Page 1

INSTALLATION GUIDE

HARDWIRED

CONTROL UNIT

Page 2

9751 Hardwired Control Unit Installation Guide

This document applies to control panels using software versions 4.x. and 5.x.

© Cooper Security Ltd. 2009

Every effort has been made to ensure that the contents of this book are correct. However, neither the authors nor Cooper Security

Limited accept any liability for loss or damage caused or alleged to be caused directly or indirectly by this book. The contents of this book

are subject to change without notice.

Printed and published in the UK.

Page 3

11976798 Page i

Contents

1. INTRODUCTION..........................................................................................1

About this Manual........................................................................................................................................1

Features of the Control Unit.........................................................................................................................2

Elements of the IAS .....................................................................................................................................3

9941 and 9943 Keypads............................................................................................................................5

Expanders .................................................................................................................................................5

Partitioned or Single System......................................................................................................................7

User Control ..............................................................................................................................................7

2. TECHNICAL DESCRIPTION ....................................................................... 9

Control Unit Specification.............................................................................................................................9

General......................................................................................................................................................9

Power Supply ............................................................................................................................................9

Outputs....................................................................................................................................................10

Inputs.......................................................................................................................................................10

Fuses.......................................................................................................................................................10

Compatible Equipment...............................................................................................................................11

Control Unit PCB Layout............................................................................................................................12

3. INSTALLATION......................................................................................... 13

Overview....................................................................................................................................................13

Cabling for Keypads and Expanders..........................................................................................................14

Fitting the System ......................................................................................................................................16

Fitting the Control Unit Case....................................................................................................................16

Fitting a 9941 or 9943 Keypad.................................................................................................................16

Wiring the Control Unit...............................................................................................................................17

Cable Entries ...........................................................................................................................................17

Mains Connection....................................................................................................................................17

Keypads...................................................................................................................................................18

Connecting Sounders ..............................................................................................................................19

Connecting Detector Circuits to the Main PCB ........................................................................................21

Connecting Expanders ............................................................................................................................24

Programming Outputs..............................................................................................................................26

Wiring Keyswitches..................................................................................................................................27

Communicator ...........................................................................................................................................28

Connecting the Communicator ................................................................................................................28

Statutory Information ...............................................................................................................................29

Safety Notice .............................................................................................................................................30

Connecting the Telephone Line...............................................................................................................32

Fitting a Plug-by Communicator...............................................................................................................33

Fitting a Battery..........................................................................................................................................35

Initial Start Up ............................................................................................................................................36

Index.............................................................................................................. 37

Page 4

Contents 9751 Installation Guide

Page ii 11976798

List of Figures

Figure 1. Elements of an Intruder Alarm System..........................................................................................4

Figure 2. 9941 and 9943 Keypads ...............................................................................................................5

Figure 3. Control Unit PCB Layout.............................................................................................................12

Figure 4. Star and Bus Wiring for Keypads and Expanders .......................................................................14

Figure 5. Backplate of the 9941/9943 Keypad ...........................................................................................16

Figure 6. Mains Connection .......................................................................................................................17

Figure 7. Keypad Connections...................................................................................................................18

Figure 8. 9941, 9943 Panic Attack Connections ........................................................................................18

Figure 9. Keypad Addressing.....................................................................................................................19

Figure 10. Sounder Connections ...............................................................................................................20

Figure 11. CCL Connections (common tamper).........................................................................................21

Figure 12. FSL Connections ......................................................................................................................22

Figure 13. Colour Code for FSL Resistors .................................................................................................22

Figure 14. Wiring Zones that use Anti-Masking..........................................................................................23

Figure 15. 9954 Expander .........................................................................................................................24

Figure 16. RFX08/RFX16 Radio Expander ................................................................................................25

Figure 17. Connecting an Expander ..........................................................................................................25

Figure 18. Link Positions to Select Wiring Method .....................................................................................26

Figure 19. Link Positions to Allocate Expanders to Zones .........................................................................26

Figure 20. Wiring Examples for Open Collector Outputs............................................................................27

Figure 21. Connecting a Keyswitch............................................................................................................27

Figure 22. SELV and TNV connectors .......................................................................................................31

Figure 23. Connecting the Internal Communicator.....................................................................................32

Figure 24. Plug-By Communicator Wiring ..................................................................................................33

Figure 25. Fitting a Plug-by Communicator................................................................................................33

Figure 26. Fitting Control Unit PCB............................................................................................................34

Figure 27. Fitting a Battery.........................................................................................................................35

Page 5

11976798 Page 1

1. INTRODUCTION

About this Manual

This manual is divided into three chapters:

1. Introduction: this describes the parts of an Intruder Alarm System (IAS)

based on the 9751 control unit.

2. Technical description: this defines the operating parameters of the different

parts of the system.

3. Installation: this explains the tasks involved in installing an IAS using the

9751 control unit.

The control unit is designed to be fully programmable to suit individual user

and site requirements. Installers can program units either from a keypad or

using a program called Downloader on a PC running Windows (Windows XP).

When programming from a keypad, instructions are entered using the threedigit commands described in the Programming Guide.

Page 6

1. Introduction 9751 Installation Guide

Page 2 11976798

Features of the Control Unit

The control unit provides:

° On-board connections for 8 Fully Supervised Loop (FSL) zones or 8

Closed Circuit Loop (CCL) zones with a common tamper.

Separate expander units enable a further 16 zones to be connected: a

combination of wired and radio expanders can be used.

° Connections for 3 fully programmable outputs.

° A 4-wire bus for keypads and hardwired or radio expanders.

° Internal sounder loudspeaker output with Chime, Alarm, Fire and Entry/Exit

tones (the volume of the Entry/Exit and Chime tones can be adjusted).

° Built-in communicator for reporting to an Alarm Receiving Centre (ARC).

° 8 programmable plug-by outputs (for connecting a standalone

communication device).

° Alarm Abort and Alarm Confirmation outputs (to reduce the likelihood of

false alarms).

° Facility to download from a remote PC via a telephone line.

° Support for a range of European countries and languages.

° Fully programmable operation for zones, levels and partitions.

° Flexible reporting formats and communication configurations.

° Installer-programmable Engineer and Guard Codes.

° Support for up to 50 separate users.

User facilities include:

° 4 different security levels, which can be programmed by the Installer either

as a full set and 3 part sets, or as 4 independent partitions.

° Proximity tag reader for setting and unsetting the system.

° Dual key alarms from the keypads (Panic Alarm, Medical and Fire).

° Remote Panic Alarm input to 9941 or 9943 keypads.

° Remote set/unset when using a radio expander.

° User-programmable Duress Code.

Test facilities include:

° 700-entry event log.

° Output test commands.

° Engineer walk test command.

