DM4-2067

NIDEC COPAL CORPORATION

DPB-1500

INSTRUCTION

First Edition

January 2005

FCC Compliance Statement

WARNING

Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

Properly shielded and grounded cable and connectors must be used for connection to host

computer and / or peripherals in order to meet FCC emission limits.

NOTICE

Operation is subject to the following two conditions

(1) This device may not cause interference, and

(2) This device must accept any interference received, including interference that may cause

undesired operation of the device

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

- Reorient or relocate receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

- Consult the dealer or an experienced radio/TV technician for help.

CONTENTS

Safety Precautions................................................................................................1

During installation.........................................................................................2

Environmental Consideration........................................................................2

During operation...........................................................................................3

During maintenance......................................................................................4

Other precautions.........................................................................................4

Handing of the print media............................................................................4

Preparation............................................................................................................5

Unpack .........................................................................................................5

Installation ....................................................................................................5

Changing paper width...................................................................................6

Printer drivers ...............................................................................................7

1. Windows 2000/XP printer driver...........................................................7

1.1 Plug and Play Installation for the Printer Driver............................... 7

1.2 Printer Driver Settings......................................................................9

- Selection of Paper Size...................................................................9

- Set up for print size “6x4inchX2” ...................................................10

- Set up for Print Mode (Hi-Speed / Hi-Quality)................................11

