Cooper Surgical LEEP 1000 SERVICE MANUAL

LEEP SYSTEM 1000™

SERVICE MANUAL

TABLE OF CONTENTS

SYSTEM FEATURES...............................................................................................2

SPECIFICATIONS..................................................................................................3

TECHNICAL ASSISTANCE MANUAL. ......................................................................4

EQUIPMENT REQUIRED ......................................................................................4

A) PRELIMINARY PROCEDURES ............................................................................4

B) LOW VOLTAGE POWER (BOARD 801278) .......................................................4

1) Testing Power Supply Voltage +5V And +15V (TP1, TP2) ...........................4

C) MICROCONTROLLER (BOARD 801282)............................................................4

1) Testing Once Equipment Is Turned On - Self Test .......................................4

2) Calibrating Vref Voltage (Reference Voltage)..............................................4

3) Testing RF Modulation Signals ...................................................................4

D) POWER SUPPLY (BOARD 801278)...................................................................4

1) Calibrating Reference Voltage (Vref A) .......................................................5

2) Testing PWM Signal Controlling Power Supplier.........................................5

3) Calibrating Minimum Voltage....................................................................6

4) Calibrating Maximum Voltage ...................................................................6

E) RADIO FREQUENCY (BOARD 801278..............................................................6

1) Testing The Neutral Plate Circuit ................................................................6

2) Testing Working Frequency.......................................................................6

3) Calibrating The Sloped Signal [Saw Tooth Signal].......................................6

4) Calibrating Dead Time ..............................................................................7

5) Testing RF Power Amplifier ........................................................................7

6) Calibrating Current Limiter ........................................................................8

7) Testing Output Power ...............................................................................8

8) Calibrating Maximum Level Of RF Current Leakage....................................8

F) CALIBRATING RF PROTECTION SYSTEMS ..........................................................8

1) Protection Against Malfunction Caused By Modulation Signal ....................8

2) Protection Against Malfunction Caused By Power Supply...........................9

G) CHECKING AUDIO SIGNAL LEVEL. ..................................................................9

H) CHECKING RF CURRENT LEAKAGE................................................................10

POWER OUTPUT CAPACITY CURVES ..................................................................11

SCHEMATICS AND PARTS LISTS......................................................................12-24

Manufactured by: Distributed by:

95 Corporate Drive

Trumbull, CT 06611

Phone: (203) 601-5200

Toll Free: (800) 243-2974

Fax: (800) 262-0105

International Division

Phone: (203) 601-9818

Fax: (203) 601-4747

Rev.10/02 LEEP System 1000™ Service Manual

1

Part # 34886

SYSTEM FEATURES

•

Microprocessor controlled for increased precision, accuracy, repeatability, and safety.

• Adequate power for all LEEP™ monopolar electrosurgical procedures.

• Accurate selection of discrete power levels.

• Digital display of output power levels.

• Choice of radio frequency wave forms including CUT, BLEND, and COAG to

accommodate subtle differences in technique and accessory performance.

• Patient plate continuity monitoring with audible alarm.

• Distinct audible tones for CUT/BLEND modes and COAG mode with associated

MODE light.

• Fully regulated isolated output power.

• Meets or exceeds IEC 601-2-2, second edition.

• Non-electric pneumatic foot pedal to maximize safety.

• Choice of reusable or disposable patient plate.

• Reusable handpiece.

• Choice of reusable or disposable electrodes.

• Output power safety audible alarm with automatic power shut off.

• Class 1, type BF, protected for use with defibrillator.

• Membrane switching to maximize cleanliness and ease of use.

Controls

1. Main switch

2. Socket for foot pedal

3. Socket for active electrodes

4. Socket for patient plate

5. Warning light of patient plate alarm (red)

6. Coagulation light (blue)

7. Pure cut and blend light (yellow)

8. Mode control

9. Power control

Classification I Type BF protected against defibrillator effects

Floating output circuit

Cautions, consult this manual for safety precautions

Pedal connection

Active handle connection

Patient plate connection

①② ⑧ ⑨

⑤⑥⑦

③ ④

Pure Cut

Blend Cut

Coag

F

Rev.10/02 LEEP System 1000™ Service Manual

2

LEEP System 1000

TM

POWER

F

Specifications:

Meets or Exceeds IEC 601-1-1, IEC 601-1-2 and IEC 601-2-2 specifications.