Page 7

9751 Installation Guide 1. Introduction

11976798 Page 3

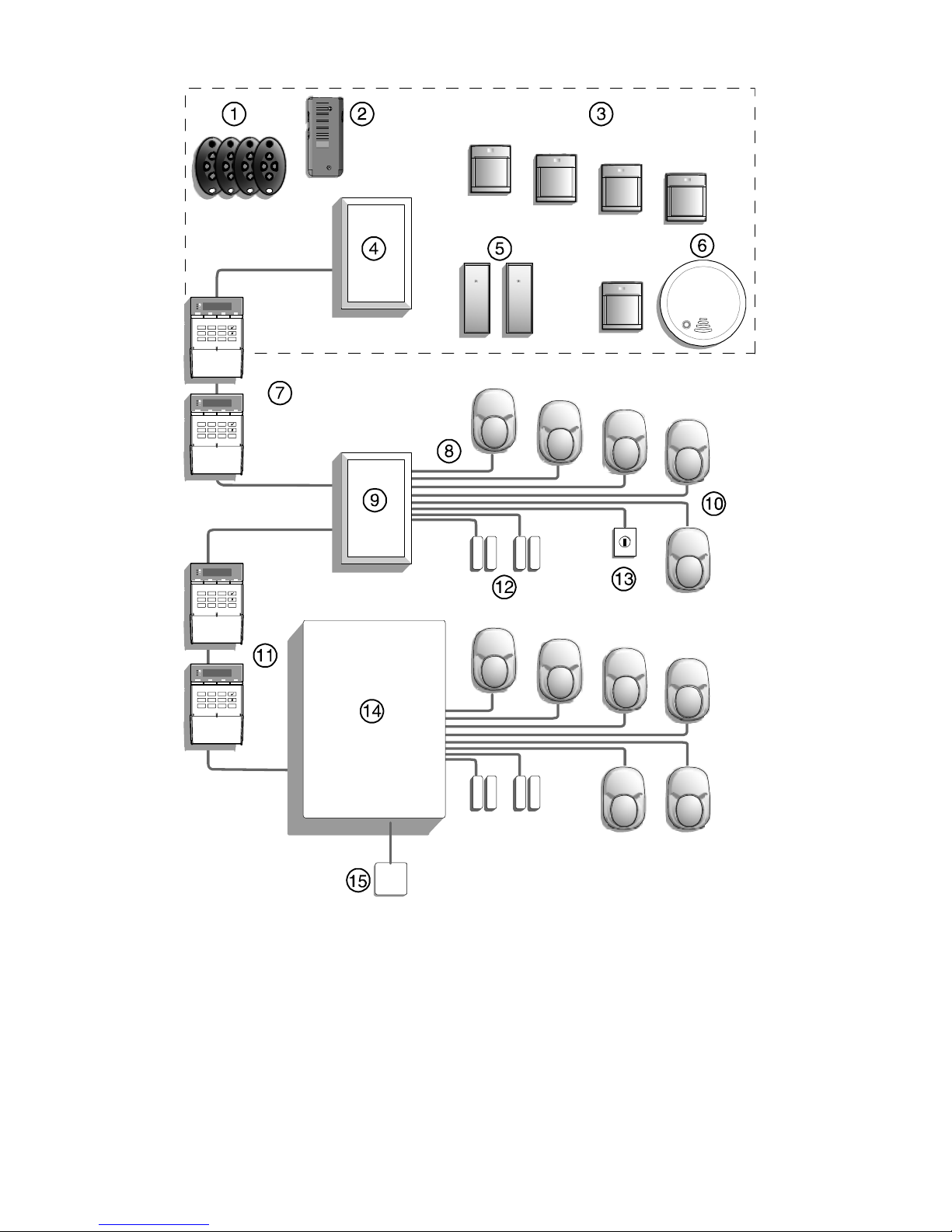

Elements of the IAS

An IAS comprises a control unit in a shielded case, with 1 to 4 separate

keypads and various detectors, transmitters and other devices connected to

programmable zones. If required, a keyswitch can be connected to a zone.

Each control unit has zone connectors on its printed circuit board (PCB).

Separate expanders enable more zones to be connected: each hardwired

expander adds up to 8 wired zones and each radio expander adds up to 8 or

16 wirefree zones (depending on the model used).

The control unit has 8 zones as standard, expandable to a maximum of 24.

Figure 1 shows how these elements are connected. In this example, the

control unit (14) is directly connected to 6 detectors and 2 door contacts.

Further zones are then connected to it through a hardwired expander (9) and

a radio expander (4). There are 4 keypads (7 and 11) on the bus.

Page 8

1. Introduction 9751 Installation Guide

Page 4 11976798

ABCD

123

456

7890

ABCD

123

456

7890

ABCD

123

456

7890

ABCD

123

456

7890

1. 723r EUR Telecommand 9. 9954 hardwired expander

2. 726r EUR PA 10. Passive Infra Red detectors

3. 714r EUR wirefree Passive Infra Red detectors 11. Keypads

4. RFX radio expander 12. Door contacts

5. 735r EUR universal transmitter 13. Keyswitch

6. 720r EUR smoke detector 14. Control unit

7. Keypads 15. Fused mains spur

8. Wired detectors

Figure 1. Elements of an Intruder Alarm System

Page 9

9751 Installation Guide 1. Introduction

11976798 Page 5

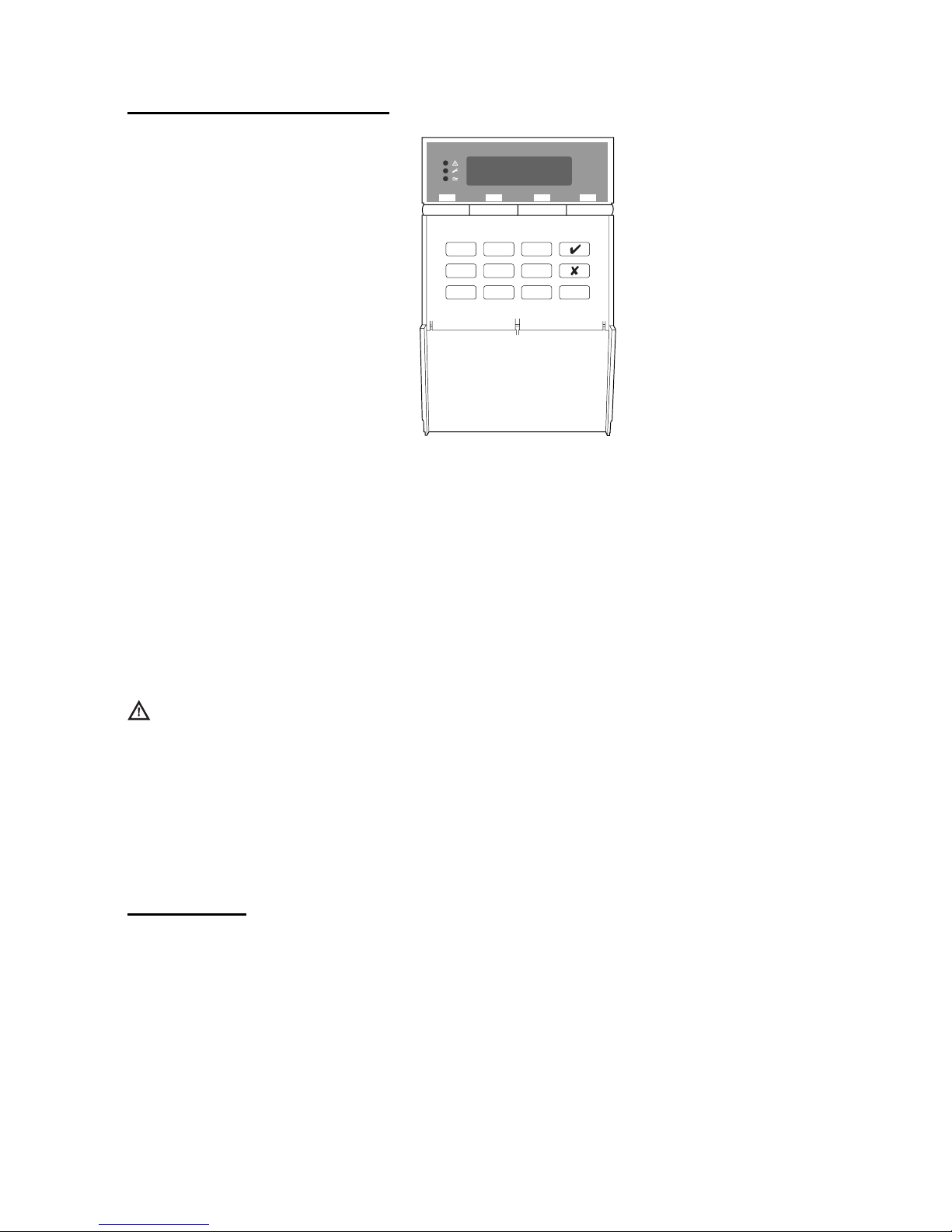

9941 and 9943 Keypads

AB CD

123

456

7890

Figure 2. 9941 and 9943 Keypads

The control unit supports the connection of 9941 and 9943 keypads. The

9943 has a built-in wide-area proximity reader and connections for an external

panic alarm switch. Both have a two-line 16-character Liquid Crystal Display

(LCD) that can display alarm information, programming settings and other

information. There are three LEDs that have the following functions.