INSTRUCTION.....................................................................................................12

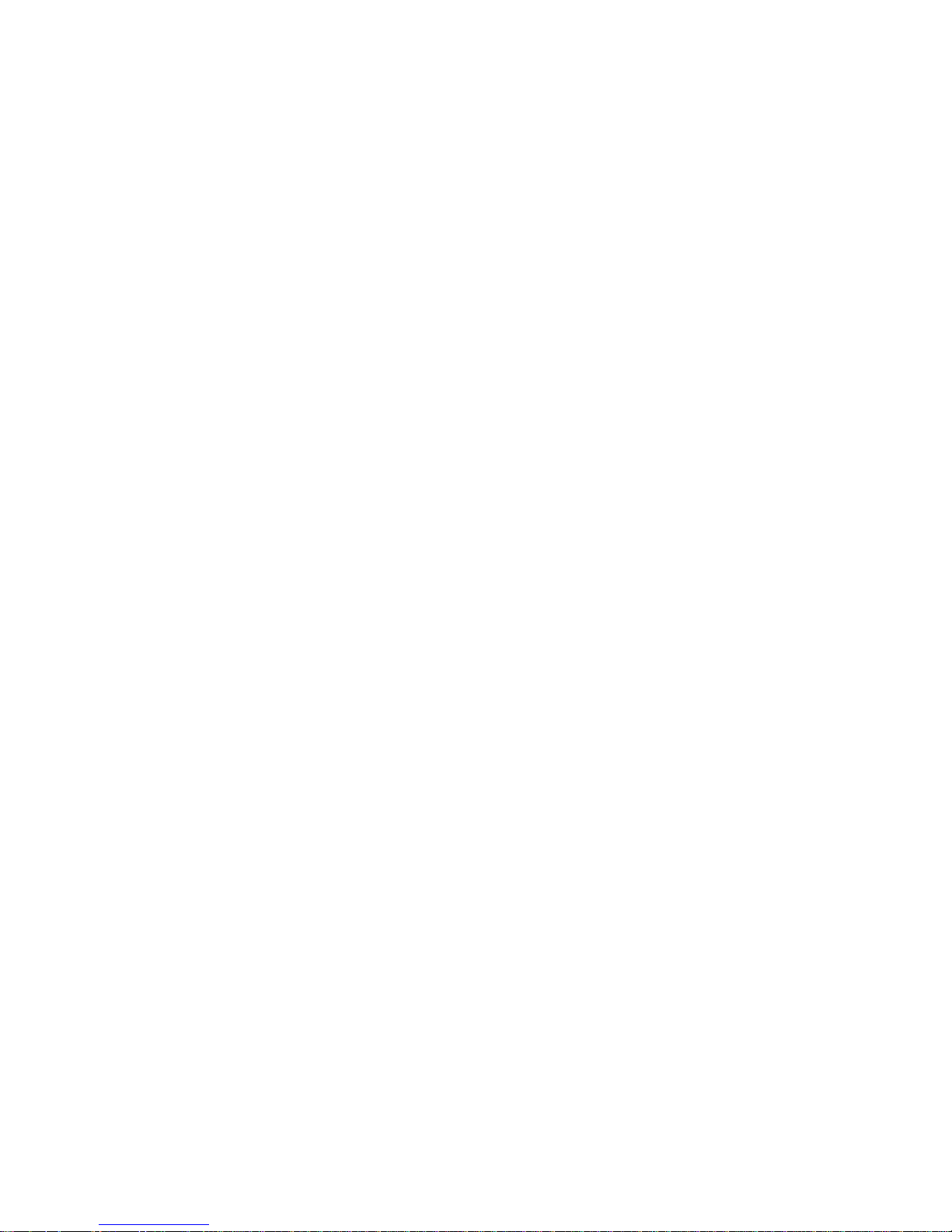

1. Overall View ................................................................................................12

(1) Front..................................................................................................12

(2) Rear..................................................................................................12

(3) Ink Ribbon Tray Section....................................................................13

(4) Print Head Section.............................................................................13

(5) Roll Paper Tray Section.....................................................................14

2. Operating Panel ..........................................................................................15

(1) Operating Panel LED........................................................................15

(2) Panel Switches..................................................................................16

3. Print media ..................................................................................................17

(1) Loading the roll paper........................................................................17

(2) Loading the ink ribbon.......................................................................22

(3) Printing .............................................................................................24

4. Daily Maintenance ........................................................................................25

Weekly Maintenance .................................................................................26

5. Troubleshooting ...........................................................................................27

(1) In case of ribbon error .......................................................................27

(2) In case of a paper transport error......................................................28

6. Error Messages.............................................................................................29

(1) Error messages upon startup............................................................29

(2) Recoverable Errors...........................................................................31

7. Specifications ...............................................................................................33

1

Safety Precautions

Please be sure to read this entire manual before using the product.

Pay special attention to this section “Safety Precautions”.

The precautions listed herein are designed to provide for safe operation of the product, and

to protect the user from experiencing bodily harm and property damage.

Safety notices herein are presented in two formats, “Warning” and “Caution” -- depending on the

degree of danger associated with accidental or other misuse of the product:

Be sure to keep this instruction manual in a safe and readily accessible location.

WARNING:

Failure to follow warning could result in

death or serious injury.

CAUTION:

Failure to follow caution could result in

minor bodily injury or property damage.

2

During installation

Environmental Considerations:

Ensure the room temperature is between 10 and 30 degrees C (50 and 85 degrees F), with

relative humidity between 30 and 70%.

Do not place unit where it will be exposed to direct sunlight or temporary freezing conditions.

CAUTION: Avoid placing the unit in areas of high humidity or dust

* Doing so could disable the unit

CAUTION: Do not allow the unit to block the ventilation holes

* Doing so could disable the unit

WARNING: Ensure the unit is properly grounded.

* Electrical discharge could cause shock and present a

fire hazard.

WARNING: Install the unit on a level surface or shelf which can

adequately handle the weight (approx. 24 Kg / 53 lbs)

* Bodily injury and property damage could result from the

unit falling from an unstable surface.

3

During operation

CAUTION: Some areas on the unit become hot and may burn the skin if

touched.

CAUTION: Do not insert hand or other objects into the power supply cooling

fan, as bodily injury and damage to the unit could result.

CAUTION: Be sure to use manufacturer-specified parts when replacing

consumables.

CAUTION: In the event of product break down, disconnect power to the unit

and call an authorized service facility.

WARNING: Provide adequate care to ensure water, chemicals or liquids do

not spill on or into the unit.

* Water and liquids can produce electric shock and present a fire

hazard.

WARNING: Do not print when cover panels are opened or removed.

* Electrical shock or other bodily harm could result.

