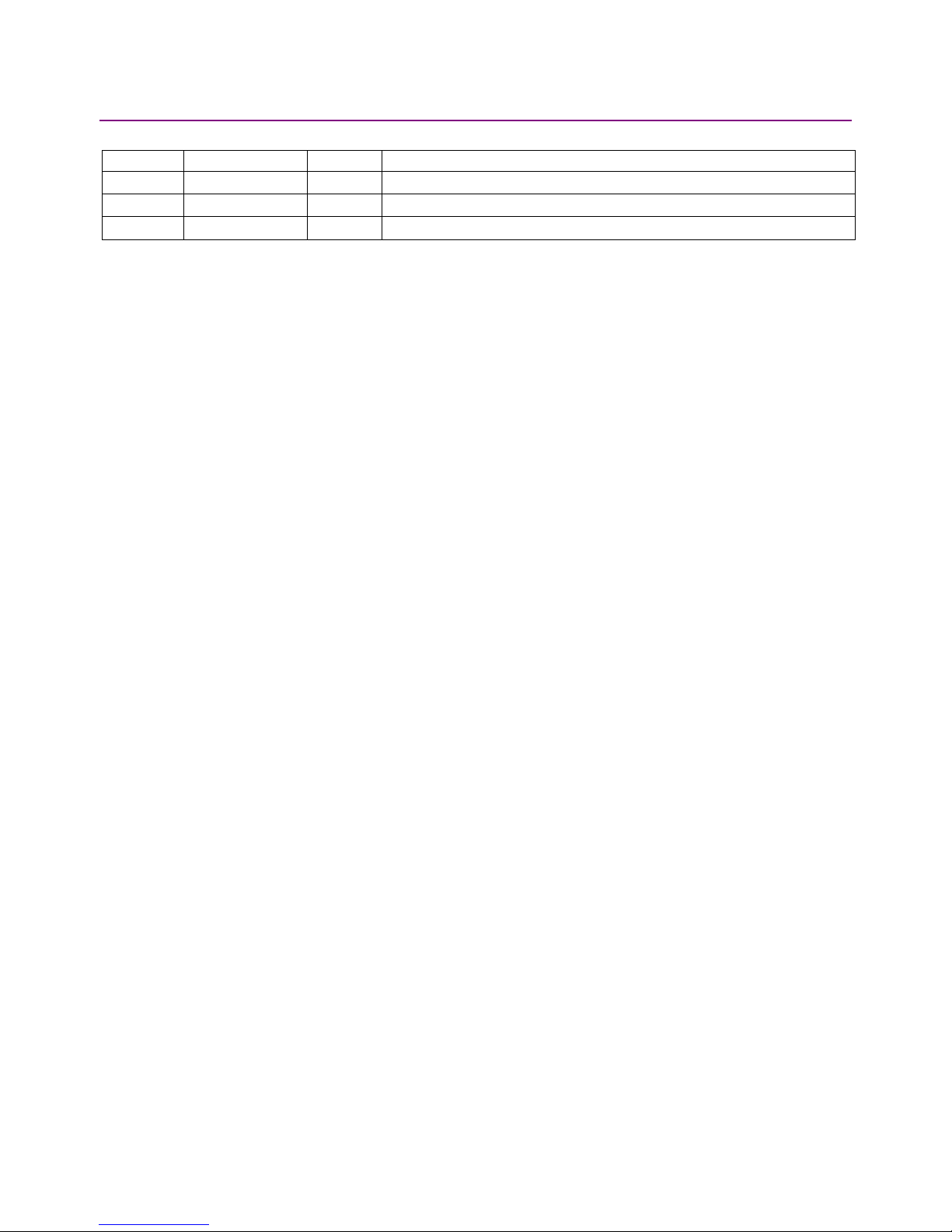

Revision History

Revision Date DECO# Comments

1 December 2007 16236 Initial release.

2 February 2008 16714 Updated Multi-Mode Port Interface Diagram (p. 66).

3 June 2008 17111 Updated Web page references and made other minor changes.

Copley Controls Corp. 7

Page 8

About this Manual Xenus XTL User Guide

This page for notes.

8 Copley Controls Corp.

Page 9

CHAPTER

1: INTRODUCTION

This chapter provides an overview of the Copley Controls Xenus XTL amplifier.

Contents include:

Title Page

1.1: Amplifier ............................................................................................................................................................................... 10

1.2: CME 2 .................................................................................................................................................................................. 11

1.3: CMO/CML ............................................................................................................................................................................11

Copley Controls Corp. 9

Page 10

Introduction Xenus XTL User Guide

1.1: Amplifier

Xenus provides 100% digital control of brushless or brush motors in an off-line powered package.

It can also control a Copley Controls ServoTube motor. Xenus can operate from single or threephase mains with a continuous power output of up to 4 kW.

Xenus is offered in three versions to support three types of feedback devices. The standard

version supports digital quadrature encoders. The –S version supports analog sin/cos encoders.

The -R version supports brushless resolvers. The –S and -R versions can emulate a digital

quadrature encoder output from the analog encoder or resolver respectively.

Xenus can operate in several basic ways:

• As a traditional motor amplifier accepting current, velocity or position commands from an

external controller. In current and velocity modes it can accept ±10 Vdc analog, digital 50%

PWM or PWM/polarity inputs. In position mode, inputs can be incremental position commands

from step-motor controllers in Pulse and Direction or Count Up/Count Down format, as well as

A/B quadrature commands from a master-encoder. Pulse-to-position ratio is programmable for

electronic gearing.

• As a node on a CANopen network. CANopen compliance allows the amplifier to take

instruction from a master application over a CAN network to perform torque, velocity, and

position profiling, interpolated motion, and homing operations. Multiple drives can be tightly

synchronized for high performance coordinated motion.

• As a node on a DeviceNet network. Xenus can be operated over a DeviceNet network by

PLCs and other controllers.

• As a stand-alone controller running Copley Virtual Machine (CVM) control programs such as

the Indexer 2 Program. It can also be controlled directly over an RS232 serial link with simple

ASCII format commands.

Mains input voltage to the amplifier can range from 100 to 240 Vac, single or three-phase, and 47

to 63 Hz. This allows Xenus the ability to work in the widest possible range of industrial settings.

Several models are available, with peak current ratings of 18 to 40 amps:

Model

Quad A/B

Encoder

XTL-230-18 XTL-230-18-R XTL-230-18-S 6 A 18 A

XTL-230-36 XTL-230-36-R XTL-230-36-S 12 A 36 A

XTL-230-40 XTL-230-40-R XTL-230-40-S 20 A 40 A

Resolver Sin/Cos Encoder Continuous

Current

Peak Current Vac

100 to

240

A separate +24 Vdc logic supply powers the internal logic and control circuits. These are isolated

from the high-voltage power supply and inverter stage that connect to the mains. This simplifies

system design by allowing the mains to be completely disconnected from the amplifier for safety

reasons while allowing the logic side of the amplifier to stay powered. This allows the amplifier to

retain position information and maintain communication through the digital I/O or over the serial or

CAN ports when disconnected from the mains.

The Xenus XTL is RoHS compliant.

10 Copley Controls Corp.

Page 11

Xenus XTL User Guide Introduction

1.2: CME 2

Amplifier commissioning is fast and simple using Copley Controls CME 2 software. CME 2

communicates with Xenus via an RS-232 link, and all of the operations needed to configure the

amplifier are accessible through CME 2.

The multi-drop feature allows CME 2 to use a single RS-232 serial connection to one amplifier as

a gateway to other amplifiers linked together by CAN bus connections.

Auto phasing of brushless motor Hall sensors and phase wires eliminates “wire and try.”

Connections are made once and CME 2 does the rest. Encoder or resolver wire swapping to

establish the direction of positive motion is also eliminated.

Motor data can be saved as .ccm files. Amplifier data is saved as .ccx files that contain all

amplifier settings plus motor data. This makes it possible to quickly set up amplifiers by copying

configurations from one amplifier to another.

1.3: CMO/CML

Copley Motion Libraries (CML) and Copley Motion Objects (CMO) make CANopen system

commissioning fast and simple. All network housekeeping is taken care of automatically by a few

simple commands linked into your application program. CML provides a suite of C++ libraries,

allowing a C++ application program to communicate with and control an amplifier over the

CANopen network. CMO provides a similar suite of COM objects that can be used by Visual

Basic, .NET, LabVIEW, or any other program supporting the Microsoft COM object interface.

Copley Controls Corp. 11

Page 12

Introduction Xenus XTL User Guide

12 Copley Controls Corp.

Page 13

CHAPTER

2: OPERATIONAL THEORY

This chapter describes the basics of Xenus operation. Contents include:

Title Page

2.1: Amplifier Internal Power........................................................................................................................................................ 14

2.2: Synchronizing PWM Switching Frequency............................................................................................................................ 16

2.3: Commutation Modes ............................................................................................................................................................ 16

2.4: Feedback.............................................................................................................................................................................. 16

2.5: Operating Modes.................................................................................................................................................................. 17

2.6: CANopen Operation .............................................................................................................................................................28

2.7: Limit Switches ...................................................................................................................................................................... 30

2.8: Brake Operation ................................................................................................................................................................... 31

2.9: Status Indicators................................................................................................................................................................... 32

2.10: Protection...........................................................................................................................................................................34

2.11: Position and Velocity Errors................................................................................................................................................ 36

2.12: Communication ..................................................................................................................................................................39

2.13: Inputs .................................................................................................................................................................................40

2.14: Outputs............................................................................................................................................................................... 41

2.15: Regen Resistor Theory....................................................................................................................................................... 42

