CooperSurgical K-Systems G185, K-Systems G185 SensorTech Standard User Manual

0086

User Manual

G185

CO2/O2 Incubator

Models: Standard and SensorTech

Document K33070 | Issue: 10 | Date: July 03, 2018 | DRF: 4578

Contents

Section 1 - Preface 5

Section 2 - Safety 6

Safety and Reliability 6

Warnings 6

Cautions 7

Section 3 - Installation 10

Placement 10

Section 4 - Intended Use 11

Applicable Part Numbers 11

Significant Performance Characteristics 11

Operation Principle 11

User Profile 11

Operating Environment 11

Product Description 12

Dish Inserts 12

Section 5 - Product Overview 13

Main Components 13

Supplied Accessories for G185 Incubator 14

Accessory Order Codes 14

Technical Specifications 15

Section 6 - G185 SensorTech 17

External pH Monitoring 17

External Temperature and CO

Monitoring 18

2

Section 7 - Set-up 19

Gas Supply 19

Factory Settings 19

Section 8 - Basic Operation 20

User Interface 20

System on Standby 21

Switching the Unit ON 21

Contents

Switching the Unit OFF (Standby Mode) 22

Activating the Heat and Gas Controls 22

Keyboard Lock 23

Alarms 23

Section 9 - Settings 25

Advanced Function 25

Menu Items 26

Front Chamber Keys 30

Timer 31

Clock 31

Alarm Switch for External Monitoring System 31

Writing Pads for Chamber Lids and Penholder 32

Section 10 - Data Logger 33

System Requirements 33

Software Installation 33

Connecting To PC 33

Activating Data Log Function for PC 34

Starting The Data Logger Software 35

Connecting Multiple Incubators 35

Zoom In 36

Zoom Out 36

Alignment 37

Temperature and Gas level 37

Gas Flow and Pressure 38

The Daily Average 38

Warnings Menu 39

Mail 40

Log Files 41

Section 11 - Troubleshooting 42

Heating System 42

CO

Gas Regulation 42

2

O

Gas Regulation 43

2

Display 44

Keyboard 44

Contents

Section 12 - Maintenance 45

Periodic Cleaning 45

Disinfection 45

Sterilizing the Dish Inserts 45

Via the Gas Sample Port 46

Validation Check 46

Gas Calibration 46

Via Gas Chamber Lids 47

Temperature Calibration 48

Section 13 - Service 50

Service Plan 50

Replacing the H13 Filter 51

Section 14 - Disposal and Recycling 52

Environmental Protection for Disposal of the Product 52

Recyclable Components 52

Section 15 - Warranty Information and Limits

on Liability 53

Technical Support/Service Representatives 54

Customer Service 54

Returned Goods Policy 54

Preface

EC REP

Section 1 - Preface

Thank you for choosing a K-Systems product. We hope you will be happy with your G185.

At CooperSurgical, we strive to provide the very best products and solutions for human IVF and the

G185 is designed to provide optimum conditions for your embryos during long-term culture.

For optimal use of your G185, please read and follow the instructions in this User Manual.

The incubator should be operated by trained personnel only. All sections of this manual should be

read and understood fully before any operation of the incubator. If you are unsure of any of the

information contained in this manual then you should contact Customer Services or an appointed

representative before attempting to use this equipment. Keep these instructions close to the device,

as this will ensure having easy access to the safety instructions and important information.

In no event does CooperSurgical assume the liability for any technical or editorial errors of commission,

or omission; nor is liable for direct, indirect, incidental, or consequential damages arising out of the

use or inability for you to use this manual.

The information in this manual is current at the time of publication. Our commitment to product

improvement requires that we reserve the right to change equipment, procedures and specifications

at any time. This user manual belongs with the G185 incubator and should be passed on with the

incubator if relocated to another facility.

1

© This manual is protected by copyright, all rights reserved, and no part hereof may be photocopied

or reproduced in any form without the prior written consent of CooperSurgical.

95 Corporate Drive

Trumbull

CT 06611

USA

EMERGO EUROPE

Prinsessegracht 20

2514 AP The Hague

The Netherlands

CooperSurgical is a registered trademark of CooperSurgical, Inc.