Meets the requirements of Annex 1 of Directive 93/42/EEC relating to

Medical Devices. UL and CUL approved.

Input Voltage: .....................................95 - 135 OAC 60 Hz

or

190 - 250 VAC 50 Hz

Current: ................................................2.3 amps max. or 1.2 amps max.

Low Frequency Leakage:...................Less than 50 microamps

Fuses:....................................................2.5 amps, T type

.........................................................or 1.6 amps, T type

Physical

Dimensions: .........................................305mm x 267mm x 115mm

Weight: .................................................7.250 Kg

Electrosurgical Output

RF Output Frequency:........................450 kHz

RF Output Power:

Volts p-p Max Duty Crest

(open circuit) Cycle Factor

CUT..................0-100 watts RMS* .............830..................—- ..........1.4

BLEND ............0-100 watts RMS* ............1200................60% .........2.0

COAG ..............0-80 watts RMS* ..............3800................10% ..5.5

NOTE: *stable to >800 ohms (calibration at 500 ohms)

RF Isolation..........Less than 100 milliamps at 200 ohms (per IEC 601-2-2)

Classification........I-Type BF

Output Circuit......Floating output. Protected against the effects of the

defibrillator.

Working Mode .....

Discontinuous maximum duty cycle: 10/30 sec.

Cooling .................Convection cooling without fan

Control ..................Foot pedal operated (pneumatic) with audible signals

and mode lights

Audible signals and lights for operation and alarm:

Main.................................................green light

Alarm, patient plate continuity..........low pitch intermittant audible

alarm - red light

Alarm, output power ........................higher pitch intermittant

audible alarm

Cut and Blend modes .......................low pitch audible signal - yellow light

Coagulation mode............................

high pitch audible signal - blue light

NOTE: specifications subject to change

3

Rev. 10/02 LEEP System 1000™ Service Manual

Electrical

SERVICE MANUAL

EQUIPMENT REQUIRED

DESCRIPTION FEATURES EXAMPLE

Double tracking Passband: Tektronix

oscilloscope DC - 100 MHz Mod. 2235A

Digital multimeter Accuracy: Hewelett Packard

DC = 1%, AC = 2% Mod. E2373A

Thermoelement Passband: YOKOYAWA

10 Hz - 5 MHz Mod. 2016

Digital Passband: Hewelett Packard

frequency meter 10 HZ - 100 MHz Mod. HP 5384A

Voltage probe Passband: Tektronix

X10 DC - 200 MHz Mod. P6063B

Voltage probe Passband: Tektronix

X1000 DC - 10 MHz Mod. P6015

Current probe Passband: Tektronix

DC - 50 MHz Mod. A6302/AM 503

A) PRELIMINARY PROCEDURES

a) Remove the F3 fuse from the MAIN BOARD (cod. 801278).

b) Insert plug from pedal control into input port.

c) Insert neutral plate plug in its appropriate outlet.

d) Insert power supply cable in current outlet.

B) LOW VOLTAGE POWER SUPPLY (BOARD 801278)

1) TESTING POWER SUPPLY VOLTAGE + 5V AND +15V (TP1, TP 2)

a) Set oscilloscope vertical sensitivity at 1V/div. (plugged in DC).

b) Connect oscilloscope probe to test point TP1.

c) Turn on electrosurgical knife and make sure voltage is between 4.7V and 5.3V.

d) Insert oscilloscope plug in AC outlet with vertical sensitivity set at 0.1V/div. and make sure that ripple voltage

is not over 10mVpp.

e) Move oscilloscope probe on test point TP2 (Vert. 2V/div.; DC) and make sure voltage is between 14.3V and

15.7V.

