Page 1

Page 2

Safety Recommendations

For your safety and the safety of others, read and understand

the safety recommendations and operating instructions before

operating an Airetrol.

For additional information on eye and face protection, refer to

Federal OSHA Regulations, 29 Code of Federal Regulations,

Section 1910.133., Eye and Face Protection, and the American

National Standards Institute, ANSI A87.1, Occupational and

Educational Eye and Face Protection. Z87.1 is available from

the American National Standards Institute, Inc., 1430 Broadway,

New York, NY 10018.

Hearing protectors are required in high noise areas, 85 dBA or

greater. The operation of other tools and equipment in the area,

reflective surfaces, process noises and resonant structures can

substantially contribute to, and increase the noise level in an

area. For additional information on hearing protection, refer to

Federal OSHA Regulations, 29 Code of Federal Regulations,

Section 1910.95, Occupational Noise Exposure, and American

National Standards Institute, ANSI S12.6 Hearing Protectors.

When using right angle Airetrols, be sure the throttle is positioned relative to the angle head so that the throttle will not become wedged against an adjacent object in the “ON” position

due to torque reaction. The angle head may be repositioned with

respect to the lever to accomodate proper location for the task. If

tool is to be reversed, locate throttle lever in a neutral position

that will prevent entrapment. Refer to operating instructions for

additional information.

Tools with clutches can stall rather than shut-off if adjusted

over the maximum power output of the tool, or if there is a drop

in air pressure. Operator must then resist the stall torque until

the throttle is released.

Higher torque right angle Airetrols can be equipped with spline

torque reaction mounting plates which accept torque reaction

bars. These bars can be braced against the work or other suitable points to absorb and relieve the operator of the torque reaction transmitted by the tool. Tool balance arms are also available to absorb the torque reaction of the tool while balancing the

weight of the tool for improved ergonomic applications.

Some individuals are susceptible to disorders of the hands and

arms when exposed to tasks which involve highly repetitive motions and/or vibration. Those individuals predisposed to

vasculatory or circulatory problems may be particularly susceptible. Cumulative trauma disorders such as carpal tunnel syn-

Airetool Airetrols are designed to operate on 90 psig (6.2 bar)

maximum air pressure. If the tool is properly sized and applied,

higher air pressure is unnecessary. Excessive air pressure increases the load and stresses on the tool parts, which may

result in cage, mandrel or roll breakage. Installation of a filterregulator-lubricator in the air supply line ahead of the tool is recommended.

Before the tool is connected to the air supply, check the throttle

for proper operation (i.e., throttle moves freely and returns to the

closed position). Clear the air hose of accumulated dust and

moisture. Be careful not to endanger adjacent personnel. Before removing a tool from service or changing sockets, make

sure the air line is shut off and drained of air. This will prevent

the tool from operating if the throttle is accidently engaged.

It is essential for the safe operation that the operator of an Airetrol use good balance, sure footing, and proper posture in anticipation of the torque reaction. Insure that the operator’s hand will

not be wedged or pinched between the work and the tool when

operating.

drome and tendonitis can be caused or aggravated by repetitious, forceful exertions of the hands and arms. These disorders

develop gradually over periods of weeks, months and years.

2

Page 3

Safety Recommendations

* T asks should be performed in such manner that the wrists

are maintained in a neutral position, which is not flexed,

hyperextended, or turned side to side.

* Stressful postures should be avoided and can be controlled

through tool selection and work location.

ADDITIONAL SAFETY RECOMMENDATIONS FOR USE

OF RIGHT ANGLE AIRETROLS

Any user suffering from prolonged symptoms of tingling, numbness, blanching of fingers, clumsiness or weakened grip, nocturnal pain in the hand, or any other disorder of the shoulders,

arms, wrists, or fingers is advised to consult with a physician. If

it is determined that the symptoms are job related or aggravated

by movements and postures indicated by the job design it may

be necessary for the employer to take steps to prevent further

occurrences. These steps might included, but are not limited to,

repositioning the work piece or redesigning the workstation, reassigning workers to the jobs, rotating jobs, altering work pace,

and/or changing the type of tool used so as to minimize stress

on the operator. Some tasks may require more than one type of

tool to obtain the optimum operator/tool/task relationship.

The following recommendations will help reduce or moderate

the effects of repetitive work motions and/or extended vibration

exposure:

* Use a minimum hand grip force consistent with proper control

and safe operation.

* Keep wrists as straight as possible.

* Keep body and hands warm and dry.

* Avoid anything that inhibits blood circulation.

Follow good machine shop practices. Rotating shafts and components can entangle and enwrap, and can result in serious injures. Never wear long hair, loose-fitting clothes, gloves, ties, or

jewelry when work

exposed rotating shaft.

