User Guide

Digital Servo Amplifier

Models 7228AC, 7228DC, 7428AC, 7428DC

Table Of Contents

Chapter 1 Introduction ......................................................... 1-1

Features ............................................................. 1-2

Models ................................................................ 1-3

Applications ........................................................ 1-3

Copley Motion Explorer Software ........................ 1-4

Software Requirements ....................................... 1-4

Terminology ........................................................ 1-5

CE Mark and UL Conformity ............................... 1-6

Unpacking and Inspection ................................... 1-7

Technical Support ............................................... 1-7

Safety ................................................................. 1-8

Chapter 2 Amplifier Connections ......................................... 2-1

Grounding ........................................................... 2-3

J1 AC & DC Power and Motor Phase ................. 2-4

DC Model Power Connections ............................ 2-6

Motor Phase Wiring Connections ....................... 2-8

J2 Motor Signal Wiring Connections ................... 2-9

Amp-Enable, Limit anf Home Switch Input ........ 2-22

Data Connector J4 ............................................ 2-27

Amplifier Status Indicator .................................. 2-30

Signal Module ................................................... 2-31

7XX8 Series Digital Servo Amplifier User Guide

1-1

Chapter 3 Getting Started ................................................... 3-1

Starting Copley Motion Explorer ......................... 3-2

Installation using Copley Motion Explorer

Development Kit Motor ........................................ 3-6

Verifying Software Parameters ............................ 3-6

First Move ........................................................... 3-7

Enabling the Amplifier ......................................... 3-8

Initiate a Move with the Pendant ......................... 3-8

Homing Sequence .............................................. 3-9

Software Parameter Notes ................................ 3-11

Position Loop Tuning ........................................ 3-11

Installation Using a Copley Motor Data File

and a New Copley Motor ................................... 3-13

Installation Using a Vendor Specification

and Motor ......................................................... 3-17

Adjusting Calculated Motor Data ...................... 3-19

Encoder Checking ............................................ 3-21

Auto Phasing .................................................... 3-24

Algorithmic Phase Initialization ......................... 3-29

Chapter 4 Operating Modes ................................................ 4-1

Torque Mode ....................................................... 4-2

Position Mode .................................................... 4-6

Velocity Mode .................................................... 4-9

Digital Position Mode ........................................ 4-11

1-2

Introduction

Chapter 5 Using Copley Explorer Motion Controller ............. 5-1

Main Window ...................................................... 5-3

File Menu ........................................................... 5-4

View Menu .......................................................... 5-5

Amplifier Menu .................................................... 5-5

On-Line Connection Screen ................................ 5-5

Amp Setup Screen ............................................. 5-6

Amplifier Status Now! Screen ............................. 5-8

Preset Manager Screen .................................... 5-29

Motor Menu ...................................................... 5-31

Motor Data Screens .......................................... 5-31

Motor Data > Specification Screen ................... 5-32

Motor Data > Specification Feedback Screen ... 5-32

Motor Data > Specification Ratings Screen ...... 5-32

Motor Data > Specification Electrical Screen ... 5-35

Motor Data > Specification Mechanical Screen 5-36

Apply Motor Data Screen .................................. 5-32

Motor Temperature Sensor Screen ................... 5-40

Tools Menu ....................................................... 5-41

Tools > Trace Graph ......................................... 5-41

Tools > Options ................................................ 5-43

Tools > Options > Directories ........................... 5-44

Tools > Options > Directories ........................... 5-45

Tools > Download Firmware .............................. 5-46

Tools > Encoder Check .................................... 5-47

Tools > Auto Phasing ....................................... 5-48

Tools > Home Sequence .................................. 5-49

Diagnostics Menus ........................................... 5-50

Diagnostics > Comm Log ................................. 5-51

Diagnostics > Special ....................................... 5-53

Help Menu ........................................................ 5-54

Amplifier Explorer Window ................................ 5-56

Stop Motor Window .......................................... 5-57

Copley Virtual Machine ..................................... 5-58

7XX8 Series Digital Servo Amplifier User Guide

1-3

NOTES

1-4

Introduction

Copyright 2000 Copley Control Corporation. All Rights Reserved.

This manual, as well as the software described in it, is furnished

under license and may only be used or copied in accordance with the

terms of such license. The information in this manual is furnished for

informational use only, is subject to change without notice, and

should not be construed as a committment by Copley Controls Corpo-

ration. Copley Controls assumes no responsibility or liability for any

errors or inaccuracies herein.

Except as permitted by such license, no part of this publication may

be reproduced, stored in a retrieval system, or transmitted in any

form without prior written permission of Copley Control Corp.

Motion ExplorerMotion Explorer

Copley

Motion Explorer

Motion ExplorerMotion Explorer

Microsoft Windows 98 is a registered trademark of Microsoft Corpora-

tion.

Copley Controls Corp. makes no warranties, express or implied,

including without limitation the implied warranties of merchantability

and fitness for a particular product regarding the Copley Motion

Explorer software.

Written and designed by Copley Controls Corporation,

410 University Avenue, Westwood MA 02090.

Printed in the U.S.A.

is a trademark of Copley Controls Corp.

Revision 1.1

Chapter 1 Introduction

The 7XX8 Series of Digital Servo Amplifiers are high

performance, DSP (Digital Signal Processor) controlled

amplifiers. They control AC brushless motors with full

sinusoidal commutation. AC models operate directly from

AC mains. DC models operate from DC power sources,

which directly rectify the line. All models have full

isolation between signal and power stages. No power

transformers are required.

Built using surface-mount technology, these amplifiers

offer a full complement of features for AC brushless motor

control. All models use industry standard

±10V analog control signals for torque or velocity

control. A two-signal digital input takes step-motor

command pulses for position control:

In either CW/CCW or PLS/DIR format, or

from quadrature encoder A/B signals.

Digital preset inputs can be used to initiate 16 predefined

velocity, torque or position indexes.

A three phase MOSFET bridge output stage delivers

power in four-quadrants for smooth and efficient

bidirectional acceleration and deceleration of motors.

Windows software is used to configure the various gain

and current limit settings and to customize the amplifiers

for a wide range of loads and applications. Settings are

held in nonvolatile flash memory. Communication with the

7XX8 Series Digital Servo Amplifier User Guide

1-1

amplifier is done through an RS-232 port for easy

interface to most computers. Software settings permit

compensation over a wide range of load inductances to

maximize bandwidth with different motors. Individual peak

and continuous current limits allow high acceleration

without sacrificing protection against continuous

overloads.

All models are protected against output short circuits

(output to output and output to ground) and heatplate

overtemperature. With Reset input open, the amplifier will

latch off until powered-down or the Reset input is toggled.

If reset from such conditions is desired, the Reset input

can be momentarily connected to ground.

A red/green status LED speeds diagnostics when the

amplifier is put into operation.

Features

The Digital Servo Amplifier Model 7XX8 Servo works with

DSP controlled torque, velocity or position modes using

only encoder feedback from the motor. It is

programmable for S-curve and trapezoidal motion files.

You can select up to 16 preset modes using a PLC or

Logic Hi/Lo line.

1-2

Introduction

Other features include:

No transformer required. AC version operates

directly from AC mains, DC version operates from

rectified line, with full optical isolation between

signal and power stages.

RS-232 digital interface used to store all settings

in internal FLASH memory for selecting preset

modes.

Separate motor signal and control signal Sub-D

type connectors for simpler cabling.

Terminals for DC Buss connect to an external

regenerative energy dissipator.

Input for motor temperature sensor with settable

thresholds and logic to protect motor windings.

Command sources: Analog ±10V inputs, Digital

PLS/DIR, CW/CCW, Digital presets and

Data RS-232.

Fault protections: short circuits from output to

output, output to gnd, over/under voltage, motor or

amplifier overtem temperatur.