WARNING: Do not touch the print head when power is on.

* High temperatures can burn skin.

WARNING: Always disconnect the power cord before cleaning the unit.

* Electrical shock or bodily injury could occur.

WARNING: Do not place the unit within reach of children.

* Electrical shock or bodily injury could occur.

WARNING: Do not bend or damage the power cable.

* This presents an electrical and fire hazard.

WARNING: Do not attempt to service the unit. Only qualified service

engineer should attempt to disassemble or repair the unit.

* Electrical shock or other bodily harm could result.

WARNING: Do not place objects on or near the unit’s ventilation area.

* This presents a fire hazard.

4

During maintenance

Other precautions

AC Power supplied to the unit should be between 100V and 240 V (Single phase)

Wear (cloth) gloves when handling paper. Undesirable printing (i.e. dirt and fingerprints)

could result should the paper come in contact with bare hands.

Handling of the print media

Storage: Keep the media away from high humidity and direct sunlight. Storage in cool

place is recommended. (Room temperature between 10 and 30 degrees C (50 and 85

degrees F), with relative humidity between 30 and 70%. Avoid dew condensation.)

Type of media: Use the genuine Copal print media. Use of the other make of media in the

Copal DPB-1500 printer may result into the bad influence to the print quality, malfunction of

the printer and/or may cause an serious damage to the printer which could not be repaired.

WARNING: Turn power switch OFF before attempting to perform any

maintenance to unit.

* The unit otherwise produces high voltage and hot surfaces which

can pose a danger to the person performing the maintenance.

WARNING: Do not force the safety interlock switch to the ON position.

* Electrical shock or bodily injury could occur.

WARNING: Ensure hands are dry before inserting power plug into outlet.

* Electrical shock or bodily injury could occur.

5

Preparation

Unpacking

Please find the following accessories when unpacking the DPB unit.

* Please store the test print carefully, as the print will be

of the reference for density check when the print head

would be replaced.

Installation

Setup the DPB unit and PC in a fixed location.

Step1. Connect the DPB unit to the PC. (USB2.0 cable should be prepared separately)

Step2. Connect the supplied power cable to the DPB-1500 unit and power supply.

(AC 100V – 240V, single phase).

Step3. Turn on the printer and PC.

Step4. Install the DPB-1500 printer driver (supplied on the CD-ROM) to the PC.

See: Printer drivers install procedures

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and

other countries.

Warning: The DPB unit is heavy and requires 2 people to carry.

USB cable (USB2.0)

AC Power cable

DPB Back Side

Personal computer

OS: Windows 2000/XP

Power Switch

Cable connections

Accessories:

1. CD-ROM (Printer Driver, Manual,

Parts List, Adjustment Tool Software)

2. Print sample (shows factory

adjustment data.) *

3. Print tray

4. AC cable

1

2 3 4

6

Changing paper width

* With moving the paper guides, the printer can be set to either 5-inch (127mm) width or

6-inch (152mm) width of paper.

* The default paper width is 6 inch (152 mm) at the factory shipment.

Replacing the left and right paper guides

Step1. Pull the paper tray forward. Fig1.

Step2. Remove the left and right guides, boards A and B. (Four guides in total, fixed by

one screw each) Fig1. Fig.2.

Step3. Set the guides to the grooves for the desired paper width.

Step4. Fix the left and right, A and B guides with screw. Fig1.

Left guide A

Left guide B

Right guide A

Right guide B

Fig.1

Fig.2 Guide

Guide A 127mm

Guide B 152mm

Guide B 127mm

Guide A 152mm

7

Printer drivers

1. Windows 2000/XP printer driver

* You need to log on as a Computer Administrator account when installing printer driver.

A Limited User cannot install it.

* After installation, ensure the printer is set to be Windows’ default printer, and select the

appropriate print format.