Drilling or other use of this tool may produce hazardous fumes,

particles, and/or dust. To avoid adverse health effects utilize

adequate ventilation and/or a respirator. Read the material safety

data sheet of any cutting fluids or materials involved in the drilling process.

* Drill bits are sharp, handle them carefully to avoid injury. The

cutting tool maximum speed rating must equal or exceed the

rated speed of the tool.

ing with or near a drill or any machine with

- Smoking Tobacco

- Cold Temperatures

- Certain Drugs

* Avoid highly repetitive movements of hands and wrists, and

continuous vibration exposure.

* Attach the mandrel and the chuck securely to the Airetrol to

prevent tool from jumping off work.

* Use precautions when drilling because of the possibility of the

cutting tool bending or breaking.

* High reaction torque may be experienced by the operator when

reversing tool to remove the expander.

* Drill bits or accessories not centered properly in the chuck can

cause excessive wobble or vibration.

3

Page 4

Operating & Service Instructions

CC-325-HP High Pressure Water Flush

Condenser Cleaner Motor

SPECIFICATIONS

Recommended Air Pressure - 90/100 psi.

Air Volume Required - 200 cfm.

Minimum Hose Size - 1” I. D.

Air Line Lubricator - 15/20 Drops Per Minute (10W Oil)

Maximum Flushing Pressure - 5000 psi (water/scavenging

Agent)

Approximate Peak Power - 6 hp.

MODEL # CC-325-HP

Weight 42 lbs.

Free Speed 800 rpm

Torque Capacity 63 ft-lbs.

OPERATING INSTRUCTIONS

AIR SUPPLY

To use the CC-325-HP cleaner, it is necessary to use a

compressor with a capacity to supply a sustained air pressure of 90 psi at 200 cfm. It is therefore necessary to use a

air supply hose with a 1” I. D. in order to be sure in having

an adequate volume to the tool. It should also be noted

that long hose runs, air hose quick connects, fittings, etc.

can cause large pressure drops between the tool and the

compressor and that is many cases, poor tool performance

can be improved by minimizing these conditions and/or increasing the air line size (ID).

LUBRICATION

It is essential that an automatic (mist type) in-line filter/lubricator be used and properly maintained to achieve maximum operating efficiency and motor life with these tools.

Lubricator should be set to deliver 15 to 20 drops of oil per

minute injected into the air line to assure that proper lubrication is going to the motor. Application of the tool should

govern how frequently it is greased. It is recommended

that the drive shaft cavity be filled periodically through the

Zerk fitting (51) on the side of the tool and that the gear

cavity be kept about half filled through the Zerk fitting in the

front cover. Use a good quality, extreme-pressure gear

grease. If the tool is to be run for extended periods without

using water or other scavenging agent, The packing gland

nut can be temporarily loosened or the packing removed

to avoid damage to the packing. The packing should be

kept well lubricated.

FLUSHING AGENT

The model CC-325-HP condenser cleaner motor coupling

as installed upon this machine is designed to operate with

(6000 psi) pressure water or scavenging agent to assist

the mechanical cleaning action of the drill bits in condenser

tubing and similar applications. The water supply hose and

couplings, NOT SUPPLIED WITH THE TOOL, should only

be of a recommended type to withstand this amount of pressure. Lower pressure may also be used with this supply

hose. The CC-325-HP uses standard Airetool condenser

cleaner shafting and couplings but requires the use of the

Airetool Model “ HP” condenser cleaner drills for best results. SEE PAGE 13 FOR SELECTION. If the tool is to be

run for extended periods without using water or other scavenging agent, The packing gland nut can be temporarily

loosened or the packing removed to avoid damage to the

packing. The packing should be kept well lubricated.

USING THE CC-325-HP CONDENSER

CLEANER

The CC-325-HP condenser cleaner can be used with lower

pressure on the scavenging agent satisfactorily, however,

maximum cleaning is done with pressure at 5000 psi. When

connecting the water connections and the shafting to the

cleaner, CAUTION should be taken to make sure that all

joints are tightened properly to prevent the possibility of

leakage of the high pressure. It is recommended that the

water be shut off when the drill bit is not inside the tube to

prevent the possibility of contacting someone with the high

pressure water spray. Therefore, it is recommended that

first the bit be placed in a tube, the water flush be turned on

and then the motor be started to drill each individual tube.

It should also be stated that the cleaner should not be run

for extended periods of time without the scavenging fluid

going through the coupling due to the close fit of the coupling. It will overheat if no fluid is present to help cool the

parts. Periodically, the thrust bearing No. 16 as shown on

the parts list page 7, should be checked to see that there is

proper lubrication on this bearing.

4

Page 5

Operating & Service Instructions - continued

- c o n t i n u e d -

STORAGE

Before storage of the tool, blow all water out of the tool and

blow in a generous amount of 10W machine oil to deter

corrosion.

