Coopra 40C, 15B, 15C, 37K, 37B Installation Manual

...

EN

Installation manual

(Boilers with printed circuit board type 585)

40C

Gas boiler for Heating E40C

2011 585 E

Coopra Advanced Heating Technologies Installation manual E40C

2

CONTENTS

CHAPTER 1. GENERAL ……………….………….. 3

Use of application

General safety regulations

Environmental conditions

Water quality

Standards / Guidelines

Conditions of delivery

1.1. Display …………………………………….…….. 4

1.2. PCB configuration

1.3. Operation indications

1.3.1. Normal state

1.3.2. Blocking state

1.3.3. Lock-out state

1.4. Menu Structure

1.4.1. View mode

1.5. Dimensional sketch

1.5.1. Technical data

1.5.2. Boiler components

1.6. Connection diagram

1.7. Operation

1.8. Boiler types

1.8.1. Coopra 40C

1.8.2. Technical characteristic

1.9. Electricity connection

1.10. Configuration of flue tube and air supply

1.10.1. Permitted flue resistance Type 40

1.11. Circulation pumps

1.11.1. Boiler pump

1.11.2. Secondary system pump

CHAPTER 2. INSTALLATION …………………….. 15

2.1. Mounting the assembly bracket

2.2. Water and gas connections

2.2.1. Gas connection

2.2.2. Water connections

2.2.3. Safety valve and Draconin connection

2.3. Expansion vessel

2.4. Filling and draining device

2.5. Dirt filter

2.6. Differential bypass valve

2.7. Unpacking the boiler

2.8. Fitting the flue tube and air supply

2.8.1. Connecting flue and air (2-pipe system)

2.8.2. Connecting flue/air adapter (80/125 mm)

2.8.3. Connecting flue/air adapter (60/100 mm)

2.9. Suspension

2.10. Green connector block

CHAPTER 3. REGULATIONS ……………..…….. 18

3.1. Central heating regulations

3.1.1. Modulation on flow sensor

3.1.2. Modulation on return sensor

3.1.3. Modulation on system sensor

3.2. Thermotats

3.2.1. On/off room thermostat

3.2.2. OpenTherm control

3.2.3. 0÷10V control

3.2.4. Outdoor sensor

CHAPTER 4. COMMISSIONING …………...…….. 20

4.1. Supply connection

4.2. Mains switch

4.3. Burner situation

4.3.1. Burner is on

4.3.2. Burner is off

4.4. Water pressure

4.5. Gas / Air Ratio

4.6.1. Full load

4.6.2. Low load

4.7. Changing over to LPG (G30/G31)

4.7.1. Full load on LPG (G30)

4.7.2. Low load on LPG (G30)

4.7.3. Labelling

CHAPTER 5. BURNER DEMAND and MONITORING

……………………………………………………….... 23

5.1. Standby

5.2. Pre purge

5.3. Ignition

5.4. In operation

5.5. Post-purge

5.6. Pump after run

5.7. Lock-out

5.8. Frost protection

5.9. System pressure monitoring

5.10. Flue temperature sensor

5.11. Limiter

5.12. Glow plug protection

CHAPTER 6. PERIODICAL MAINTENANCE …….. 25

6.1. Check the CO2 percentage on full load

6.2. Check the heat input

6.3. Clean the condensation water drain

6.4. Check the ionisation current

6.5. Water pressure

6.6. Service mode

CHAPTER 7. MALFUNCTIONS …..………...…….. 26

7.1. Serial connection

7.2. No signal on the display

7.3. Boiler does not respond to heat demand

7.4. Fitting instructions for the pressure sensor

7.5. Fitting instructions for the safety valve

7.6. Malfunction code 'F' (flashing)

7.6.1. Gas control will not open (no voltage)

7.6.2. Gas control will not open (gas inlet pressure high)

7.6.3. Gas control will not open (coils defective)

7.6.4. Check function of gas control

7.6.5. Check glow plug (no ignition)

7.6.6. Check the fan impedance

7.6.7. Gas/air mixture is not correctly adjusted

7.6.8. Inspection ionisation probe

7.6.9. Temperature sensors

CE-Certificate ………………..……………………… 28

Coopra Advanced Heating Technologies Installation manual E40C

3

CHAPTER 1. GENERAL

Use of application

The appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

General safety regulations

The installation may only be performed by a recognised installer.