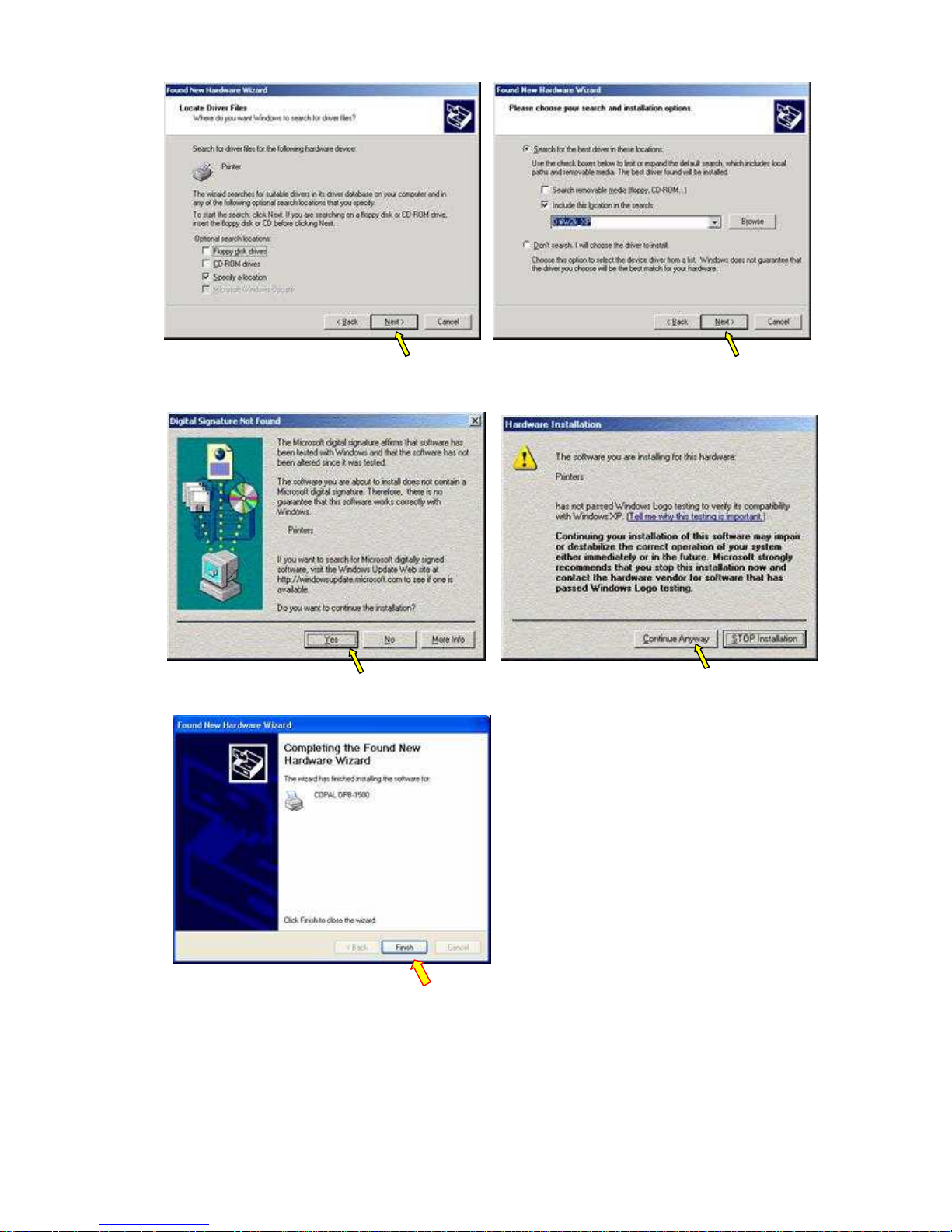

1.1 Plug and play Installation for the Printer Driver

1) Turn on computer and launch OS

2) Connect DPB to computer and turn on.

3) Plug & Play will start [Found New Hardware] dialog box will be display.

* File name W2k XP: Windows2000/XP

1. Found New Hardware will be displayed.

2. Hardware wizard Found New Hardware dialog box will be displayed.

3. Specify location where driver exists. Then click [Next].

Windows 2000 Windows XP

* Please select [Next>] button.