C) MICROCONTROLLER (BOARD 801282)

1) SELF TEST WHEN EQUIPMENT IS TURNED ON

Turn Power Switch “ON”

• Power Switch illuminates

• CUT, BLEND and COAG LED’s illuminate

• Display reads “888”

• After approximately 10 seconds, display changes to “- - - “

then CUT and BLEND activation LED’s and buzzer triggers for a second.

• Display changes to “O”

• BLEND and COAG mode LED’s deactivate

2) CALIBRATING VREF VOLTAGE

a) Connect the voltmeter to test point TP3 (BOARD 801282).

b) Turn trimmers R57 and R62 fully clockwise.

c) Set trimmer R2 so that voltage is exactly at 4.94V.

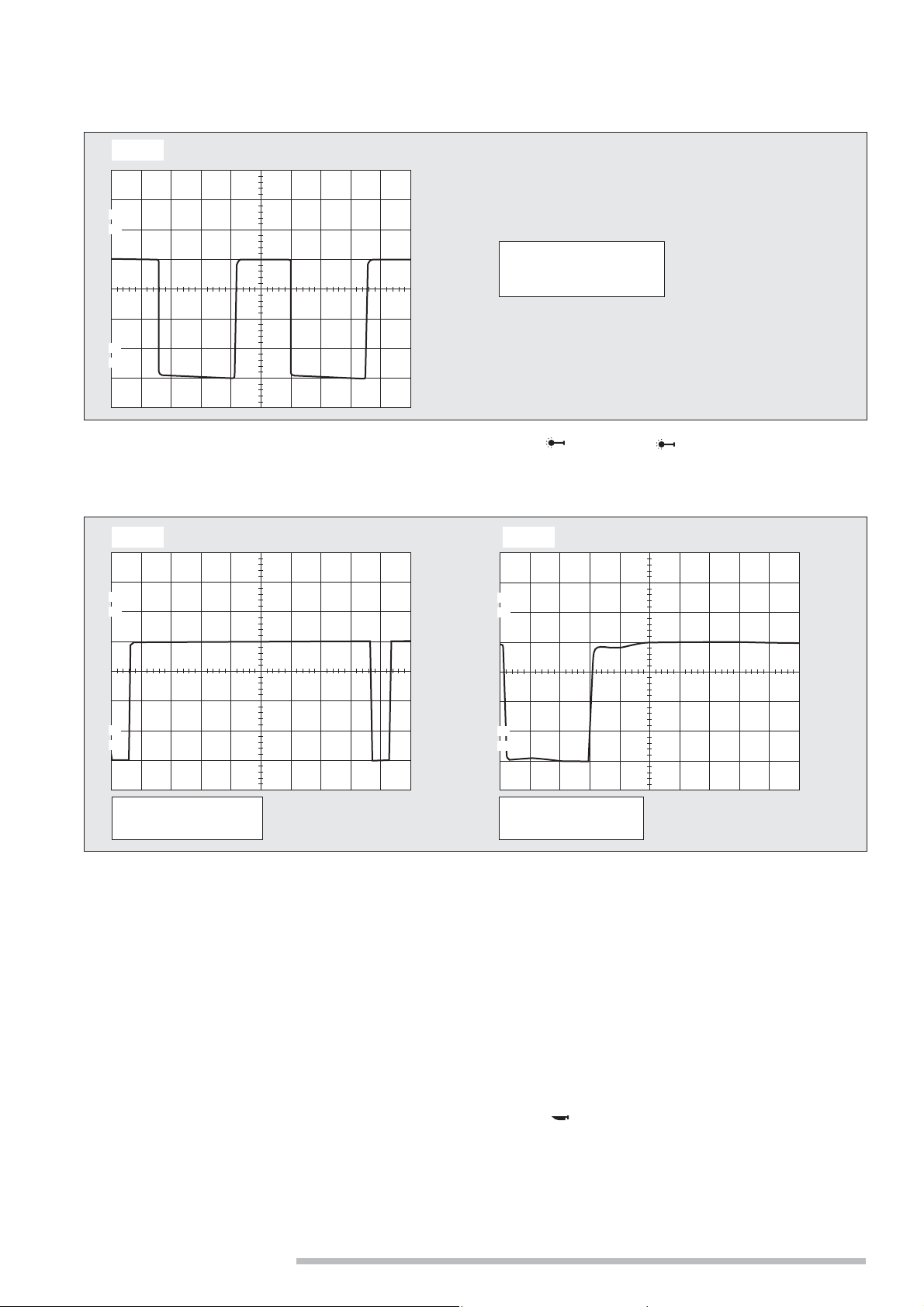

3) TESTING RF MODULATION SIGNAL

a) Connect oscilloscope probe to test point TP4 (BOARD 801282).

b) Set 10W as power index in the function.

Rev.10/02 LEEP System 1000™ Service Manual

4

c) With the electrosurgical knife turned on, test the modulation signal taking as

reference the following wave form:

e) Set 10W as power index in the function.

f) With the electrosurgical knife turned on, test the modulation signal, taking as

reference the following wave form:

D) POWER SUPPLY (BOARD 801278)

1) CALIBRATING REFERENCE VOLTAGE VREFA

a) Connect to TP5 to ground. (MOSFET drain Q6, Board 801278).

This prevents activation of the RF power generator, thus preventing possible

damage to electronic circuits that have not been tested yet.

b) Insert F3 fuse.

c) Position trimmer R4 at center position (BOARD 801278).

d) Turn on electrosurgical knife and wait for the display to show “0”.

e) Calibrate trimmer R6 (BOARD 801278) so that voltage at test point TP6 is

exactly 8.0V.

2) TESTING PWM SIGNAL CONTROLLING THE POWER SUPPLIER

a) Connect oscilloscope probe to test point TP7 (BOARD 801278).

b) Set 100W as power index in the function.