Take note that internal parts of the boiler can carry a dangerous electrical voltage (230 Volt).

Take note that the boiler, the various pipes and the flue gas exhausted by the boiler can reach high temperatures (up to

90°C).

Before carrying out maintenance activities in or on the boiler, you must close the gas tap, switch off the electricity supply

and pull the mains plug out of the socket

Environmental conditions

The area in which the boiler is installed must satisfy the applicable regulations.

The wall must be able to bear the weight of the boiler (loaded weight approx. 40 kg).

If you use a different assembly surface than a bricky wall of sufficient thickness, you must select suitable fixtures

yourself and properly install the boiler.

The boiler may not be fitted in a chemically aggressive environment.

The boiler with air feed and flue gas exhaust satisfies the requirements of protection class IP44 and may therefore be

installed in a wet area.

Although the boiler is fitted with an internal frost protection, it may not be exposed to extremely low ambient

temperatures (lower than -10°C).

Water quality

Fill the system with tap water. The composition and quality of the system water has a direct effect on the performance of

the total system and the life of the boiler. At own risk is the addition and use of chemicals, water softeners, oxygen

binders, de-aerators, aerators and water filters as they increase the chance of malfunctions. Generally, the build-up of

undesired deposits can lead to leakages with fatal damage. No warranty when corrosive elements of certain additives

have attacked the boiler.

Regulations applicable to hot water

Ask for the locally applicable regulations at the local water company as they are different in some areas.

Standards / Guidelines

With the installation of the boiler, all local regulations must be followed, where applicable, including the provisions of the

following standards and guidelines:

• Building Regulations

• Regulations for natural gas installations

• Regulations for LPG (if applicable)

• Guidelines for existing gas installations

• Safety requirements for heating installations

• Safety provisions for low voltage installations

• General regulations for drinking water installations

• Water authority regulations

• Ventilation in dwellings

• Supply of combustion air and exhaust

• House sewerage in homes and dwellings

• Fire Brigade regulations

• Factory Act regulations

Conditions of delivery

Coopra Advanced Heating Technologies b.v. supplies its products according to the general conditions of delivery for the

metal and electro technical industry. Registered with the Clerk of the District Court at Den Haag on 19 October 1998 under

no. 119/1998.

Coopra Advanced Heating Technologies Installation manual E40C

4

1.1. Display

Open the door of the casing for display operation.

On the Status display is the status indication shown.

On the 3 right segments, the Reading display, values of

the temperature, pressure, etc are shown.

Push-buttons from left to right: MIN, PLUS and Set/Reset

Left of the Status display is a LED informing the situation

of the boiler.

LED is ON = burner is ON

LED is OFF = burner is OFF

LED is FLASHING = boiler is in LOCK-OUT

Right of the Reading display is a LED, active for TWIN

boilers only.

1.2. PCB configuration

Parameter A=2 is for single boilers 15B; 15C; 37K; 37B;

37C and also 40C

Parameter A=1 is for TWIN boiler 80C; set as SLAVE

Parameter A=0 is for TWIN boiler 80C; set as MASTER

Parameter H is to set for correct type of application.

1.3. Operation indications

To protect the system from the result of failures and/or

excessive conditions, several protection functions are

implemented.

1.3.1. Normal state

The boiler is stand-by or heating. During heating the

burner may be switched off temporarily when the

regulated water temperature is above setpoint.

1.3.2. Blocking state

Blocking protection is used when a certain condition must

block the system during this condition, but when this

condition is not valid anymore, the system automatically

may run normal again.

A blocking state is indicated by a fixed letter or number

on the Status display.

Depending on the blocking state the Reading display is

used normal or can have extra information regarding the

blocking state.

The blocking state cannot be reset by the user. The

control automatically goes to normal state when the

conditions are normal again.

1.3.3. Lock-out state

Lock-out protection is used when a certain condition

must lock the system until the user resets the system.

These conditions are often more safety related then

blocking conditions.

A lockout state is indicated by a blinking letter or number

on the left display character position. Depending on the

lockout state, the right characters of the display are

empty or have extra information regarding the lockout

state.

The Alarm output is active, and the running LED on the

display left hand side blinks.

To reset the system after a lock-out, press and hold the

Set/Reset button for more than 1 second.

Some lock-out situations can only be removed by power

restoration.