CAUTION: Before operating these tools, always make

sure that the handles (41) are threaded fully and securely into the motor case and that the operator is fully

prepared to safely absorb the full stall torque of the

tool in the event that the drill hangs up during operation.

SERVICE INSTRUCTIONS

SERVICING THE HIGH PRESSURE COUPLING

If after some usage, it is found that the high pressure coupling begins to leak excessively, it may be necessary to

replace the “O” rings and back-up rings on the seal support. By removing the coupling retainer No. 22, it will be

possible to grasp part No. 23 and by slightly twisting back

and forth, pull the seal support from the shaft. It is suggested that anytime the support is removed for servicing,

that new “O” ring and back-up rings be installed on the seal

support. The back-up ring is installed in the groove first

with the radius portion of the back-up ring facing the small

end of the support. Install in the same groove beside the

back-up ring, one of the “O” rings as furnished. These “O”

rings are of special durometer hardness to stand the 5000

psi pressure. Standard “O” rings and back-up rings should

never be used as they will as they will have a tendency to

extrude from the groove and deteriorate very rapidly. After

installation of the back-up ring and“O” ring in each groove,

three in number, liberally lubricate the seal support and

“O” rings with grease and placing in the shaft and rocking

the seal support back and forth, push the support into the

shaft. Push on the support until it touches the bronze bearing. Reinstall the coupling retainer No. 22 and tighten securely. This will normally repair the coupling and stop the

leakage.

REPLACING THE DRIVE SHAFT

If after considerable usage, it is found necessary to replace

the drive shaft because of wear to the seal area, remove

the socket head cap screws No. 8 that hold the case cover

in place. This will allow removal of the case cover at this

point. With the proper size Allen wrench, reach down

through the thrust nut No. 14, in one of the elongated slots

and loosen the two set screws that are in the thrust nut.

Rotate the shaft until the set screws appear. After loosening the set screws, use a wrench and rotate the spindle in

a counterclockwise rotation which will unthread the thrust

nut from the shaft. Once the thrust nut has been unthreaded,

it will be possible then to remove the shaft from the machine. At this point it is advantageous to remove the thrust

nut No. 14, which will allow servicing of the thrust bearing

and allow inspection of this part to make sure that the thrust

bearing is in good condition before replacement in the

machine. Also, at this point, the bronze bearing No. 21 can

be inspected to make sure that it is not worn to allow excess wobble of the shaft in this area. To install the new

shaft, it will be necessary to press the old shaft from the

gear by resting the gear on the inner diameter and pushing

the large threaded end of the shaft. This will allow the spindle

to be pressed from the gear in this direction. Install the

drive key in the new shaft and replace the large drive gear

on the new shaft by pressing it until the diameter of the

shaft is flush with the back of the large gear. At this point, it

would be advantageous to run the shaft between centers

to make sure that the gear has been pressed on square to

prevent problems in operation of the machine after assembly. If it is found that the gear does not run true, the gear

should be realigned by pressing on the proper spot for

seating the gear squarely on the shaft. If other bearings or

seals are excessively worn, they should be replaced in this

area before reinstalling the shaft. To reinstall the shaft, feed

the shaft down through the housing until the small diameter of the shaft protrudes from the front portion of the case.

At this point, place on the shaft the thrust nut along with the

thrust bearing washers, thrust bearing and adjusting nut.

The shaft can then be pushed father into the motor to allow

the shaft to start entering into the rear bronze bearing. As

soon as this is done, the thrust nut No. 14 should be tightened into position and again placing an Allen wrench down

through one of the crescent shaped holes in the side of the

thrust nut, the adjusting nut can be screwed on the shaft.

Continue to thread the adjusting nut on the shaft while the

shaft is being rotated and also being pushed rearward as

this operation is being performed. As soon as possible, the

front gear cover should be reinstalled and the cap screws

tightened. By continuing rotating the shaft, adjust the thrust

adjusting nut until a slight resistance is felt on the Allen

wrench when the shaft is rotated. At this point, turn the

shaft and wrench together until it touches the right-hand

side of the crescent shaped opening until the wrench

reaches the end. Then rotate the nut back the entire length

of the opening and at this point, tighten the set screw. Ro-

5

Page 6

Operating & Service Instructions

- c o n t i n u e d -

tate the shaft 180 degrees and tighten the other set screw.

This adjustment should be adequate to allow the bearing

to absorb the hydraulic thrust from the high pressure but

should not induce preloading on the bearing during assembly. With the seal support installed, the shaft should rotate

freely without binding.