Copley Controls Corp. 13

Page 14

Operational Theory Xenus XTL User Guide

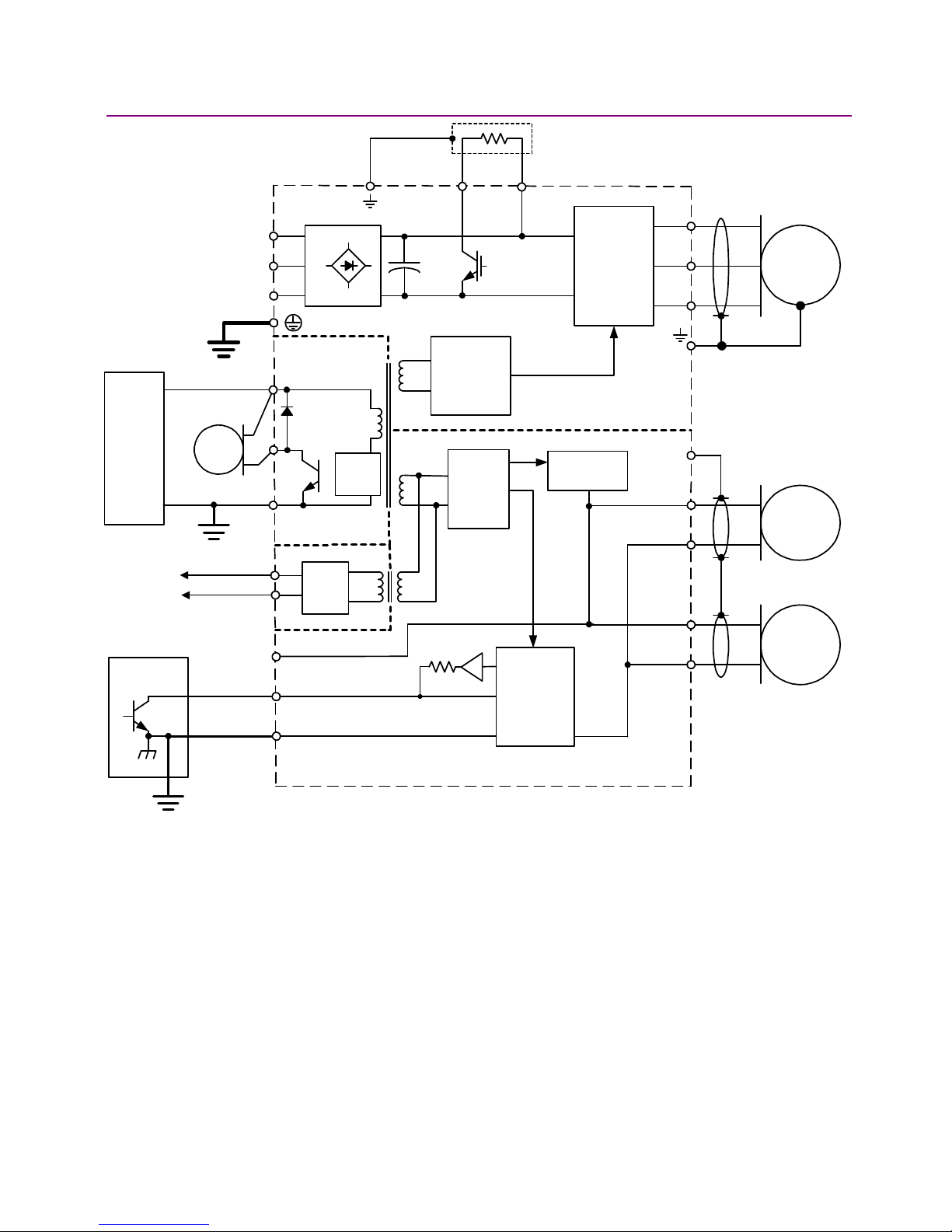

2.1: Amplifier Internal Power

Power distribution within Xenus is divided into three sections: +24 Vdc, logic/signal, and high

voltage. Each is isolated from the other.

2.1.1: Logic/Signal Power

An internal DC/DC converter operates from the +24 Vdc Logic Supply input and creates the

required logic/signal operating voltages, the isolated voltages required for the high-voltage control

circuits, and a +5 Vdc supply for powering the motor encoder and Hall circuits. All the digital and

analog inputs, digital outputs (with the exception of OUT4), Hall and encoder inputs are referenced

to the same signal common. OUT4 is controlled through an opto-isolator, and is referenced to the

+24 Vdc return. The CAN interface is also optically isolated.

Deriving internal operating voltages from a separate source enables the amplifier to stay on-line

when the mains have been disconnected for emergency-stop or operator-intervention conditions.

This allows CAN bus and serial communications to remain active so that the amplifier can be

monitored by the control system while the mains power is removed.

2.1.2: High Voltage

Mains power drives the high-voltage section. It is rectified and capacitor-filtered to produce the DC

bus: the DC “link” power that drives the PWM inverter, where it is converted into the voltages that

drive a three-phase brushless or DC brush motor. An internal solid-state switch, together with an

external power resistor, provides dissipation during regeneration when the mechanical energy of

the motor is converted back into electrical energy. This prevents charging the internal capacitors

to an overvoltage condition.

14 Copley Controls Corp.

Page 15

Xenus XTL User Guide Operational Theory

2.1.3: Power and Grounding Diagram

SHIELD

AMPLIFIER

CHASSIS

REGEN(-)

REGEN(+)

FRAME

(SAFETY)

GROUND

+24

VDC

+24 Vdc

GROUND

CAN

Network

CONTROL

SYSTEM

MAINS

BRAKE

J1

J4

J6

L1

L2

L3

+24 Vdc

BRAKE

RTN

+5 Vdc

~

~

~

CAN

Bus

Ckt

DC/DC

Cntrl

DC/DC

Converter

+

-

1760 PF

+

J3

PWM

STAGE

CONTROL

POWER

LOGIC

&

SIGNAL

POWER

DC BUSS(+)

INVERTER

DC BUSS(-)

ISOLATION BARRIER

+5 Vdc @

400mA

PWM

SHIELD

+5 Vdc

SIGNAL GND

+5 Vdc

W

J2

U

V

MOTOR

CASE

HALLS

J8

ENCODER

J7

CONTROL

SIGNAL

GROUND

ENABLE [IN1]

SIGNAL GND

CONTROL

LOGIC

SIGNAL GND

Copley Controls Corp. 15

Page 16

Operational Theory Xenus XTL User Guide

2.2: Synchronizing PWM Switching Frequency

In some situations, such as when sampling small analog signals, it is desirable to synchronize the

PWM switching frequency among multiple amplifiers. In these cases, one amplifier serves as a

master for one or more slave amplifiers. The PWM sync output of the master sends a signal that

is received as a PWM sync input by each slave.

2.3: Commutation Modes

The amplifier supports three commutation modes to drive brush and brushless motors: AC

brushless sinusoidal, AC brushless trapezoidal, and DC brush.

In most applications, sinusoidal commutation is preferred over trapezoidal, because it reduces

torque ripple and offers the smoothest motion at any velocity or torque. In the sinusoidal

commutation mode, an encoder or a resolver are required for all modes of operation.

In AC brushless trapezoidal commutation mode, the amplifier provides traditional six-step

commutation.

When driving a DC brush motor, the amplifier operates as a traditional H-Bridge amplifier.

2.4: Feedback

2.4.1: Encoder and Resolver Support

The Xenus amplifier is offered in three versions to support encoder or resolver feedback. The

standard version supports digital quadrature encoders. The -S version supports analog sin/cos

encoders. These versions normally require the use of Hall switches for the commutation of

brushless motors. The resolver version supports standard, single speed, transmit-type resolvers.

2.4.2: Multi-Mode Port

All versions support a multi-mode port. This interface can be configured to:

• Provide a buffered digital encoder output based on the digital encoder input.

• Provide an emulated digital encoder output based on the analog encoder or resolver input.

• Provide a second digital encoder input to be used in the dual encoder position mode. In this

mode, an encoder attached to the load provides position loop feedback, and the motor

encoder or resolver provides velocity loop feedback.

16 Copley Controls Corp.

Page 17

Xenus XTL User Guide Operational Theory

2.5: Operating Modes

2.5.1: Modes and Control Loops

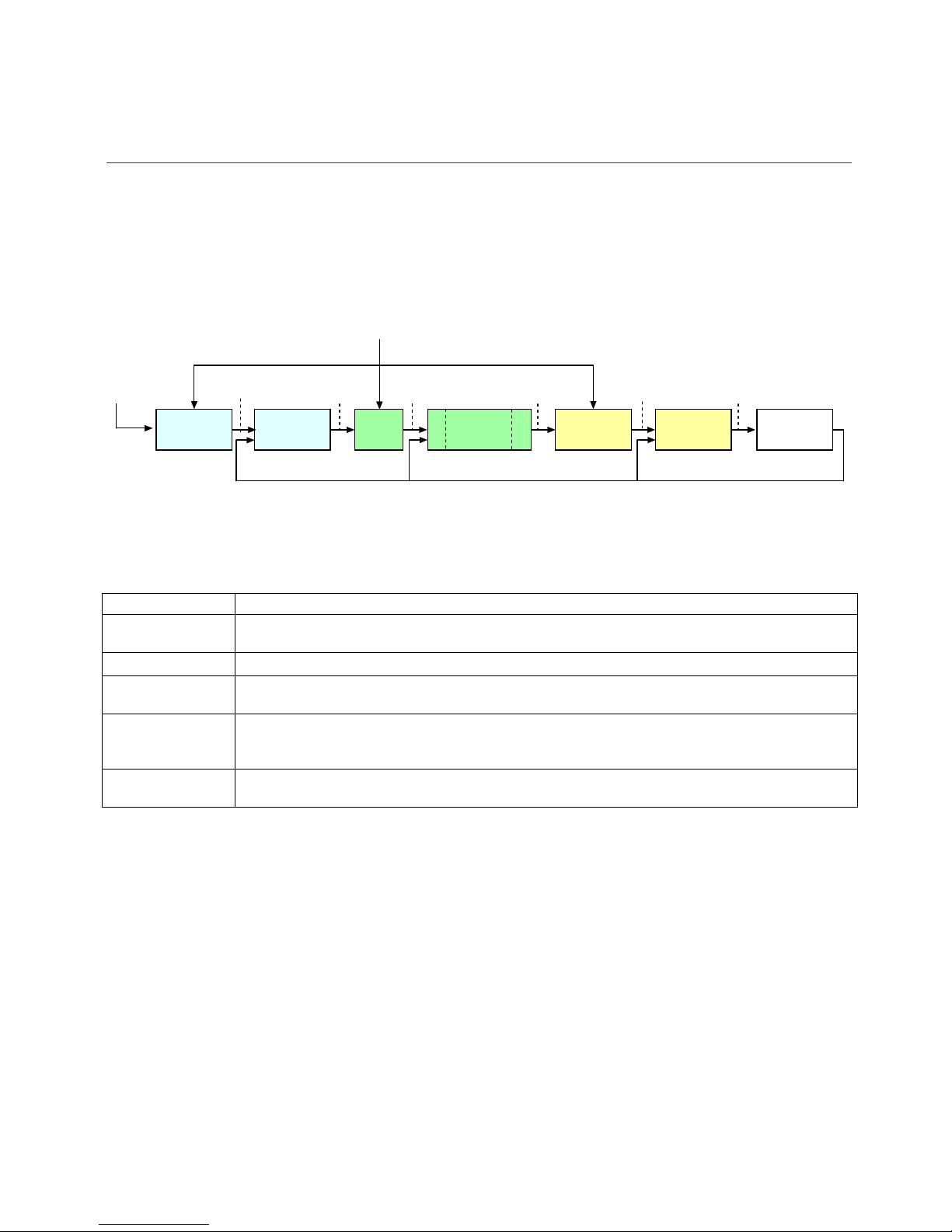

Nesting of Control Loops and Modes

Copley Controls amplifiers use up to three nested control loops - current, velocity, and position - to

control a motor in three associated operating modes.

Control Loops Illustration

In position mode, the amplifier uses all three loops. As shown below, the position loop drives the

nested velocity loop, which drives the nested current loop.

Limits

Target

Position

Trajectory

G

enerator

Position

Command

Position

L

oop

Ve loc ity

Command

Velocity

L

imiter

Limited

Velocity

Cur re nt

FILTER

Veloc ity

L

oop

Co mman d

FILTER

Cur re nt

L

Limited

Current

Current

imiter

Ac tual CurrentDerived VelocityActual Position

PWM

Command

L

oop

Motor/

S

ensors

In velocity mode, the velocity loop drives the current loop. In current mode, the current loop is

driven directly by external or internal current commands.