c) Activate and make sure the following wave form appears:

5

Rev. 5.22.95 LEEP System 1000™ Service Handbuch

Vert.: (DC) 1 V/div.

Hor.: 10 µs/div.

Vert.: (DC) 1 V/div.

Hor.: 2 µs/div.

100

90

10

0%

[TP4]

[TP4] [TP4]

Vert.:(DC) 1V/div.

Hor.: 20 μs/div

100

90

10

0%

100

90

10

0%

3) CALIBRATING MINIMUM VOLTAGE

a) Set 2W as power index in the function.

b) Make sure that, when the electrosurgical knife is not turned on, voltage is

lower than 3V in test point TP8.

c)

Press the activation pedal and bring voltage to 7V on TP8, by using trimmer R4

.

4) CALIBRATING MAXIMUM VOLTAGE

a) Set 80W as power index in the function.

b)

Press activation pedal and bring voltage to 134V on TP8, by using trimmer R6.

Calibration of the two voltages, the maximum and minimum, is interactive;

thus, it is necessary to repeat calibrations until the values that have been

indicated are reached.

d) Remove the jumper used to create electical bonding on TP5 (MOSFET drain

Q6, BOARD 801278).

E) RADIO FREQUENCY (BOARD 801278)

Remove F3 fuse

1) TESTING NEUTRAL CIRCUIT PLATE

a) Select function.

b) Disconnect the two end conductors in the plate and then insert a 1000 ohm

resistor in series.

c) Check that red LED is turned on, at the same time that the LED turns on,

a repetetive acoustic signal will give warning of an error in the neutral plate.

d) Once again, short the end conductors on the neutral plate.

2) TESTING WORKING FREQUENCY

a) Set 10W as power index in the function.

b) Connect frequency meter to test point TP9.

c) With the electrosurgical knife turned on, make sure that working frequency is

900 KHz (+ 10KHz).

d) Calibrate the capacity trimmer C24 in such a way that the wave form is the

following:

Vert.:

(Gleich-

Vert.: (DC) 2 V/div.

Hor.: 20 µs/div.