SERVICING THE AIR MOTOR

To service the air motor assembly, remove the large cap

screws in back of the motor coupling and remove the coupling No. 27. This will allow the entire motor to be removed

from the tool for servicing. Upon replacement of worn parts,

the motor can be reassembled and slid back into the motor

case. Rotor blades should always be replaced when

the motor is serviced. Reinstall the coupling and the large

cap screws and the motor should be ready for operation. It

is important when servicing the motor and gear package,

that lubrication be used on all bearing surfaces and the

gear case should be packed with a semi-solid grease. The

unit should be ready for operation upon the completion of

the above mentioned service.

SERVICING THE THROTTLE VALVE

To service the throttle valve, unscrew the valve retainer

(320 and remove the valve (29), valve spring (42). washer

(30), gasket (31) and valve seat (28). Take care to avoid

damaging the valve seat. Clean and inspect all parts

and replace if worn or damaged.

REASSEMBLY

bly. Gears, bearings and grease retainers should be packed

with grease. Essentially, reassembly of all the various subassemblies should be in the reverse order of disassembly,

with particular attention paid to the following points.

1. When assembling the motor, the cylinder pins must go

into the proper holes in the thrust plates and the motor assembly must be inserted into the case oriented such that

the front cylinder pin goes into the proper hole in the motor

case.

2. If replacing the drive shaft (3) or the drive gear (39) is

required, the gear should be supported on its inner flange

and care be taken to avoid damage to the key when pressing the drive shaft into the drive gear. It is recommended

that the assembly be checked between centers and trued

up if required before assembly into the tool.

3. Care should be taken when pushing the shaft through

the grease retainer (13) and while installing the front cap

(36) with grease retainer (34) over the drive shaft to avoid

damaging the seals.

4. The valve retainer (32) is dimpled for its retaining set

screw (48). The set screw should be secured in place with

Loctite 242 or equivalent.

5. The valve nut (49) should be adjusted so that there is

still a small amount of play in the valve lever (48) to insure

that the valve (29) seals off when the lever is released.

Secure the nut in position with a 1/16” x 1” cotter pin (50).