Basic Attributes of All Control Loops

These loops (and servo control loops in general) share several common attributes:

Loop Attribute Description

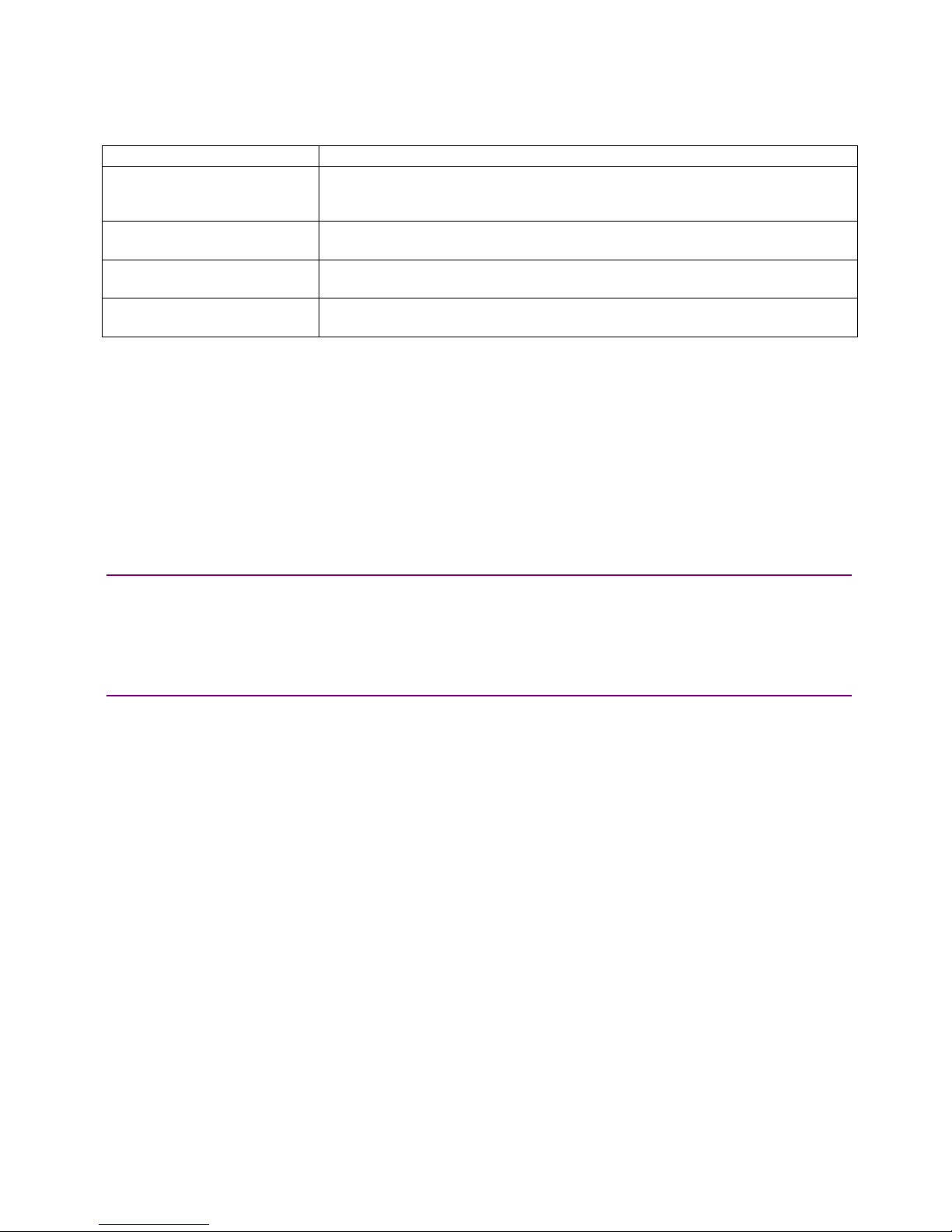

Command input Every loop is given a value to which it will attempt to control. For example, the velocity loop

receives a velocity command that is the desired motor speed.

Limits Limits are set on each loop to protect the motor and/or mechanical system.

Feedback The nature of servo control loops is that they receive feedback from the device they are

controlling. For example, the position loop uses the actual motor position as feedback.

Gains These are constant values that are used in the mathematical equation of the servo loop. The

values of these gains can be adjusted during amplifier setup to improve the loop

performance. Adjusting these values is often referred to as tuning the loop.

Output The loop generates a control signal. This signal can be used as the command signal to another

control loop or the input to a power amplifier.

Copley Controls Corp. 17

Page 18

Operational Theory Xenus XTL User Guide

2.5.2: Current Mode and Current Loop

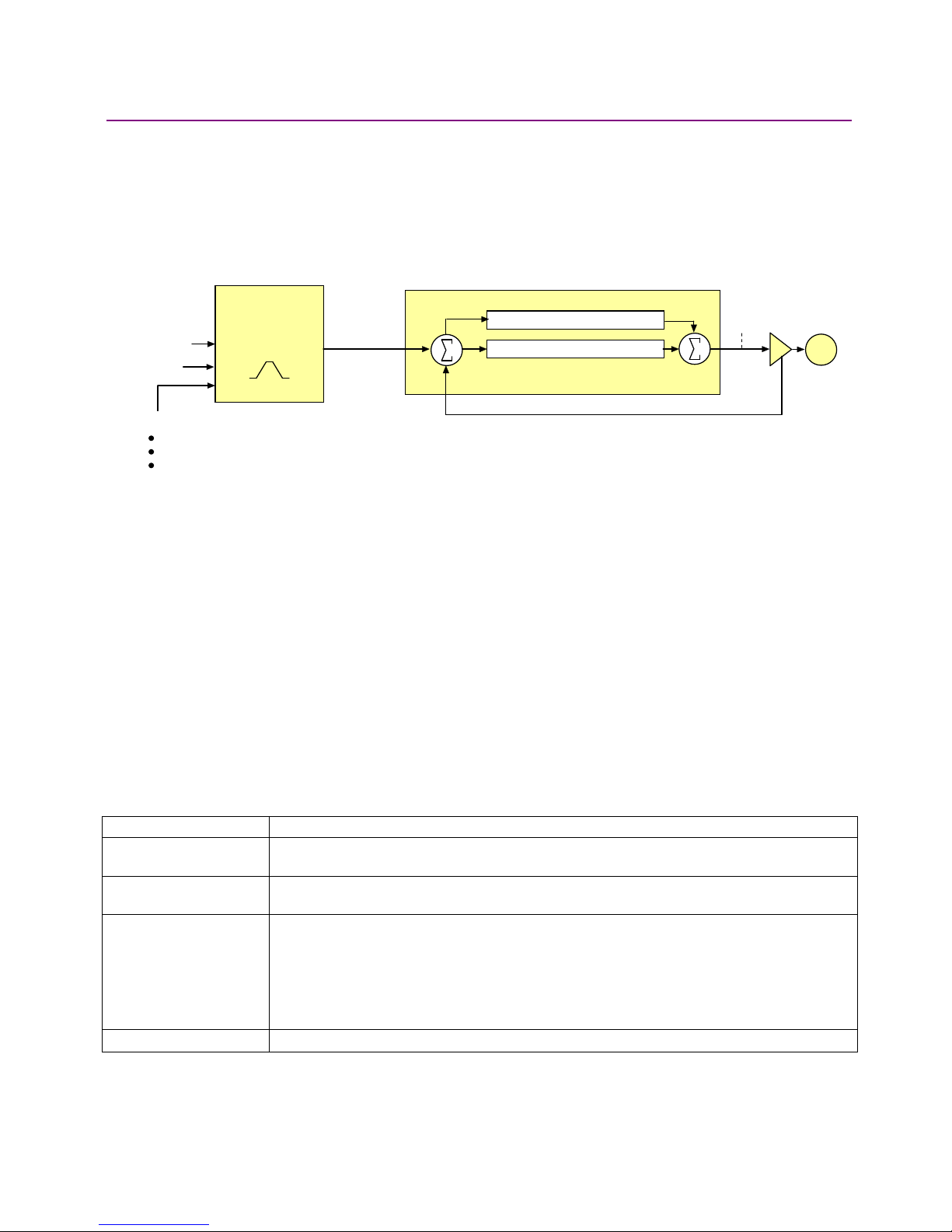

Current Loop Diagram

As shown below, the “front end” of the current loop is a limiting stage. The limiting stage accepts a

current command, applies limits, and passes a limited current command to the summing junction.

The summing junction takes the limited current command, subtracts the actual current

(represented by the feedback signal), and produces an error signal. This error signal is then

processed using the integral and proportional gains to produce a command. This command is

then applied to the amplifier’s power stage.

Current Command

Current Off set

Limits:

Peak Current

Continuous Current

Peak Curr ent Limit Time

Current Lim iter

Limited Current

Current Loop

Current Integral Gain (Ci)

+

-

Current Proportional Gain (Cp)

Feedback (A ctual Current)

+

+

PWM

Comman d

Mot or

Current Loop Inputs

• The amplifier’s analog or PWM inputs.

• A network command, CANopen, DeviceNet, or RS-232 Serial.

• A Copley Virtual Motion (CVM) control program.

• The amplifier’s internal function generator.

In velocity or position modes, the current command is generated by the velocity loop.

Offset

The current loop offset is intended for use in applications where there is a constant force applied

to, or required of, the servomotor and the system must control this force. Typical applications

would be a vertical axis holding against gravity, or web tensioning. This offset value is summed

with the current command before the limiting stage.

Limits

The current command is limited based on the following parameters:

Limiter Description

Peak Current Limit Maximum current that can be generated by the amplifier for a short duration of time. This

value cannot exceed the peak current rating of the amplifier.

Continuous Current

Limit

I2T Time Limit Maximum amount of time that the peak current can be applied to the motor before it must

Ramp Rate of change in current command.

18 Copley Controls Corp.

Maximum current that can be constantly generated by the amplifier.

be reduced to the continuous limit or generate a fault.

For more details, see I

Note: Although the current limits set by the user may exceed the amplifier's internal limits,

the amplifier operates using both sets of limits in parallel, and therefore will not exceed its

own internal limits regardless of the values programmed.

2

T Time Limit Algorithm (p. 153).

Page 19

Xenus XTL User Guide Operational Theory

Current Loop Gains

The current loop uses these gains:

Gain Description

Cp - Current loop proportional The current error (the difference between the actual and the limited commanded

current) is multiplied by this value. The primary effect of this gain is to increase

bandwidth (or decrease the step-response time) as the gain is increased.

Ci - Current loop integral The integral of the current error is multiplied by this value. Integral gain reduces the

current error to zero over time. It controls the DC accuracy of the loop, or the

flatness of the top of a square wave signal. The error integral is the accumulated

sum of the current error value over time.

Current Loop Output

The output of the current loop is a command that sets the duty cycle of the PWM output stage of

the amplifier.

Auto Tune

CME 2 provides a current loop Auto Tune feature, which automatically determines optimal Cp and

Ci values for the motor. For more information, see Auto Tune the Current Loop (p. 117).