8

4.Select [YES] button Select [Continue Anyway] button

Windows 2000 Windows XP

5. Select [Finish] button, and DPB-1500 is registered

9

1.2 Printer Driver Settings

Printer default values can be set at printer property.

■ Selection of Paper Size

3. Printing Preference Dialog box

Select [Landscape] in the “Orientation”

box – Portrait or Landscape.

Select [Advance]

1. Select Properties of Printer

(COPAL DPB-1500)

2. COPAL DPB-1500 Properties Dialog

box

10

4. Click “Paper Size” and select paper size from drop 14down list

■ Set up for the print size “ 6 x 4inch x2”

Change the “Pages Per Sheet” from “1 “ to “2”

Select Paper Size

1. 5 x 3.5inch (127x89mm)

2. 6 x 4inch (152x102mm) Default

3. 5 x 7inch (127x178mm)

4. 6 x 8inch (152x203mm)

5. 6 x 9inch (152x230mm)

6. 6 x 4inch x 2 (152x102mm x2)

Note: “6 x 4inch x 2” format requires 6x9

format of media.

Change

1→2

Display

2 Sheet

11

■ Set up for Print Mode (Hi-Speed / Hi-Quality)

(Note) Hi-Speed is the default setting for regular print.

Hi-Speed: 300X300 dpi

Hi-Quality:300X600 dpi

Choice of Hi-Speed / Hi-Quality

12

INSTRUCTION

1. Overall View

(1) Front

(2) Rear

No. Name

1 Upper Cover

2 Ink Ribbon Tray

3 Display

4 Print Tray

5 LED lamp

6 Key Switch

7 Paper door

No. Name

1 Power Switch

I: ON O: OFF

2 AC Connector

3 USB2.0 Connector

WARNING:

To avoid electrical shock, always

ensure hands are dry when inserting

power cable.

Fig.4

Fig.3

13

(3) Ink Ribbon Tray Section

(4) Print Head Section

No. Names

1 Upper Cover

2 Print Head

3 Ink Ribbon supply

4 Ink Ribbon take up

5 Ink Ribbon Tray

WARNING:

The print head gets very hot.

Allow the head to cool for at least 5

minutes before handling.

No. Name

1 Print Head

14

(5) Roll Paper Tray Section

No.

Name

1 Release Lever

2 Control Card *

3 Pressure Roller

4 Slug Box

Fig.7 Print head assembly

WARNING:

The print head can break when

touched with bare hands.

Fig.8

* A control card is a factory option

15

2. Operating Panel

(1) Operating Panel LED

LED Lighting Status

Lit Power Switch ON (indicates ready status)

POWER Flashing --------- Off Power Switch OFF

Lit Paper is loaded to the print position.

DATA Flashing Image data being transmitted

Off Paper is rewound and can be exchanged

Lit Error: Paper/ Ribbon Empty (replace paper / ribbon)

ERROR Flashing Error: Power needs to be cycled off/on

Off No Errors (OK to print)

Ready

0

POWER

DATA

ERROR

REWIND

CUT

REPRINT

Display

LED lamps Panel switches

Fig.9

LED Push button switches

Display

POWER DATA ERROR

16

(2) Panel Switches

Switch Function

REWIND Rewind roll paper

CUT Cut paper tip (About 5 cm)

REPRINT

Repeat the last print

* The unit will be reset when this PEPRINT button is kept

pushing for more than five seconds.

REWIND

CUT

REPRINT

17

3. Print media

Ensure roll paper and ink ribbon is installed before printing.

(Note): Paper and ink ribbon maintenance

* Use manufacturer-specified materials.

* Place the unit where it will be in a cool and somewhat humid location, out of the

direct rays of the sun.

* Do not touch paper with bare hands.

(1) Loading the roll paper

(Note 1) Use cloth gloves when handling roll paper.

(This avoids transfer of fingerprints and other printing errors)

(Note 2) Do not shut off power to the unit when paper or ribbon runs out.

Normally both the paper and ribbon are replaced at the same time.

* Printing automatically re-starts after the roll paper is replaced.

* Data in process is erased should power be shut off.

* Approximately 500 PC-size papers can be printed with one ink ribbon and

roll paper set.