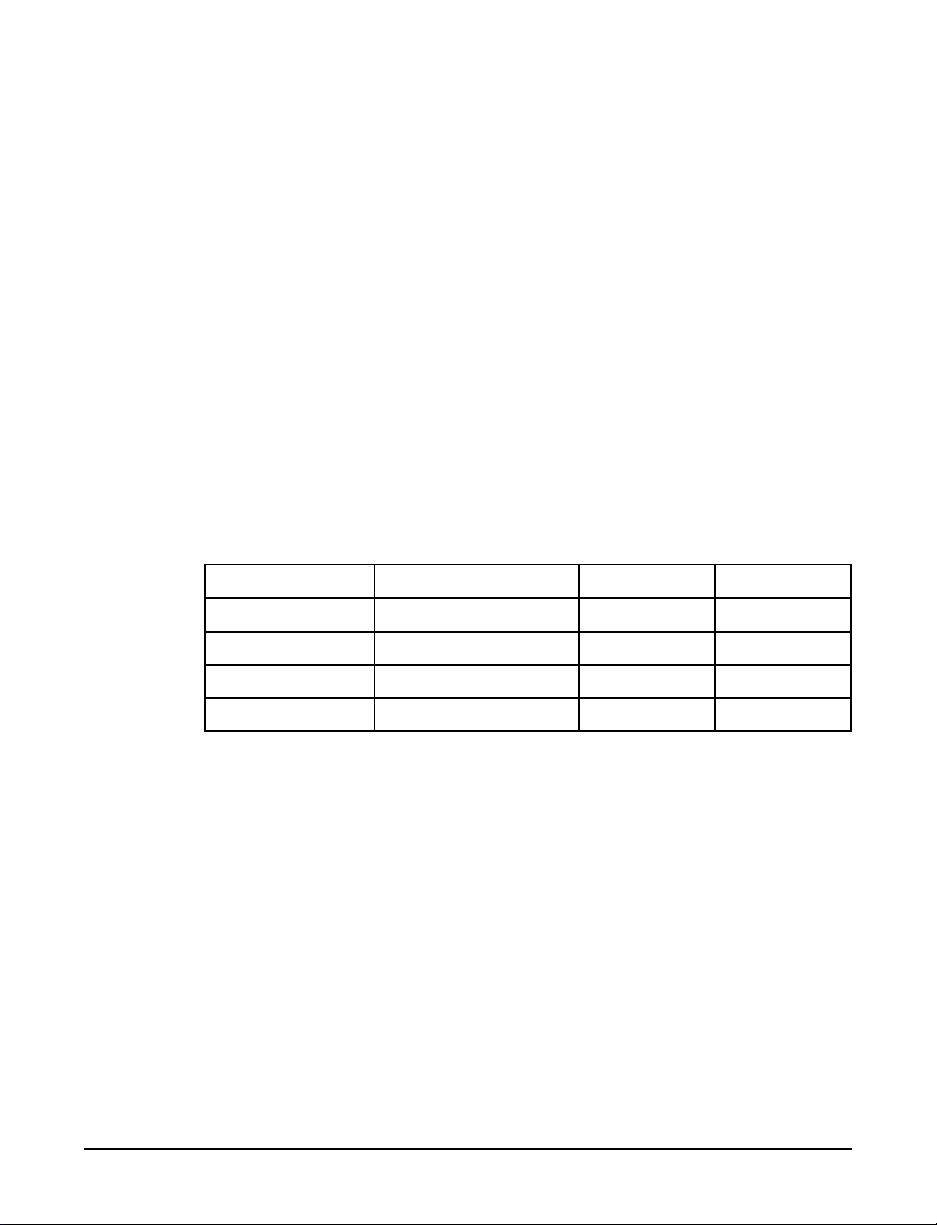

Models

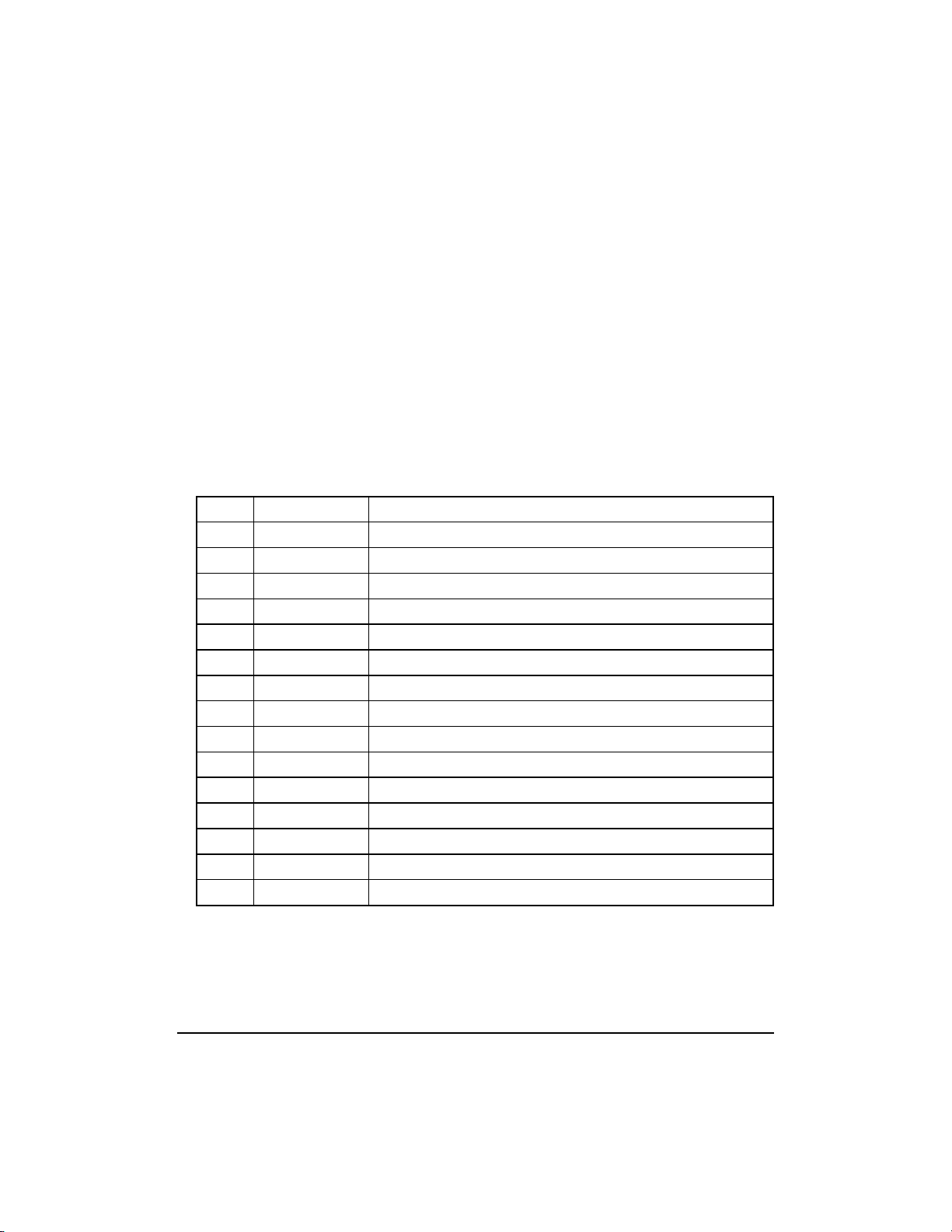

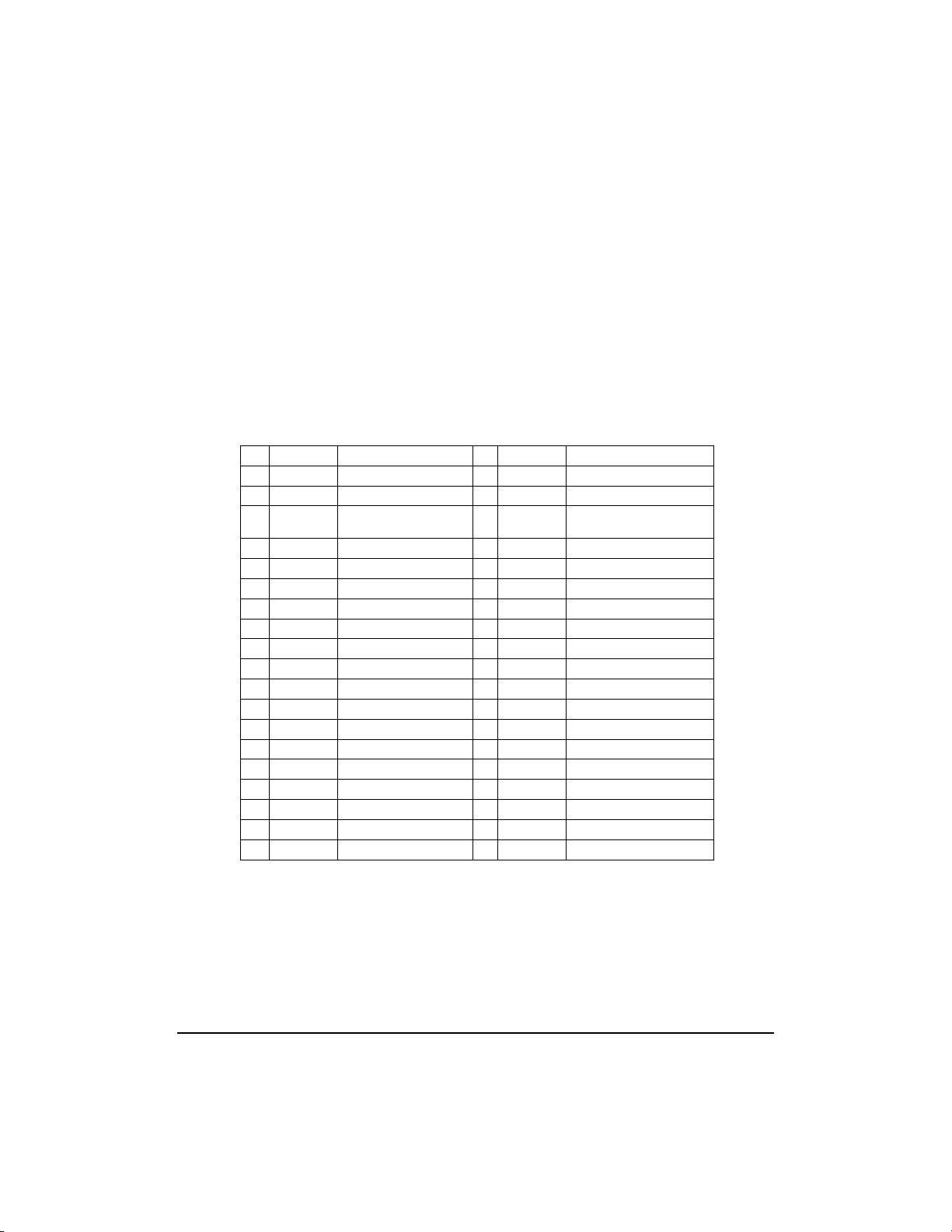

The following table describes the 7XX8 Series Digital

Servo Amplifiers model variations.

ledoMegatloVkaeP-ItnoC-I

CA8227CAV231~230201

CA8247CAV462~230201

CD8227CDV681~540201

CD8247CDV373~540201

Table 1-1 7XX8 Models

Applications

The 7XX8 Series of Digital Servo Amplifiers are

compatible with a wide range of controllers. Applications

include:

Sinusoidal brushless motors

Linear brushless motors

X-Y stages

Robotics

Automated assembly machinery

7XX8 Series Digital Servo Amplifier User Guide

1-3

Motion Explorer Software

You can manage the 7XX8 Series of Digital Servo

Amplifiers from the Windows-based Copley Motion

ExplorerTM (CME) software. Some of the high level tasks

that you can perform from the CME screens include:

Create a new motor file, or load an existing

motor file.

Generate a new amplifier file, or load an existing

amplifier file.

Adjust motor phasing.

Fine tune current and position loops with trace

feature.

Select operating modes.

Generate new presets that you can store in

flash memory on the amplifier.

Execute diagnostics that display statistical or

graphical data about system performance.

1-4

Introduction

Software Requirements

The Copley Motion ExplorerTM software is

recommended for Windows 98 systems. The 7XX8 Series

Digital Servo Amplifier interfaces to a PC via a simple

RS-232 connection.

For more information about the Copley Motion

ExplorerTM software see Chapter 5.