Copley Controls Corp. 19

Page 20

Operational Theory Xenus XTL User Guide

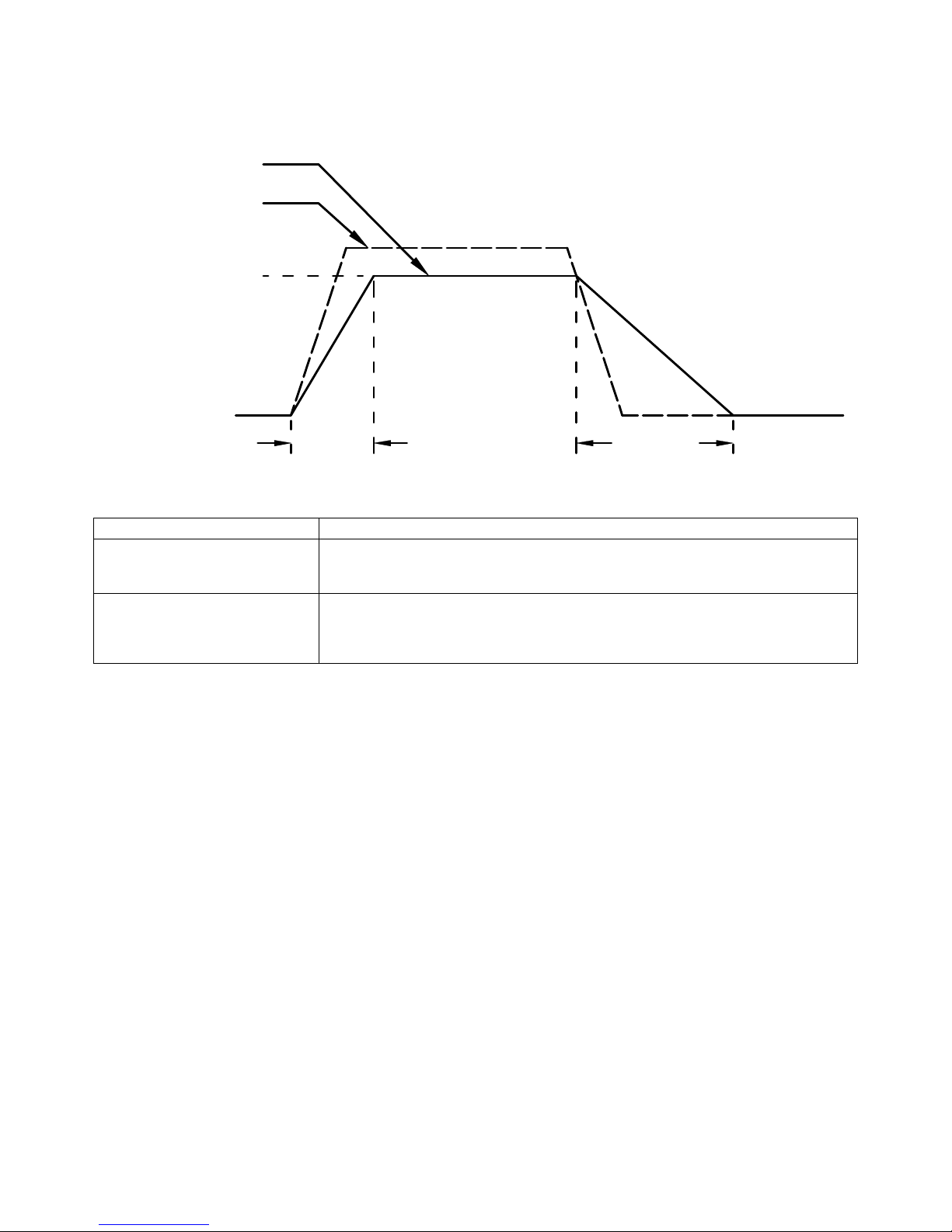

2.5.3: Velocity Mode and Velocity Loop

Velocity Loop Diagram

As shown below, the velocity loop limiting stage accepts a velocity command, applies limits, and

passes a limited velocity command to the input filter. The filter then passes a velocity command to

the summing junction. The summing junction subtracts the actual velocity, represented by the

feedback signal, and produces an error signal. (The velocity loop feedback signal is always from

the motor feedback device even when an additional encoder is attached to the load.) The error

signal is then processed using the integral and proportional gains to produce a current command.

Programmable digital filters are provided on both the input and output command signals.

Velocity Loop

Velocity

C

ommand

Limits:

*Not used w hen velocity loop is c ontrolled by position loop. See "V elocity Loop Limits" f or details.

Ve lo city L im ite r

Velocity

Acceleration*

Deceleration*

E

mergenc y Stop Deceleration*

Fil te r

Limited

Velocity

+

Feedback (Derived V elocity )

-

Veloc ity Integral Gain (V i)

V

elocity Proportional Gain (V p)

+

+

Filter

Current

Command

Inputs

In velocity mode, the velocity command comes from one of the following:

• The amplifier’s analog or PWM inputs.

• A network command, CANopen, DeviceNet, or RS-232 Serial.

• A Copley Virtual Motion (CVM) control program.

• The amplifier’s internal function generator.

In position mode, the velocity command is generated by the position loop.

Velocity Loop Limits

The velocity command is limited based on the following set of parameters designed to protect the

motor and/or the mechanical system.

Limiter Description

Velocity Limit Sets the maximum velocity command input to the velocity loop.

Acceleration Limit Limits the maximum acceleration rate of the commanded velocity input to the velocity loop.

This limit is used in velocity mode only.

Deceleration Limit Limits the maximum deceleration rate of the commanded velocity input to the velocity loop.

This limit is used in velocity mode only.

Fast Stop Ramp Specifies the deceleration rate used by the velocity loop when the amplifier is hardware

disabled. (Fast stop ramp is not used when amplifier is software disabled.) If the brake

delay option is programmed, the fast stop ramp is used to decelerate the motor before

applying the brake.

Note that Fast Stop Ramp is used only in velocity mode. In position mode, the trajectory

generator handles controlled stopping of the motor. There is one exception: if a non-latched

following error occurs in position mode, then the amplifier drops into velocity mode and the

Fast Stop Ramp is used.

For more information, see Following Error Fault Details (p. 37).