K-Systems is a CooperSurgical brand.

©2018 CooperSurgical, Inc.

5

2

Safety

Section 2 - Safety

Safety and Reliability

Please read this manual carefully and follow the instructions to ensure that the system will work safely

and reliably. Safety is the responsibility of the laboratory. Risk assessment and working practices

should comply with local regulatory policies.

Warnings

WARNING: Use only 100% pure CO2 and 100% pure N2 gas. Use of other gases could

result in serious injury, depending on the gas connected

DO NOT: Disassemble or modify any part of the G185, or substitute any component

for any other. Doing so may result in damage to samples. This voids the warranty and/

or service contract

WARNING: To avoid the risk of electric shock, this equipment must only be connected

to a mains supply with protective earth

WARNING: Not to be used in a patient environment

WARNING: Use of accessories, transducers and cables other than those specified

or provided by the manufacturer of this equipment could result in increased

electromagnetic emissions or decreased electromagnetic immunity of this equipment

and result in improper operation

6

Cautions

Safety

CAUTION

• DO NOT use the incubator if ShockWatch or TipNTell has been triggered or if the package is

damaged

• Read and understand the manual completely before use. Keep the manual close to the unit

• Never use or handle this unit in ways other than specified in this manual. Your safety may be at

risk and the unit may get damaged

• Never try to move the unit without consulting Technical Support

• Never use the unit if the alarm system of the device has issued a failure message and the cause

of the failure has not been identified

• Protect the power cord from being damaged or being restricted in any way. Unplug the power

cord from the wall socket or at the rear of the instrument to disconnect the mains supply

• Make sure that CO

• Always keep the red caps on unused gas inlets and the sample port at the back of the unit

• Never use the unit without an original K-Systems H13 filter

• DO NOT expose the filter to liquids. Change filters that have been exposed to liquids

• DO NOT leave lids open for more than 10 seconds

• DO NOT use the unit at ambient temperatures exceeding 30°C. Ambient temperature above

30°C will compromise the incubation process. The relative humidity must not exceed 75% (noncondensing)

