Page 1

Scroll Compressors

Replacement Guidelines

Page 2

1 Compressor Replacement...................................................................................................... 2

2 Scroll Compressor Replacement Procedure.........................................................................2

Torque Settings.................................................................................................................................................5

Copeland Replacement Part No’s..................................................................................... ................................5

Assembly Procedure.........................................................................................................................................6

Compressor Mounts .......................................................................... ................................................................6

Approved Oils................................................................................................................ ....................................6

Service Refill Quantity ... .... ..... ..... ......... .... ..... .... .......... .... ..... .... ..... ......... ..... .... ..... ......... .... ................................6

Lubricant Handling................................................................................................................................... .........7

3 System Evacuation and Charging Procedure ....................................................................... 7

Qualified Refrigerants........................................................................................... .... ..... ............. .......................7

4 Performance / Visual Checks..................................................................................................7

R404A Application Envelopes................................ ....................................................................................... ....8

C05.2.4/1007/E 1

Page 3

1 Compressor Replacement

The following is intended to assist the service engineer to ensure the correct method for fitting of a new scroll

compressor where replacement is necessary. In the event that a compressor ne eds replacement it is vital to

diagnose and rectify the system fault which caused the problem in order to avoid the need for further

replacements. It is important to ensure that when a scroll compressor replacement is required, certain

procedures are carried out in the same manner as when first built and installed by the original manufacturer.

The main areas to note are correct torque values for service valves and the use of correct rubber mounts for the

application. For ease and clarity the following procedure has been provided as a pictorial sequence (Our

thanks to Space Engineering Ltd, in the UK who provided the photo sequence).

In the case of a motor burn, the majority of contaminated oil will be removed with the compressor. The rest of

the oil is cleaned through the use of suction and liquid line filter driers. A 100% activated alumina suction filter

drier is recommended but must be removed after 72 hours. It is highly recommended that the suction

accumulator be replaced if the system contains one. This is because the accumulator oil return orifice or screen

may be plugged with debris or may become plugged shortly after a compressor failure. This will result in

starvation of oil to the replacement compressor and a second failure.