20 Copley Controls Corp.

Page 21

Xenus XTL User Guide Operational Theory

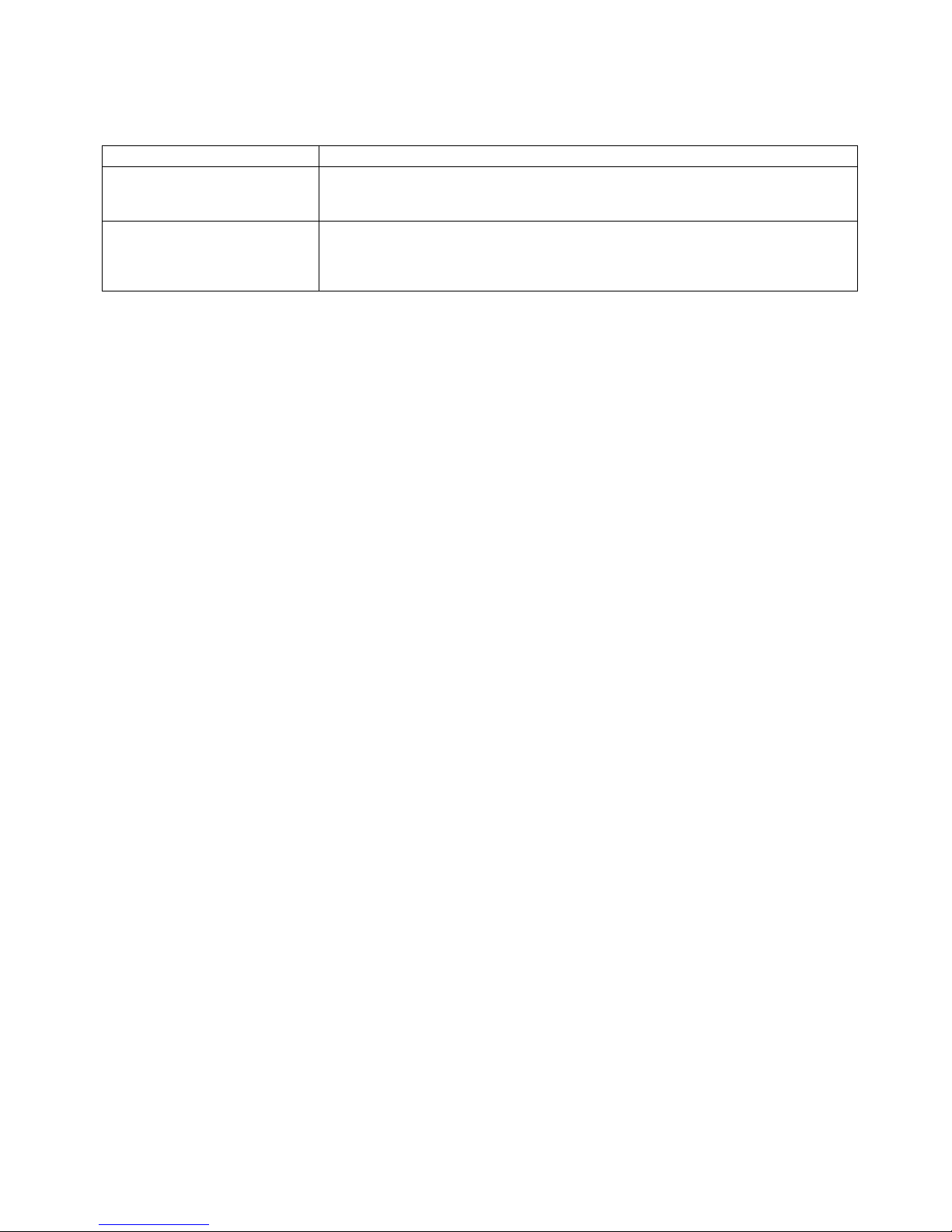

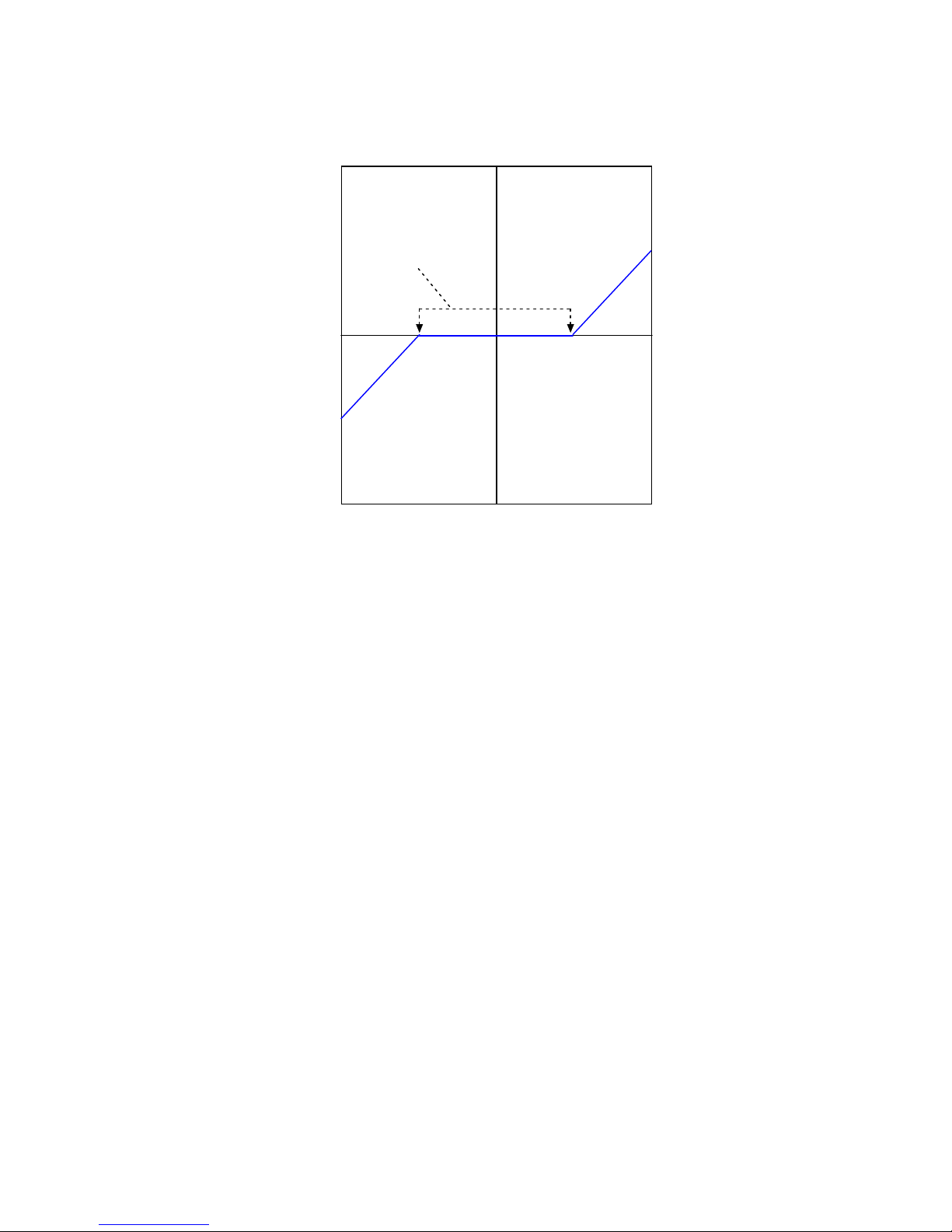

Diagram: Effects of Limits on Velocity Command

The following diagram illustrates the effects of the velocity loop limits.

Limited Velocity

Commanded Velocity

Vel Limit

Accel Limit Decel Limit

Velocity Loop Gains

The velocity loop uses these gains:

Gain Description

Vp - Velocity loop proportional The velocity error (the difference between the actual and the limited commanded

velocity) is multiplied by this gain. The primary effect of this gain is to increase

bandwidth (or decrease the step-response time) as the gain is increased.

Vi - Velocity loop integral The integral of the velocity error is multiplied by this value. Integral gain reduces the

velocity error to zero over time. It controls the DC accuracy of the loop, or the

flatness of the top of a square wave signal. The error integral is the accumulated

sum of the velocity error value over time.

Velocity Loop Gains Scalar

The Enable Gains Scalar feature increases or decreases the resolution of the units used to

express Vp and Vi, providing more precise tuning.

Velocity Loop Command and Output Filters

The velocity loop contains two programmable digital filters. The input filter should be used to

reduce the effects of a noisy velocity command signal. The output filter can be used to reduce the

excitation of any resonance in the motion system.

Two filter classes can be programmed: the Low-Pass and the Custom Bi-Quadratic. The LowPass filter class includes the Single-Pole and the Two-Pole Butterworth filter types. The Custom

Bi-Quadratic filter allows advanced users to define their own filters incorporating two poles and two

zeros.

For more information on the velocity loop filters, see the CME 2 User Guide.

Velocity Loop Outputs

The output of the velocity loop is a current command used as the input to the current loop.

Copley Controls Corp. 21

Page 22

Operational Theory Xenus XTL User Guide

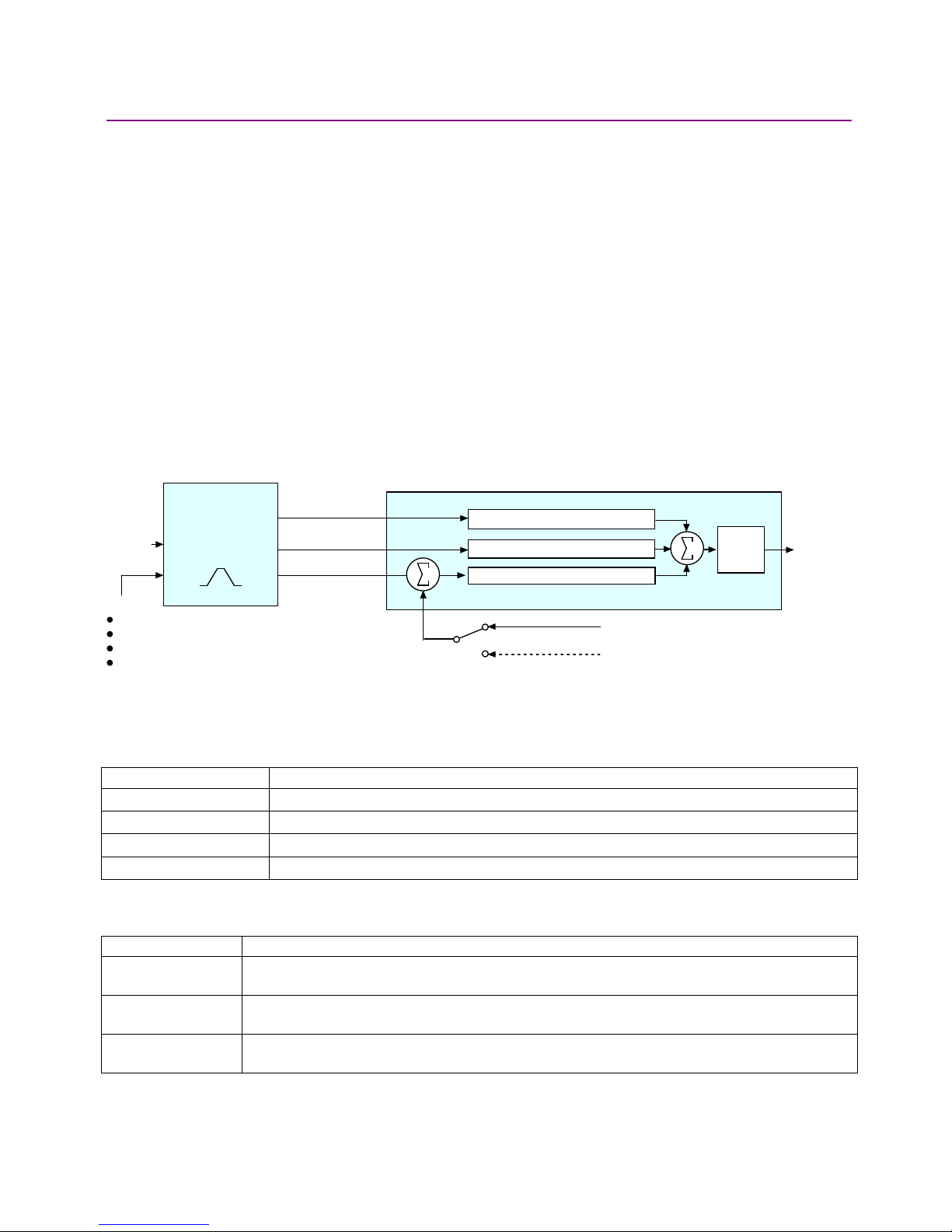

2.5.4: Position Mode and Position Loop

Position Loop Diagram

The amplifier receives position commands from the digital or analog command inputs, over the

CAN interface or serial bus, or from the CVM Control Program. When using digital or analog

inputs, the amplifier's internal trajectory generator calculates a trapezoidal motion profile based on

trajectory limit parameters. When using the CAN bus, serial bus, or CVM Control Program, a

trapezoidal or S-curve profile can be programmed. The trajectory generator updates the

calculated profile in real time as position commands are received.

The output of the generator is an instantaneous position command (limited position). In addition,

values for the instantaneous profile velocity and acceleration are generated. These signals, along

with the actual position feedback, are processed by the position loop to generate a velocity

command.

To bypass the trajectory generator while in digital or analog position modes, set the maximum

acceleration to zero. The only limits in effect will now be the velocity loop velocity limit and the

current limits. (Note that leaving the maximum acceleration set to zero will prevent other position

modes from operating correctly.)

The following diagram summarizes the position loop.

Position Loop

from motor encoder or resolver

from optional position encoder (on load)

+

+

+

Gain

Multiplier

Veloc ity

Command

Target

Po s it io n

Limits:

Max v elocity

Ma x accel

Ma x decel

Abort decel

Trajector y

Generator

Prof ile Velocity

Prof ile Acceleration

Limited Position

+

Feedback

Velocity Feed Forw ard (V ff)

Acceleration Feed Forw ard (Aff)

Position Proportional Gain (Pp)

-

Trajectory Limits

In position mode, the trajectory generator applies the following user-set limits to generate the

motion profile.

Limiter Description

Maximum Velocity Limits the maximum speed of the profile.

Maximum Acceleration Limits the maximum acceleration rate of the profile.

Maximum Deceleration Limits the maximum deceleration rate of the profile.

Abort Deceleration Specifies the deceleration rate used by the trajectory generator when motion is aborted.

Position Loop Inputs From the Trajectory Generator

The position loop receives the following inputs from the trajectory generator.

Input Description

Profile Velocity The instantaneous velocity value of the profile. Used to calculate the velocity feed forward

value.

Profile Acceleration The instantaneous acceleration/deceleration value of the profile. Used to calculate the

acceleration feed forward value.

Limited Position The instantaneous commanded position of the profile. Used with the actual position feedback to

generate a position error.

22 Copley Controls Corp.

Page 23

Xenus XTL User Guide Operational Theory

Position Loop Gains

The following gains are used by the position loop to calculate the velocity command:

Gain Description

Pp - Position loop proportional The loop calculates the position error as the difference between the actual and

limited position values. This error in turn is multiplied by the proportional gain value.

The primary effect of this gain is to reduce the following error.

Vff - Velocity feed forward The value of the profile velocity is multiplied by this value. The primary effect of this

gain is to decrease following error during constant velocity.

Aff - Acceleration feed forward The value of the profile acceleration is multiplied by this value. The primary effect of

this gain is to decrease following error during acceleration and deceleration.

Gain Multiplier The output of the position loop is multiplied by this value before being passed to the

velocity loop.

Position Loop Feedback

Xenus supports two position feedback configurations

• Single sensor. Position loop feedback comes from the encoder or resolver on the motor.

• Dual sensor. Position loop feedback comes from the encoder attached to the load.

(Note that in either case, velocity loop feedback comes from the motor encoder or resolver.) For

more information, see Feedback (p. 16).

Position Loop Output

The output of the position loop is a velocity command used as the input to the velocity loop.

2.5.5: Input Command Types

The amplifier can be controlled by a variety of external sources: analog voltage or digital inputs,

CAN network (CANopen or DeviceNet), or over an RS-232 serial connection using ASCII

commands. The amplifier can also function as a stand-alone motion controller running an internal

CVM program or using its internal function generator.

2.5.6: Analog Command Input

Overview

The amplifier can be driven by an analog voltage signal through the analog command input. The

amplifier converts the signal to a current, velocity, or position command as appropriate for current,

velocity, or position mode operation, respectively.

The analog input signal is conditioned by the scaling, dead band, and offset settings.

Scaling

The magnitude of the command generated by an input signal is proportional to the input signal

voltage. Scaling controls the input-to-command ratio, allowing the use of an optimal command

range for any given input voltage signal range.