and N2 gas supply pressures are not above 1.0 bar and not below 0.5 bar

2

2

7

2

Safety

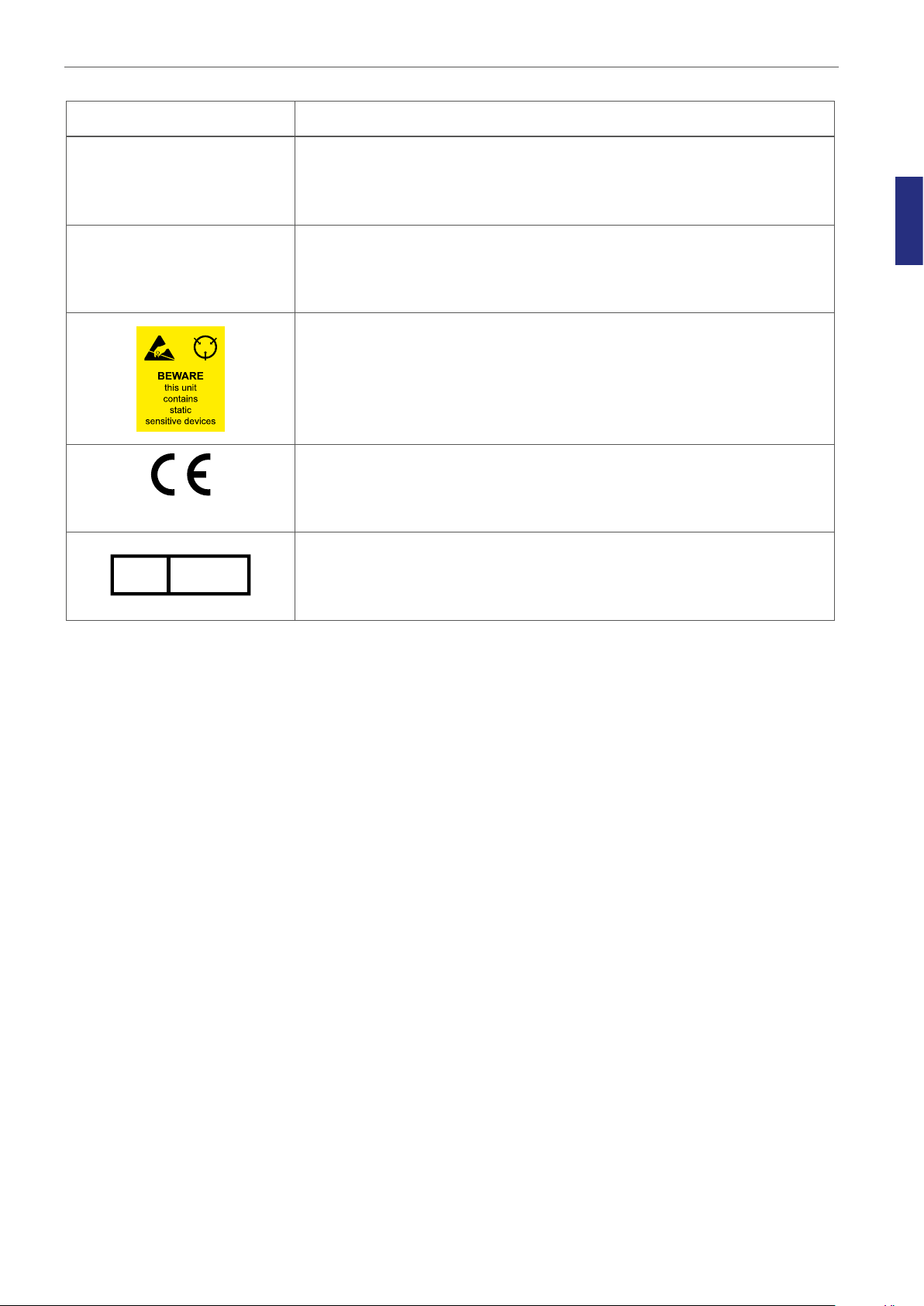

Symbol Meaning

WARNING: Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used

to alert against unsafe practices

Consult the User Manual for information needed for proper use of

the device

Manufacturer

S

N

REF

Date of manufacture

Waste electrical and electronic equipment

• CooperSurgical, and its distributors within the European Union

and associated states, have taken the necessary steps to comply

with the directive 2012/19/EU on waste electrical and electronic

equipment (WEEE)

• The instrument, when reaching its end of life, must be collected

and recycled separately from other waste according to national

requirements

Environmental implications: WEEE contains materials that are

potentially hazardous to the environment and to human health (see

page 52)

Serial Number

Catalog Number

Warranty label

8

Symbol Meaning

0086

Safety

Sample Port

GAS (MAX 1 BAR)

EC REP

Sample port

Gas Inlets CO2/N

Static sensitive (ESD)

In accordance with Annex II of the European Medical Device Directive

93/42/EEC, as amended by Directive 2007/47/EC

Authorized Representative in the European Community

2

2

9

3

HANDLE WITH CARE

WARNING

RED INDICATES ROUGH HANDLING.

IF RED, NOTE ON THE BILL OF LADING

AND INSPECT PRODUCT

PRODUCT OF MEDIA RE COVERY

MODEL:

L-65 (25g)

MADE IN THE USA

www.shockwatch.com 1.800.527.9497

TIP

Installation

Section 3 - Installation

Installation of the G185 should be carried out by a CooperSurgical Service Technician or other

authorized personnel. Incorrect installation could result in overall poor performance.

The G185 is designed as a stationary unit and, therefore, not to be moved once it has been installed.

If the incubator needs to be relocated, please contact technical support.

Before Installation

This incubator is transported in a crate and we recommend you inspect its delivery. If the ShockWatch

or TipNTell has been triggered, inform customer service.

Check the contents to ensure all parts listed on the packing list are present.