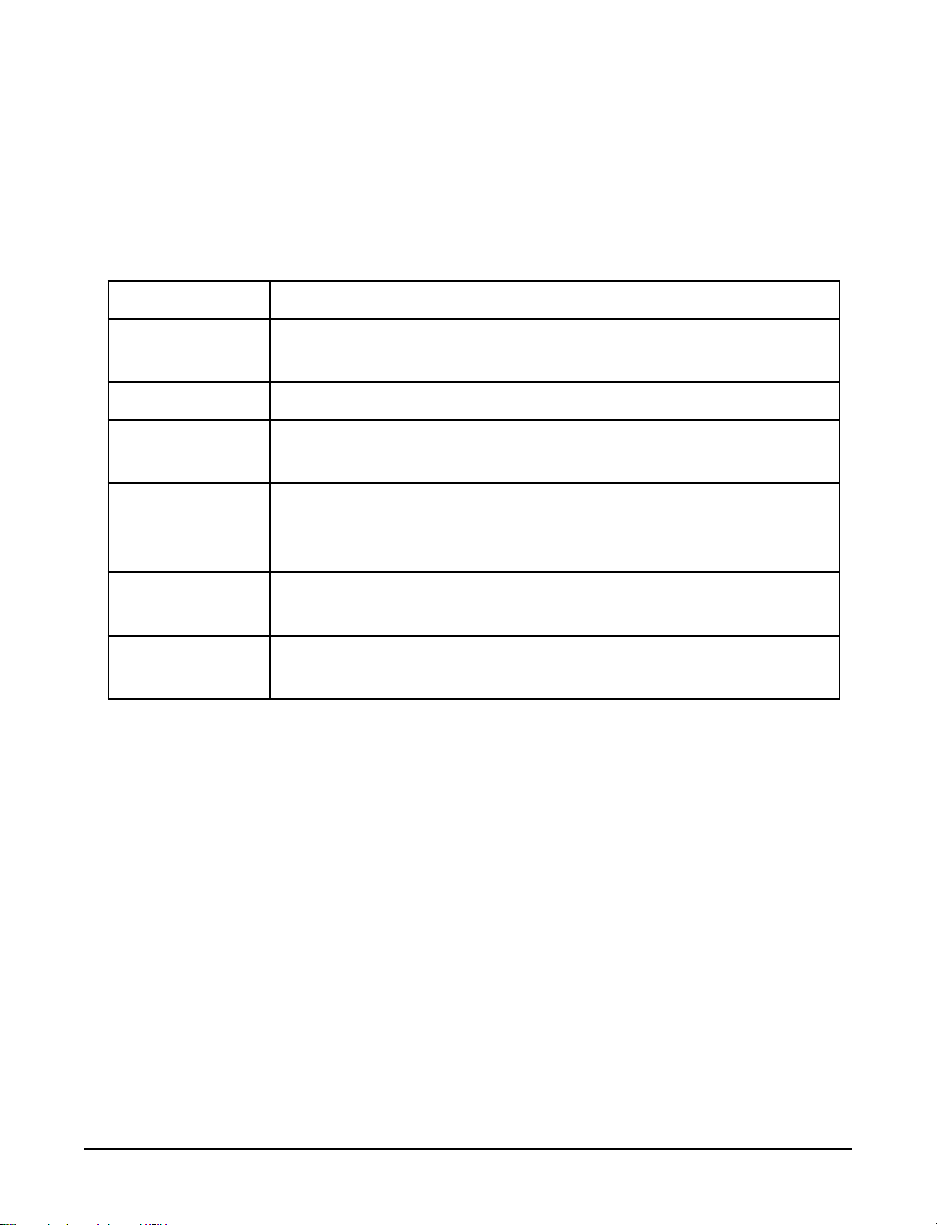

Terminology

Some new terminology is introduced herein with this

product. The terms are defined below, and may be added

to as necessary.

mreTnoitinifeD

rotomdetaluclaC

atad

elif)rotom(mcc. tahtseulavetaluclacotatadelifacc.sesuEMC.atadrotomgniniatnocelifA

tnadneP ehtmorfslangisrorrednasutatsstpecretnidnasteserpstcelestahteludomA

rotomyranimilerP

atad

teserP otnoitamrofniehtllaniatnoctahtyromemHSALFniderotsseulavfotesA

rerolpxEnoitoMyelpoCybdetarenegatadrotomdnareifilpmafostsisnoC

.snoitacificepsrotomroselifmcc.rehtiemorfatadyranimilerpnodesab

elif)reifilpma(acc. .putesreifilpmadnasteserp61:seulavHSALFreifilpmallagniniatnocelifA

.atadteserpfotrapsayromemHSALFniderotsebnac

fosesopruproftnempiuqeresuafoecalpehtsekattI.sublangisehtnoreifilpma

.gubeddnatsetnoitacilppa

detaluclacneebsahtierofebnoitacificepsrotomaroelifmcc.arehtiE

yelpoCyb)deledom( .rerolpxEnoitoM

.elbaliavaerasteserp61otpU.reifilpmaehtetarepo

Table 1-2 New Terms

7XX8 Series Digital Servo Amplifier User Guide

1-5

CE Mark and UL Conformity

In compliance with CE Mark, the 7XX8 Series of Digital

Servo Amplifiers are in conformity with the following

standards:

EN 50081-1 : 1992 Electromagnetic Compatibility

Generic Emission Standard

EN 50082-1, 1992 Electromagnetic Compatibility

Generic Immunity Standard.

EN 61010-1, 1993 Safety Requirements for Electrical

Equipment for Measurement, Control

and Lab Use.

The 7XX8 Series of Digital Servo Amplifiers are in

conformity to the following UL standard.

UL 508C Standard for Safety, Power

Conversion Equipment.

1-6

Introduction

Unpacking and Inspection

Verify that the model number(s) of the product match

your order. Refer to the Read Me First document for a

parts checklist, cabling connections and Copley Motion

ExplorerTM software installation instructions.

Technical Support

For technical support, you may contact us in several

ways:

Online at our web site: www.copleycontrols.com

Email: sales@copleycontrols.com

Telephone: (781) 329- 8200

Fax: (781) 329-4055

7XX8 Series Digital Servo Amplifier User Guide

1-7

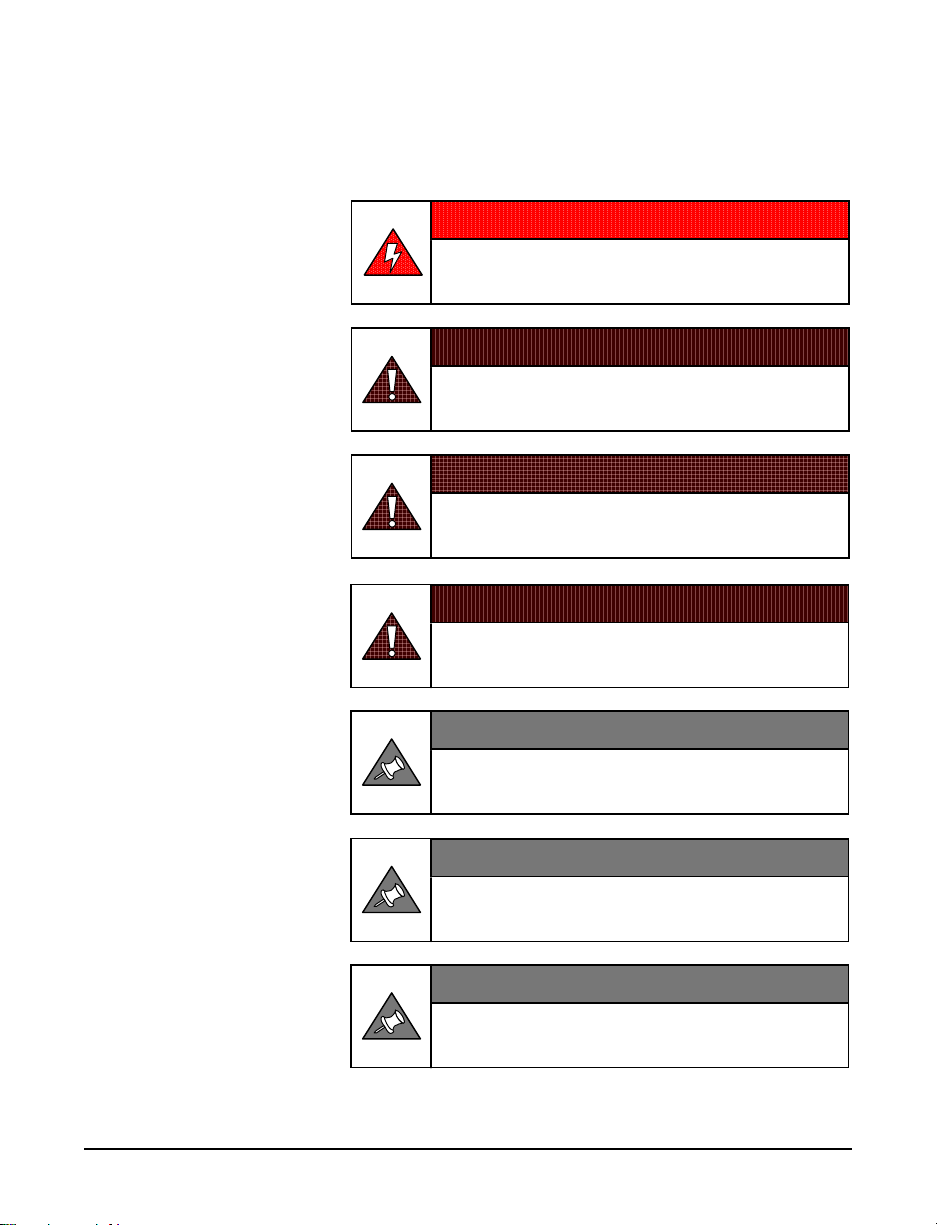

Safety

g

g

g

Review the safety guidelines provided below.

DANGER!

HAZARDOUS VOLTAGES

Exercise caution when installing and adjusting.

WARNING!

DO NOT make connections to motor or drive with power applied!

WARNING!

DO NOT spin motors with power off.

Volta

es generated by the motor can damage drives!

WARNING!

DO NOT switch operating modes with out using precautions.

Values set for one operatin

mode may not be proper for another!

1-8

Introduction

NOTE!

DO connect drives using good wiring and

workmanship practices.

NOTE!

DO operate drives within specifications

provided in this manual.

NOTE!

DO disconnect motors from loads while

settin

-up or servicing systems.