Step1: Remove print tray Step2: Draw out paper tray from front

Step3: Remove Slug Box (The slug Box is attached with a magnet)

Slug Box

Fig.12

Fig.10

Fig.11

Release

18

Step4: Pull the pressure release lever toward the front of the unit

Step5: Take out the new Roll Paper, inserting the supplied Paper Core

Fig.15

Paper Core Roll Paper

Fig.16

Pin

Tape

Fig.14

Fig.13

Release

19

Step6: Set the paper into the tray Step7: Set securely

Step8: Hold the paper tip, and again engage the Pressure Roller

* Securely fit the pins on both sides of the core

into the tray groove. Fig.18

(Note): The paper surface is to the rear.

Fig.19 Paper placement

Paper Surface

Paper tip

Rear

Front

Fig.17 Fig.18

PIN

Fig.20

Paper tip

Fig.21

Paper tip

20

Step9: Turn the gear to move the paper tip about 2mm into the roller

Step10: Mount the Slug Box

Step11: Set paper tray (Standard Size: 5x3.5, 6x4 inch)

As it opened a roll paper tray, it hitches a paper tray.

Fig.22

Paper tip 2mm

Gear

(Ensure it is securely locked)

(Note)

The roll paper tray cannot be pushed

back if the Slug Box isn’t mounted

Slug Box

Stopper lever

Fig.23

Paper Tray

Hook

Fig.24-1

Fig.24-2 Paper tray set condition

21

Option: Set universal tray. (Big Size / Standard Size) Fig.24-3, 24-4, 24-5

Step12: Push the roll paper tray into the main body.

(Note):

In the case that the paper tray is closed while the printer is turned ON, the printer is

initialized and exhausts leading edge of the paper roll by 20cm.

Fig.24-3 A: Plate

B: Big size tray

C:Standard size tray

A

Fig.24-5 Big tray is attached

Universal tray (Option)

Part No. P5A-F4572

The hook of the tray upper part is

hooked on a plate.

B

Fig.25-1

Fig.25-2 Universal tray

22

(2) Loading the ink ribbon.

Remove the Ink Ribbon tray from the unit.

Prepare the new roll of ribbon.

Step1. Open the upper cover. Step2. Push the lever

Step 3. Raise the upper cover Step 4. Remove the Ink Ribbon Tray

Fig.26

* The Take-Up Core gear is installed to the left

Gear

Ribbon

Take-up core

Fig.27

1.Push lever

2.Lift up

Fig.28

Fig.29

Fig.30

23

Step 5. Install the Ink Ribbon on the tray

Step 6. Set the Ink Ribbon Tray onto the body of the unit. Fig.33, 34

Place the take-up core into the set position.

Place the ribbon on the tension roller

and press it to the set position.

Fig.31 Setting the Ribbon (1)

Tension Roller

Setting the New Ribbon:

Turn the take-up core shaft more than once,

and remove a slack of the ribbon.

Take-up core

Fig.32 Setting the Ribbon Set (2)

Gear

Fig.34 Fig.33

Green marks

24

Step 7. Close Upper Cover securely, and close upper cover door Fig. 35, 36

(3) Printing

1. Turn on the printer and the PC.

2. Confirm that the LED is showing the ready status.

3. Check the print size and print mode with the printer driver.

4. Begin printing

(Note): There is a n interlock switch at the upper cover.

Should the upper cover be opened while printing, the interlock switch

will stop the unit. (Motor and head power will be shut down).

It is locked securely

Fig.35

Fig.36

25

4. Daily Maintenance

Ensure that dust & etc. does not go inside the printer..

Maintenance to the rollers, paper tray, print head and ribbon tray.

Paper tray section:

Cleaning of a base and a guide inside the paper tray.

Print head / Paper transport:

Cleaning the transport rollers:

* Normally a damp cloth is used.

* Ethyl Alcohol may be used for hard-to-remove items such as ribbon residue.

* Ethyl Alcohol may also be used to clean the print head.

(Note: Do not apply ethyl alcohol to the print head too much,

as it would cause a damage to the head.)

