Page 1

Copeland Scroll™ compressor

for subcritical R-744 (CO2)

CO2 low temperature refrigeration

Emerson Climate Technologies has been a critical resource in past refrigerant transitions. As the the market leader with the

broadest compressor line up, our experience with refrigerants and products to fi t the industry needs make us uniquely qualifi ed

to provide a compressor solution for CO

Increasing environmental concerns about the potential direct emissions from HFC-based refrigeration systems into the

atmosphere have led system designers to revisit refrigerant R-744 (CO

properties of CO

has been designed to exploit the characteristics of CO

advantages of Copeland Scroll technology make it ideal for these applications.

require changes in the design of the refrigeration system. The ZO range of Copeland Scroll compressors

2

.

2

). In comparison with HFC refrigerants, the specifi c

2

refrigeration systems. The effi ciency, reliability and liquid handling

2

Page 2

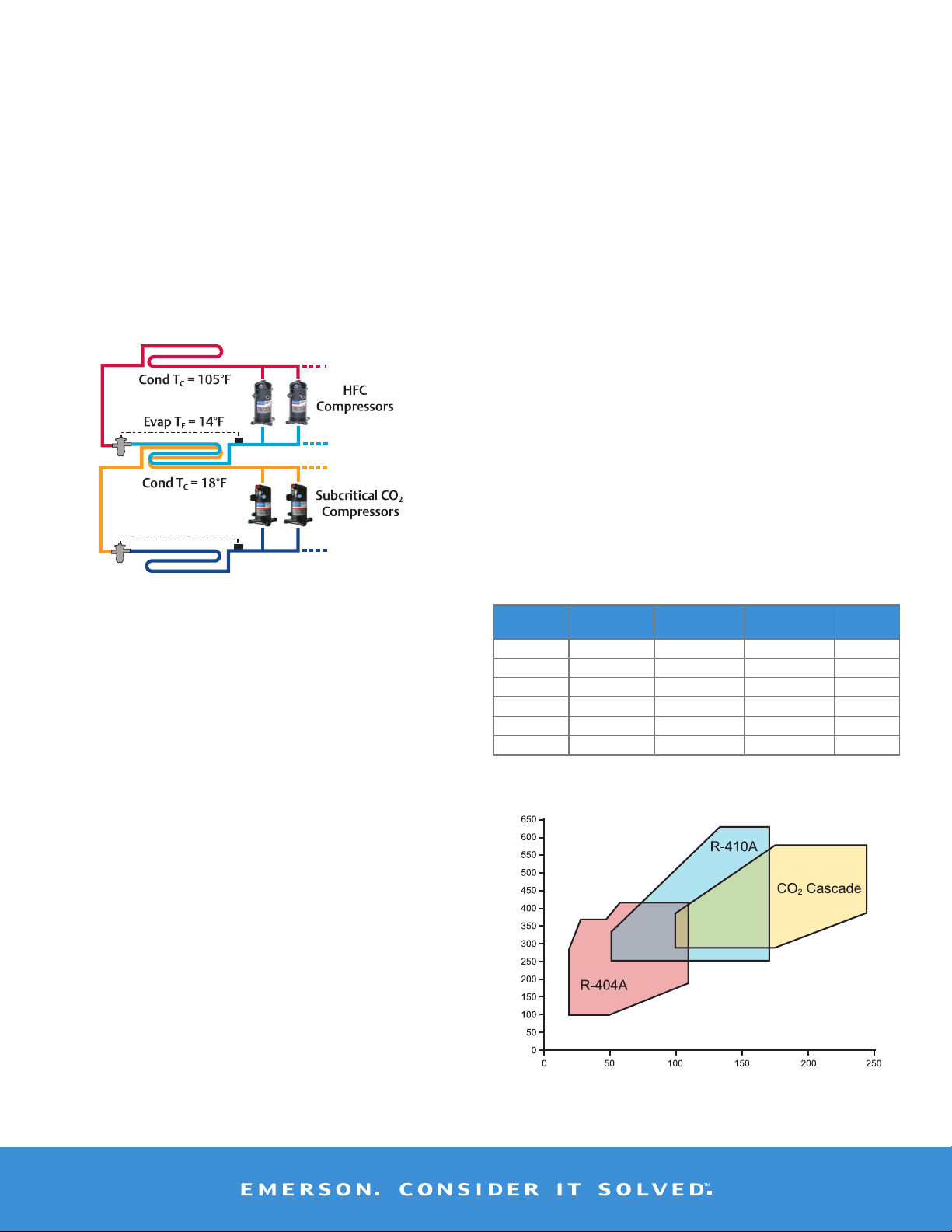

Low temperature cascade systems

Optimized design for CO2 applications

The comparably high pressure level and thermodynamic

properties of the refrigerant CO

have driven system

2

designers towards cascade systems, where CO2 is used as

a direct expanding fl uid in the low temperature stage. In

these subcritical cascade applications, the CO2 compressor

in the low temperature stage is still exposed to pressure

levels higher than in standard HFC-based systems. However,

they are limited to pressure levels similar to those already

known from air-conditioning applications with refrigerant

R-410A. An HFC refrigerant is typically used in the medium

temperature stage of the cascade system.

The challenges for CO2 compressors compared to HFC

compressors lie in the high pressure levels, the higher mass fl ow

for a given displacement, and designing for proper lubrication.

In terms of mechanical strength, ZO scroll compressors

benefi t from many years of experience with R-410A

air-conditioning compressors, which operate at similar

pressure levels as subcritical CO2 compressors. For piston

compressors, particular attention has to be paid to

redesigning the suction and discharge valves for the higher