BLUE BEADS IN

ARROW INDICATES

CONTAINER WAS

TIPPED OR

MISHANDLED

TELL

MADE IN THE U.S.A

Placement

The G185 should be placed on a level, secure surface, away from heaters, coolers,

air-conditioning outlets, mists, splash and direct sunlight. Allow 10cm of clearance on all sides to allow

adequate ventilation.

Allow the G185 to acclimatize for two hours before installation.

To maintain a device setpoint between 35-40°C the preferred ambient temperature should be

between 20-30°C. DO NOT use the incubator at ambient temperatures exceeding 30°C as this may

compromise the incubation process.

This unit is designed for use at altitudes under 2,000 meters.

• Installation of the unit should only be performed by an authorized CooperSurgical Service

Technician

• Never block any of the ventilation holes on the unit

• Make sure that all devices emitting electromagnetic radiation are kept at a reasonable distance

from the unit in order to avoid any potential interferences

• Make sure the power circuits used are intended for medical equipment

• Make sure there is sufficient access to the device for ease of disconnection if required

10

CAUTION

Intended Use

Section 4 - Intended Use

To provide an environment with controlled temperature at or near body temperature and gas level

(CO2, O2 and N2), for the development of human gametes and embryos during in vitro fertilization

(IVF) treatment.

Applicable indications for use are subject to the regulations of the country into which the device is

sold and also the availability of the G185 for clinical use is dependent on the regulatory approval

status of the incubator within the country.

Applicable Part Numbers

Order Code Description

K22400-110

K22400-230

K22200-110

K22200-230

Standard Incubator

SensorTech Incubator

Significant Performance Characteristics

The incubator has been developed and optimized for gametes and embryos cultured with an overlay

of either paraffin or mineral oil. Each chamber is designed to contain dishes from one patient only.

Operation Principle

The fertilized egg (zygote) is cultured for up to 6-7 days in a growth medium in the incubator with

a controlled environment (temperature and CO2/O2). It is then implanted in the same or another

woman’s uterus, with the intention of establishing a successful pregnancy.

User Profile

A trained health professional, who has the appropriate assisted reproduction technologies

qualifications. Only qualified personnel trained in using the G185 should operate the incubator.

4

CAUTION: If the equipment is used in a manner not specified by this manual, the

safety of the user may be at risk and the equipment may be damaged. Always use the

equipment as stated in this User Manual

Operating Environment

To be used at ambient temperature in a medical environment, clinic or hospital laboratory under

normal working conditions.