Chapter 2 Amplifier Connections

In general, use the Copley Motion ExplorerTM Kits'

Read Me First sheet for connection of the

amplifier to:

AC (or DC) power

A 3-phase brushless motor

Quadrature encoders

The control pendant or controller

PC or laptop (running Copley Motion

Explorer

Should you require it during installation, this chapter

provides specifics about amplifier connectors, including:

Ground

AC/DC Power and Motor Phase Connector (J1)

Motor Connector (J2)

Signal Connector (J3)

Data Connector (J4)

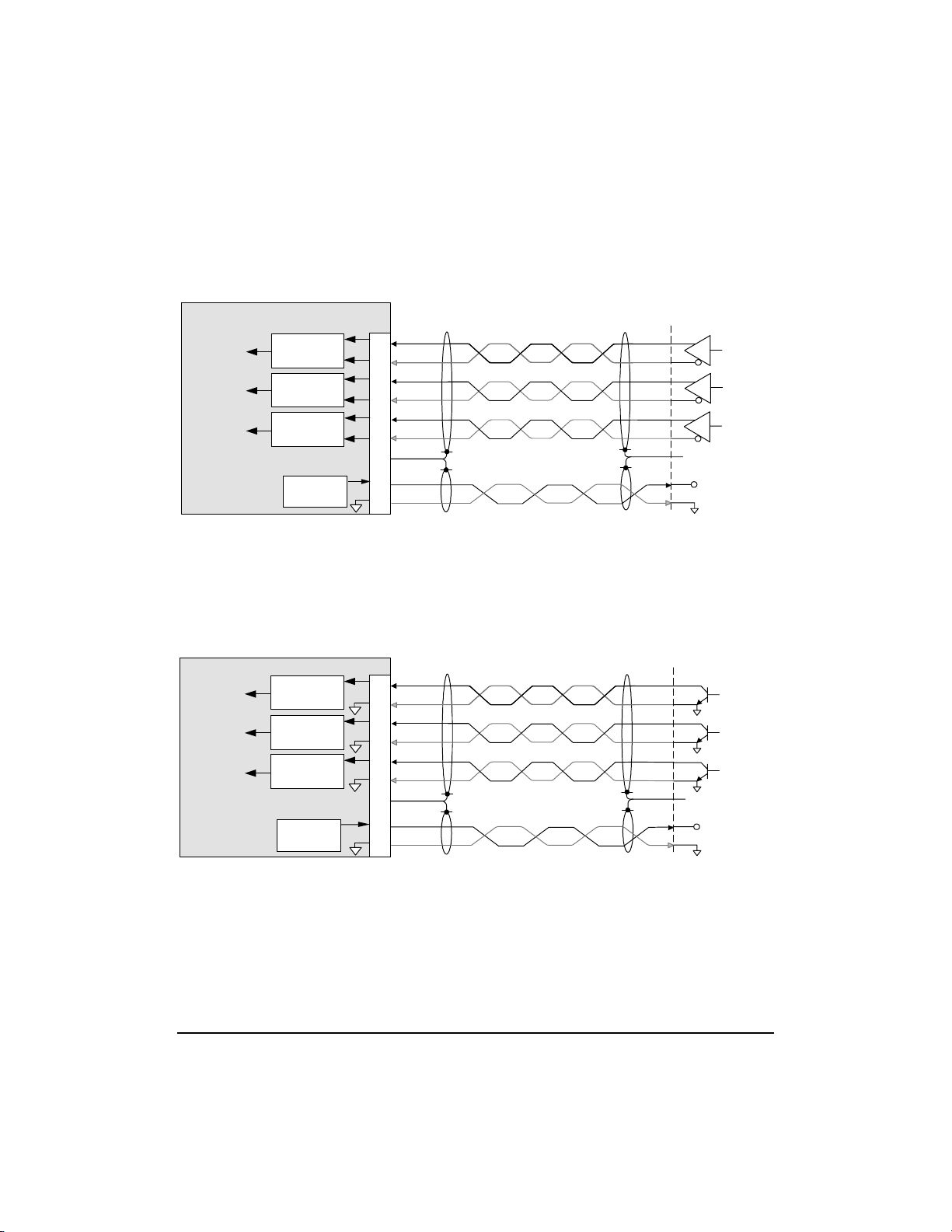

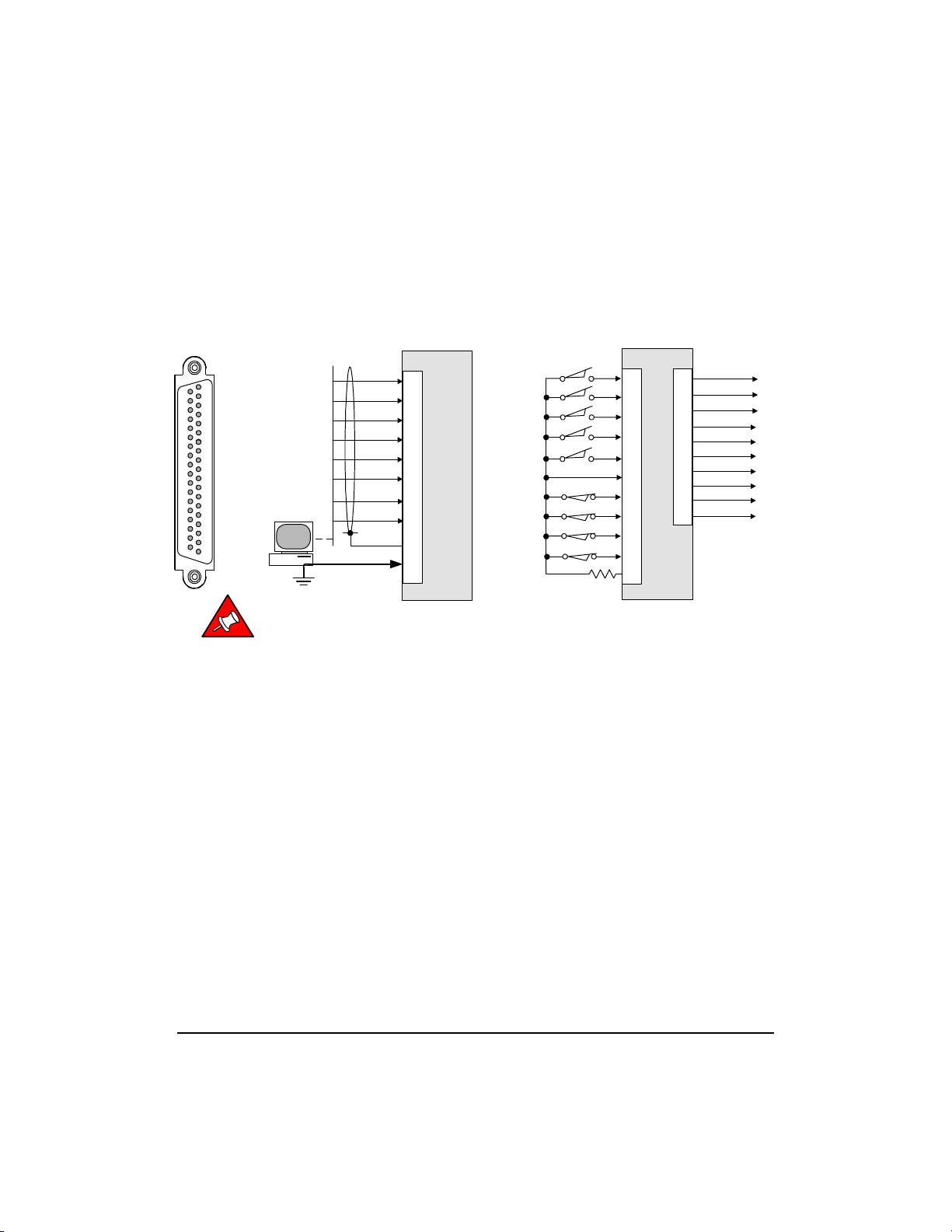

Figure 2-1 is a functional diagram of amplifier

connections.

At the end of this chapter, you'll find information

about the amplifier's signal module and Status

indicator.

TM

)

7XX8 Series Digital Servo Amplifier User Guide

2-1

Note:

Amplifier signal ground must be

connected to controller ground.

Buffered Enc A out

Buffered Enc /A out

Buffered Enc B out

Buffered Enc /B out

Buffered Enc X out

Buffered Enc /X out

Inputs

/Preset-0

/Preset-1

/Preset-2

/Preset-3

/Reset

Signal Gnd

/Enable

/Pos enable

/Neg enable

/Home

Outputs

Analog monitor

Status-0

Status-1

Ch. A

Ch. /A

Ch. B

Ch. /B

Ch. X

Ch. /X

Ref(+)

Ref(-)

Signal ground

Shld

Signal Gnd

Shld

J3

17

35

18

36

19

37

2

20

1

11

J3

12

30

13

31

14

32

1

5

24

6

25

23

26

3

21

22

4

J3

9

7

8

34

Pulse and

Direction

Format

Logic

Mode Selects

Dif Amp

&

ADC

Mode Selects

DSP

&

FLASH RAM

Encoder

buffer

Group Prog.

Pull-up/down

Preset

input

logic

Active

state Prog.

Group Prog.

Pull-up/down

Enable

input

logic

Active state

Prog.

Monitor

DAC

Status

FETS

RS-232

OR

RS-485

Driver/

Receiver

Jumper Selects

Hall

Receiver

Encoder

Receiver

&

Home

pulse

logic

+5V

Power

Sensor

ADC

PWM

Stage

"H"

Bridge

Current

Sense

Internal

DC

supply

Inrush

limiter

Note: Circuits within dashed line are

HOT! (At mains potential)

J4

Tx

2

Rx

3

Gnd

5

RS-232

Data Port

J2

Hall U

2

3

4

8

15

7

14

6

13

11

12

1

9

12

Hall V

Hall W

Enc A

Enc /A

Enc B

Enc /B

Enc X

Enc /X

+5V

0V

Shld

/Motemp

Gnd

Halls

Encoder

Motor Overtemp

Switch

J1

U

6

V

7

W

8

&

&

Shld

9

1

See Figure 2-4 for

information regarding

2

3

Motor

shielding

Figure 2-1 Functional Diagram Amplifier Connectors

Amplifier Connections

2-2

GrGr

oundingounding

Gr

ounding

GrGr

oundingounding

A single-point star ground should be used with all

device grounds converging. Do not daisy-chain the

connections to ground. The ground connections should

be as short a distance as possible. The motor ground

should be connected directly to the amplifier.

Safety GroundingSafety Grounding

Safety Grounding

Safety GroundingSafety Grounding

For safety, it is important that amplifier frame

ground on J1 be connected to earth ground, typically

through the power cable.

Note: Frame ground on AC models is at J1-3. Frame

ground on DC models is at J1-1.