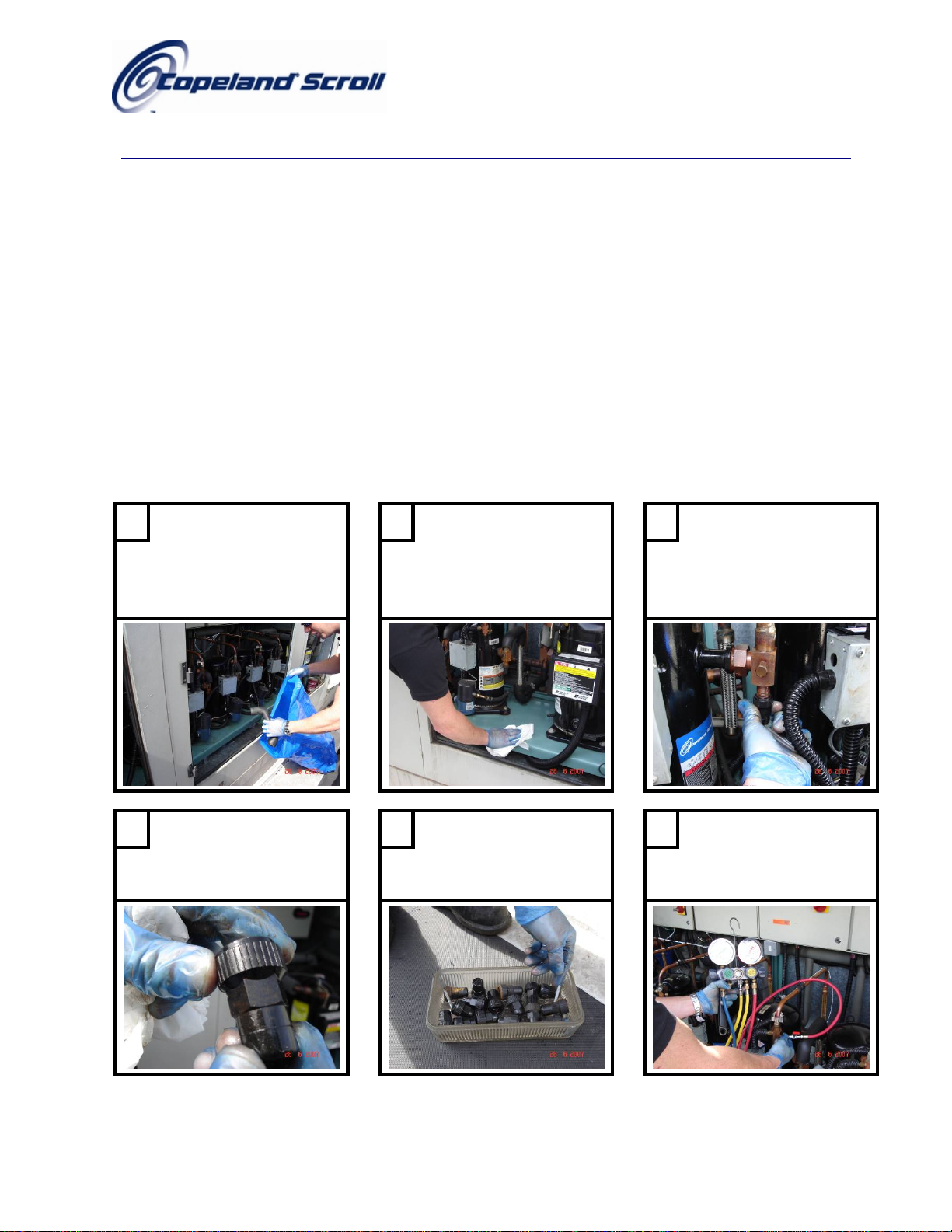

2 Scroll Compressor Replacement Procedure

1

Begin by removing any

waste or rubbish from the

2

… clean away any dirt or

debris.

3

Remove all valve caps…

plant housin g …

4

… inspect for cracks or

damage…

5

… and store saf el y.

6

Select compressor, fit

service gauges, check

pressures.

2 C05.2.4/1007/E

Page 4

7

Isolate the oil supply to the

faulty compressor.

10

Fully 'front seat' the

discharge and suction

valves, isolate the

compressor from the

system.

8

Electrically isolate the

compressor (3 phase

9

… and the supply to the

crankcase heater).

supply…

11

Recover the compressor’s

12

Release the suction…

contained refrigerant to a

reclaim container.

13

… and discharge Rotalock

nuts and oil management.

14

Remove compressor

bolts…

15

… and discard the existing

rubber mounts and sleeves.

C05.2.4/1007/E 3

Page 5

16

Fit replacement hard rubber

mounts to new compressor.

Kit Part Number 8030450

17

… ensuring correct

placement of washers and

metal sleeve.

22

Apply thread lock paste to

compressor discharge and

suction connections.

23

Refit Rotalock nuts and

using the correct valve

retaining tool…

18

Refit mounting bolts and

tighten to correct torque

(see table). 2 mm gap

between bolt & rubber.

24

… tighten to correct torque

(see table). Ensure valve

position does not stress the

pipe work.

25

Remove oil sight glass and

assemble oil management.

Evacuate the compressor

using vacuum pump.

26

Open the oil supply to the

compressor.

27

'Back seat' the discharge

and suction ser v i ce valves

to remove service gauges.

4 C05.2.4/1007/E

Page 6

28

Leak test the Rot alock

fittings.

29

Refit all valve caps.

30

31 32 Correct tools (L to R) 33

Clear and correctly dispose

of all waste .

Valve retaining bar

Discharge torque spanner

Suction torque spanner

½” drive torque wrench

Restore the electrical power

supplies.

All Done!

(Return in 7 days to check

torque settings)

Torque Settings

Application Torque Nm

Compressor Mounting Bolt M8 12-14

Rotolock 3/4" - 16UNF 40-50

Rotolock 1" - 14UNF 70-80

Rotolock 1 1/4" - 12UNF 120-135

Rotolock 1 3/4" - 12UNF 135-160

Rotolock 2 1/4" - 12UNF 165-190

Sight glass 25

Copeland Replacement Part No’s

Description Part No.