For example, in current mode, with default scaling, +10 Vdc of input generates a command equal

to the amplifier’s peak current output; +5 Vdc equals half of that.

Scaling could also be useful if, for example, the signal source generates a signal range between 0

and +10 Vdc, but the command range only requires +7.5 Vdc of input. In this case, scaling allows

the amplifier to equate +7.5 Vdc with the amplifier’s peak current (in current mode) or maximum

velocity (in velocity mode), increasing the resolution of control.

Dead Band

To protect against unintended response to low-level line noise or interference, the amplifier can be

programmed with a “dead band” to condition the response to the input signal voltage. The

Copley Controls Corp. 23

Page 24

Operational Theory Xenus XTL User Guide

amplifier treats anything within the dead band ranges as zero, and subtracts the dead band value

from all other values. For instance, with a dead band of 100 mV, the amplifier ignores signals

between –100 mV and +100 mV, and treats 101 mV as 1 mV, 200 mV as 100 mV, and so on.

200

100

0

Output

-100

-200

Dead Band

0 200-200 -100 100

Input

Offset

To remove the effects of voltage offsets between the controller and the amplifier in open loop

systems, CME 2 provides an Offset parameter and a Measure function. The Measure function

takes 10 readings of the analog input voltage over a period of approximately 200 ms, averages

the readings, and then displays the results. The Offset parameter allows the user to enter a

corrective offset to be applied to the input voltage.

The offset can also set up the amplifier for bi-directional operation from a uni-polar input voltage.

An example of this would be a 0 to +10 Vdc velocity command that had to control 1000 rpm CCW

to 1000 rpm CW. Scale would be set to 2000 rpm for a +10 Vdc input and Offset set to -5V. After

this, a 0 Vdc input command would be interpreted as -5 Vdc, which would produce 1000 rpm CCW

rotation. A +10 Vdc command would be interpreted as +5 Vdc and produce 1000 rpm CW rotation.

Monitoring the Analog Command Voltage

The analog input voltage can be monitored in the CME 2 control panel and oscilloscope. The

voltage displayed in both cases is after both offset and deadband have been applied.

Analog Command in Position Mode

The Xenus Analog Position command operates as a relative motion command. When the amplifier

is enabled the voltage on the analog input is read. Then any change in the command voltage will

move the axis a relative distance, equal to the change in voltage, from its position when enabled.

To use the analog position command as an absolute position command, the amplifier should be

homed every time it is enabled. The Homing sequence may be initiated by CAN, ASCII serial, or

CVM Indexer program commands.

24 Copley Controls Corp.

Page 25

Xenus XTL User Guide Operational Theory

2.5.7: PWM Input

Two Formats

The amplifier can accept a pulse width modulated signal (PWM) signal to provide a current

command in current mode and a velocity command in velocity mode. The PWM input can be

programmed for two formats: 50% duty cycle (one-wire) and 100% duty cycle (two-wire).

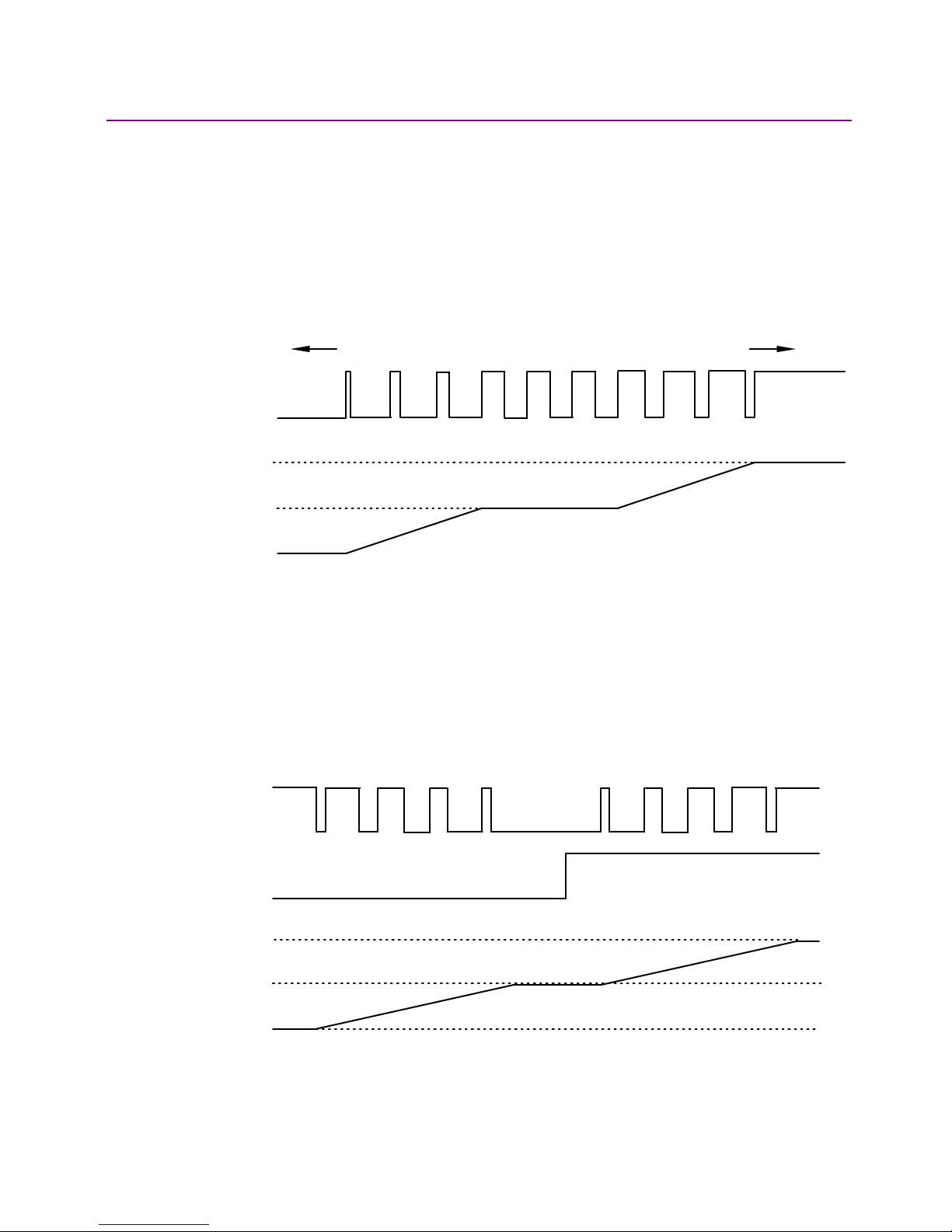

50% Duty Cycle Format (One-Wire)

The input takes a PWM waveform of fixed frequency and variable duty cycle. As shown below, a

50% duty cycle produces zero output from the amplifier. Increasing the duty cycle toward 100%

commands a positive output, and decreasing the duty cycle toward zero commands a negative

output.

Decreasing Duty Cycle Increasing Duty Cycle

P

WM Input

50 % Duty Cycle

Max +

Amplifier Output

0

Max -

The command can be inverted so that increased duty cycle commands negative output and vice

versa.

100% Duty Cycle Format (Two-Wire)

One input takes a PWM waveform of fixed frequency and variable duty cycle, and the other input

takes a DC level that controls the polarity of the output. A 0% duty cycle creates a zero command,

and a 100% duty cycle creates a maximum command level. The command can be inverted so that

increasing the duty cycle decreases the output and vice versa.

100%

Duty Cycle

PWM Input

Direction Input

Max +

100%

Duty Cycle

Amplifier Output

0

Min -

Failsafe Protection from 0 or 100% Duty Cycle Commands

In both formats, the amplifier can be programmed to interpret 0 or 100% duty cycle as a zero

command. This provides a measure of safety in case of a controller failure or a cable break.

Copley Controls Corp. 25

Page 26

Operational Theory Xenus XTL User Guide

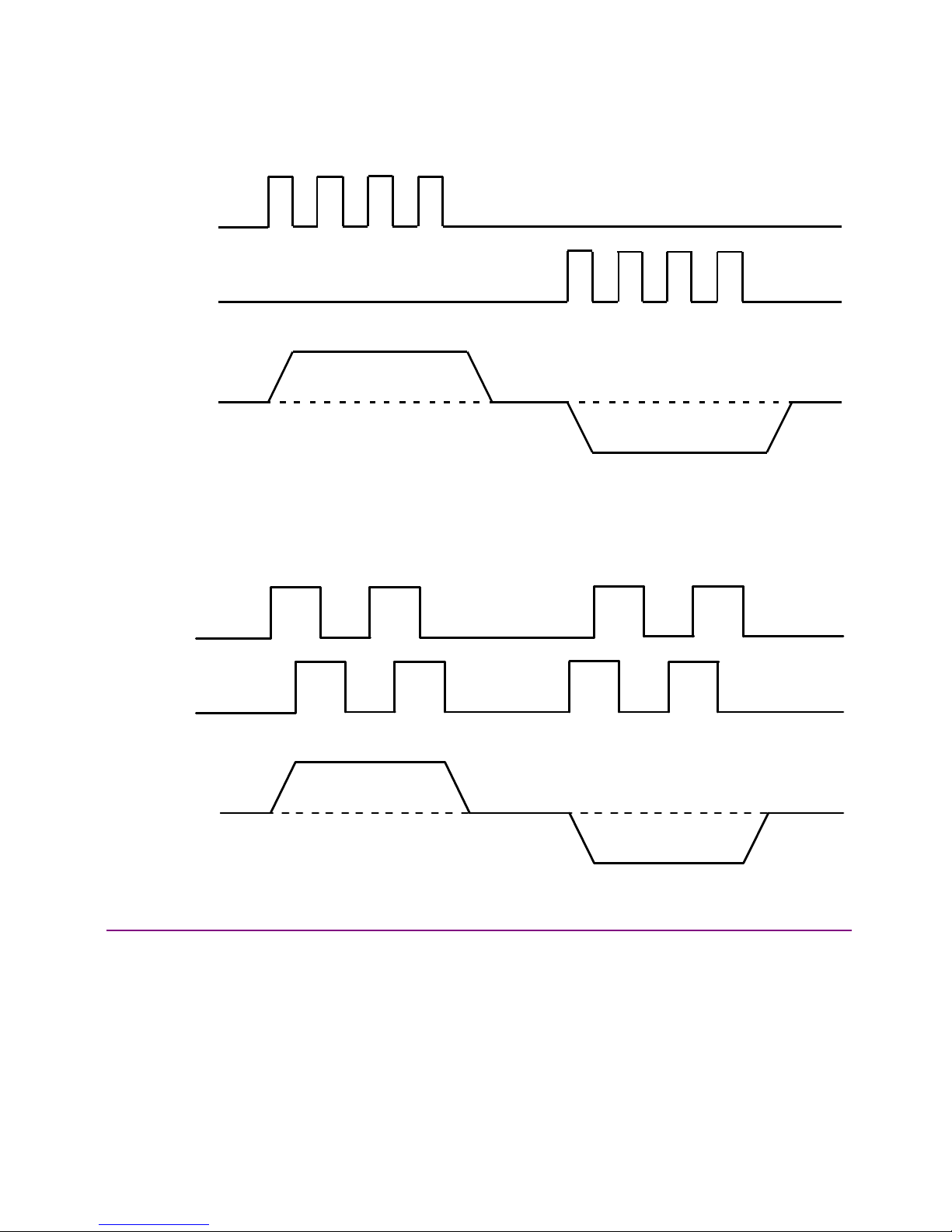

2.5.8: Digital Input

Three Formats

In position mode, the amplifier can accept position commands via two digital inputs, using one of

these signal formats: pulse and direction, count up/count down, and quadrature.