Fig.38 Paper Transport/Print Head

Paper Transport

Print Head

Fig.37 Paper Tray

Base

Roller

26

Ribbon tray section.

* Always keep the tension roller clean because, if the roller gets dirt, it would cause slip of

the ribbon that would result into the spoiled quality of the print and/or printer malfunction

* Wipe up lightly while soaking ethyl alcohol in the cloth and turning a tension roller.

(At least, once in a month)

* Remove the residue of the ribbon bobbin from its receiver. (Four receivers)

Weekly Maintenance

Fig.41 Bobbin tray (Four)

Cleaning part

Fig.39 Ribbon Tray

Tension roller

Fig.40 Tension roller

Cleaning part

(Note):

It would affects the print quality should

should the dust gets into the body.

Air Filter

Fig.42

Clean the air filter every week.

(Set the filter dry)

Replace an old air filter with the new air filter.

27

5. Troubleshooting

(Note) Paper and Ribbon End error messages are indicated with a solid red LED.

Do not turn off the unit, but rather replace the ribbon or paper with the DPB power on.

(1) In case of ribbon breakage

Turn of the printer.

1. Pull the ribbon tray out toward the front

2. Reel the ribbon on to the take up core (use tape), turn the core to set the

ribbon to its initial position. Fig.43

3. When in the middle of a print job, the paper printed so far is worthless, so

eject it. Turn on the power switch and once the red error LED turns off press the

tip cut switch (one cuts 5cm)

Ribbon supply Take up core

Over coat

Use tape to splice if necessary

Fig.43

Position of ribbon set

Set the position where an overcoat

(transparent) part comes between ribbon

supply and take-up cores.

28

(2) In case of a paper jam

Switch off the printer.

1. Pull the ink ribbon tray out and ensure there is no paper jam in the paper

transport area.

2. If there is a jam, use scissors, etc. to remove it. Fig.44

3. Paper tip is put into the paper guide. Fig.45

4. Turn on power, and once the red error LED turns off perform the following:

* If the paper tip is being printed, then press the Tip Cut key a number of times to

remove the printed area.

* If the paper tip has not been exposed, then press the Rewind key to rewind the

paper back into the paper tray.

* Pull the paper tray forward, and check to see if the paper tip is damaged.

If so, use scissors to cut the tip of the paper.

Cut at right angles

Fig.44

Paper guide

Fig.45

29

6. Error Messages

(1) Error messages upon startup “PC” = Personal Computer

Error No. Description

Error LED Flashing

LCD E01: Print head malfunction-up

PC

Error at Printer on USBXXX

Motor or Sensor Trouble.

Please restart printer.

01

Action Check head actuator mechanism sensor

Error LED Flashing

LCD E02: Print head malfunction-down

PC

Error at Printer on USBXXX

Motor or Sensor Trouble

Please restart printer.

02

Action Check head actuator mechanism sensor

Error LED Flashing

LCD E03: Faulty ink ribbon transport

PC

Error at Printer on USBXXX

Please check the position of ink ribbon.

Please restart printer.

03

Action Check head actuator mechanism sensor

Error LED Flashing

LCD E04: HDC error occurred

PC

Error at Printer on USBXXX

System Error

Please restart printer

04

Action The CPU PCB board needs to be replaced (10S-MAIN)

Error LED Flashing

LCD E05: Faulty paper transport - front

PC

Error at Printer on USBXXX

Paper Jam

Please restart printer

05

Action Check transport mechanism sensor

Error LED Flashing

LCD E06: Faulty paper transport - back

PC

Error at Printer on USBXXX

Paper Jamming

Please restart printer

06

Action Check transport mechanism sensor

Error LED Flashing

LCD E07: Paper cutter malfunction

PC

Error at Printer on USBXXX

Motor or Sensor Trouble

Please restart printer

07

Action Check cutter mechanism sensor

30

Error No. Description

Error LED Flashing

LCD E08: Timeout of CMD response

PC

Error at Printer on USBXXX

System Error.

Please restart printer.