Note: Depending on how the system is set up, the LEDs may not operate until

a user code is presented.

Alert lamp – Flashes to highlight unacknowledged alert, glows for

acknowledged conditions, and goes out when all conditions have

been rectified.

s Service lamp – Glows if the system needs an installer reset.

a Mains lamp – Glows when using mains power. Flashes when using

the stand-by battery.

Expanders

You can attach up to two hardwired or radio expanders to the control unit to

expand the number of zones to a maximum of 24. You can use a combination

of the two types.

Hardwired Expanders

The 9954 hardwired expander enables you to connect wired detectors to the

control unit. Wired detectors can be connected in the following ways:

1. Four-wire Closed Circuit Loop (CCL).

Page 10

1. Introduction 9751 Installation Guide

Page 6 11976798

2. Two-wire Fully Supervised Loop (FSL).

Radio Expanders

° 703r. Four channel programmable transmitter, when used in two door

contact mode only.

° 710r. A compact, long range, two button PA transmitter.

° 713r and 714r. These are Passive Infra-Red (PIR) movement detectors.

The 713r has a detection range of 10m and is pet tolerant (up to 25kg size

animals). The 714r has a greater radio range, and has a detection range of

at least 15m. The detectors have a three-minute lockout time after

detection, which lengthens battery life.

° 720r. A smoke detector.

° 722r/727r. A keyfob sized telecommand with two button PA transmitter (not

PD6662 compliant). The 727r version uses encrypted codes.

° 723r/728r. Remote setting device (also known as a "telecommand") that

can be used to full set, part set or unset the system. The 728r version uses

encrypted codes.

° 726r. A hand held radio transmitter that can be used to start a PA.

° 734r. A universal transmitter that can be used as a door contact or for

connecting hardwired inputs.

° 738r. A Spyder shock sensor with transmitter.

° 739r. A radio transmitter that fits into a break-glass detector. The -00

version is the transmitter only. The -50 version comes with a break glass

detector.

° 790r. A Radio Strength Monitor, which can be used in conjunction with a

734r.

The RFX08 radio expander can handle eight wireless detectors, while the

RFX16 can handle 16 detectors. The units support eight Telecommands

and/or PA transmitters in addition to the eight or 16 radio detectors.

The radio expanders communicate with the control unit using the same wiring

as the keypads. The radio detectors operate on 868.6625MHz, which is a

dedicated frequency for intruder alarms and reduces the possibility of

interference from other radio services.

Each radio detector and remote setting device contains a digital identity code

that the RFX unit "learns" during installation. The code is one of over 16

million possibilities. This ensures that the RFX unit will not respond to any

other detectors or remote setting switches apart from the ones it has learned.

For more information, refer to the appropriate "Installation and Programming

Guide" for the radio expanders you are using.

Page 11

9751 Installation Guide 1. Introduction

11976798 Page 7

Partitioned or Single System

During installation, the Installer can configure the system as a single system

or as a partitioned system.

In a single system, the control unit has one full set level (security level A) and

three part set security levels (levels B, C and D). Users can set only one level

at a time. Level A sets the whole system. Levels B, C and D set parts of the

system. The Installer allocates zones to levels, but all keypads operate the

entire system. There is only one sounder output for the whole system, and

you can use a loud-speaker for setting tones and local alarms. All users

belong to the whole system.

When working as a partitioned system, the control unit effectively provides

four smaller alarm systems. Within a partitioned system:

• Each partition can be set, unset or in alarm independently of the others.

• You can assign individual keypads to one or more partitions. The keypads

can only set or unset the partitions to which they are assigned.

• Each partition can have its own Bell and Strobe Set output.

• Zones can be assigned to more than one partition; for example, an entry

door zone may be shared by several companies using separate partitions.

You can set up the control unit as a single or partitioned system using

Command 98 (this will also restore the control unit to factory defaults).

For an overview of the programming steps required to set up a partitioned

system, see Chapter 4 in the Programming Guide.

User Control

The control unit provides 50 independent User access codes and a separate

Duress Code. Users can change these codes at any time but cannot use

them to program the system. During installation, the Installer can select

whether access codes use four or six digits.

Page 12

1. Introduction 9751 Installation Guide

Page 8 11976798

Page 13

11976798 Page 9

2. TECHNICAL DESCRIPTION

Control Unit Specification

General

Environmental Class 2

Security EN50131-1 or PD6662 Grade 2

Operating temperature -10° to +55°C

Humidity 96% RH

Dimensions 235mm W, 245mm H, 90mm D

Weight 3.3 kg

Internal Clock ±10 minutes over one year (depending on the

accuracy of the mains supply frequency).

Radio detector differs 16,777,214 (2

24

-2)

Suitable for use in a system that is designed to comply with EN50131-1,

ACPO-IAS Policy, NSI NACP14.

This equipment is compliant with EN 50136-2-1 and EN 50136-2-2. It allows

the alarm transmission system to meet the performance requirements of

prEN 50131-1: 2004 ATS 2 provided that:

a) It is installed in accordance with the installation instructions.

b) The connected PSTN is functioning normally.

c) The ARC is adequately equipped.

Power Supply

All currents accurate to ±5%.

Mains power supply 230VAC +10%/-15%, 200mA max, 50Hz ±5%

System power supply Type A. 13.8VDC, 1.0A

Battery charge current limit 250mA

To comply with the requirements of EN50131, the total current taken from the

power supply, not including the battery recharge current, but including

auxiliary outputs and other devices, must not exceed 750mA.

Nominal power requirements (DC):

9751 130mA quiescent, 220mA active

9941 20mA quiescent, 60mA backlight on

9943 30mA quiescent, 70mA backlight on

9954 20mA typical, 30mA maximum

RFX08/16 55mA

Page 14

2. Technical Description 9751 Installation Guide

Page 10 11976798

Standby battery (not supplied) 12V rechargeable lead-acid, gel-type battery.

Low battery voltage cutoff = 10V.

Recommended manufacturers: Yuassa, Yucel

or Fiamm.

Note: Grade 1 and 2 compliance requires the control unit to continue for a

minimum period of 12 hours on a standby battery. To calculate the

minimum capacity battery to achieve this requirement, determine the

total current taken by external devices and the control unit and multiply

by 12. Cooper Security Ltd recommend that you fit at least a 7Ah battery.

Note that a 17Ah battery cannot fit inside the case.

Outputs

OP 1, 2, 3 Open-collector transistor outputs, 500mA,

12VDC, negative applied.

LS Supports two parallel-connected, externally

mounted loudspeakers for internal sounder or

EE tones: minimum speaker impedance 16Ω.