In all three formats, the amplifier can be configured to invert the command.

Pulse Smoothing

In position mode, the amplifier’s trajectory generator ensures smooth motion even when the

command source cannot control acceleration and deceleration rates.

When using digital or analog command inputs, the trajectory generator can be disabled by setting

the Max Accel limit to zero. (Note that when using the CAN bus, serial bus, or CVM Control

Program, setting Max Accel to zero prevents motion.)

Pulse and Direction Format

In pulse and direction format, one input takes a series of pulses as motion step commands, and

another input takes a high or low signal as a direction command, as shown below.

Pulse Input

Direction Input

Velocity

Command

The amplifier can be set to increment position on the rising or falling edge of the signal. Stepping

resolution can be programmed for electronic gearing.

26 Copley Controls Corp.

Page 27

Xenus XTL User Guide Operational Theory

Count Up/Count Down Format

In the count up/count down format, one input takes each pulse as a positive step command, and

another takes each pulse as a negative step command, as shown below.

Up Input

Down Input

Velocity

Command

The amplifier can be set to increment position on the rising or falling edge of the signal. Stepping

resolution can be programmed for electronic gearing.

Quadrature Format

In quadrature format, A/B quadrature commands from a master encoder (via two inputs) provide

velocity and direction commands, as shown below.

A Input

B Input

Vel oc ity

Command

The ratio can be programmed for electronic gearing.

2.5.9: CVM Program

The Copley Virtual Machine (CVM) is a software program that runs motion control programs on

supported Copley Controls amplifiers. When a CVM program is running, the amplifier can receive

input commands from the CVM program.

For more information, see the Copley Indexer Program User’s Guide.

Copley Controls Corp. 27

Page 28

Operational Theory Xenus XTL User Guide

2.6: CANopen Operation

2.6.1: CAN Network and CANopen Profiles for Motion

In position mode, the amplifier can take instruction over a two-wire Controller Area Network

(CAN). CAN specifies the data link and physical connection layers of a fast, reliable network.

CANopen is a set of profiles (specifications) built on a subset of the CAN application layer

protocol. These profiles specify how various types of devices, including motion control devices,

can use the CAN network in a highly efficient manner. Xenus supports the relevant CANopen

profiles, allowing it to operate in the following modes of operation: profile torque, profile velocity,

profile position, interpolated position, and homing.

2.6.2: Supported CANopen Modes

In profile torque mode, the amplifier is programmed with a torque command. When the amplifier is

enabled, or the torque command is changed, the motor torque ramps to the new value at a

programmable rate. When the amplifier is halted, the torque ramps down at the same rate.

In profile velocity mode, the amplifier is programmed with a velocity, a direction, and acceleration

and deceleration rates. When the amplifier is enabled, the motor accelerates to the set velocity

and continues at that speed. When the amplifier is halted, the velocity decelerates to zero.

In profile position mode, the amplifier is programmed with a velocity, a relative distance or

absolute position, and acceleration and deceleration rates. On command, a complete motion

profile is executed, traveling the programmed distance or ending at the programmed position. The

amplifier supports both trapezoidal and s-curve profiles.

In PVT mode, the controller sends the amplifier a sequence of points, each of which is a segment

of a larger, more complex move, rather than a single index or profile. The amplifier then uses

cubic polynomial interpolation to “connect the dots” so that the motor reaches each point at the

specified velocity at the programmed time.

Homing mode is used to move the axis from an unknown position to a known reference or zero

point with respect to the mechanical system. The homing mode is configurable to work with a

variety of combinations of encoder index, home switch, and limit switches.

28 Copley Controls Corp.

Page 29

Xenus XTL User Guide Operational Theory

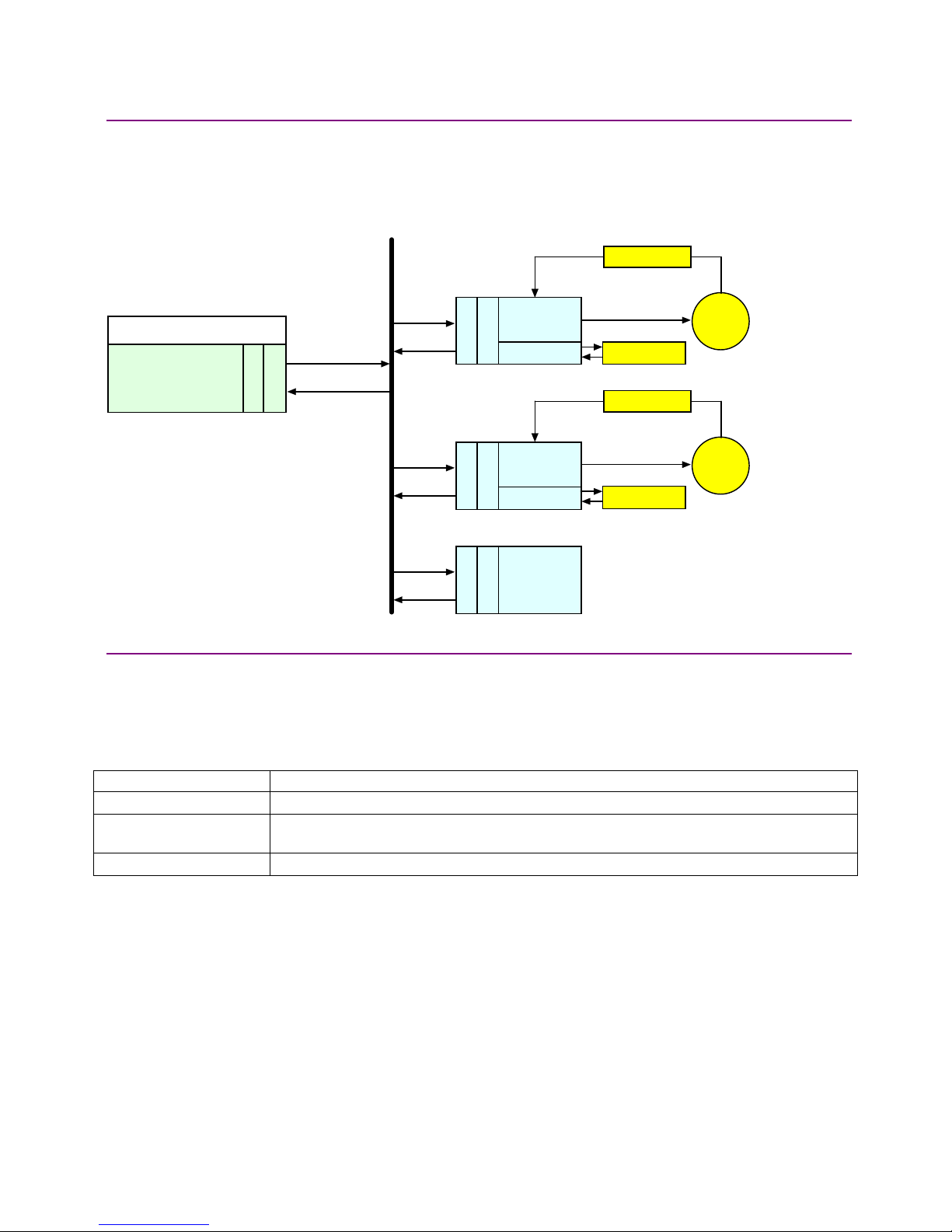

2.6.3: Architecture

As shown below, in a CANopen motion control system, control loops are closed on the individual

amplifiers, not across the network. A master application coordinates multiple devices, using the

network to transmit commands and receive status information. Each device can transmit to the

master or any other device on the network. CANopen provides the protocol for mapping device

and master internal commands to messages that can be shared across the network.

Feedback

S

oftw are Application

Master Controller

Xenus

Amplifier

CANopen

CANopen

CANopen

I/O

Xenus

Amplifier

I/O

Other

CANopen

Device

C

ontrol

Status

CAN port

CANopen

CAN Network

CAN port

CAN port

CAN port

Local Control

Sensor

Feedback

Local Control

Sensor

Motor

Motor

2.6.4: CAN Addressing

A CANopen network can support up to 127 nodes. Each node must have a unique and valid

seven-bit address (Node ID) in the range of 1-127. (Address 0 is reserved and should only be

used when the amplifier is serving as a CME 2 serial port multi-drop gateway.)

There are several basic methods for setting the CAN address, as described below. These method

can be used in any combination, producing a CAN address equal to the sum of the settings.

Addressing Method Description

Use switch If the address number <= 15, CAN address can be set using the CAN ADDR switch only.

Use inputs Use the amplifier’s programmable digital inputs (user selects how many (1-7) and which

inputs are used).

Use programmed value Program address into flash only.

For more information on CAN addressing, see CAN Interface (p. 109).

For more information on CANopen operations, see the following Copley Controls documents:

• CANopen Programmer’s Manual

• CML Reference Manual

• Copley Motion Objects Programmer’s Guide

Copley Controls Corp. 29

Page 30

Operational Theory Xenus XTL User Guide

2.7: Limit Switches

2.7.1: Use Digital Inputs to Connect Limit Switches

Limit switches help protect the motion system from unintended travel to the mechanical limits. Any

of the digital inputs 2-12 can be can be programmed as positive or negative limit switch inputs.

With the amplifier operating as a CAN node, an input can also be programmed as a home limit

switch for CANopen homing operations.