All parts should be cleaned and lubricated before reassem-

6

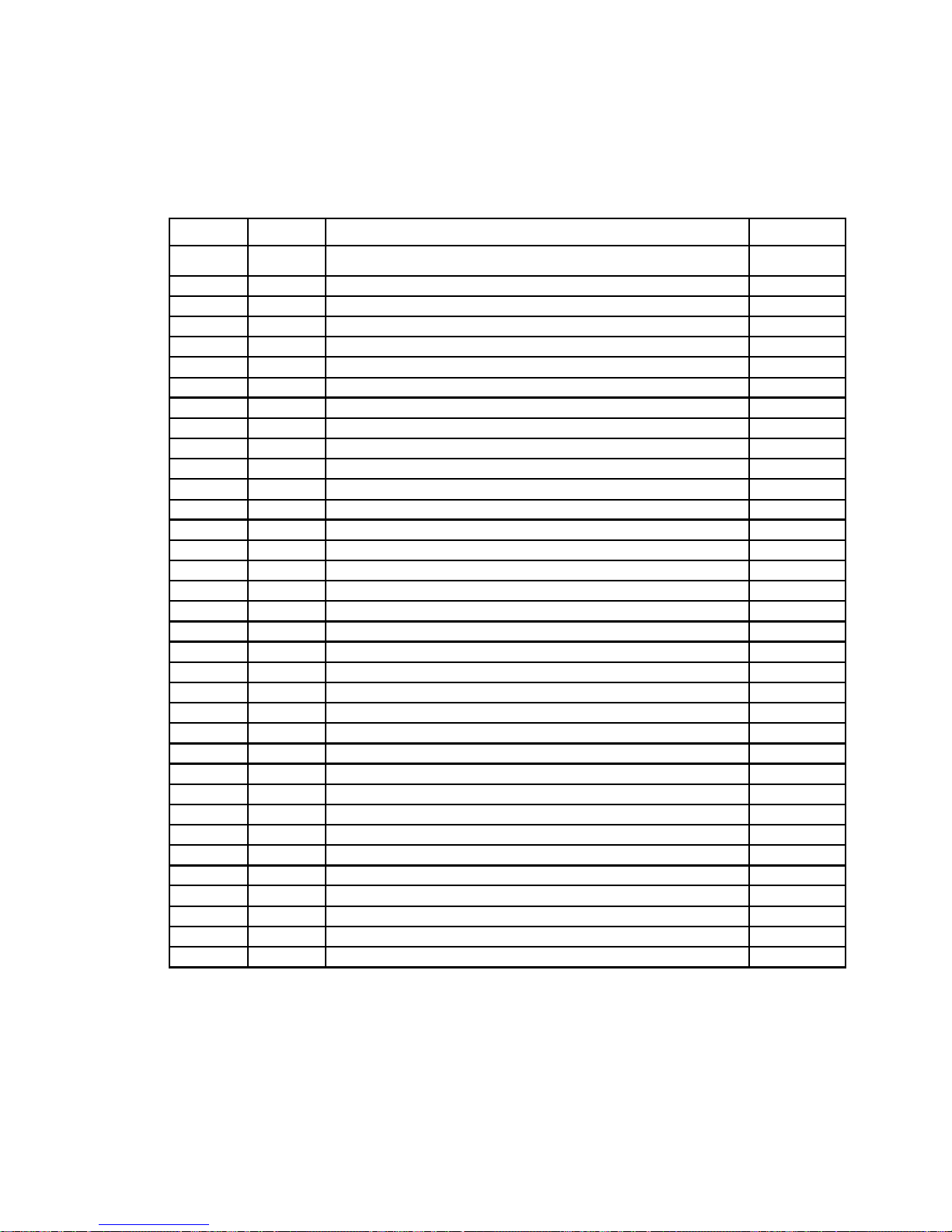

Page 7

Parts List For

Model CC-325-HP Condenser Cleaner Motor

With High Pressure Water Flush

ITEM # PART # DESCRIPTION QUANTITY

1 8010619 CD-11 Cap 1 1/4" 1

2 1715657 CC32519-HP Gasket 1

3 1715320 CC-32511-HP Drive Shaft 1

4 1235700 CC-35027-1 Bearing 1

5 1234500 CC-32501-A-1 Cover 1

6 8010024 3/8" Medium Lock Washer 15

7 1228900 CC-121 Bearing 1

8 8010075 3/8"-16 x 3/4" Socket Head Cap Screw 6

9 1228800 CC-120 Bearing 1

10 1228100 CC-112 Bearing 1

11 8010001 Hex Nut 1

12 1228700 CC-119 Support Ring 1

13 1238300 CC-37538 Retainer 1

14 1715340 CC-32513-HP Thrust Nut 1

15 3229500 1000-66 Washer 2

16 3229400 1000-65 Bearing 1

17 8000800 10-32 x 1/4" Socket Set Screw 2

18 1715360 CC-32515-HP Thrust Adjusting Nut 1

19 3167600 500-31 "O" Ring 3

20 1715390 CC-32518-HP Back Up Ring 3

21 1715330 CC-32512-HP Bearing 1

22 1715370 CC-32516-HP Coupling Retainer 1

23 1715350 CC-32514-HP Seal Support 1

24 1236200 CC-37503 Rear Head 1

25 1147500 33009 Bearing 1

26 1030700 713 Rear Head Cap 1

27 1236300 CC-37504 Coupling 1

28 1237600 CC-37530 Valve Seat 1

29 1237200 CC-37526 Valve 1

30 1237500 CC-37529 Washer 1

31 1237400 CC-37528 Gasket 1

32 1236900 CC-37523 Valve Retainer 1

33 1238200 CC-37537 Valve Cover 1

34 1235500 CC-35017 Retainer 1

35 8010023 1/4"-20 x 3/4" Socket Head Cap Screw 1

NOTE: See Parts List Drawing on Page 9.

7

Page 8

Parts List For

Model CC-325-HP Condenser Cleaner Motor

With High Pressure Water Flush

ITEM # PART # DESCRIPTION QUANTITY

36 1236100 CC-37501-B-1 Front Cap 1

37 1237900 CC-37533 Front Cap Gasket 1

38 1234700 CC-32532 Case Cover Gasket 1

39 1234600 CC-32510 Drive Gear 1

40 1236400 CC-37508 Bearing 1

41 1235100 CC-35007-F Thrust Plate 1

42 1234800 CC-35002 Cylinder 1

43 1234900 CC-35005 Rotor 1

44 1181100 63506-F Blade 5

45 1234400 CC-32501-1 Case 1

46 1238000 CC-37534 Gasket 1

47 1238100 CC-37536 Spring 1

48 1237000 CC-37524 Valve Lever 1

49 1237300 CC-37527 Valve Nut 1

50 8005600 1/16" x 1" Cotter Pin 1

NS 3241600 1100-100 Wrench 1" 1

NS 1228600 CC-118 Handle 2

NS 1236600 CC-37520 Pivot Screw 1

NS 1715661 Socket Head Cap Screw 9

NS 2996558 MU-100 Muffler 1

NS 2996559 1 1/4" x 1" Pipe Reducer 1

NS 1716357 5000 - 1 1/8" Zerk Fitting 2

NS 8010318 #2 x 1/8" Drive Screw 4

NS 8566880 1650-CT-P Caution Tag 1

NOTE: See Parts Drawing on Page 9.

8

Page 9

Parts Drawing For

Model CC-325-HP Condenser Cleaner Motor

With High Pressure Water Flush

9

Page 10

DRIVE DRIVE

COUPLING COUPLING

SHAFT for for

TUBE I.D. DIAMETER DRIVE DRIVEN SHAFT CC-475 DRIVE CC-325-1 DRIVE

Inch.