11

Intended Use

Product Description

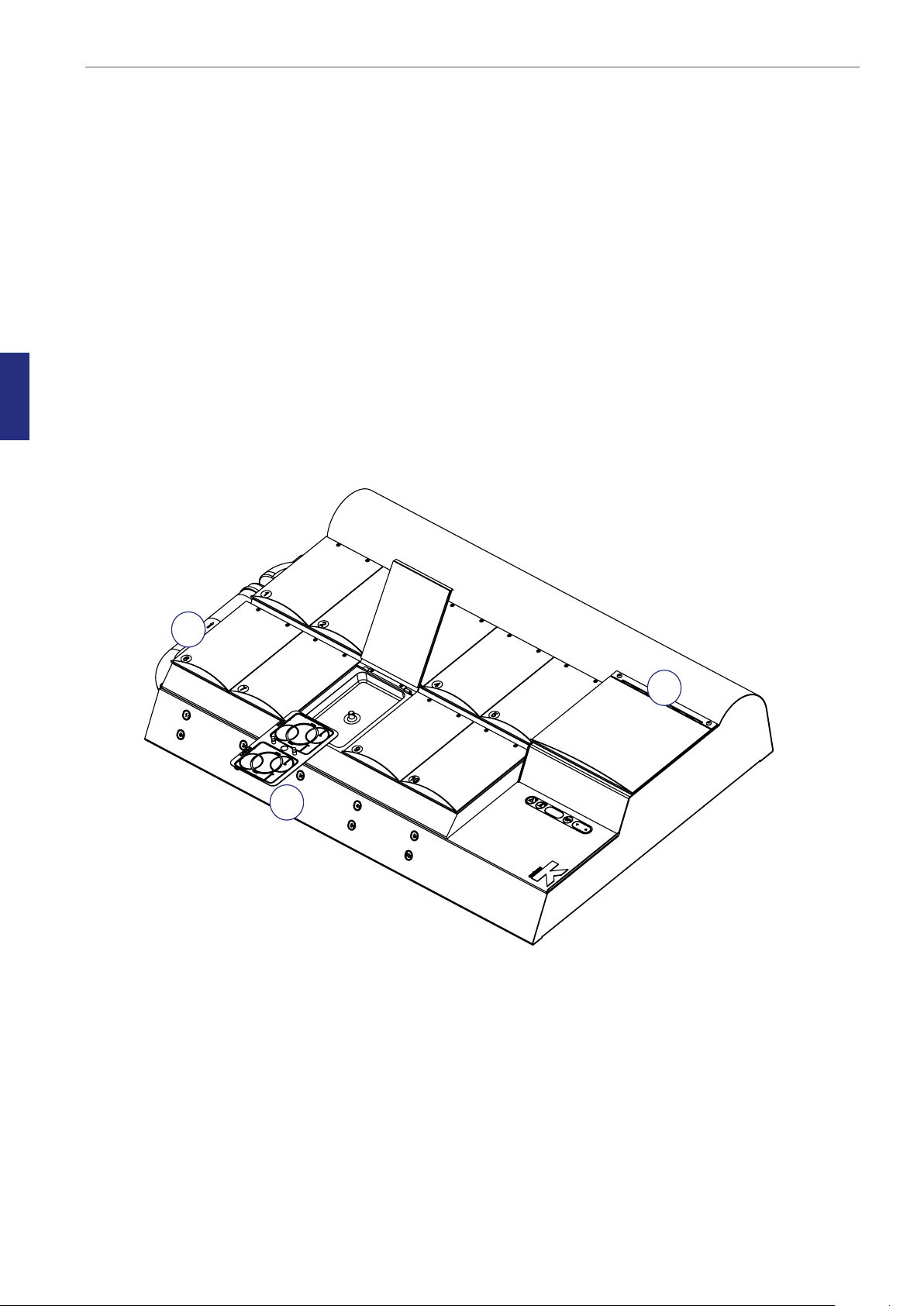

The G185 is composed of 10 separate culture chambers (2) and one larger warming chamber (3).

The 10 culture chambers are exposed to both heat and gas mixtures while the Dry Bath Chamber is

exposed only to heat.

The gas is constantly cleaned for particles, volatile organic compounds and bacteria by circulation

through a HEPA and VOC filter and through a 254nm UV chamber.

4

The CO

sensor placed in the gas mixing chamber (built inside the incubator).

concentration is monitored by using a CO2 sensor and the O2 level is monitored by an O

2

2

Dish Inserts

The chambers should only be fitted with special Dish Inserts (1), that allow safe placement of standard

culture dishes (Falcon, Nunc, Vitrolife).

Ensure the culture dishes are placed securely in the correct milled grooves of the Dish Inserts.