08

Action Verify communication with host computer

Error LED Flashing

LCD E09: Writing FROM not successful

PC

Error at Printer on USBXXX

System Error

Please restart printer.

09

Action The CPU PCB board needs to be replaced (10S-MAIN)

Error LED Flashing

LCD E10: Power supply error

PC

Error at Printer on USBXXX

System Error

Please restart printer.

10

Action Replace power unit, verify power supply control

Error LED Flashing

LCD E11: Grip roller malfunction

PC

Error at Printer on USBXXX

Motor or Sensor Trouble.

Please restart printer.

11

Action Check roller actuator mechanism sensor

31

(2) Recoverable Errors

Error No. Description

Error LED Lit

LCD W50: Printer not ready

PC No message

50

Action Wait

Error LED Lit

LCD W51: ink ribbon end

PC

Warning W51 at Printer on USBXXX

Ribbon end.

Please replace an ink ribbon.

51

Action Check new ink ribbon sensor

Error LED Lit

LCD W52: Different type of ribbon

PC

Warning W52 at Printer on USBXXX

Media miss match.

Please place a proper size of paper or ink ribbon.

52*1

Action Reset with proper ribbon and check sensor

Error LED Lit

LCD W53: Ink ribbon cover open

PC

Warning W53 at Printer on USBXXX

A cover for an ink ribbon is opened.

Please close a cover.

53

Action Close cover securely and check sensor

Error LED Lit

LCD W54: Ink ribbon not set

PC

Warning W54 at Printer on USBXXX

An ink ribbon is not set.

Please set an ink ribbon.

54

Action Set the ribbon and check sensor

Error LED Lit

LCD W55: Paper end

PC

Warning W55 at Printer on USBXXX

A paper roll is empty.

Please replace a paper roll.

55

Action Exchange paper roll and check sensor

Error LED Lit

LCD W56: Paper not found

PC

Warning W56 at Printer on USBXXX

A paper is not loaded properly.

Please re-set a paper roll a printer.

56

Action Insert paper and check sensor

32

Error No. Description

Error LED Lit

LCD W57: Different type of paper

PC

Warning W57 at Printer on USBXXX

Media miss match.

Please place a proper size of paper or ink ribbon.

57

Action Reset with proper paper and check sensor

Error LED Lit

LCD W58: Paper door is opened

PC

Warning W58 at Printer on USBXXX

Paper door is open.

Please close a door.

58

Action Close paper tray securely and check sensor

Error LED Lit

LCD W59: Invalid command

PC No message.

59

Action Resend the proper command

Error LED Lit

LCD W60: Invalid parameter

PC No message

60

Action Retransmit the proper command parameter

Error LED Lit

LCD W73: Transferring not successful

PC

Error at Printer on USBXXX

Please Check USB Communication.

73

Action Check the USB cable and Power Supply

33

7. Specifications

Item Specifications

Type High Speed Dye Sublimation Printer

Print Resolution

Hi-Speed: 300 x 300dpi

Hi-Quality: 300 x 600dpi

Maximum Print Width 154mm

Print Speed

6X4inch

Hi-Speed: Approx. 12 Sec/Sheet

Hi-Quality: Approx. 19 Sec/Sheet

Interface USB 2.0

Buffer Memory 32MB

Paper Transport Roll paper

Print Size Borderless 5X3.5inch (127 x 89mm)

6X4inch (152 x 102mm)

5X7inch (127 x 178mm)

6X8inch (152 x 203mm)

6X9inch (152 x 230mm)

6X4inch X2 (152 x 102mm) X2

Paper Loading Tray Direct Loading

Paper Slug 5mm Width

Ink Ribbon YMC+OC

Ribbon Loading Tray set

Dimensions 300 (W) x 360 (D) x 340 (H) mm

Weight Approx. 24 Kg (53 lb)

Power Voltage

Power Consumption

100 – 240V AC

100VAC / 3A – 240VAC / 1.3A

Media Set 5X3.5inch 6X4inch 5X7inch 6X8, 6X9inch

Prints/Roll 500 500 250 225

Loading...

Loading...