(mm) (mm) SHAFT THREAD SHAFT THREAD COUPLING THREAD & WF -100 THRE AD CC-3 75-1 THREAD

.291"-.358" 1/4" 1/4" NFM 10-32 F 5/8" NFF

7.39-9.09 mm 6. 35 mm CC-336 X CC-335 X CC-334 10-32 M AT-337-A X NA NA

.359"-.420" 5/16" 5/16" NFM 1/4" NFF 5/8" NFF 1" NF

9.09-10.67mm 7.94 mm CC-332 X CC-33 1 X CC-330 1/4" NFM AT -333-A X AT-333 X

.421"-.483" 3/8" 3/8" NFM 1/4" NFF 5/8" NFF 1" NF

10.67-12.27 mm 9.52 mm CC-324 X CC-323 X CC-322 1/4" NFM AT-321-A X AT-352 X

.484"-.608" 7/16" 7/16" NFM 5/16" NFF 5/8" NFF 1" NF

12.27-15.44 mm 11.11 mm CC-316 X CC-315 X CC-314 5/16" NFM AT-313-A X AT-353 X

.609"-.737" 1/2" 1/2" NFM 3/8" NFF 5/8" NFF 1" NF

15.44-18.72 mm 12.7 mm CC-312 X CC-311 X CC-310 3/8" NFM AT-309-A X AT-359 X

.738"-.831" 9/16" 9/16" NFM 3/8" NFF 5/8" NFF 1" NF

18.72-21.11 mm 14.29 mm CC-308 X CC-307 X CC-306 3/8" NFM AT-305-A X AT-355 X

.832"-1.055" 5/8" 5/8" NFM 3/8" NFF 5/8" NFF 1" NF

21.11-26.80 mm 15.88 mm CC-304 X CC-303 X CC-302 3/8" NFM AT-301-A X AT-351 X

1.056"-1.561 3/4" 3/4" NFM 7/16" NFF 5/8" NFF 1" NF

26.80-39.65 mm 19.05 mm CC-320 X CC-319 X CC-318 7/16" NFM AT-317-A X AT-357 X

1/650"-2 .374" 1" 1" NFM 7/16" NFF 5/8" NFF 1" NF

39.65-60.30 mm 25.40 mm CC-328 X CC-327 X CC-326 7/16" NFM AT-325-A X AT-354 X

Inch.

DRIVE SHAFT DRIVEN SHAFT SHAFT COUPLING CC-475-PS COUPLING CC-325-HP COUPLING

10-32 F 10-3 2 F 1/4" NFF

1/4" NFF 1/4" NFF 5/16" NFF 5/16" NF

1/4" NFF 1/4" NFF 3/8" NFF 3/8" NF

5/16" NFF 5/1 6" NFF 7/16" NFF 7/16" NF

3/8" NFF 3/8" NFF 1/2" NFF 1/2" NF

3/8" NFF 3/8" NFF 9/16" NFF 9/16" NF

3/8" NFF 3/8" NFF 5/8" NFF 5/8" NF

7/16" NFF 7/16" NFF 3/4" NFF 3/4" NF

7/16" NFF 7/16" NFF 1" NFF 1" NF

10

Page 11

"AT" "CB" "CT" "TW" "B"

f

TUBE

I. .D

DIAMETER o

DRILL or BRUSH

STUD Straight Straight Twist Twist Wire

Tool Steel Carbide Carbide Tool Steel Steel

inch mm inch mm THREAD DRILL # DRILL # DRILL # DRILL # BRUSH #

.291-.306

.307-.321

.322-.337

.338-.353

.359-.389

.390-.420

.421-.452

.453-.483

.484-.514

.515-.545

.546-.577

.578-.608

.578-.608

.609-.639

.640-.675

.676-.706

.707-.737

.738-.769

.770-.800

.801-.831

.832-.862

.863-.894

.895-.925

.926-.956

.957-.987

.988-1.024

1.025-1.055

1.056-1.086

1.087-1.117

1.118-1.149

1.150-1.180

1.181-1.211

1.212-1.242

1.243-1.280

1.281-1.311

7.39-7.77

7.77-8.15

8.18-8.56

8.59-8.97

9.12-9.88

9.91-10.67

10.69-11.48

11.48-12.27

12.29-13.06

13.08-13.84

13.87-14.66

14.68-15.44

14.68-15.44

15.47-16.23

16.26-17.15

17.17-17.93

17.96-18.72

18.75-19.53

19.56-20.32

20.35-21.11

21.13-21.89

21.92-22.71

22.73-23.50

23.52-24.28

24.31-25.07

25.35-26.01

26.04-26.80

26.82-27.58

27.61-28.37

28.40-29.18

29.21-29.97

30.0-30.76

30.78-31.55

31.57-32.51

32.54-33.30

.281 "