The connections on the power board, such as the motor

phase, are at line potential.

Signal GroundingSignal Grounding

Signal Grounding

Signal GroundingSignal Grounding

The signal board is fully isolated from the power section

in this series of amplifiers. For proper operation,

connect the signal ground on J3 to the controller

ground.

Chassis & Cable Shield Grounding for EMIChassis & Cable Shield Grounding for EMI

Chassis & Cable Shield Grounding for EMI

Chassis & Cable Shield Grounding for EMIChassis & Cable Shield Grounding for EMI

Reduction & CEReduction & CE

Reduction & CE

Reduction & CEReduction & CE

To minimize noise radiation from the motor and power

cabling, wires should be twisted and shielded. Motor

sensor signals are often routed near the motor phase

winding cables. To minimize coupling of PWM noise,

sensor signal wiring should be multiple-conductorshielded cable. Further more, all cable shields should be

case grounded at both ends for compliance with CE

emissions limits. See Figure(s) 2-1 through 2-4 for

details.

7XX8 Series Digital Servo Amplifier User Guide

2-3

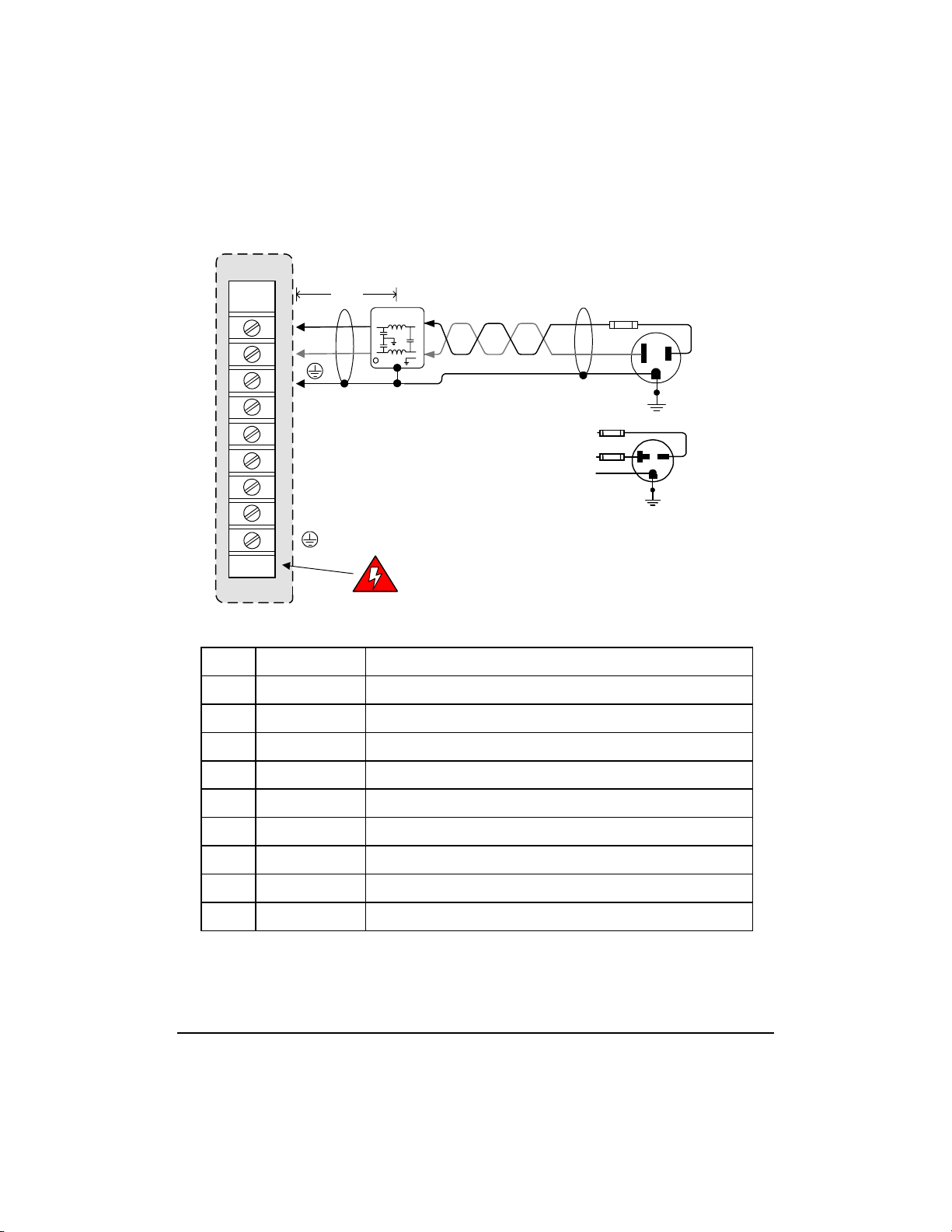

AC & DC Power & Motor Phase (J1)

Power supply and motor connections (Figure 2-2) should

be made with wire that has a rating to support the

amplifiers continuous current. AWG 14 wire supports all

amplifiers in this series. Additional recommendations: use

wire insulation with a voltage rating of 600V DC and a

temperature range of 105°C.

VV

oltaolta

gg

V

olta

VV

oltaolta

The mains for high voltage units that use 240V AC, 50/

60Hz, 1 phase, should be rated for a current of 20 amps.

The mains for low voltage units that use 120V AC, 50/

60Hz, 1 phase, should be rated for a current of 20 amps.

FusingFusing

Fusing

FusingFusing

Model 7228AC 7228DC 7428AC 7428DC

Fuse 120V@20A 120V@20A 250V@20A 230V@20A

Fusing should be time delayed and installed on any hot

lines coming from the mains. For low voltage units,

install the fuse on the hot line. For high voltage units,

install fuses on both hot lines.

e & Current Ratings of Mainse & Current Ratings of Mains

g

e & Current Ratings of Mains

gg

e & Current Ratings of Mainse & Current Ratings of Mains

Amplifier Connections

2-4

Line FilterLine Filter

Line Filter

Line FilterLine Filter

A line filter, such as the Corcom P/N20VDK6, must be

installed no more than three feet from the amplifiers

power entry terminal strip for compliance with CE

emissions limits.

s fs f

or EMI Reduction & CEor EMI Reduction & CE

s f

or EMI Reduction & CE

s fs f

or EMI Reduction & CEor EMI Reduction & CE

AC Model

J1

< 3ft

L1

1

L2

2

3

4

Buss +

5

Buss -

6

Motor U

7

Motor V

8

Motor W

9

Copley Amplifier

niPlangiSnoitcnuF

11L)sniamCAmorferiwnworbrokcalb(toHtupnIrewoPCA

Line Filter

c

Corcom

Note: All lines in this

power stage are HOT!

(At mains potential)

Figure 2-2 AC Model J1 Connector

Fuses: 20A

time-delay

Wht (Blu)

Grn (Grn/Yel)

Fuses: 20A

time-delay

Grn (Grn/Yel)

Blk (Brn)

120VAC

Blk (Brn)

230VAC

Wiring for 74XXAC

22L)sniamCAmorferiweulbroetihw(lartueNtupnIrewoPCA

3DNG)sniamCAmorferiwley/neergroneerg(dnuorgytefassissahC

4)+(ssuBylppusrewopCDlanretnifolanimretevitisoP

5)-(ssuBylppusrewopCDlanretnifolanimretevitageN

6UrotoMrotomfognidniwUottuptuoreifilpmA

7VrotoMrotomfognidniwVottuptuoreifilpmA

8WrotoMrotomfognidniwWottuptuoreifilpmA

9DNG.elbacrotomfodleihselbacrofoslA.dnuorgytefassissahC

Table 2-1 AC Model J1 Pin(s) Description

7XX8 Series Digital Servo Amplifier User Guide

2-5

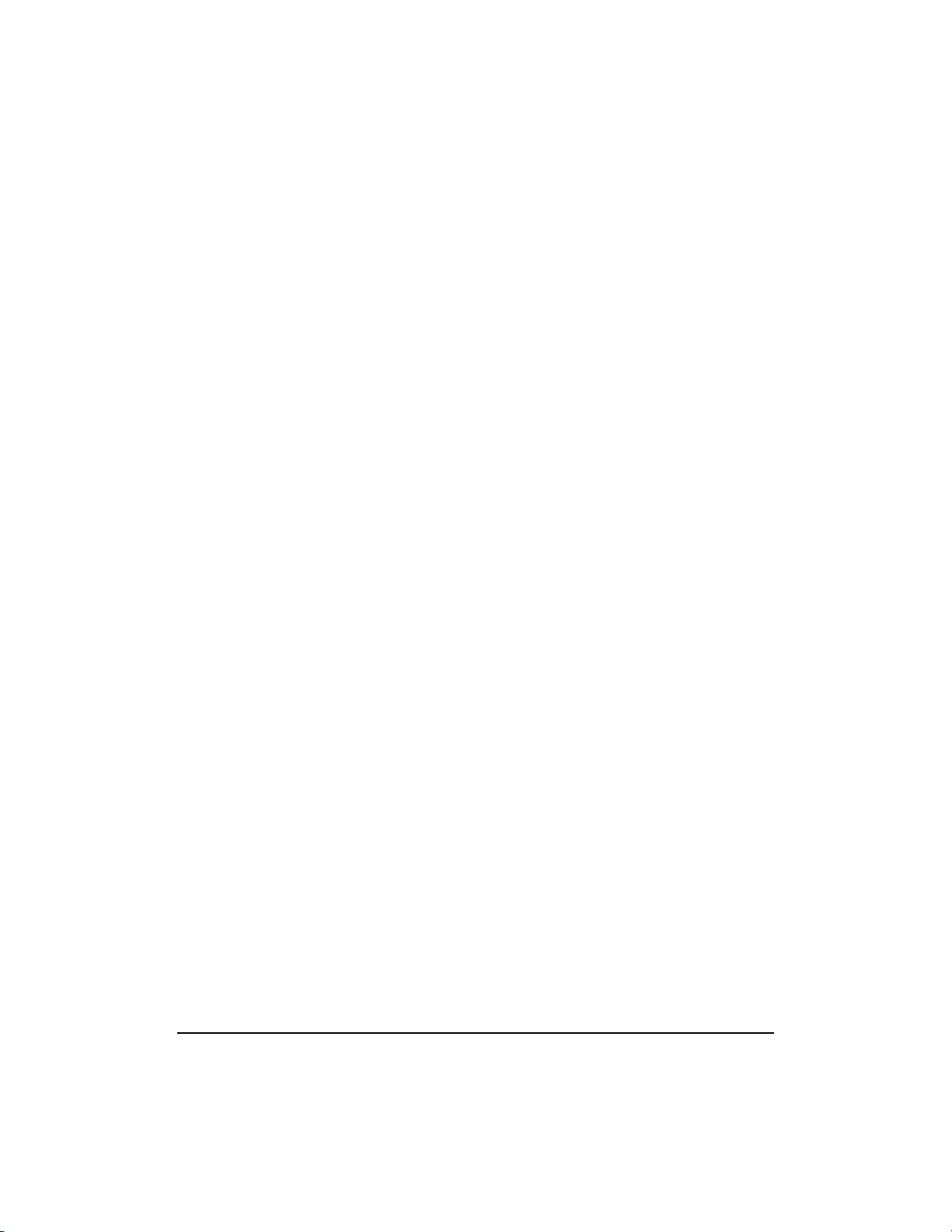

DC Model PDC Model P

DC Model P

DC Model PDC Model P

No Transformer Required! This model operates from

power supplies that rectify the line directly with

full optical isolation between signal and power stages.