Note:

With repeating failures in short period of time always let

your installer or maintenance man check and repair

unconditionally.

(-)

button

(+)

button Set/Reset

Status

Reading

Coopra Advanced Heating Technologies Installation manual E40C

5

Status Reading

1.3.1. Normal state (continuous code)

P

With initialisation and after restoration of supply power de-aeration programme runs for 2 minutes.

The boiler pump and 3-way valve (if applicable) switch several times, with the purpose to move

eventual air out of the boiler; burner off

0

Stand-by (no heat demand)

C

Heating heat demand, temperature above setpoint, burner off

C.

Heating heat demand, temperature below setpoint, burner on

J

Heating heat demand, 3 minutes anti-cycling time, burner off

c

Pump after run heating mode, burner off

d

DHW heat demand, temperature return sensor of Combi-boiler above setpoint, burner off

d.

DHW heat demand, temperature return sensor of Combi-boiler below setpoint, burner on

b

HWS heat demand, temperature external cylinder above setpoint, burner off

b.

HWS heat demand, temperature external cylinder below setpoint, burner on

o

Frost protection 8°C; burner off, pump on

o.

Frost protection 3°C; burner on, pump on

C

flashing

Chimney sweeper function (ionisation current on the right hand segments)

Status Reading

1.3.2. Blocking state (continuous code)

2

Return sensor temperature 5°C above flow sensor temperature, pump on, burner off

6

Combi boiler internal tank sensor not connected or open (parameter H=01)

6.

Combi boiler internal tank sensor shortcut fault (parameter H=01)

9

Flow or return sensor temperature > 95°C

A

Flue gas sensor temperature > 100°C

b/r

Hot water on right unit of TWIN boiler

E

No SLAVE connected / PCB is set as MASTER, (parameter A=0)

SLA/01

No MASTER connected / PCB is set as SLAVE, (parameter A=1)

P

Water pressure low or high, display shows ‘P’+ pressure

t

Outdoor sensor summer switch on, burner off, (parameter O/t)

Status Reading

1.3.3. Lock-out state (flashing code)

1

Max delta temperature, differential temperature between flow and return sensor limits 50°C

1

Boiler does not pass temperature test. After burner start the flow sensor must rise 3°C more in

temperature than return sensor within 20 seconds (after 3 start attempts follows lock-out)

2

Flame signal lost 3 times during operation

5

Fan speed error (fan speed deviates > 30% from the speed setpoint)

8

Flame signal detected with closed gas valve

9

Eeprom programmed (to reset press the Set/Reset button)

A

Flue gas temperature > 100°C for more then 3 times within 30 minutes

E

Internal regulation fault / A/D conversion fault (depending type of error display shows ‘E’ or “EEE”)

E t1

Flow sensor open or shortcut fault

E t2

Return sensor open or shortcut fault

E t3

Flue gas sensor open or shortcut fault

F

Too many (4 times) consecutive start attempts

H

Flow or return sensor temperature > 105°C

O

Safety limiter contact is open (no limiter on this boiler, contacts bridged)