Hard Mounts and Ferrules 8030450

PTFE Suction Gasket 2495939

PTFE Discharge Gasket 2495928

PTFE DTC Injection Gasket 8536083

DTC Injector Complete 8530541

NOTE: New PTFE gaskets are supplied and fitted to new compressors.

C05.2.4/1007/E 5

Page 7

The above sc roll compress or replacement procedure sho ws replacement typically for ZB medium temperature

application. For replacement of Copeland ZF Scroll typically low temperature application the same procedure

can be used but for one exception. The ZF scroll has a DTC valve fitted or for older models possibly capillary

injection.

IMPORTANT: Liquid line feed to the compressor injection port has to be isolated and compressor evacuated

before attempting to remove the injector.

Assembly Procedure

1 Verify Coil Spring is seated in the “Groove” located in the well on top of the compressor.

2 Thread the Discharge Temperature (DTC) valve onto the injection stub on the side of the compressor.

Torque setting 24-27N/M (216-240 in/Lbs)

3 Press the DTC bulb into the well on top of the compressor until the DTC bottoms out in the well.

4 Snap the Thermo. cap onto the DTC bulb on top of the compressor.

5 The copper tube from the DTC bulb should be approximately 0.125mm (1/8”) from the top of the compressor.

Compressor Mounts

New compressor mounts are recommended when a compressor is replaced. When purchasing a replacement

scroll compressor soft mounts are included. These soft mounts should not be used for multiple compressor pack

/ rack application.

Scroll compressors used in pack / rack design must use harder mounts which allow more load to be transmitted

via the feet. This will give flexibility and minimise the risk of resonance to connecting pipe work.

Hard Rubber Mount Set Part Number 8030450 Steel Mount Set Part Number 8522911

Approved Oils

Copeland only approves the use of the following polyolester lubricants: Mobil Arctic EAL 22CC or Emkarate

RL32-3MAF. Either oil can be used for top up and are suitable for use with both HCFC and HFC systems.

Service Refill Quantity

Model Name HP

Oil charge

supplied [l]

Oil charge

Service [l]

ZB15 2 1,0 1,0

ZB19 2,5 1,0 1,0

ZF09 ZS21 ZB21 3 1,24 1,12

ZF11 ZS26 ZB26 3,5 1,24 1,12

ZF13 ZS30 ZB30 4 1,95 1,83

ZF15 ZS38 ZB38 5 1,95 1,83

ZF18 ZS45 ZB45 6 1,77 1,66

ZF24 ZS56 ZB56 7,5 4,14 4,05

ZF33 ZS75 ZB75 10 4,14 4,05

ZF40 ZS92 ZB92 13 4,14 4,05

ZF48 ZS11M ZB11M 15 4,14 4,05

6 C05.2.4/1007/E

Page 8

Lubricant Handling

Polyolester lubricant products should pose little or no significant adverse health effects when properly used or

handled properly. Prolonged repeated skin contact should always be avoided. The lubricant supplier should be

contacted for specific health and safety documentation.

3 System Evacuation and Charging Procedure

Evacuating the system only on the suction side of a scroll compressor can occasionally result in a temporary nostart condition for the compressor. The reason for this is that the floating seal c ould axially seal with the scroll

set, with the higher pressure on the floating seal. Consequently, until the pressures equalize, the floating seal

and scroll set can be held tightly together.

The installation should be evacuated down to 0.3 mbar / 0.22 Torr or lower. Subsequently, the factory holding

charge of dry air in the compressor is released to the ambient. The shutoff valves are opened and the

installation, including the compressor, are once more evacuated as described after the system has been

recharged with dry nitrogen.

Highest demands are placed on the leak proof design of the installation and also on the leak testing methods

(please refer to EN378).

Rapid charging on the suction side of scroll compressors can occasionally result in a temporary no-start

condition for the compressor. The reason for this is that if the flanks of the spirals happen to be in a sealed

position, rapid pressurization of the low side without opposing high s ide pressure can cause the spirals to seal

axially. Consequently, until the pressures eventually equalize, the spirals can be held tightly together, preventing

rotation. The best way to avoid this situation is to charge on both the high and low side simultaneously at a rate

which does not result in axial loading of the spirals.

Qualified Refrigerants

R404A, R507, R22 and R134a are qualified for all refrigeration scroll compressors.

The ZB compressor family is also qualified for R407C.