Voltage & Current Ratings of PowerVoltage & Current Ratings of Power

Voltage & Current Ratings of Power

Voltage & Current Ratings of PowerVoltage & Current Ratings of Power

SuppliesSupplies

Supplies

SuppliesSupplies

The power supply should deliver sufficient power P,

to supply the power delivered to the motor, and the

power lost in the amplifier.

In general, the supply voltage V should be larger

than the motors nominal voltage rating for the

absolute maximum voltage rating. Consult the motor

manufacturer for more information.

The current delivered by the supply can be calculated

from the equation I = P / V. Furthermore, the power

supply should be able to handle any current surge that

occurs during power up. The Copley amplifier limits

the current surge to 37 Amps maximum on power-up.

oo

wer Connectionswer Connections

o

wer Connections

oo

wer Connectionswer Connections

Amplifier Connections

2-6

External Capacitance RequiredExternal Capacitance Required

External Capacitance Required

External Capacitance RequiredExternal Capacitance Required

The capacitor used in the bridge rectifier circuit must be

able to keep the voltage ripple, or Vrip, at sufficient

levels and the capability of storing 10 times the energy

regenerated from the load. The capacitor C may be

calculated from this equation:

C = I / (120Hz * Vrip)

DC Model

J1

7

6

5

4

Buss -

3

Buss+

2

1

Copley Amplifier

Note: All lines in this

power stage are HOT!

(At mains potential)

Figure 2-3 DC Model J1 Connector

Note: Circuits shown are typical connections and are not

for design purposes.

niPlangiSnoitcnuF

1DNG)sniamCAmorferiwley/neergroneerg(dnuorgytefassissahC

2)+(ssuBylppusrewopCDmorflanimretevitisoptupnirewopCD

3)-(ssuBylppusrewopCDmorflanimretevitagentupnirewopCD

4UrotoMrotomfognidniwUottuptuoreifilpmA

5VrotoMrotomfognidniwVottuptuoreifilpmA

6WrotoMrotomfognidniwWottuptuoreifilpmA

7DNG.elbacrotomfodleihselbacrofoslA.dnuorgytefassissahC

Buss+

Buss-

DC

Power

Supply

Inrush limiter

Wht (Blu)

Grn (Grn/Yel)

Fuses

time-delay

Grn (Grn/Yel)

NTC

Fuses

time-delay

Blk (Brn)

120VAC

Wiring for 72XXDC

Blk (Brn)

230VAC

Wiring for 74XXDC

Table 2-2 DC Model J2 Pin(s) Description

7XX8 Series Digital Servo Amplifier User Guide

2-7

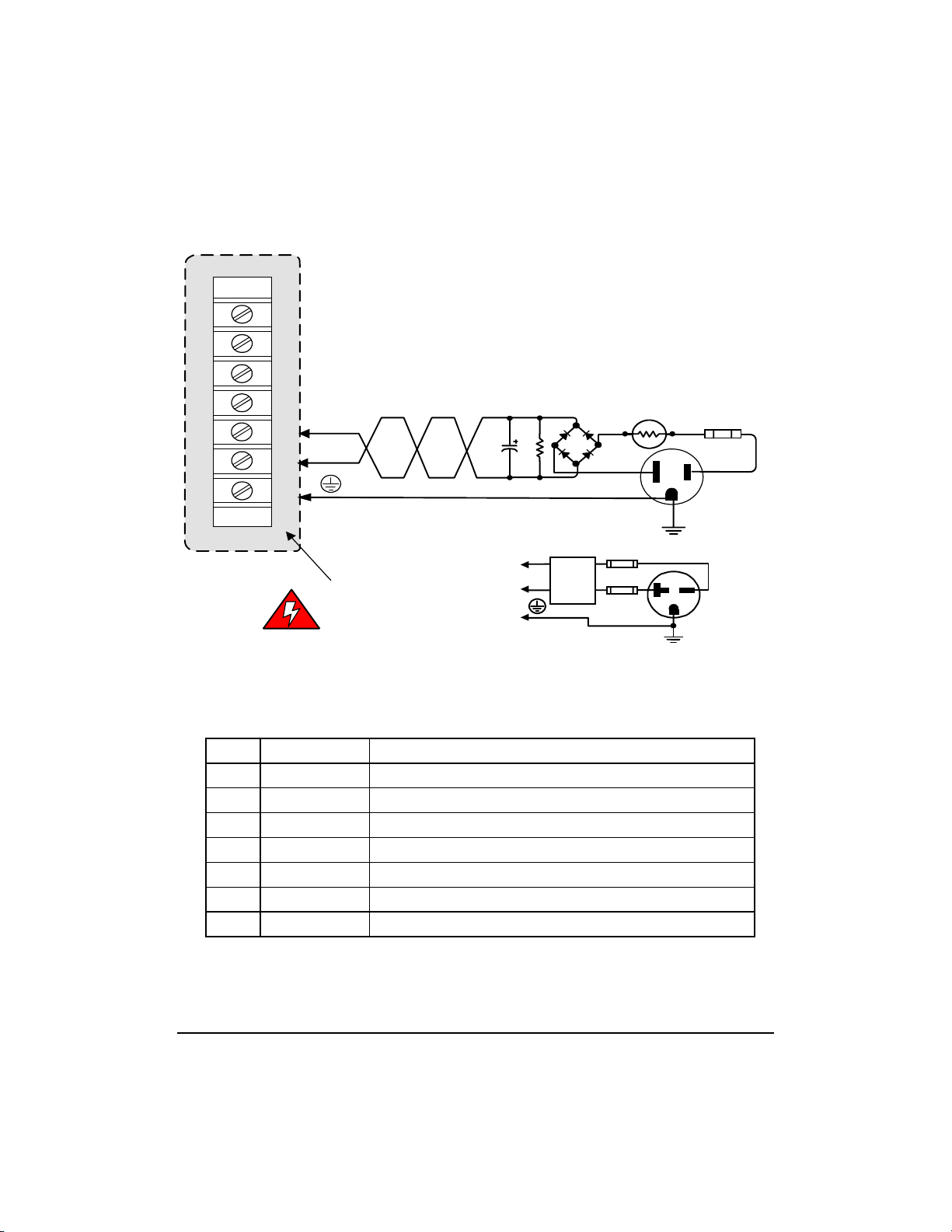

Motor Phase Wiring ConnectionsMotor Phase Wiring Connections

Motor Phase Wiring Connections

Motor Phase Wiring ConnectionsMotor Phase Wiring Connections

Motor Protection: Fusing & Circuit BreakersMotor Protection: Fusing & Circuit Breakers

Motor Protection: Fusing & Circuit Breakers

Motor Protection: Fusing & Circuit BreakersMotor Protection: Fusing & Circuit Breakers

To protect the motor, during the prototype phase, it is

the recommendation of Copley Controls Corp. to use

time delayed fusing in line with the motor. To protect

the motor from an unintentional event the current rating

should be no greater than the motors continuous stall

current.

ShieldingShielding

Shielding

ShieldingShielding

To minimize noise radiation from the motor cabling,

wires should be twisted and shielded. Furthermore, all

cable shields should be case grounded at both ends for

compliance with CE emissions limits.

DC Model

J1

4

5

6

7

2

Buss +

Buss -

3

1

Copley Driver

Note: All lines in this

power stage are HOT!

(At mains potential)

AC Model

J1

U

U

V

W

OR

6

V

7

W

8

9

Shield

L1

1

L2

2

3

Buss +

4

Buss -

5

Copley Driver

Figure 2-4 Motor Phase Wiring

Temporary Fuses

time-delayed

Phase U

Phase V

Phase W

Case Gnd

Motor

Note: Circuits shown are typical connections and are not

for design purposes.

Amplifier Connections

2-8

Motor Signal Connector (J2)Motor Signal Connector (J2)

Motor Signal Connector (J2)

Motor Signal Connector (J2)Motor Signal Connector (J2)

Connectors & CablingConnectors & Cabling

Connectors & Cabling

Connectors & CablingConnectors & Cabling

Motor signal connections should be made with wire that

has a rating to support the signal current. AWG 24 wire

will support all motor signals in this series. Additional

recommendations for wire insulation are for a voltage

rating of 300 V DC and a temperature range of 80°C. To

minimize coupling of PWM noise, encoder signal wiring

should be multiple-conductor twisted-pair shielded

cable. Furthermore, all cable shields should be case

grounded at both ends for compliance with CE

emissions limits.

niPlangiSnoitcnuF

1DNGytefaS.dnuorglangislanretniotdetcennoctoN.dnuorgsissahC

2UllaHUrofstupnillaHlatigiD

3VllaHVrofstupnillaHlatigiD

4WllaHWrofstupnillaHlatigiD

5devreseR

6X.hCcnEXlennahCredocnE

7B.hCcnEBlennahCredocnE

8A.hCcnEAlennahCredocnE

9pmetoMrosneserutarepetrotoM

01.C.NnoitcennocoN

11.Am052@V5+)1etoN(sllaHdnasredocnerofrewopCD

21.V0.sllaHdnaV5+rofdnuorglangiS

31X/.hCcnEX/lennahCredocnE

41B/.hCcnEB/lennahCredocnE

51A/.hCcnEA/lennahCredocnE

Table 2-3 J2 Hall and encoder Connections

Note 1: +5VDC @ 250mA also connects to J3-15, J3-27 and J2-11.