Coopra Advanced Heating Technologies Installation manual E40C

6

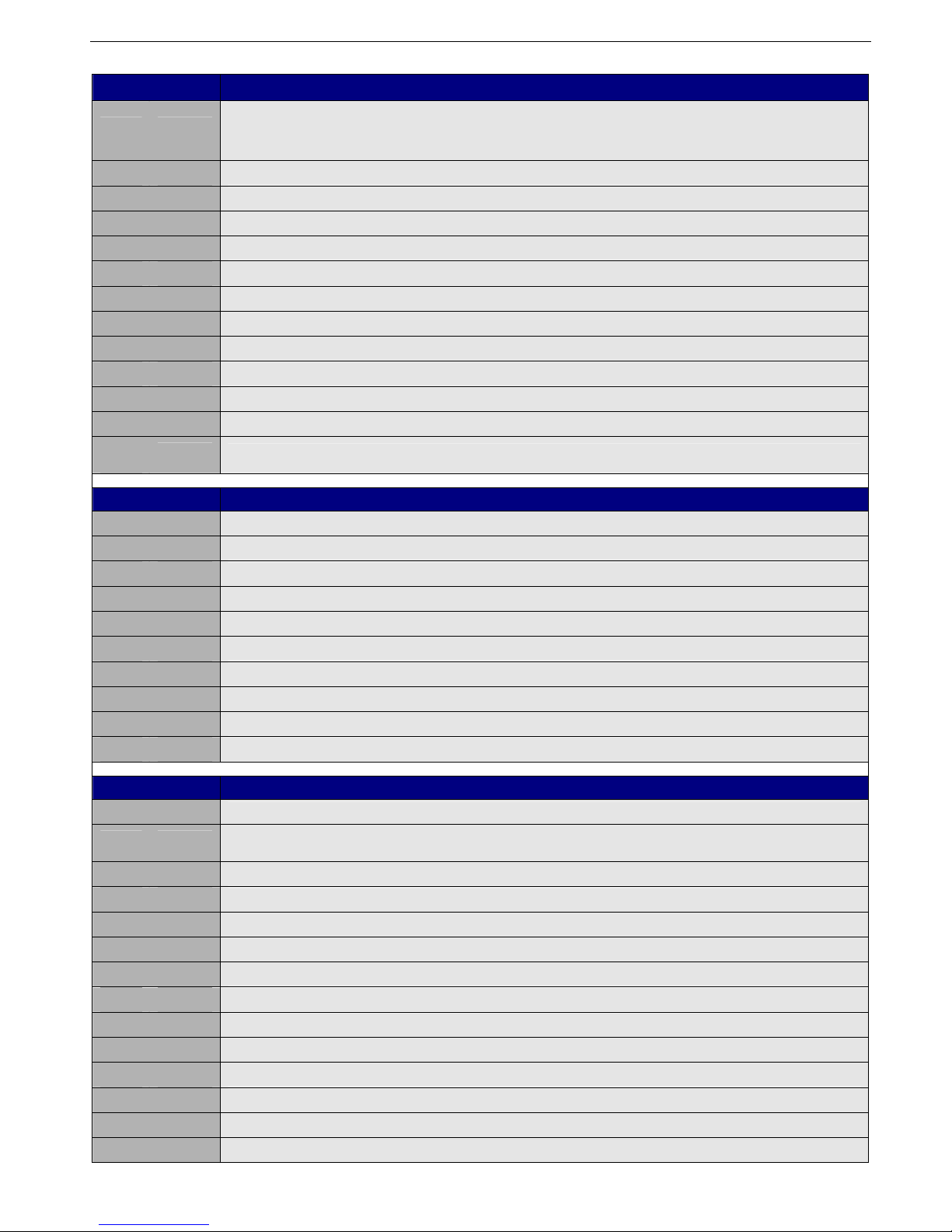

1.4. Menu structure

To enter the menu structure press and hold the Set/Reset button for longer than 10 seconds. The menu mode opens

with the password mode h=10. To unlock menu structure make h=18, use the (+) and (-) buttons. To go to the first

parameter press the Set/Reset button.

To change the parameter value, use the (+) and (-) buttons. To go to the next parameter press the Set/Reset button.

To save altered parameter settings, walk through the complete menu with the Set/Reset button until normal status

indication appears.

Timeout: When inside the menu structure the keys are untouched for 3 minutes, the system will switch back to the

normal status indication. Settings are not saved.

Menu structure

Status

parameter

Description Range

Factory

setting

h

Password protected

To unlock menu structure make h=18

10 - 99 h=10

C Heating max. flow temperature 25 - 90°C 82°C

C/r Modulation option

0 = Regulation on flow sensor (default)

1 = Regulation on return sensor or regulation on

system sensor

0

O Heating pump after run 1 - 25 min; CO=24uur 5 min

P Heating max input 45 - 100 % (fan 1800 – 5400 rpm) 100 %

A Boiler application

2=Standalone (for single boiler)

1=Slave (for TWIN right hand PCB)

0=Master (for TWIN left hand PCB)

2

H Type of application

00 = Adjustment for heating only

01 = Combi-boiler (with internal DHW tank)

02 = HWS storage cylinder 12kOhm (use for large

volume cylinders)

03 = HWS storage cylinder 10kOhm (use for large

volume cylinders)

04 = HWS storage cylinder 12kOhm (use for small

volume cylinders)