[TP7]

Vert.: (DC) 1 V/div.

Hor.: 50 ns/div.

[TP9]

Rev.10/02 LEEP System 1000™ Service Manual

6

100

90

10

0%

100

90

10

0%

3) CALIBRATING THE SLOPED SIGNAL (SAW-TOOTH SIGNAL)

a) Always with the CUT function activated, regulate the R53 trimmer in such a

way that the wave form on test point TP10 will be the following:

b) Turn the electrosurgical knife off.

4) CALIBRATING DEAD TIME

a) Connect a load of 500 ohm to the output hook up

b) Set 10W as power index in the function.

c) Turn the R 61 trimmer fully counterclockwise.

d) Using both inlets of the oscilloscope, connect probe “1” to test point TP11,

and probe “2’ on test point TP12.

e) With the electrosurgical knife turned on, turn the R53 trimmer so that dead

time (i.e., the time at which both signals are at zero level) is equal to 250ns.

g) Increase dead time by another 25ns by using trimmer R61.

h) Insert the F3 fuse.

5) TESTING THE RF POWER AMPLIFIER

a) Set 100W as power index in the function.

b) Insert the RF current probe in series in the output.

7

Rev. 5.22.95 LEEP System 1000™ Service Handbuch

Vert.: (DC) 1 V/div.

Hor.: 200 ns/div.

[TP10]

Vert.: (DC) 5 V/div.

Hor.: 500 ns/div.

[TP11]

100

90

10

0%

100

90

10

0%

c)

activate the electrosurgical knife and make sure it has the following wave form:

6) CALIBRATING CURRENT LIMITER

a) Bring output load to 200 ohm.

b) Set 80W as power index in the function.

c) Calibrate the R76 trimmer in such a way that the current running through the

output load is 580mA.

7) TESTING OUTPUT POWER

a) Bring the output load to 500 ohm.

b)

With power set at 80W in , make sure that effective current in the load is

equal to 400mA (+ 5%). If necessary, it is possible to adjust the maximum output

power by intervening on the R6 trimmer. Calibrating the R6 trimmer is allowed

only if the voltage that is supplying the final stage does not exceed 135V.

c) Set 10W as power index in the function

d)

Make sure that the effective current in the load is equal to 140mA (+ 5%). If necessary,

it is possible to adjust the maximum output power by intervening on the R4 trimmer.

e) Set 100W as power index in the function

f) Make sure that effective current in the load is equal to 450mA (+ 5%).

NOTE: This manual contains a chapter with drawings of the power output

capacity curves for the electrosurgical knife; for a complete test of the device,

refer to these curves, page 11.

8) CALIBRATING MAXIMUM LEVEL OF RF CURRENT LEAKAGE

a) Bring load resistor to 1500 ohm.

b) Set 100W as power index in the function.

c) Connect the oscilloscope probe to test point TP8.

d) By calibrating the R115 trimmer, find the point in which the tension displayed

in the oscilloscope decreases abruptly from 52V to 42V (+ 20%).

F) CALIBRATING RF PROTECTION SYSTEMS

1) PROTECTION FROM MALFUNCTION CAUSED BY MODULATION SIGNAL

a) Bring load resistor to 1000 ohm.

b) Set 40W as power index in the function.

c) With the electrosurgical knife activated, turn the R64 trimmer (BOARD

801282) slowly counterclockwise, until the audio signal becomes intermittent

and, at the same time, the RF output signal stops.

d) Now turn the R64 trimmer (BOARD 801282) clockwise 15 degrees

e) Always keeping the power index at 40W, make sure that all functions are

properly activated.

f) In order to simulate a malfunction condition, short the R49 resistance (BOARD

801278) and activate in . The audio signal must warn of a malfunction

condition.

g) Remove jumper shorting the R49 resistance.

Vert.: (AC) 0.2 A/div.

Hor.: 500 ns/div.

1 LOAD + 500 ohm

_

Rev.10/02 LEEP System 1000™ Service Manual

8

100

90

10

0%

Loading...

Loading...