Combined not to exceed 250mA.

7XX8 Series Digital Servo Amplifier User Guide

2-9

15

J2

U

2

Hall

Receiver

Case Gnd

Encoder

Receiver

&

Home

pulse

logic

Case Gnd

8

+5V Power

250mA max.

J2

MOTOR

9

1

Sensor

ADC

Copley Driver

3

4

1

6

13

8

15

7

14

1

11

12

9

12

V

W

Enc X

Enc /X

Enc A

Enc /A

Enc B

Enc /B

+5V

0V

/Motemp

Gnd

Shld

Shld

Twisted Pair

Case Gnd

Encoder

Case Gnd

Motor Overtemp

Switch

Halls

Figure 2-5 J2 Signal Connector

Amplifier Connections

2-10

The J2 connector is a female Sub-D, 15 position with

#4-40 standoffs for the cable shell.

More About Encoder and Hall Sensor ConnectionsMore About Encoder and Hall Sensor Connections

More About Encoder and Hall Sensor Connections

More About Encoder and Hall Sensor ConnectionsMore About Encoder and Hall Sensor Connections

Encoder SensorEncoder Sensor

Encoder Sensor

Encoder SensorEncoder Sensor

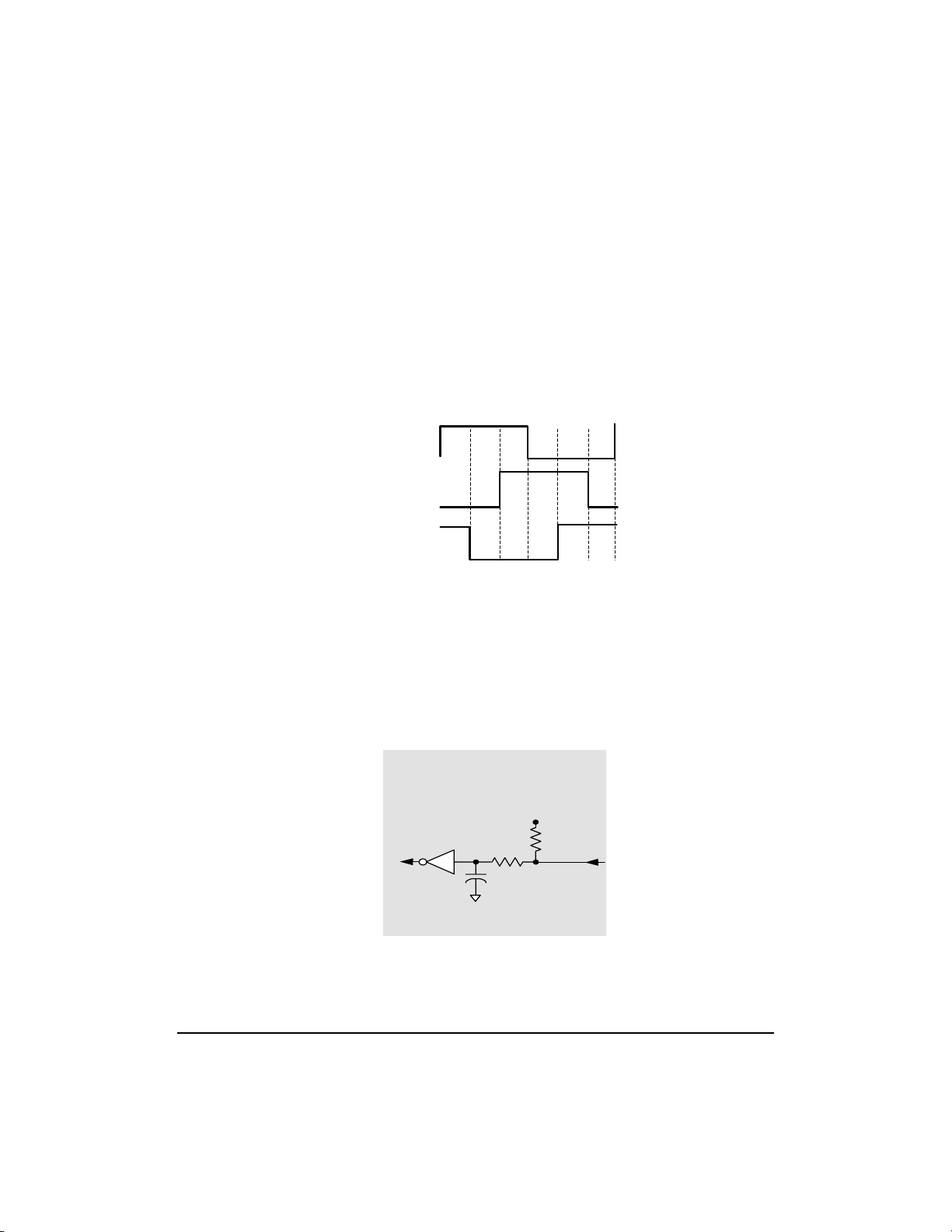

Quadrature encoders typically provide three signals

(Figure 2-6): two square waves (phase A and B) that

are 90° apart, and an index pulse, which will typically

occur once per revolution.

There are several ways to configure the encoder

interface. However, differential signals are

recommended for their inherently large CMRR (common

mode noise rejection ratio). For more information about

encoder formats see Chapter 3.

Index

Phase A

Phase B

Figure 2-6 Quadrature Encoder Pulses

Encoder ReceiverEncoder Receiver

Encoder Receiver

Encoder ReceiverEncoder Receiver

The same encoder receiver circuit (Figure 2-7) is used

to receive the quadrature encoder pulses: phase A,

phase B, and index. This circuit is designed to work with

differential signals (Figure 2-8), single-ended TTL

signals and open collector circuits (Figure 2-9).

Receiver circuit

same for all encoder inputs

+5V

47pF

26LS32

A,B,X

1k

2.2k

/A, /B, /X

47pF

Figure 2-7 Encoder Receiver Circuirt

7XX8 Series Digital Servo Amplifier User Guide

1k

Copley Driver

2-11

Receiver circuit

same for all encoder inputs

Enc X

Enc A

Enc B

Copley Amplifier

J2

Index

Receiver

Phase A

Receiver

Phase B

Receiver

+5V Power

250mA max.

6

13

8

15

7

14

1

11

12

Enc X

Enc /X

Enc A

Enc /A

Enc B

Enc /B

Case Gnd

+5V

0V

Shld

Index

/Index

Phase A

Phase /A

Phase B

Phase /B

Figure 2-8 Quadrature Encoder, Differential Configuration

+5V

Gnd

Motor

Case Gnd

Index

Phase A

Phase B

Encoder

circuit power

Receiver circuit same for all encoder inputs

Enc X

Enc A

Enc B

Copley Amplifier

Index

Receiver

Phase A

Receiver

Phase B

Receiver

+5V Power

250mA max.

Figure 2-9 Quadrature Encoder, Single-ended Open Collector

Amplifier Connections

2-12

J2

6

12

8

12

7

12

1

11

12

Enc X

Enc A

Enc B

Case Gnd

+5V

0V

Shld

Index

Phase A

Phase B

+5V

Gnd

Motor

Case Gnd

Encoder

circuit power

Index

Phase A

Phase B

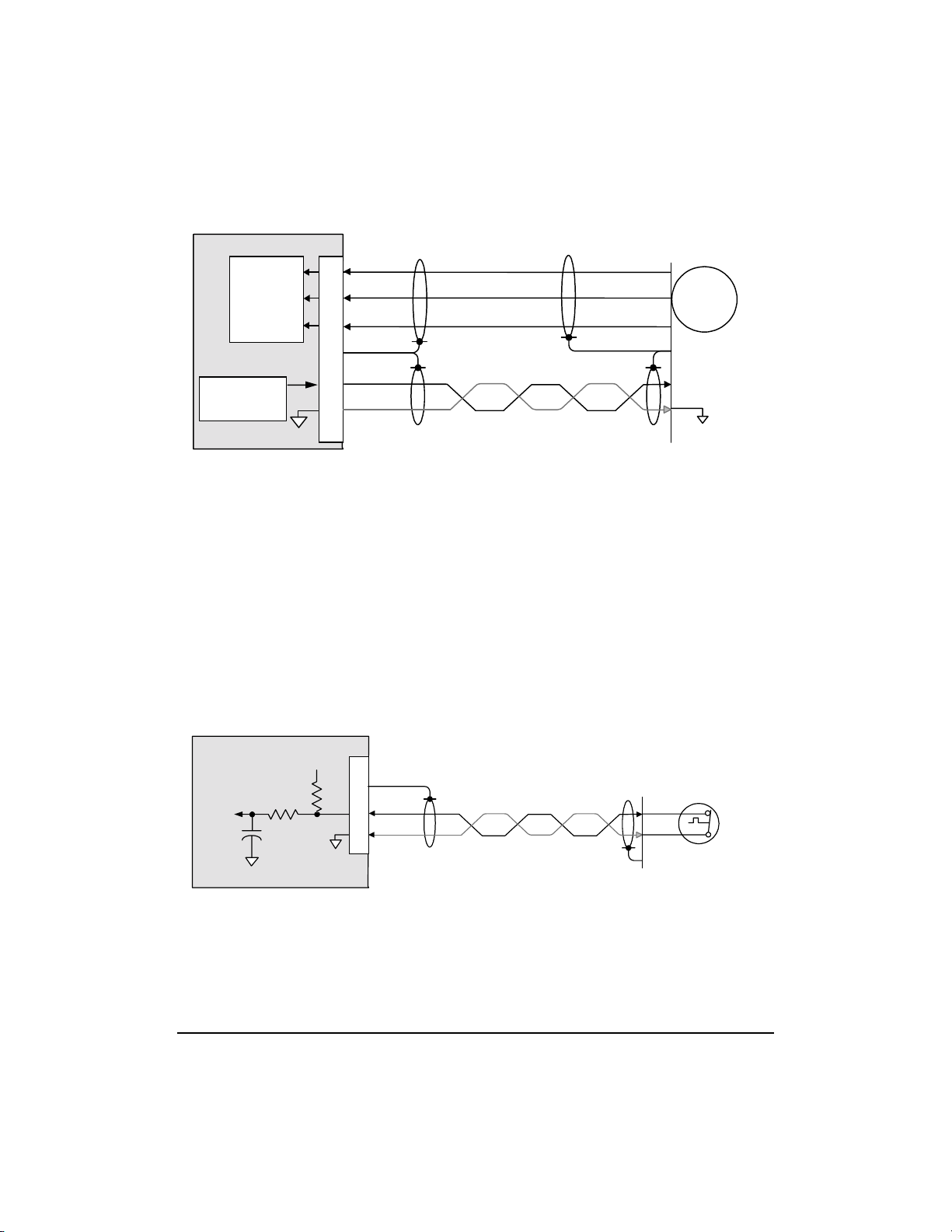

Hall SensorsHall Sensors

Hall Sensors

Hall SensorsHall Sensors

The controller performs a phase initialization routine,

using the encoder for proper commutation. However,

improved phase initialization can be achieved using Hall

sensors to determine initial positioning. Typical Hall

signals are shown in Figure 2-10.