01

d (1) Setpoint temperature (Combi boiler) 40°C - 65°C 60°C

t (1) Hold temperature internal tank 40°C - 65°C 40°C

b (2) Setpoint temperature storage cylinder 25°C - 70°C 60°C

O/b (3) Basic temperature 10 - 90°C 40°C

O/S (3) Slope 01 - 99 20

O/d (3) Day reference temperature 10 - 90°C 40°C

O/t (3) Outdoor summer switch temperature 1 - 50°C 40°C

r

Return to “Factory setting”

Press (+) button for at least 5 seconds

Note: some settings do not return

= factory setting

= customised setting

u Configuration 0÷10V input

0 = Regulation on temperature

1 = Regulation on boiler output

0

o (4) Configuration of TWIN

01 = power mode (input 14,6 kW – 74,0 kW)

00 = comfort mode (input 7,3 kW – 74,0 kW)

01

F (2) Storage cylinder max flow temperature 65 - 90°C 85°C

S

Configuration pump

(2-stage pump regulation)

00 = automatic

= pump always high

= pump always low

00

Notes: (1) Active when H=1; (2) Active when H=2 or H=3 or H=4; (3) Active with outdoor sensor; (4) TWIN only

Coopra Advanced Heating Technologies Installation manual E40C

7

1.4.1. View mode

At the end of the menu structure, the view mode is shown.

The view mode is a reading only entry; no parameters can be changed in here.

The view mode is to enter directly.

Press the (+) button for at least 10 seconds. First upcoming is the water pressure P / u; in the Reading display on the

right hand segments is the actual water pressure in bar.

Press the Set/Reset button to next parameter.

To switch out of the view mode press the (-) button shortly or after timeout.

When the keys are untouched for 3 minutes, the system will switch out of the view mode automatically.

View mode

Single boiler

Status Description

P / u Actual water pressure left hand unit (in bar)

ﬤ / u

Setpoint temperature on flow sensor (in °C) (parameter C/r = 0)

Setpoint temperature on return or system sensor (in °C) (parameter C/r = 1)

1 / u Actual flow sensor temperature (in °C)

2 / u Actual return sensor temperature (in °C)

3 / u 0÷10V control (in Volt)

4 / u Outdoor sensor temperature (in °C)

5 / u Combi-boiler internal tank or external storage cylinder temperature (in °C)

6 / u Flue gas sensor temperature (in °C)

7 / u Flame signal (in µA DC)

9 / u Last lock-out

A / u Last blocking

d / u Actual system sensor temperature (in °C) (parameter C/r=1)