AUX 500mA, 12VDC minimum, 13.8VDC

maximum, ripple ±2% maximum.

Communications outputs 12V logic outputs, negative applied in alarm

(positive removed), 50mA maximum.

Inputs

TR Tamper return for Bell

Tellback/Remote reset** +12V applied to operate reset.

Line Fault input** +12V applied to indicate line failure.

** These inputs appear as pins on the connector for the plug-by

communicator. See page 33.

Fuses

The control unit uses fast-acting polyswitch fuses for overcurrent protection:

F1 – 12V AUX output F2 – Battery output

F3 – Bus 1

Note: Polyswitch fuses automatically reset when the load is entirely removed.

The control unit uses a T-250mA mains fuse.

Page 15

9751 Installation Guide 2. Technical Description

11976798 Page 11

Compatible Equipment

703rEUR-00 Programmable four channel transmitter

710rEUR-00 Long range, compact, dual button PA transmitter

713rEUR-00 Pet tolerant wireless PIR detector (10m range)

714rEUR-00 Wireless PIR detector (15m range)

720rEUR-00 Wireless Smoke Detector

722rEUR-00 Wireless, key fob, two button PA (PD6662:2004 non

compliant)

723rEUR-00 Wireless remote setting device (telecommand)

726rEUR-50/60 PA transmitter

727rEUR-00 Encrypted code, key fob, two button wireless PA

(PD6662:2004 non compliant)

728rEUR-00 Encrypted code wireless remote setting device

726rEUR-00 Two-button handheld wireless panic alarm (PA)

734rEUR-00 CC door contact transmitter

734rEUR-01 FSL door contact transmitter

738rEUR-00 Wireless Spyder shock sensor (-01 version brown case)

739EUR-00 Central break glass detector transmitter interface.

739EUR-50 Glass break detector transmitter

790rEUR-00 Radio strength monitor

Proxtagpk5 Pack of five proximity tags

958EUR-00 Windows Mk3 Downloader PC software

9941EN LCD keypad without PROX interface

9943EN LCD keypad with built in PROX detector

9954EN-00 Hardwired 8-Zone Expander (supports three-resistor anti-

masking)

RFX-08 868MHz "Class VI" Radio Expander (8 Zones)

RFX-16 868MHz "Class VI" Radio Expander (16 Zones)

XCELR Wireless PIR detector (12m range)

XCELRPT Wireless PIR detector (per tolerant)

XCELW Wired PIR detector (12m range)

XCELWPT Wired PIR detector (pet tolerant)

Page 16

2. Technical Description 9751 Installation Guide

Page 12 11976798

Control Unit PCB Layout

Figure 3 shows the layout of the PCB used in the control unit.

3

1

2

4

5

6

7

9

8

10

11

12

1. Outputs (3 open collector outputs) 8. NVM Reset pins

2. AUX power 9. Plug-by (standalone) communicator connector

3. Lid tamper switch 10. Battery connector

4. Zone connectors 11. Kick Start pins

5. Keypad and expander bus (bus 2 not fitted) 12. 21VAC from transformer

6. Telephone line terminals for built-in communicator

7. Telephone line socket for built-in communicator

Figure 3. Control Unit PCB Layout

Page 17

11976798 Page 13

3. INSTALLATION

Caution: Always remove mains power before opening the case lid. Do

not work inside the control unit with mains power present.

Overview

A typical installation comprises the following main steps:

1. Survey the site and decide on positions for wired detectors, 9954 wired

expanders, control unit, keypads, external and internal sounders. As part

of the survey ask the users what facilities they need.

2. If you are going to use wirefree detectors, carry out a radio site survey

and decide on positions for the wirefree detectors and the radio

expanders. For more information, refer to the "Installation and

Programming Guide" for the expander you are using.

3. Ensure that there is a suitable mains supply present at the site of the

control unit.

4. If you are going to use a communicator, arrange for a PTT (Public

Telephone and Telegraph) connection point near to the control unit.

5. Install the wired detectors and run cables to the site of the control unit or

9954 wired expanders. Connect each detector to its cable.

6. Run cables from the sites of the keypads, expanders, and external and

internal sounders to the site of the control unit.

7. Install keypads and expanders, and connect them to their cabling.

Ensure that each one has the correct address setting.

8. Install internal and external sounders and connect them to their cabling.

9. Install the control unit and connect it to the mains supply cabling. Do not

apply power at this point.

10. At the control unit, complete all connections to keypads, expanders and

sounders.

11. Apply power and program the control unit.

12. Let the radio expanders learn the wirefree detectors and then install the

detectors at their selected sites.

13. Test that the intruder alarm system operates as required.

14. If required, install a communicator, connect it to the PTT network and

check that it operates correctly.

15. Hand the system over to the users and instruct them in its use.

Page 18

3. Installation 9751 Installation Guide

Page 14 11976798

Cabling for Keypads and Expanders

Cooper Security recommends that you use 8-core 7/0.2 or 16/0.2 alarm cable

for wiring keypads and expanders. You can connect the keypads and

expanders in either a star or bus configuration (see Figure 4). If you intend to

use long cable runs, Cooper Security recommends that you use star wiring

with no more than 200m of cable per branch.

Control Unit

Keypads or expanders

Distribute devices along

cable for better performance.

200m

200m 200m

200m200m

Figure 4. Star and Bus Wiring for Keypads and Expanders

The maximum length of any one run from the control unit to the most remote

keypad or expander depends on the number of items connected to the cable.

You can double the maximum length for 7/0.2 cable by using two cores each

for the 0V and 12V terminals or by using 16/0.2 cable. The table below shows

the maximum recommended cable lengths in metres for 7/0.2 cable,

assuming that you connect all items at the end of a single cable run. (An item

is either a keypad or an expander.) You may be able to improve on these

figures by spreading items along the cable length (Figure 4).

8-core 7/0.2 cable

Number of items 1 core 2 cores on 0V and 12V

One 200 –

Two 100 200

Three 65 130

Four 50 100

Five 40 80

Six 33 66

Seven 28 56

Eight 25 50

Page 19

9751 Installation Guide 3. Installation

11976798 Page 15

It is possible to extend the keypad cable run by using additional power

supplies, but only up to the recommended maximum of 200m.

When carrying out the cabling, there are two important points to remember:

1. Do not connect anything other than keypads or expanders to the bus. The

keypad bus power supply is limited to a maximum of 400mA.

2. Check between 0V and 12V on the keypad bus at the point furthest from

the control unit: the voltage must be at least 12.0VDC when all the keypad

backlights are on.

Note: The following instructions assume that you have already run all the

necessary cabling.

Page 20

3. Installation 9751 Installation Guide

Page 16 11976798

Fitting the System

Fitting the Control Unit Case

1. Remove the control unit case from its packaging.

2. Remove the front screws and slide off the case lid.

3. The upper part of the case back has a central keyway. Mark and drill a

hole for the keyway. Temporarily fix the case back to the wall. Mark the

position of two more fixing holes, remove the case back and drill the

holes.

4. Refit the case back to the wall using screws no less than 30mm x No 8,

with dome or pan heads.

Fitting a 9941 or 9943 Keypad

Note: If you are fitting more than one 9943 keypad to a control unit then make

sure that there is at least 1m distance between individual 9943 keypads.

Beware of mounting 9943’s back to back on opposite sides of a wall.

When 9943 keypads are closer than 1m to each their prox tag readers

interfere, and neither keypad can read prox tags.

Figure 5 shows the backplate and the position of mounting holes.