One Electrical Cycle

Phase U

Phase V

Phase W

Typical 120 Degree Halls shown

Figure 2-10 Hall Signals

Hall Input CircuitHall Input Circuit

Hall Input Circuit

Hall Input CircuitHall Input Circuit

All 6 states

The same Hall input circuit (Figure 2-11) is used to

receive Hall signals: phase U, phase V, and phase W.

The circuit is designed to work with single-ended TTL

signals and single-ended open-collector signals.

Input circuit

same for all Hall signals

+5V

HCT14

10k

22k

10nF

Copley Amplifier

Figure 2-11 Hall Input Circuit

7XX8 Series Digital Servo Amplifier User Guide

2-13

Hall

Receiver

Case Gnd

+5V Power

250mA max.

Copley Amplifier

J2

11

12

Motor

U

2

V

3

W

4

1

Shld

+5V

Phase U

Phase V

Phase W

Halls

Case Gnd

Hall power

0V

Figure 2-12 Hall Connections

Temperature Sensor Input CircuitTemperature Sensor Input Circuit

Temperature Sensor Input Circuit

Temperature Sensor Input CircuitTemperature Sensor Input Circuit

The temperature sensor input circuit (Figure 2-13)

receives signals from sensing devices, such as thermal

sensors. The circuit works with resistive sensors, or an

open/closed switch to ground.

The 7XX8Series work well with N.O. (Normally Open),

N.C. (Normally Closed), or resistive sensors. The

overtemp threshold(s) are adjustable with CME and may

be stored as part of a preset.

Input circuit

Sensor signal

DSP

ADCN3

100nF

Copley Amplifier

Amplifier Connections

2-14

10k

+5V

5k

Figure 2-13 Temperature Sensor Input Circuit

J2

1

9

12

Case Gnd

/Motemp

Gnd

Motor

Motor Overtemp

Case Gnd

Switch

Normally

Closed

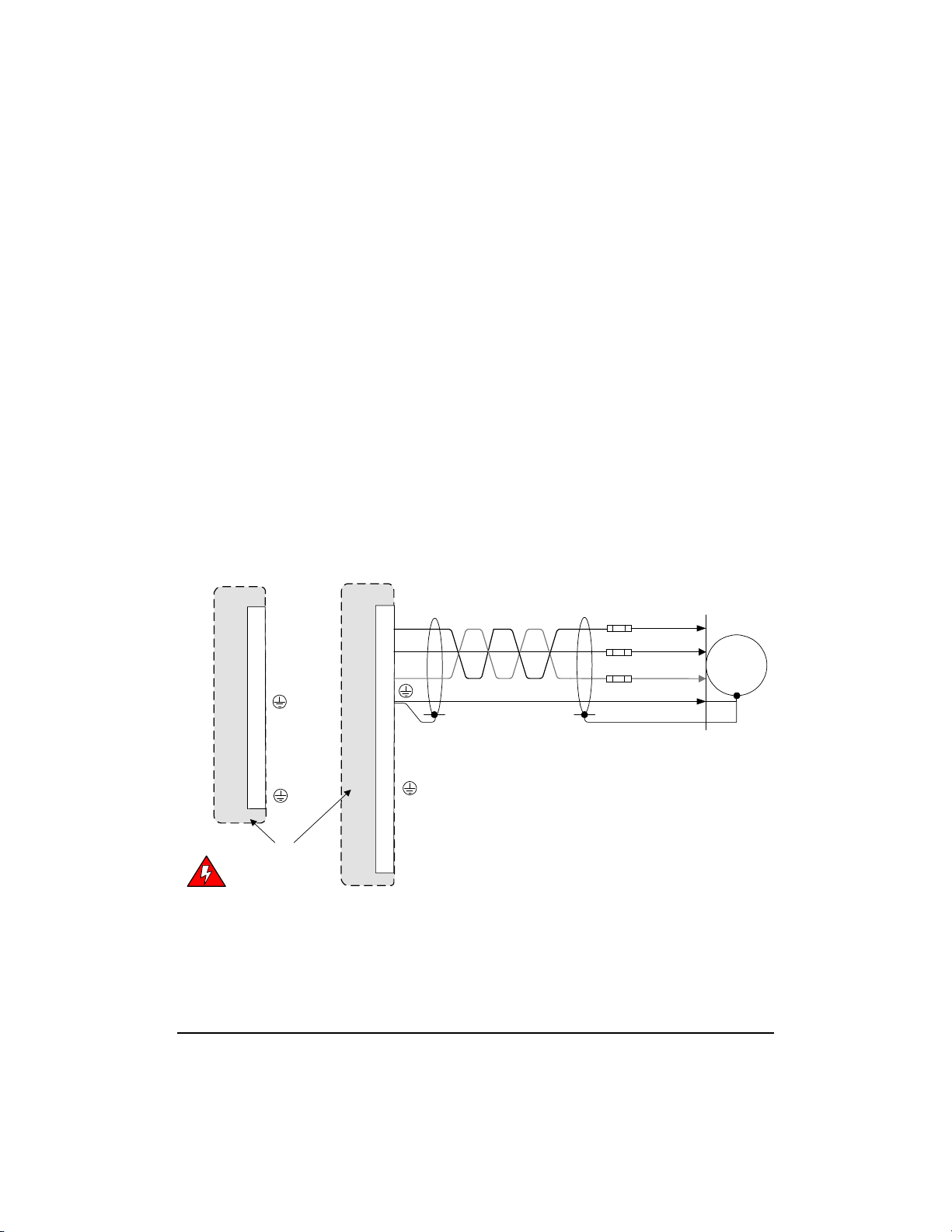

Signal Connector (J3)Signal Connector (J3)

Signal Connector (J3)

Signal Connector (J3)Signal Connector (J3)

Control signal connections should be made with wire

that has a rating to support the current signal. AWG 24

wire will support all motor signals in this series.

Additional recommendations are for a voltage rating of

300 V DC and a temperature range of 80° C. To

minimize coupling of PWM noise, sensor signal wiring

should be multiple-conductor twisted-pair shielded cable.

Further more, all shielded cables should be case

grounded at both ends for compliance with CE

emissions limits.

niPlangiSnoitcnuFniPlangiSnoitcnuF

1DNGytefaS.dnuorgemarf/sissahC

2)+(feRtupnidnammocgolanaV01-/+02)-(feRtupnidnammocgolanaV01-/+

3*tupnielbanE/elbanereifilpmA12*elbanEsoP/elbanenoitceridevitisoP

4*emoH/tupnihctiwsemoH22*elbanEgeN/elbanenoitceridevitageN

5*0-teserP/seniltcelesedomteserp4fo132*teseR/tupnitesertluafreifilpmA

6*2-teserP/seniltcelesedomteserp4fo142*1-teserP/seniltcelesedomteserp4fo1

7tuO0-sutatS1#tuptuosutatsreifilpmA52*3-teserP/seniltcelesedomteserp4fo1

8tuO1-sutatS2#tuptuosutatsreifilpmA62dngSV0dnuorGlangiS

9noMgolanAtuptuorotinomelbammargorP72tuptuOV5+tuptuoAm052@CDV5+

01timiLrruCtupnitimil-tnerruclanretxE82tuptuOV21+tuptuoAm52@CDV21+

11dngSV0dnuorGlangiS92tuptuOV21-tuptuoAm52@CDV21-

21tuoA.hCAhCtuptuoredocnedereffuB03tuoA/.hCA/hCtuptuoredocnedereffuB

31tuoB.hCBhCtuptuoredocnedereffuB13tuoB/.hCB/hCtuptuoredocnedereffuB

41tuoX.hCXhCtuptuoredocnedereffuB23tuoX/.hCX/hCtuptuoredocnedereffuB

51tuptuOV5+Am052@CDV5+33A.hCA.nahCtupniredocnE

61.C.NnoitcennocoN43.dnGgiSV0dnuorGlangiS

71niA.hCA.nahCtupniredocnE53niA/.hCA/.nahCtupniredocnE

81niB.hCB.nahCtupniredocnE63niB/.hCB/.nahCtupniredocnE

91niX.hCX.nahCtupniredocnE73niX/.hCX/.nahCtupniredocnE

Table 2-4 Signal Connections J3

Note: +5VDC @ 250 mA connects to J3-15, J3-27 and

J2-11. Combined current from all pins must not

exceed 250mA.

7XX8 Series Digital Servo Amplifier User Guide

2-15

* Pull-up to +5V, or pull-down to GND are selectable

and may be stored in a preset. In addition, the active

level (Hi or Lo) may also be selected and store as a

preset.

Outputs

A mon

Status-0

Status-1

Ch A out

Ch /A out

Ch B out

Ch /B out

Ch X out

Ch /X out

Signal Gnd

/Preset-0

/Preset-1

/Preset-2

/Preset-3

/Reset

Signal Gnd

/Enable

/Home

Curr Limit

Inputs

J3

5

24

6

25

23

26

3

21

22

4

10

Copley Driver

J3

9

7

8

12

30

13

31

14

32

34

3

7

19

Command Inputs

J3

SIGNAL

2

0

1

Note:

Amplifier signal ground must be

connected to controller ground.

Signal ground

Ch. A

Ch. /A

Ch. B

Ch. /B

Ch. X

Ch. /X

Ref(+)

Ref(-)

Shld

J3

17

35

18

36

19

37

2

20

1

11

Copley Driver

/Pos enable

/Neg enable

Figure 2-15 J3 Connector and Cabling

The J3 connector is a female Sub-D, 37-position with

#4-40 standoffs for cable shells.

Amplifier Connections

2-16

Loading...

Loading...