Coopra Advanced Heating Technologies Installation manual E40C

8

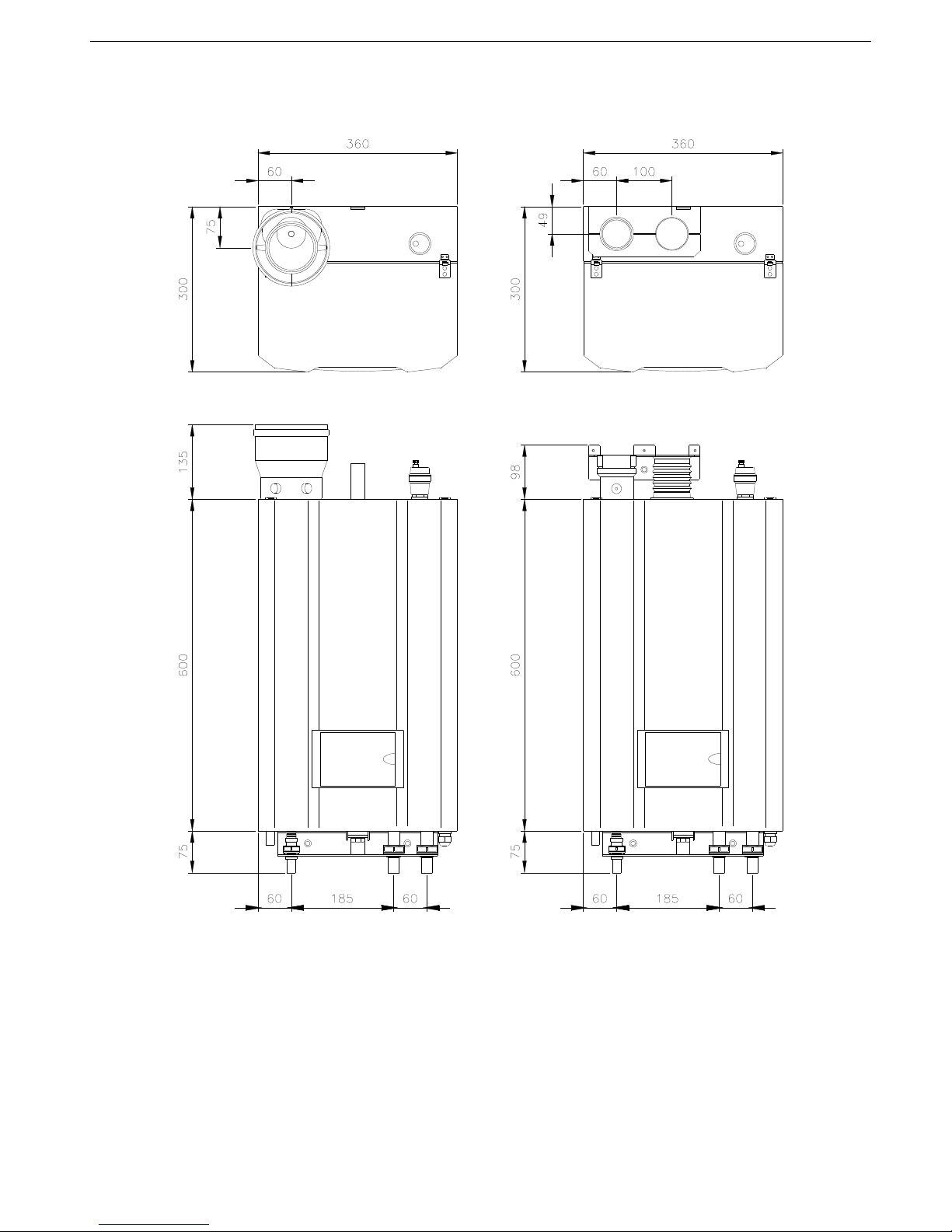

1.5. Dimensional sketch

Dimensions in mm

Free Space

There must be sufficient space at the top and bottom to be able to suspend the unit and to be able to connect all feed

and drain pipes. Normally, roughly 300 mm is required.

It is recommended to leave a free space of 150 mm on the left (for servicing reasons) and 50 mm on the right of the unit.

The front of the unit must be easily accessible for servicing at all times.