2

3

1

12

Section 5 - Product Overview

Main Components

Components

1 Incubator Chambers

2 User Interface

3 Dry Bath Chamber

4 H13 Filter

5 Product label

Product Overview

6 Mains connection with fuse

7 Gas inlet connectors

8 Alarm output

1

5

G185 Standard and SensorTech models front view

3

2

G185 Standard model - back view

5

7

8

6

4

13

5

Product Overview

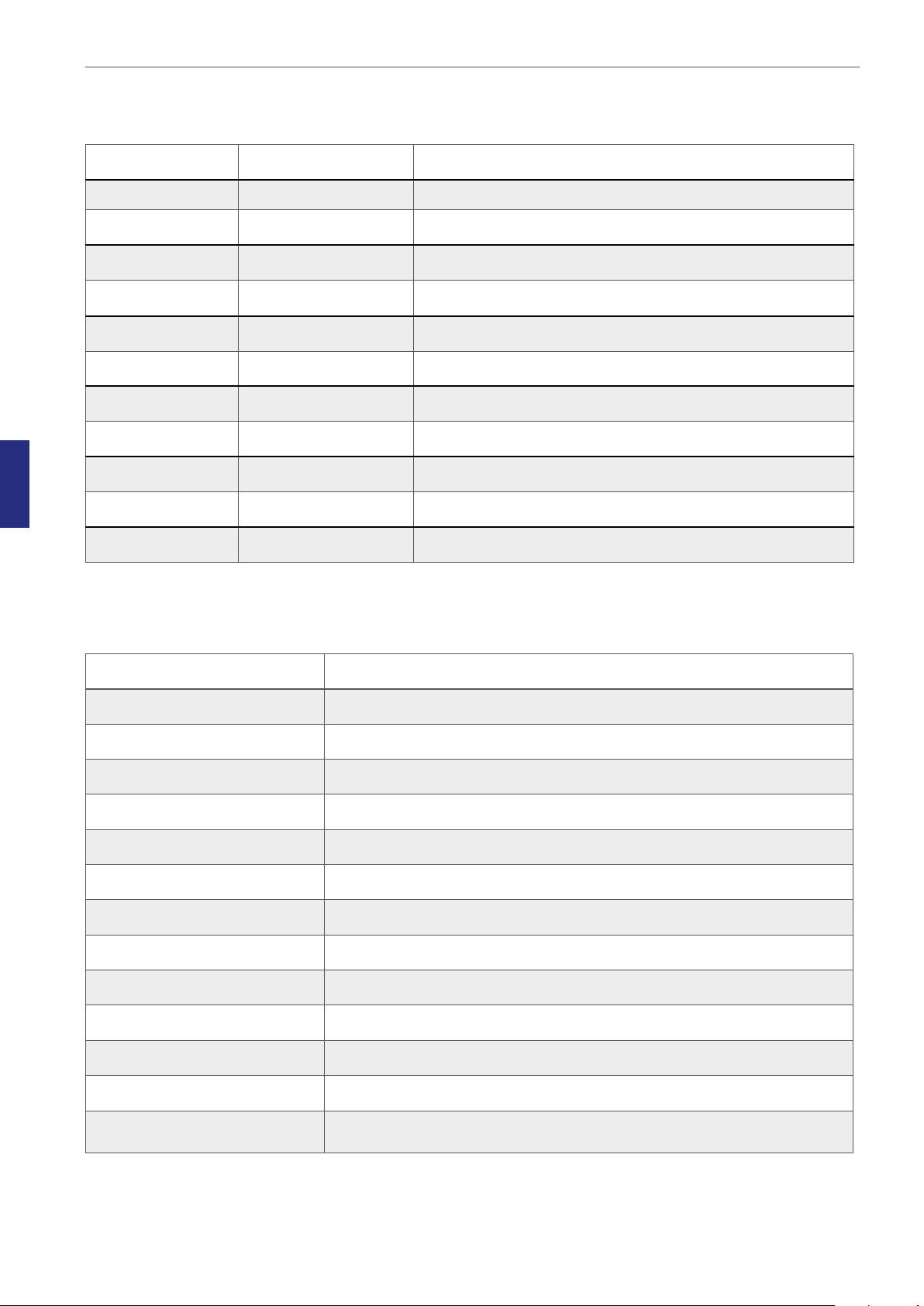

Supplied Accessories for G185 Incubator

Quantity Part Number Description

1 2-02-650 Mains Cable UK Plug 230V

1 2-02-651 Mains Cable Schuko Plug 230V

1 2-02-652 Mains Cable USA Plug 115V

1 2-02-662 Mains Cable Aus/China Plug 230V

2 K11066 Silicone Tube (3 metre)

4 K22123 Silicone Sealing Rings

2 K53830 HEPA VOC Filters

2 K22166 HEPA Filter for Input Gas Supply

10 K57263 Magnetic Pads for Incubator

1 K33098 USB (Datalogger Software)

1 K57314 USB Converter Cable

Accessory Order Codes

Order Code Description

23063-1 Dish Insert Falcon 1 pc

23064-1 Dish Insert Nunc 1 pc

23069 Dish Insert Vitrolife 1 pc

23060-1 Dish Insert Nunc pH Online Sensor (SensorTech models only)