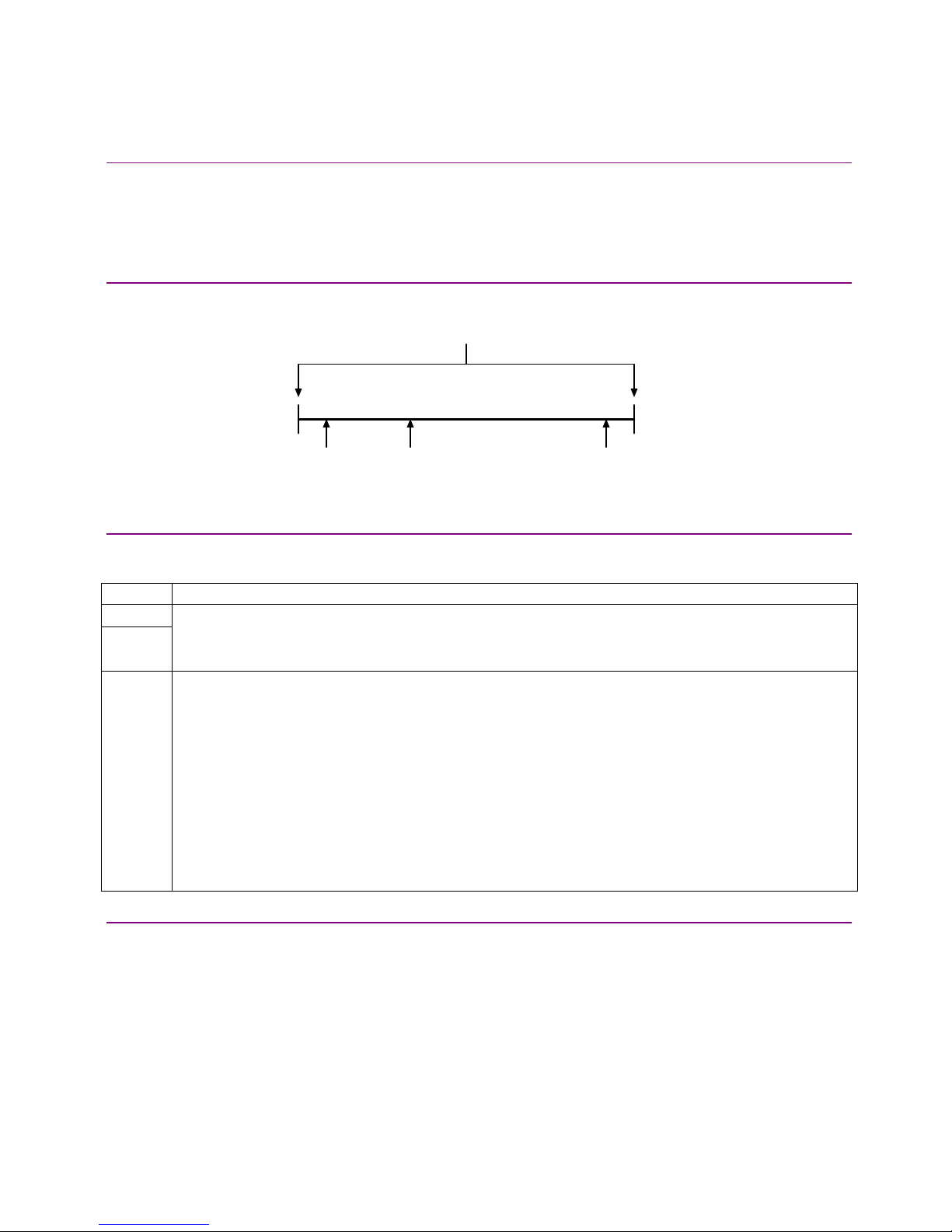

2.7.2: Diagram: Sample Placement of Limit Switches

The following diagram shows these limit switches in use on a sample motion stage.

Mechanical Limits of Motion Stage

Negative

Limit

Sw itch

Home

Sw itch

Positive

Limit

Sw itch

2.7.3: How the Amplifier Responds to Limit Switch Activation

The amplifier stops any motion in the direction of an active limit switch, as described below. The

response is identical in current and velocity modes, and slightly different in position mode.

Mode Amplifier Response to Active Positive (or Negative) Limit Switch

Current

Velocity

Position Amplifier stops responding to position commands until the amplifier is disabled and re-enabled, or the fault

Amplifier prohibits travel in positive (or negative) direction. Travel in the opposite direction is still allowed.

Amplifier status indicator flashes green at fast rate.

Warning is displayed on CME 2 Control Panel and CME 2 Control Panel limit indicator turns red.

is cleared over the CANopen interface.

Amplifier status indicator flashes green at fast rate.

Warning is displayed on CME 2 Control Panel and CME 2 Control Panel limit indicator turns red.

Default behavior: If, after re-enabling the amp, the limit switch is still active, the amplifier will only allow

movement in the opposite direction.

“Hold position” behavior: If the *Hold position when limit switch is active option is set, the amplifier

prevents any motion while a limit switch is active.

CAUTION: If the amplifier is switched back to current or velocity mode with this option selected, the limit

switches will no longer function.

For more information on *Hold position when limit switch is active, see Digital Inputs (p. 93).

2.7.4: Using Custom Output to Signal Limit Switch Activation

In addition to the response described above, any of the amplifier’s digital outputs can be

configured to go active when a positive or negative limit switch is activated. For more information,

see Custom Digital Output Settings: Custom Event (p. 96).

30 Copley Controls Corp.

Page 31

Xenus XTL User Guide Operational Theory

2.8: Brake Operation

2.8.1: Digital Output Controls Brake

Many control systems employ a brake to hold the axis when the amplifier is disabled. Digital output

4 (OUT4) is designed specifically for a brake output. (Other outputs can be used for brake control,

but OUT4 is recommended.) Unlike the other outputs, OUT4 is optically isolated from the control

signals and has an internal fly back diode connected to the +24 Vdc input. By eliminating the need

to connect into the amplifier control connector, having the brake output on the +24 Vdc power

connector simplifies wiring when the brake wires are in the power cable of the motor.

For more information, see Brake Output (p. 47) and Logic Supply / Brake (J4) (p. 60).

2.8.2: Brake/Stop Sequences

Disabling the amplifier by a hardware or software command starts the following sequence of

events.

• The motor begins to decelerate (at Abort Deceleration rate in position mode or Fast Stop

Ramp rate in velocity mode). At the same time, the Brake/Stop Delay Time count begins. This

allows the amplifier to slow the motor before applying the brake.

• When the motor slows to Brake/Stop Activation Velocity OR the Brake/Stop Delay Time

expires, the brake output activates and PWM Delay Brake/Stop Response Time count begins.

• When response time has passed, the amplifier’s output stages are disabled. This delay

ensures the brake has time to lock in before disabling the power section.

This sequence is not available in the current mode of operation. Instead, in current mode, the

amplifier output turns off and the brake output activates immediately when the disable command is

received.

Copley Controls Corp. 31

Page 32

Operational Theory Xenus XTL User Guide

2.9: Status Indicators

2.9.1: Amplifier and CAN Interface Status Indicators

The amplifier’s status indicator is a bicolor LED labeled STATUS on the amplifier front panel. The

CAN interface status indicator is a bicolor LED labeled CAN. Locations are shown below.

Xenus Status Indicator

CAN Status Indicator

2.9.2: Amplifier Status Indicator Operation

Amplifier status indicator color/blink codes are described below.

Color/Blink Code Meaning

Not illuminated No +24 Vdc power to amplifier.

Steady green Amplifier is enabled and operational.

Slow-blinking green Amplifier is disabled. No faults or warnings are active.

Fast-blinking green A limit switch is active. The amplifier is enabled.

Steady red A non-latched fault has occurred.

Blinking red A latched fault has occurred.

32 Copley Controls Corp.

Page 33

Xenus XTL User Guide Operational Theory

2.9.3: CAN Interface Status Indicator Operation

The amplifier status indicator color/blink codes comply with CAN Indicator Specification 303-3 as

described below. Note that green and red codes are often interlaced, each indicating a different

set of conditions. The green codes indicate the CANopen state machine mode of operation (preoperational, operational, or stopped). The red codes indicate the status of the physical bus

(warning or error conditions).

CANopen State Machine Mode of Operation

Indicator State Diagram

Blinking green Pre-operational.

green

off

Steady green Operational

green

off

Single flash green Stopped

green

off

200

ms

200

ms

1 second

200

ms

Physical Bus Status

Single flash red Warning Limit

Reached

Double flash red Error Control Event

Triple flash red Sync Error

Steady red Bus Off

red

off

red

red

off

off

red

off

200

ms

200

ms

200

ms

200

ms

200

ms

1 second

1 second

1 second

200

ms

In addition, the CAN status indicator is turned off when the CAN node ID selector (CAN ADDR) is

set to 0. A setting of 0, which is invalid, shuts down most operations on the CAN interface, and the

light is shut off to indicate this status.

Copley Controls Corp. 33

Page 34

Operational Theory Xenus XTL User Guide

2.10: Protection

2.10.1: Faults

Overview

Xenus detects and responds to a set of conditions regarded as faults, such as amplifier over

temperature and excessive following error. When any fault occurs, with the exception of a

following error, the amplifier’s PWM output stage is disabled, the fault type is recorded in the

amplifier’s internal error log (which can be viewed with CME 2), and the status LED changes to

indicate a fault condition exists. A digital output can also be programmed to activate on a fault

condition. The following error fault behaves with slight differences, as described in

Following Error Fault Details (p. 37).

The amplifier’s PWM output stage can be re-enabled after the fault condition is corrected and the

amplifier faults are cleared. The process for clearing faults varies depending on whether the fault

is configured as non-latched or latched.

The fault-clearing descriptions below apply to all faults except for the following error fault, which is

described in Following Error Fault Details (p. 37).

Clearing Non-Latched Faults

The amplifier clears a non-latched fault, without operator intervention, as soon as the fault

condition is corrected.

Risk of unexpected motion with non-latched faults.

After the cause of a non-latched fault is corrected, the amplifier re-enables the PWM

!

DANGER

Clearing Latched Faults

A latched fault is cleared only after the fault has been corrected and at least one of the following

actions has been taken:

• power-cycle the +24 Vdc to the amplifier

• cycle (disable and then enable) an enable input that is configured as

Enables with Clear Faults or Enables with Reset

• access the CME 2 Control Panel and press Clear Faults or Reset

• clear the fault over the CANopen network or serial bus

Example: Non-Latched vs. Latched Faults

For example, the amplifier temperature reaches the fault temperature level and the amplifier

reports the fault and disables the PWM output. Then, the amplifier temperature is brought back

into operating range. If the Amplifier Over Temperature fault is not latched, the fault is

automatically cleared and the amplifier’s PWM outputs are enabled. If the fault is latched, the fault

remains active and the amplifier’s PWM outputs remain disabled until the faults are specifically

cleared (as described above).

output stage without operator intervention. In this case, motion may re-start

unexpectedly. Configure faults as latched unless a specific situation calls for nonlatched behavior. When using non-latched faults, be sure to safeguard against

unexpected motion.

Failure to heed this warning can cause equipment damage, injury, or death.

34 Copley Controls Corp.

Page 35

Xenus XTL User Guide Operational Theory

Fault Descriptions

The set of possible faults is described below. For details on limits and ranges, see

Fault Levels (p. 49).

Fault Description Fault Occurs When… Fault is Corrected When…

*Amplifier Over

Temperature

Motor Phasing Error Encoder-based phase angle does not

*Feedback error

*Motor Over Temperature Motor over-temperature switch changes

Under Voltage Bus voltage falls below specified voltage

Over Voltage Bus voltage exceeds specified voltage

*Following Error User set following error threshold

*Short Circuit Detected Output to output, output to ground, internal

Over Current (Latched) Output current I2T limit has been

*Latched by default.

Amplifier's internal temperature exceeds

specified temperature.

agree with Hall switch states. This fault can

occur only with brushless motors set up

using sinusoidal commutation. It does not

occur with resolver feedback or with Halls

correction turned off.

Over current condition detected on the

output of the internal +5 Vdc supply used

to power the feedback. Resolver or analog

encoder not connected or levels out of

tolerance.

state to indicate an over-temperature

condition.

limit.

limit.

exceeded.

PWM bridge fault.

exceeded.

Power module temperature falls below

specified temperature.

Encoder-based phase angle agrees

with Hall switch states.

Encoder power returns to specified

voltage range.

Feedback signals stay within specified

levels.

Temperature switch changes back to

normal operating state.

+ DC bus voltage returns to specified

voltage range.

+ DC bus voltage returns to specified

voltage range.

See

Position and Velocity Errors (p. 36).

Short circuit has been removed.

Amplifier is reset and re-enabled.

Copley Controls Corp. 35

Page 36

Operational Theory Xenus XTL User Guide

2.11: Position and Velocity Errors

2.11.1: Error-Handling Methods