Coopra Advanced Heating Technologies Installation manual E40C

9

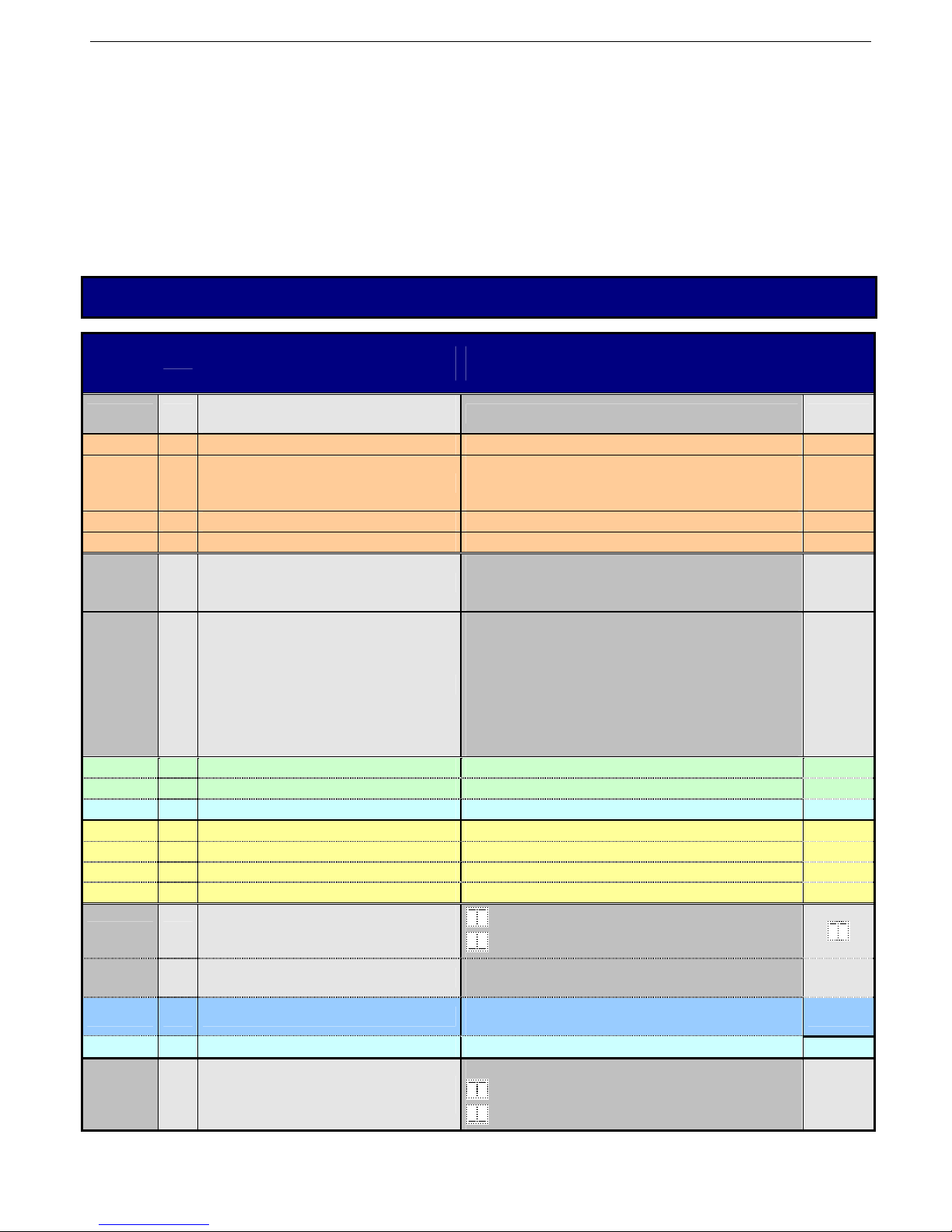

1.5.1. Technical data

Boiler type

35C

power reduced boiler to meet Italian market

Gas type

natural gas G20 natural gas G25 LPG G30/G31

Nominal gas pressure 20 mbar 25 mbar 37/50 mbar

Heat input CH (gross) 8.1 – 38.5 kW

Heat input CH (net) 7.3 – 34.7 kW

Nominal output CH at 80/60ºC 7.2 – 33.7 kW

Nominal output CH at 50/30ºC 7.9 – 36.1 kW

Efficiency at 80/60ºC (net) Low load = 98.7 %; High load = 97.2 %

Gas technical

data

Efficiency at 50/30ºC (net) Low load = 108.3 %; High load = 104.1 %

Boiler type 40C

Gas type

natural gas G20 natural gas G25 LPG G30/G31

Mains voltage / Frequency 230 V / 50 Hz

Power consumption (max.) 144 W

Electrical data

Automatic recognition of thermostat

connection

(potential free contact)

on/off thermostat or

OpenTherm control

Height 700 mm

Width 360 mm

Depth 300 mm

Dimensions

and weight

Weight 35 kg

Heat input CH (gross) 8.1 – 41.1 kW

Heat input CH (net) 7.3 – 37.0 kW

Nominal output CH at 80/60ºC 7.2 – 36.0 kW

Nominal output CH at 50/30ºC 7.9 – 37.9 kW

Efficiency at 80/60ºC (net) Low load = 98.7 %; High load = 97.2 %

Gas technical

data

Efficiency at 50/30ºC (net) Low load = 108.4 %; High load = 104.2 %

CO2 on low-high fire 8.2% - 8.8% 8.2% - 8.8% 9.2% - 9.8%

CO (0% 02) on low-high fire 12 – 100 ppm

Emission value

NOX (0% O2) on low-high fire 10 – 30 ppm

at 80/60ºC < 70ºC

Flue gastemperature

at 50/30ºC < 35ºC

Maximum

chimney

resistance

Air feed and flue tube together

85 Pa

Gas Ø 15 mm

CH (flow and return) Ø 20 mm

Connections

Overflow Ø 15 mm

2-pipe system Ø 60 – Ø 60 mm or Ø 80 – Ø 80 mm

Air feed and

flue tube

system

Concentric system Ø 60 / 100 mm or Ø 80 / 125 mm

Water contents 0,8 L

Max. temperature 90°C

Boiler primary

heat

exchanger

Max. Water pressure 3 bar

Pump high 40 dB(A)

Sound level

Pump low 30 dB(A)