.296 "

.312 "

.328 "

.343 "

.375 "

.406 "

.437 "

.468 "

.500 "

.531 "

.562 "

.562 "

.593 "

.625 "

.656 "

.687 "

.718 "

.750 "

.781 "

.812 "

.843 "

.875 "

.906 "

.937 "

.968 "

1.000 "

1.031 "

1.062 "

1.093 "

1.125 "

1.156 "

1.187 "

1.218 "

1.250 "

7.14

7.52

7.92

8.33

8.71

9.52

10.31

11.10

11.89

12.70

13.49

14.27

14.27

15.06

15.88

16.66

17.45

18.24

19.05

19.84

20.62

21.41

22.23

23.01

23.80

24.59

25.40

26.19

26.97

27.76

28.58

29.36

30.15

30.94

31.75

10-32

10-32

10-32

10-32

1/4" NF

1/4" NF

1/4" NF

1/4" NF

5/16" NF

5/16" NF

5/16" NF

5/16" NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

7/16" NF

7/16" NF

7/16" NF

7/16" NF

7/16" NF

7/16" NF

7/16" NF

7/16" NF

AT-199

AT-199-5

AT-200

AT-200-5

AT-201

AT-202

AT-203

AT-204

AT-205

AT-206

AT-207

AT-208

AT-108

AT209

AT-210

AT-211

AT-212

AT-213

AT214

AT-215

AT-216

AT-217

AT-218

AT-219

AT-220

AT-221

AT-222

AT-223

AT-224

AT-225

AT-226

AT-227

AT-228

AT-229

AT-230

CB-199

CB-199-5

CB-200

CB-200-5

CB-201 TW-201

CB-202 TW-202

CB-203 TW-203

CB-204 TW-204

CB-205

CB-206

CB-207

CB-208

CB-108

CB-209

CB-210

CB-211

CB-212

CB-213

CB-214

CB-215

CB-216

CB-217

CB-218

CB-219

CB-220

CB-221

CB-222

CB-223

CB-224

CB-225

CB-226

CB-227

CB-228

CB-229

CB-230

CT-205

CT-206

CT-207

CT-208

CT-108

CT-209

CT-210

CT-211

CT-212

CT-213

CT-214

CT-215

CT-216

CT-217

CT-218

CT-219

CT-220

CT-221

CT-222

CT-223

CT-224

CT-225

CT-226

CT-227

CT-228

CT-229

CT-230

TW-205

TW-206

TW-207

TW-208

TW-108

TW-209

TW-210

TW-211

TW-212

TW-213

TW-214

TW-215

TW-216

TW-217

TW-218

TW-219

TW-220

TW-221

TW-222

TW-223

TW-224

TW-225

TW-226

TW-227

TW-228

TW-229

TW-230

199-B

199-5-B

200-B

200-5-B

201-B

202-B

203-B

204-B

205-B

206-B

207-B

208-B

108-B

209-B

210-B

211-B

212-B

213-B

214-B

215-B

216-B

217-B

218-B

219-B

220-B

221-B

222-B

223-B

224-B

225-B

226-B

227-B

228-B

229-B

230-B

11

Page 12

Selection Guide - continued

f

"AT" "CB" "CT" "TW" "B"

TUBE I. D. DIAMETER o

DRILL or BRUSH

STUD Straight S traight Twist Twist Wire

inch mm inch mm THREAD DRILL # DRILL # DRILL # DRILL # BRUSH #

Tool Steel Carb id e Carbide Tool Steel Steel

.291-.306

.307-.321

.322-.337

.338-.353

.359-.389

.390-.420

.421-.452

.453-.483

.484-.514

.515-.545

.546-.577

.578-.608

.578-.608

.609-.639

.640-.675

.676-.706

.707-.737

.738-.769

.770-.800

.801-.831

.832-.862

.863-.894

.895-.925

.926-.956

.957-.987

.988-1.024

1.025-1.055

1.056-1.086

1.087-1.117

1.118-1.149

1.150-1.180

1.181-1.211

1.212-1.242

1.243-1.280

1.281-1.311

7.39-7.77

7.77-8.15

8.18-8.56

8.59-8.97

9.12-9.88

9.91-10.67

10.69-11.48

11.48-12.27

12.29-13.06

13.08-13.84

13.87-14.66

14.68-15.44

14.68-15.44

15.47-16.23

16.26-17.15

17.17-17.93

17.96-18.72

18.75-19.53

19.56-20.32

20.35-21.11

21.13-21.89

21.92-22.71

22.73-23.50

23.52-24.28

24.31-25.07

25.35-26.01

26.04-26.80

26.82-27.58

27.61-28.37

28.40-29.18

29.21-29.97

30.0-30.76

30.78-31.55

31.57-32.51

32.54-33.30

.281 "