It is essential that the glide of R407C refrigerant blends be given careful consideration when adjusting p ressure

controls.

4 Performance / Visual Checks

When having to replace a compressor installed in a pack design it is worthwhile to visually

check the condition of the remaining compressors, the rubber mounts and associated pipe

work.

Check the gauge pressure readings.

• Is the pack operating correctly?

• Is the operation within the manufacturer’s specification? (Check with the application envelope shown on

the following pages).

• Ensure the low pressure switch is set correctly if system pump down is applied. If the setting is too low

the compressor might be operating outside its operating envelope.

Compressor mounts

• Check to see that all mounts are secure and not damaged.

• Are the correct hard mounts fitted?

Lubrication

• Check that the regulator oil levels are correct including oil reservoir.

• Check the oil is still in an acceptable condition i.e. check for dirt and acidic content.

C05.2.4/1007/E 7

Page 9

Electrical

• Check all electrical connections for tightness.

• Check contactors for spring tension and contactor wear. If connectors are pitted, replace, DO NOT

FILE.

• Check overload functioning correctly.

• Check the compressor run current values.

• Check operation of crankcase heater, if fitted.

R404A Application Envelopes

ZF09K4E to ZF18K4E

Tc °C

Te °C

Tc °C

ZB15KC to ZB45KC

Te °C

8 C05.2.4/1007/E

Page 10

Benelux

Deltakade 7

NL-5928 PX Venlo

Tel. +31 (0) 77 324 0234

Fax +31 (0) 77 324 0235

UK & Ireland

17 Theale Lakes Business Parc

GB-Theale, Nr Reading-Berkshire RG7 4GB

Tel. +44 (0)1189 83 8000

Fax +44 (0)1189 83 8001

Asia/Pacific

10/F, Pioneer Building, 213 Wai Yip Street,

Kwun Tong, Kowloon - Hong Kong

Tel. +852 28 66 31 08

Fax +852 25 20 62 27

Deutschland/Österreich & Schweiz

Senefelder Straße 3

D-63477 Maintal

Tel. +49 (0)6109 6059 0

Fax +49 (0)6109 6059 40

France/Greece & Maghreb

8, Allee Du Moulin Berger

F-69130 Ecully

Tel. +33 (0)4 78668570

Fax +33 (0)4 78668571

Italia

Via Ramazzotti, 26

I-21047 Saronno (va)

Tel. +39 02 961781

Fax +39 02 96178888

España & Portugal

Diputacion, 238 AT.8

E-08007 Barcelona

Tel. +34 93 4123752

Fax +34 93 4124215

C5.2.4/1007/E

Sweden/Denmark/Norway & Finland

Pascalstr. 65

D-52076 Aachen

Tel. +49 (0) 2408 929 127

Fax +49 (0) 2408 929 528

Eastern Europe, Turkey & Iran

Pascalstr. 65

D-52076 Aachen

Tel. +49 (0) 2408 929 0

Fax +49 (0) 2408 929 525

Poland

11A, Konstruktorska

PL-02-673 Warszawa

Tel. +48 22 458 9205

Fax +48 22 458 9255

Russia & CIS

Letnikovskaya, 10, building 2, 5th floor

RUS-113114 Moscow

Tel. +7 495 981 9811

Fax +7 495 981 9816

Latin America

7975 North West 154Th Street - Suite 300

Miami Lakes, FL, 33016 - USA

Tel. +1 305 818 8880

Fax +1 305 818 8888

Middle East & Africa

PO BOX 26382, R/A 8, FD-2

Jebel Ali, Dubai - UAE

Tel. +9714 883 2828

Fax +9714 883 2848

Emerson Climate Technologies - European Headquarters - Pascalstrasse 65 - 52076 Aachen, Germany

Phone: +49 (0) 2408 929 0 - Fax: +49 (0) 2408 929 570 - Internet: www.eCopeland.com

The Emerson Climate Technologies logo is a trademark and service mark of Emerson Electric Co. Copeland Corporation is a subsidiary of Emerson Electric Co. Copeland is a registered trademark and Copeland Scroll is a trademark of Copeland

Corporation. All other trademarks are property of their respective owners. Information contained in this brochure is subject to change without notification.

© 2006 Copeland

Loading...

Loading...