Certification

CE Identification number CE0063-AT3070

Coopra Advanced Heating Technologies Installation manual E40C

10

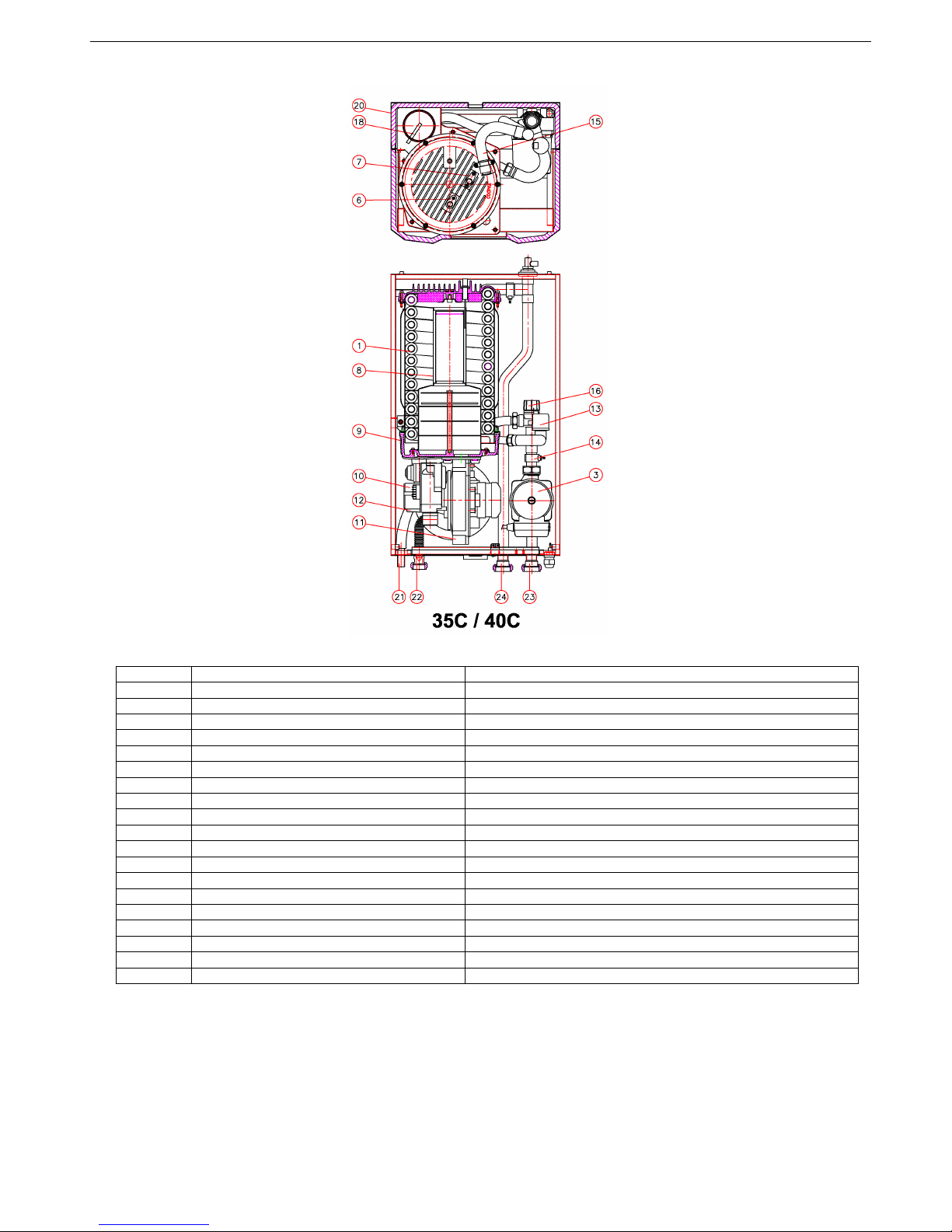

1.5.2. Boiler components

No Description

1 Primary heat exchanger

3 Pump

6 Glow plug

7 Ionisation probe

8 Burner type 30/40

9 Vapour tray

10 Gas valve

11 Fan

12 Venturi type 40

13 Water pressure sensor

14 Return sensor

15 Flow sensor

16 Safety device

18 Flue gas sensor

20 Type plate

21 Condensation water overflow

22 Gas connection

23 Central heating return connection

24 Central heating flow connection

Loading...

Loading...