23061-1 Dish Insert Falcon pH Online Sensor (SensorTech models only)

23079 Dish Insert Vitrolife pH Online Sensor (SensorTech models only)

22166 H13 Filter

53830 HEPA Inline Filter

57214 Lid Seal for culture chambers

14

57272 Lid Seal for Dry Bath Chamber

11103 G100 Gas Analyzer

11006 Solid Temperature Sensor (use with K-Systems F100 Thermometer)

33070 User Manual

Product Overview

Technical Specifications

Overall dimensions, (L x W x H) 922 x 570 x 165mm (with filter connected)

Weight 38kg

Ambient conditions

Max. ambient temperature during operation 30°C

Min. ambient temperature during operation 20°C

Max. storage temperature 30°C

Min. storage temperature -10°C

Humidity

Max. humidity during operation % R.H. 75, non-condensing

Max. storage humidity % R.H. 95, non-condensing

Filters

high-efficiency, acid-washed,

VOC Filter H13 filter capsule 1 pc

granular-activated carbon

combined with HEPA

Gas inline filter, HEPA 2 pcs

50mm HEPA disc filter for the

protection of internal circuits

Gas and Temperature

Temperature Range From ambient T°- 42.9°C

range 2 - 10%

CO

2

O

range 2 - 20%

2

Temperature specification (zone) accuracy Better than +/- 0.3°C deviation

gas control accuracy Better than +/- 0.2% average

CO

2

gas control accuracy Better than +/- 0.2% average

O

2

Gas Consumption (typical)

5

CO

N

2

CO

O

2

1.5l/h

7l/h

Recovery time

2

2

2 min

4 min

15

Product Overview

Voltage

5

Rated Voltage (system)

Current

Power consumption max. 240 VA

Connecting gas

inlet 1.0 bar/14.5 psi

CO

2

inlet 1.0 bar/14.5 psi

N

2

Dish Inserts

Nunc dish insert

Falcon dish insert

Vitrolife dish insert Vitrolife 4 well dishes

Software

To monitor, record and display key performance Data logger, including alarm functions

1/N/PE AC, 100-120VAC 60Hz or 220240VAC 50Hz

Suitable for Nunc Ø35mm, Ø51mm and

4 well IVF dishes

Suitable for Falcon Ø50mm, 4 well IVF

dishes

Fuses

External fuses (220-240V) 2 x F 1.6AH (250V)

External fuses (100-120V) 2 x F 3.15AH (250V)

Degree of protection

Type of protection against electric shock Class I

Degree of protection against the ingress

of water

IP30

16

G185 SensorTech

Section 6 - G185 SensorTech

G185 supports external and independent monitoring of the most critical parameters regarding CO2

concentration, temperature and pH measurement.

CAUTION: Installations of external sensors must be performed by CooperSurgical or

by persons authorized by CooperSurgical only

External pH Monitoring

This G185 SensorTech has been designed to work with Octax pH online. These parts are available

from MTG GmbH.

A fiber optic cable is built into chamber 1.

A special Dish Insert must be used in the chamber where the pH optical fiber sensor is installed. There

are three different Dish Inserts available depending on the dishes used:

• Dish Insert Nunc pH Online Sensor: Order code: 23060-1

• Dish Insert Falcon pH Online Sensor: Order code: 23061-1

• Dish Insert Vitrolife pH Online Sensor: Order code: 23079

Fiber Optic Cable in chamber 1

The fiber optic cable is attached to a cover plate

on the rear panel.

Special dish insert hole for Optical Fiber Sensor

6

When this cover plate is removed the fiber optic

cable will follow out. An O-ring in the rear panel

protects the cable from scratching against

metal.

A stopper is mounted on the cable inside to

prevent the cable from being pulled out too far,

thereby breaking the fiber.

Outlet of Fiber Optic Cable in rear panel

17

Loading...

Loading...