3

4

1. Cable entry. 3. Back tamper aperture.

2. Fixing holes. 4. Sounder aperture.

Figure 5. Backplate of the 9941/9943 Keypad

Cooper Security recommend that you mount the keypad using No 8 or 6

screws (M4/M3.5) as follows:

1. Select which cable entry you are going to use and break out the

appropriate plastic sections.

Page 21

9751 Installation Guide 3. Installation

11976798 Page 17

2. Hold the backplate in place against the wall and mark the position of one

fixing hole.

3. Drill and plug the hole, and screw the backplate to the wall. Do not

tighten the screw completely home.

4. Make sure the backplate is level and mark, drill and plug another fixing

hole. Tighten the fixing screws.

6. Mount the front of the keypad (containing the keypad pcb) onto the

backplate and make sure that the tamper switch operates.

Wiring the Control Unit

Cable Entries

The control unit case back provides several cable entries. It is designed to

stand away from the wall to leave space for the cables.

Mains Connection

Connect the control unit to a suitable supply using a double pole disconnect

device in accordance with EN60950-1:2001 Clause 3.4.3. Connect the supply

to the control unit using the 3-way terminal block located on the case back.

Secure the cable to the case anchor point using the cable tie provided.

Notes:

1. The control unit has a T-250mA internal mains fuse.

2. All electrical connections should be carried out by a qualified

electrician.

To Control Panel

Transformer

L

N

T 250mA 250V

230V ~50Hz 200mA

Figure 6. Mains Connection

Connect the 21VAC lead from the mains transformer to the main PCB. See

Figure 3 for the location of the 21VAC connector.

Page 22

3. Installation 9751 Installation Guide

Page 18 11976798

Caution: Do not apply mains power at this point. Do not work inside the

control unit case when mains power is present.

Keypads

Connecting Keypads

Figure 7 shows the connections for keypads. Use the "ET" connector

terminals on the keypad PCB to connect an exit terminate button or lock

switch. If you are using a lock switch, do not connect any other devices to

these terminals.

9941,9943 Keypad

Figure 7. Keypad Connections

The 9943 keypad can be connected to an external panic attack button, as

shown in Figure 8. If the panic attack does not contain a tamper switch, link

the pair of "EXT TAMPER" terminals. Separately link both pairs of terminals if

no panic button is used.

Figure 8. 9941, 9943 Panic Attack Connections

Note: Wired PA switches connected to the keypad work only with software

version 4.03.05 onwards.

Page 23

9751 Installation Guide 3. Installation

11976798 Page 19

Keypad Addressing

The control unit is supplied with one keypad. If you have fitted more keypads,

each one must be given a separate "address". Links LK2 to LK4 set the

keypad address, as shown in Figure 9.

2

3

4

ON

BACKLIGHT

2

3

4

2

3

4

2

3

4

2

3

4

ON

BACKLIGHT

ON

BACKLIGHT

Keypad 1

Address

Backlight ON Backlight OFF

Keypad 2

Keypad 3 Keypad 4

Figure 9. Keypad Addressing

Backlight

When supplied from the factory, the control unit is configured with the

backlight On. To turn the backlight Off, remove the jumper from the "ON

BACKLIGHT" link, shown in Figure 9.

Connecting Sounders

Figure 10 and the following tables show the wiring required to connect the

external sounder (bell box) and optional internal sounders.

Note: If a 2k2 resistor is fitted at the tamper return (TR) terminal at the bell

box, use Command 59 to select this EOL mode of termination.

Note: The ST terminal on the control panel PCB is the Siren Test output for

France only. Do not connect it to the strobe input on the external sounder.

See Command 81 in the Programming Guide and the output wiring examples

on page 27.

Page 24

3. Installation 9751 Installation Guide

Page 20 11976798

To Bell Box

16 Ohm Loudspeaker

(2 Max. in parallel)

Internal Sounder

6-core

OP1

OP2

12V AUX

0V

TR

LS

+

Figure 10. Sounder Connections

Lyntech Ltd - 120 LED/120 lexon

Control Unit

Terminals

OP1 OP2 TR 12V AUX 0V

Bell-Box

Terminals

TRG STRB HOLD +

Elmdene Rapier 300, 4000, 5000, 6000; Prima 100-600; Starlight 020

Control Unit

Terminals

OP1 OP2 TR 12V AUX 0V

Bell-Box

Terminals

-R -ST RTN +H -H

CQR Security - Sigma, Cequera, Plus and Ultima

Control Unit

Terminals

OP1 OP2 TR 12V AUX 0V

Bell-Box

Terminals

SIREN

TRIG

STROBE

TRG

A/T RET

SIG

HOLD OFF

+VE

HOLD

OFF -VE

Ventcroft Security - Vision, Classic and Spirit

Control Unit

Terminals

OP1 OP2 TR 12V AUX 0V

Bell-Box

Terminals

TRIG - STB - RTN HOLD OFF

+VE, STB

+VE

HOLD

OFF -VE

Flashguard - Xtra

Control Unit

Terminals

OP1 OP2 TR 12V AUX 0V

Bell-Box

Terminals

TRIGGER STROB- SUPPLY - SUPPLY +

STROBE +

TAMP

OUT

Intellisense - AG3

Control Unit

Terminals

OP1 OP2 TR 12V AUX 0V

Bell-Box

Terminals

S- ST- TR V+ V-

Page 25

9751 Installation Guide 3. Installation

11976798 Page 21

Connecting Detector Circuits to the Main PCB

The connectors for the detector circuits, or zones, are on the left-hand edge of

the main PCB in the control unit. The table below summarises the number

and type of zones that can connect to the main PCB of the control unit. Use

Command 21 to specify which of these wiring types you are using. You

cannot specify different wiring types for different zones.

If you require more zones, fit one or more expanders as explained on page

22). There can be up to 16 zones on expanders.

Control Unit Wiring Type

Zones

8 four-wire CCL with common tamper

8 two-wire FSL

CCL Connections

Figure 11 shows how to connect four-wire CCL zones.

1

2

Zone 1

Zone 2

Global Anti-tamper

Zone 3

Zone 4

Zone 5

Zone 6

Zone 7

Zone 8

Tamper loop

Zone 1

Zone 2

Alarm contacts

Alarm contacts

Figure 11. CCL Connections (common tamper)

NOTE: If you use CCL wiring then you must program zone 1 as Normal Alarm

(see 9x5x Programming Manual) and fit a wire link to Zone 1 terminals in

order to enable the global tamper.

FSL Connections

Each FSL zone is a "Fully Supervised Loop" using a two-wire closed loop. As

shown in Figure 12, the loop uses resistors of different values to differentiate

between "Circuit" and "Tamper" signals: a 2K2 resistor fitted in series at the

end of the wired loop (EOL) and a 4K7 resistor fitted across the alarm contact.

With the loop in a normal state and the alarm contacts closed (shorting out the

4K7 resistor), the total resistance of the loop is 2K2. When the alarm contacts

open (removing the short from the 4K7 resistor), the resistance of the loop

increases to 6K9 and so the control unit detects an alarm condition. If a

Page 26

3. Installation 9751 Installation Guide

Page 22 11976798

tamper device opens, the loop resistance becomes infinite (open circuit) and

so the control unit detects a tamper signal.

To connect a detector to an FSL loop, you must wire suitable high-tolerance

resistors to the detector. Always check resistor colour coding and tolerance

before wiring resistors into circuit (see Figure 13).

The wiring resistance of the cable to the detector (including joints) should not

exceed 100 ohms. The recommended maximum cable length within a zone is

200–300m.