mass fl ow. Copeland Scroll compressors eliminate this

problem up-front by not utilizing suction and discharge

valves to control the compression process.

Lubrication is always of particular concern during the design

stage of new compressors and has to be proven during

reliability and fi eld testing. The effort has resulted in the

development of a dedicated polyolester oil (POE). Moreover,

ZO compressors feature internal design details which ensure

higher bearing durability and lubrication to all critical parts

at any time during run-time and system start-up. This

includes the use of polymer bearings.

Illustrative purposes only

Safeguarding your product and our environment

Environmental concerns must address potential direct

refrigerant emissions as well as those arising from the

energy consumption of the refrigeration system. The use

of the refrigerant CO2 has the potential to reduce direct

emissions. However, refrigerant leakage is still undesirable

as it jeopardizes system reliability. With its hermetic design,

Copeland Scroll technology eliminates any compressorrelated leakage, contributing to reliable system operation

and thus safeguarding your refrigerated product.

Additionally, the ZO range of scroll compressors transfers

the high effi ciency inherent in the Copeland Scroll design to

subcritical CO2 refrigeration systems.

The extended operating envelope of the ZO compressors

can further boost overall system effi ciency when taking

advantage of low load night time operation.

Copeland Scroll™ ZO model summary

Model

ZO21K5E 1.0 112 CFH 20,800 btuh 15.4

ZO34K3E* 2.0 172 CFH 32,000 btuh 15.4

ZO45K3E 2.5 228 CFH 44,000 btuh 16.5

ZO58K3E 3.5 291 CFH 57,000 btuh 16.7

ZO88K3E 5.0 431 CFH 85,300 btuh 16.3

ZO104K3E* 6.0 498 CFH 98,500 btuh 16.3

*Digital model available

1

Capacity with R-744 at -31oF evap, 14oF cascade cond, 5oF RG, 14oF liquid

Dicharge Pressure (psia)

Nominal

Horsepower

Displacement Capacity EER

EmersonClimate.com

Suction Pressure (psia)

2010ECT-91 R2 (7/13) Emerson and Copeland Scroll are trademarks of Emerson Electric Co. or one of its affiliated companies. ©2013 Emerson Climate Technologies, Inc. All rights reserved. Printed in the USA

Loading...

Loading...