.296 "

.312 "

.328 "

.343 "

.375 "

.406 "

.437 "

.468 "

.500 "

.531 "

.562 "

.562 "

.593 "

.625 "

.656 "

.687 "

.718 "

.750 "

.781 "

.812 "

.843 "

.875 "

.906 "

.937 "

.968 "

1.000 "

1.031 "

1.062 "

1.093 "

1.125 "

1.156 "

1.187 "

1.218 "

1.250 "

7.14

7.52

7.92

8.33

8.71

9.52

10.31

11.10

11.89

12.70

13.49

14.27

14.27

15.06

15.88

16.66

17.45

18.24

19.05

19.84

20.62

21.41

22.23

23.01

23.80

24.59

25.40

26.19

26.97

27.76

28.58

29.36

30.15

30.94

31.75

10-32

10-32

10-32

10-32

1/4" NF

1/4" NF

1/4" NF

1/4" NF

5/16" NF

5/16" NF

5/16" NF

5/16" NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

3/8' NF

7/16" NF

7/16" NF

7/16" NF

7/16" NF

7/16" NF

7/16" NF

7/16" NF

7/16" NF

AT-199

AT-199-5

AT-200

AT-200-5

AT-201

AT-202

AT-203

AT-204

AT-205

AT-206

AT-207

AT-208

AT-108

AT209

AT-210

AT-211

AT-212

AT-213

AT214

AT-215

AT-216

AT-217

AT-218

AT-219

AT-220

AT-221

AT-222

AT-223

AT-224

AT-225

AT-226

AT-227

AT-228

AT-229

AT-230

CB-199

CB-199-5

CB-200

CB-200-5

CB-201 TW-201

CB-202 TW-202

CB-203 TW-203

CB-204 TW-204

CB-205

CB-206

CB-207

CB-208

CB-108

CB-209

CB-210

CB-211

CB-212

CB-213

CB-214

CB-215

CB-216

CB-217

CB-218

CB-219

CB-220

CB-221

CB-222

CB-223

CB-224

CB-225

CB-226

CB-227

CB-228

CB-229

CB-230

CT-205

CT-206

CT-207

CT-208

CT-108

CT-209

CT-210

CT-211

CT-212

CT-213

CT-214

CT-215

CT-216

CT-217

CT-218

CT-219

CT-220

CT-221

CT-222

CT-223

CT-224

CT-225

CT-226

CT-227

CT-228

CT-229

CT-230

TW-205

TW-206

TW-207

TW-208

TW-108

TW-209

TW-210

TW-211

TW-212

TW-213

TW-214

TW-215

TW-216

TW-217

TW-218

TW-219

TW-220

TW-221

TW-222

TW-223

TW-224

TW-225

TW-226

TW-227

TW-228

TW-229

TW-230

199-B

199-5-B

200-B

200-5-B

201-B

202-B

203-B

204-B

205-B

206-B

207-B

208-B

108-B

209-B

210-B

211-B

212-B

213-B

214-B

215-B

216-B

217-B

218-B

219-B

220-B

221-B

222-B

223-B

224-B

225-B

226-B

227-B

228-B

229-B

230-B

LARGE DIAMETER TWIST BRUSHES

DIAMETER STUD PART DIAMETER STUD PART

OF BRUSH DESCRIPTION THREAD NO. OF BRUSH DESCRIPTION THREAD NO.

1/1/2 " Brush LDTB-1 500 5/8 " NC 1003700 2 3/4 " Brush LDTB-2750 5/8 " NC 1005900

1 5/8" Brush LDTB-1625 5/8 " NC 1004500 2 7/8 " Brush LDTB-2875 5/8 " NC 1006200

1 3/4" Brush LDTB-1750 5/8 " NC 1004300 3 " Brush LDT B-3000 5/8 " NC 1006500

1 7/8" Brush LDTB-1875 5/8 " NC 1004600 3 1/4 " Brush LDTB-3250 5/8 " NC 1007100

2 " Brush LDT B-2000 5/8 " NC 1004900 3 1/2 " Brush LDTB-3 500 5/8 " NC 1006900

2 1/8 " Brush LDTB-2125 5/ 8 " NC 1005800 3 3/4 " Brush LDTB-3750 5/8 " NC 1007200

2 1/4 " Brush LDTB-2250 5/ 8 " NC 1005700 4 " Brush LDTB-4 000 5/8 " NC 1007300

2 1/2 " Brush LDTB-2500 5/ 8 " NC 1005400

12

Page 13

Airetool Operation

302 South Center Street

Springfield, Ohio 45506

13

Loading...

Loading...