Zone 1

Zone 2

1

2

2K2 EOL

4K7

Alarm contacts

Tamper contacts

2K2 EOL

4K7

Alarm contacts

Tamper contacts

Figure 12. FSL Connections

Yellow

Violet

Red

Gold

4k7

Red

Red

Red

Gold

2k2

Figure 13. Colour Code for FSL Resistors

Anti-Masking Zone Connections

Note: Connecting an anti masking detector to the 9752 does NOT make the

9752 a Grade 3 control unit.

Page 27

9751 Installation Guide 3. Installation

11976798 Page 23

Some PIR detectors are fitted with an anti-masking facility to detect cases

where the detector has been obscured. Depending on the type of detector,

the masking status is conveyed by one of two methods:

• Method 1: Using two pairs of contacts at the sensor. One pair reports the

alarm/tamper status and the other reports the anti-masking status. This

method requires two adjacent zones to be used at the 9751 control unit

(one for each pair of contact at the sensor), with the highest zone number

for anti-masking. For example, you could use zones 3 and 4, and in this

case, zone 3 must connect to the alarm/tamper contacts, and 4 to the antimasking contacts. The anti-masking zone (zone 4 in this example) must be

programmed as type "Anti-Mask". The alarm/tamper zone could, for

example, be programmed as type "Normal Alarm".

The anti-masking contacts from the sensor can connect to the 9751 using

the CCL, FSL or EOL connection method. In the case of FSL, there would

be no in-line tamper contacts (just the 2K2 end-of-line resistor and the 4K7

resistor across the anti-masking contacts). In the case of CCL, the zone's

tamper terminals at the 9751 must be shorted.

• Method 2: Applying a specified resistance value to a zone. The zone must

be wired as shown in Figure 14.

Note: Depending on the sensor, a 4K4 resistance means either

"masked" or "fault". Use command 88 to specify which reporting method

to use. All sensors with anti-masking contacts must use a 4K4 resistance

for the same meaning (masked or fault).

Short Circuit Tamper Alarm

Open Circuit Tamper Alarm

Zone

Resistance

Healthy

Sensor

failure/Fault/Masked

Masked

Alarm

9.1k

2.2k

4.4k

6.9k

2K2

2K2

2K2

2K2

4K7

4K7

Tamper

Zone 1

Zone 2

Tamper

Alarm

Alarm

Anti-mask

Anti-mask

Figure 14. Wiring Zones that use Anti-Masking

Page 28

3. Installation 9751 Installation Guide

Page 24 11976798

Connecting Expanders

9954 Hardwired Expander

The 9954 hardwired expander provides connectors for eight CCL, FSL or EOL

zones (EOL zones are not relevant for the 9751). Figure 15 shows the layout

of the PCB. See the wiring diagram supplied with the 9954 hardwired

expander for more details.

0V 12V CLK DATA

FSL

EOL

AT5

AT6

CCT5

CCT6

AT7

AT8

CCT7

CCT8

2

3

4

AT1

AT2

CCT1

CCT2

AT3

AT4

CCT3

CCT4

FSL

EOL

Four-wire CC

Two-wire FSL

Two-wire EOL

1

2

3

4

5

7

6

1. Zone connectors 5. Address jumpers

2. Lid tamper switch 6. Zone connectors

3. Spare connectors (not connected) 7. CCL/FSL/EOL

4. Keypad bus

Figure 15. 9954 Expander

RFX08/RFX16 Radio Expander

The RFX08/RFX16 are Class VI radio expanders. Class VI is the grading

given by the British standard for Wirefree Alarm Systems and is required for

signalling systems that require a police response. It receives signals from the

radio detectors on a frequency of 868.6625MHz.

The RFX08 radio expander supports eight wirefree zones, while the RFX16

supports 16. Figure 16 shows the layout of the PCB in both models.

Page 29

9751 Installation Guide 3. Installation

11976798 Page 25

0V 12V CLK DATA

12

14

15

11

8

10

7

9

13

5

6

3

4

2

1

1. Red "Fail" LED 9. Radio section

2. Green "Pass" LED 10. Learn sensor

3. Sounder 11. Supervision jumper

4. 2 x 7-segment display 12. Jamming response jumper

5. Select button 13. Address jumpers

6. Delete button 14. Bus connector

7. Built-in aerial 15. Cable entry

8. Tamper switch

Figure 16. RFX08/RFX16 Radio Expander

Refer to the "Installation and Programming Guide" of each version for more

details.

Connecting an Expander

Figure 17 shows how to connect an expander to the control unit.

0V 12V CLK DATA

To other keypads

12V

0V

DATA

CLK

Expander

Control Unit

Figure 17. Connecting an Expander

Page 30

3. Installation 9751 Installation Guide

Page 26 11976798

When fitting a 9954 hardwired expander, make sure that you place the jumper

link on the expander in the correct position to select either four-wire CCL, or

two-wire FSL (see Figure 18).

FSL

EOL

Four-wire CC

Two-wire FSL

Figure 18. Link Positions to Select Wiring Method

Once you have connected an expander, refer to the instructions supplied with

it for connecting hardwired detectors or "learning" radio detectors as

appropriate.

Addressing Expanders

If you fit expanders, you must allocate each expander to a specific range of

zone numbers. Do not allocate two expanders to the same range of zones.

Select the zone numbers by fitting a jumper link to one pair of the set of pins

marked "Address" on the expander PCB, as shown in Figure 19.

2

3

4

2

3

4

Zones 9 to 16

Zones 17 to 24

Figure 19. Link Positions to Allocate Expanders to Zones

Note: Other link positions are not valid for the control unit.

Programming Outputs

Control unit outputs can be programmed using the commands shown in the

table below. Open collector outputs are of a "pull down" type that provides

negative-applied control signals; the system adjusts the output polarity when

you select the output type.

Output Type Command

OP1 open collector 81

OP2 open collector 82

OP3 open collector 83

Figure 20 shows some examples of applications for open collector outputs

(OP3 is used in these examples).

Page 31

9751 Installation Guide 3. Installation

11976798 Page 27

OP3

+ve 12V Aux

Shock Sensor Reset

Use Command 83 4

VIPER

+ve

0V

OP3

+ve 12V Aux

Bell Follow Buzzer/Relay

Use Command 83 0

Relay energises/buzzer sounds

when bell activates.

BUZZER/RELAY

OP3

PIR Set Latch/Walk Test

For:

Set Latch use Command 83 3

Walk Test use Command 83 5

PIR

Figure 20. Wiring Examples for Open Collector Outputs

Wiring Keyswitches

To allow a user to set and unset the system using a keyswitch, connect a

fixed position or spring loaded (momentary) key switch to a zone input. When

programming the control unit select zone type (KM) for momentary or (KF) for

fixed position keyswitches. See Command 185 for keyswitch auto-reset.

Figure 21 shows the connections for a keyswitch.

Fixed Keyswitch (KF)

Keyswitch CC FSL System

OFF Closed 2k2 Unset

ON Open 6k9 Set

Momentary Keyswitch (KM)

Keyswitch CC FSL System

Operate Close-Open-

Close

2k2-6k9-2k2 Unset

Operate Close-Open-

Close

2k2-6k9-2k2 Set

Figure 21. Connecting a Keyswitch

Note:

If you connect a keyswitch as a zone it can be used to set and unset the

level to which the zone is assigned.

4k7

2k2

CC Wiring CCT(n)

CCT(n)

FSL Wiring

Page 32

3. Installation 9751 Installation Guide

Page 28 11976798

Communicator

Connecting the Communicator

The control unit has an internal communicator on its main PCB. This is an

auto-dialling modem.

If necessary, a standalone communication device can be connected through a

wiring harness to interface pins on the main PCB (this is known as a plug-by

communicator).

The communicator can be used for:

• Transmitting alarm signals to alarm receiving equipment at a central

monitoring station using Scancom Fast Format, Scancom SIA (Security

Industry Association) or Contact ID (set with Command 103).

• Connecting to a PC based at a remote engineering centre. Using

Scantronic Downloader software, the remote PC can upload and download

system parameters (including the event log and diagnostics), set and unset

the alarm system, and carry out other special functions.

Telephone Line

Ideally, the internal communicator should be connected to an ex-directory line

used exclusively for alarm communications.

If an exclusive line is not available and other apparatus is connected to the

line (for example, an answer machine), the internal communicator provides a

series connection with line divert for the other apparatus. When triggered, the

communicator seizes the line and disconnects the other apparatus. When the

communicator shuts down, it reconnects the other apparatus.

Three-way Calling

The control unit provides a three-way calling facility to make sure the internal

communicator can always use a shared telephone line.

To use this facility, the local exchange must provide the three-way calling

service on the customer's line.

Line Monitoring for the Internal Communicator

The control unit provides a line monitoring function to check that a telephone

line connected directly to the control unit is working, and to indicate a line

failure if it is not. While enabled, this function continually checks the line

voltage to ensure that the line is connected. If it detects a failure, the system

gives the Line Fault Response selected with Command 106.

Page 33

9751 Installation Guide 3. Installation

11976798 Page 29

Test Calls

The control unit can be programmed to make test report calls to an ARC.

"Static" test calls can be programmed to occur at set times or intervals.

"Dynamic" test calls occur 24 hours after the last call made by the unit. See

the Programming Guide for details on how to program these functions with

Commands 105 and 108.

Statutory Information

Applications

The built-in communicator is suitable for connection to the following types of

networks:

(a) Direct exchange lines (PSTN) supporting DTMF (tone) dialling.

(b) PABX exchanges (with or without secondary proceed indication).

Note: The built-in communicator is not suitable for connection as an extension

to a pay-phone or to 1 + 1 carrier systems.

Approval

The built-in communicator is manufactured to meet all European Economic

Area telecommunication networks requirements. However, due to differences

between the individual PSTNs provided in different countries, the approval

does not, of itself, give an unconditional assurance of successful operation on

every PSTN network termination point.

The built-in communicator has been approved for the following usage:

(a) Automatic call initialisation.

(b) Operation in absence of indication to proceed.

(c) Automatic dialling.

(d) Modem.

(e) Serial connection.

(f) Multiple repeat attempts.

(g) Line status monitoring.

Usage other than approved usage or failure to comply with the installation and

programming instructions may invalidate any approval given to the apparatus

if, as a result, the apparatus ceases to comply with the standards against

which approval was granted. Note the approval label on the main PCB.

In the event of problems you should contact your equipment supplier in the

first instance.

Page 34

3. Installation 9751 Installation Guide

Page 30 11976798

Ringer Equivalence Number

The Ringer Equivalence Number (REN) of the built-in communicator is 1. As a

guide to the number of items that can be simultaneously connected to an

exclusive line, the sum of the REN values should not exceed 4. A standard

telephone (as provided, for example, by BT in the UK) has a REN value of 1.

Safety Notice

Figure 22 identifies connectors for Safety Extra-Low Voltage (SELV) and

Telecommunications Network Voltage (TNV) circuits on the control unit's main

PCB. These terms are used in accordance with the definitions in Safety

Standard EN60 950.

The Installer must ensure that TNV terminals are connected only to other

circuits designated as TNV circuits (for example, the PTSN) and that SELV

terminals are connected only to other circuits designated as SELV circuits.

Strict adherence to the installation instructions will ensure that the equipment

continues to comply with the safety regulations to which it was approved.

Page 35

9751 Installation Guide 3. Installation

11976798 Page 31

1

2

3

4

5

6

7

1. Main connector (SELV) 5. Wire in comms connector (SELV)

2. Keypad connector (SELV) 6. Battery connector (SELV)

3. Telephone line connector (TNV) 7. 21VAC from transformer (SELV)

4. RJ11 connector (TNV)

Figure 22. SELV and TNV connectors

Page 36

3. Installation 9751 Installation Guide

Page 32 11976798

Connecting the Telephone Line

Connecting the telephone line directly to the terminals on the internal

communicator, or indirectly through other apparatus, can produce hazardous

conditions on the telephone network. Always seek advice from a competent

telephone engineer if in any doubt about connecting to these terminals.

Example – connecting a line in the UK:

The internal communicator must be connected to the PABX system by:

a) If the wiring is owned by British Telecom:

British Telecom.

b) If the wiring is not owned by British Telecom, one of:

(i) British Telecom.

(ii) The authorised maintainer.

(iii) A professional Installer, after 14 days written notice to the

authorised maintainer.

To connect the telephone line:

a) If the telephone line is already terminated with a suitable lead and plug:

Insert the plug into the RJ11 connector.

b) Otherwise (see Figure 23):

(i) Using a two-core telephone cable, strip off 5mm and feed the cable

through one of the entries in the rear of the control unit. Connect

the two cores to terminals A and B on the main PCB.

(ii) Connect the other end of the two cores to the corresponding

terminals on the BT master box.

(iii) If other apparatus is to share the telephone line with the internal

communicator (in series), connect the main apparatus to the series

switched line connections marked A1 and B1.

Caution: Only one such series apparatus is allowed to be connected

between a main apparatus (such as a telephone) and the PSTN.

Ensure that the A and B lines are connected the right way around. The

internal communicator continuously monitors the line for ringing tones.

5 or A

2 or B

Primary

Line

Diverted

Line

A

B

B1

A1

BT master Box

(Exclusive Line)

Telephone line to other equipment

for example: Fax, answer machines.

Figure 23. Connecting the Internal Communicator

Page 37

9751 Installation Guide 3. Installation

11976798 Page 33

Fitting a Plug-by Communicator

The control unit can be fitted with a communicator or speech dialler (for

example, the Scantronic 8400, 8440, 660 or RedCare STU). Figure 24 shows

the connections for the communications wiring harness.

Comms O/P1 (Brown) -ve applied (+ve removed) in alarm

Comms O/P2 (Orange) -ve applied (+ve removed) in alarm

Comms O/P3 (Yellow) -ve applied (+ve removed) in alarm

Comms O/P4 (Green) -ve applied (+ve removed) in alarm

Comms O/P5 (Blue) -ve applied (+ve removed) in alarm

Comms O/P6 (Purple) -ve applied (+ve removed) in alarm

Comms O/P7 (White) -ve applied (+ve removed) in alarm

Comms O/P8 (Grey) -ve applied (+ve removed) in alarm

Line Fail input (White/Brown) +12V applied to indicate telephone line fail

Tell Back input (White/Orange) +12V applied to change from engineer to customer reset

0V (Black)

12V (Red)

Com Connector Cable, Part No. 485210

Figure 24. Plug-By Communicator Wiring

Note: Comms O/P4 will be active when the system is unset. This is normal, as

a system being unset is equivalent to an alarm signal.

To fit a communicator, follow the instructions below.

Caution: Follow the instructions in the order shown, or you may damage

the control unit and/or communicator.

1. Disconnect mains and battery power from the control unit and remove

the case lid, if the system has already been installed.

2. Detach the main PCB from the support pillars in the control unit case,

and lift the PCB carefully to the left. Fit the communicator between the

PCB support pillars, making sure that the main PCB can fit back into

position (see Figure 25).

Figure 25. Fitting a Plug-by Communicator

Page 38

3. Installation 9751 Installation Guide

Page 34 11976798

3. Make any necessary connections from the communicator to the

communication wiring harness. The default is a positive voltage when the

output is inactive but this can be inverted if required using Command

159.

Refer to the next section if you are using a dual-path communicator.

4. Plug the Communication Wiring Harness onto the communications

connector on the main PCB.

5. Re-fit the PCB to the support pillars. Secure the PCB to the support

pillars with the screws provided (Figure 26). Make sure that the bottom

left corner of the PCB is seated on its support pillar.

Figure 26. Fitting Control Unit PCB

If the system has already been installed:

6. Re-connect the battery.

7. Fit the case lid.

8. Apply mains power.

9. Test communicator operation.

Page 39

9751 Installation Guide 3. Installation

11976798 Page 35

Line Monitoring for a Dual-Path Communicator

If a standalone dual-path (landline and mobile) communication device, such

as a RedCARE STU, is connected to the plug-by connector, you need to do

the following to obtain correct line fault reporting:

1. Wire a control unit output programmed as type "ATS Test" to the ATS Test

input of the communicator. Invert the sense of the output at the control unit

if a "positive applied" input sense is used at the communicator.

2. Wire the Line Fault output of the communicator to the Line Fault input of

the plug-by connector. The communicator must provide +12Vdc to indicate

a line fault (e.g. if the Line Fault output at the communicator uses a relay,

connect the common terminal of the relay to +12Vdc and the normallyopen terminal to the Line Fault input of the plug-by connector).

The control unit will generate an "ATE L.F. Single" alert if only one of the

networks is not available, or "ATE L.F. All" if both networks are not available.

Fitting a Battery

Fit a rechargeable battery into the back of the case. There is space in the

case for a 12V 7Ah battery; make sure the battery terminals are oriented in

the position shown in Figure 27.

Cooper Security Ltd recommend that you fit at least a 7Ah battery.

7AH

Figure 27. Fitting a Battery

Page 40

3. Installation 9751 Installation Guide

Page 36 11976798

Initial Start Up

Before applying power to the control unit, ensure that:

• All keypads and expanders have been addressed and connected.

• All external and internal sounders are connected.

• All wired zone circuits are connected.

Then:

1. Connect the battery to the control unit PCB.

2. Briefly short the Kick Start pins together (see Figure 3).

The internal sounder may sound. Ignore any display at this stage.

3. Key in the factory default User access code: 1234.

The internal sounder stops. Ignore any display or lamps.

4. Fit the case lid before applying mains power (this covers the live wiring

and closes the tamper switch).

5. Apply mains power.

6. Key in the factory default Engineer Code: 7890.

Notes:

1. With software versions earlier than 5.xx.xx key in 0 followed by the

default Engineer Code 7890.

2. You do not have to remove the case lid.

The display shows:

Installer Mode

You are now in installer (programming) mode.

The Programming Guide explains how to program the system. Cooper

security recommend that at this point you return the system to its default

settings using Command 98. See Restoring Default Command Settings in

Chapter 1 of the Programming Guide.

Note: You will also need to let the expanders learn the wirefree detectors, and

then install the detectors at their selected sites.

Page 41

11976798 Page 37

Index

9954 PCB layout...........................................................24

Access code..............................................................7, 36

Auxiliary output .............................................................10

Battery

fitting ........................................................................35

specification.............................................................10

Bell

tamper return...........................................................10

Bell-box connections.....................................................19

Break-glass detector .................................................6, 11

CCL ............................................ see Closed Circuit Loop

Clock

accuracy ....................................................................9

Closed Circuit Loop (CCL)..............................................5

zone connection ......................................................21

Code

access .................................................................7, 36

Duress ...................................................................2, 7

Communication output..................................................10

Communicator

approval...................................................................29

connecting ............................................................... 32

Connecting ..............................................................28

Dual-path.................................................................35

fitting a plug-by communicator ................................33

line monitoring ...................................................28, 35

telephone connection ..............................................28

three-way calling .....................................................28

Control unit

cable entries to case ...............................................17

fitting the case .........................................................16

PCB layout ..............................................................12

power requirements ..................................................9

Detector

Passive Infra-Red................................................6, 11

smoke..................................................................6, 11

Dimensions of control unit case .....................................9

Downloader

part number ............................................................. 11

Duress Code ...............................................................2, 7

Environmental standard..................................................9

Exit Terminate button

connecting ............................................................... 18

Expander

9954 PCB layout .....................................................24

addressing...............................................................26

hardwired.......................................................5, 24, 25

radio ..............................................................6, 11, 24

RFX08/RFX16 PCB layout......................................24

FSL.........................................see Fully Supervised Loop

Fully Supervised Loop (FSL) ..........................................6

connections .............................................................21

Fuses ......................................................................10, 17

Humidity ..........................................................................9

Input

line fault ...................................................................10

remote reset ............................................................10

tamper .....................................................................10

Keypad

addressing...............................................................19

backlight ..................................................................19

backplate ................................................................. 16

connecting ...............................................................18

power requirements ..................................................9

tamper switch ..........................................................16

Kick start pins................................................................36

Learning

wirefree detectors......................................... 6, 13, 26

Line

line fault input ..........................................................10

monitoring/faults ............................................... 28, 35

Lock switch

connecting ...............................................................18

Loudspeaker

output.......................................................................10

Mains connection ..........................................................17

Output

auxiliary ...................................................................10

communication ........................................................10

loudspeaker.............................................................10

panel........................................................................10

programming panel outputs ....................................26

PA

transmitter........................................................... 6, 11

Panel output ..................................................................10

Panic Alarm...........................................................see PA

Part numbers of compatible equipment........................11

Partition

creating......................................................................7

PCB layout

9954 expander ........................................................24

RFX08/RFX16 expander.........................................24

Personal Attack.....................................................see PA

PIR .................................see Detector:Passive Infra-Red

Power

connection ...............................................................17

requirements .............................................................9

Proximity tag reader

tag part number .......................................................11

Radio strength monitor ............................................ 6, 11

RedCare...............................................see Remote reset

Remote

PC connection .........................................................28

setting device ............................................................6

setting device part number......................................11

REN.............................. see Ringer Equivalence Number

RFX08/RFX16 PCB layout ...........................................24

Ringer Equivalence Number .........................................30

Size of control unit case..................................................9

Sounder connections ....................................................19

Start up..........................................................................36

Tamper

return for Bell ...........................................................10

Telecommand ................see also Remote setting device

Telephone line ..............................................................28

connection ...............................................................32

sharing.....................................................................32

Tellback ................................................see Remote reset

Temperature....................................................................9

Test

report call.................................................................29

Three-way calling ..........................................................28

Time

accuracy ....................................................................9

Page 42

Index 9751 Installation Guide

Page 38 11976798

Transmitter

PA transmitter ..................................................... 6, 11

universal ............................................................. 6, 11

Universal transmitter ................................................ 6, 11

Weight ............................................................................ 9

Zone

CCL ......................................................................... 21

FSL.......................................................................... 21

wiring....................................................................... 21

Page 43

9751 Installation Guide Index

11976798 Page 39

Page 44

Cooper Security Ltd.

Security House

Vantage Point Business Village

Mitcheldean

Gloucestershire

GL17 0SZ

www.scantronic.co.uk

Product Support (UK) Tel: +44 (0)1594 541979

Available between: 08:15-12:30 and 13:00-17:00 Monday to Friday.

Product Support Fax: +44 (0)1594 545401

Part Number 11976798

Declarations of conformance to standards can be obtained from our Web site, www.coopersecurity.co.uk

Loading...

Loading...