Page 1

R

Y

SparSpar

Spar

SparSpar

e pare par

e par

e pare par

tsts

ts

tsts

COOPER PEGLE

SPRAYING TECHNOLOG

FF

ALAL

AL

ALAL

CONCON

CON

CONCON

F

FF

SpecifSpecif

Specif

SpecifSpecif

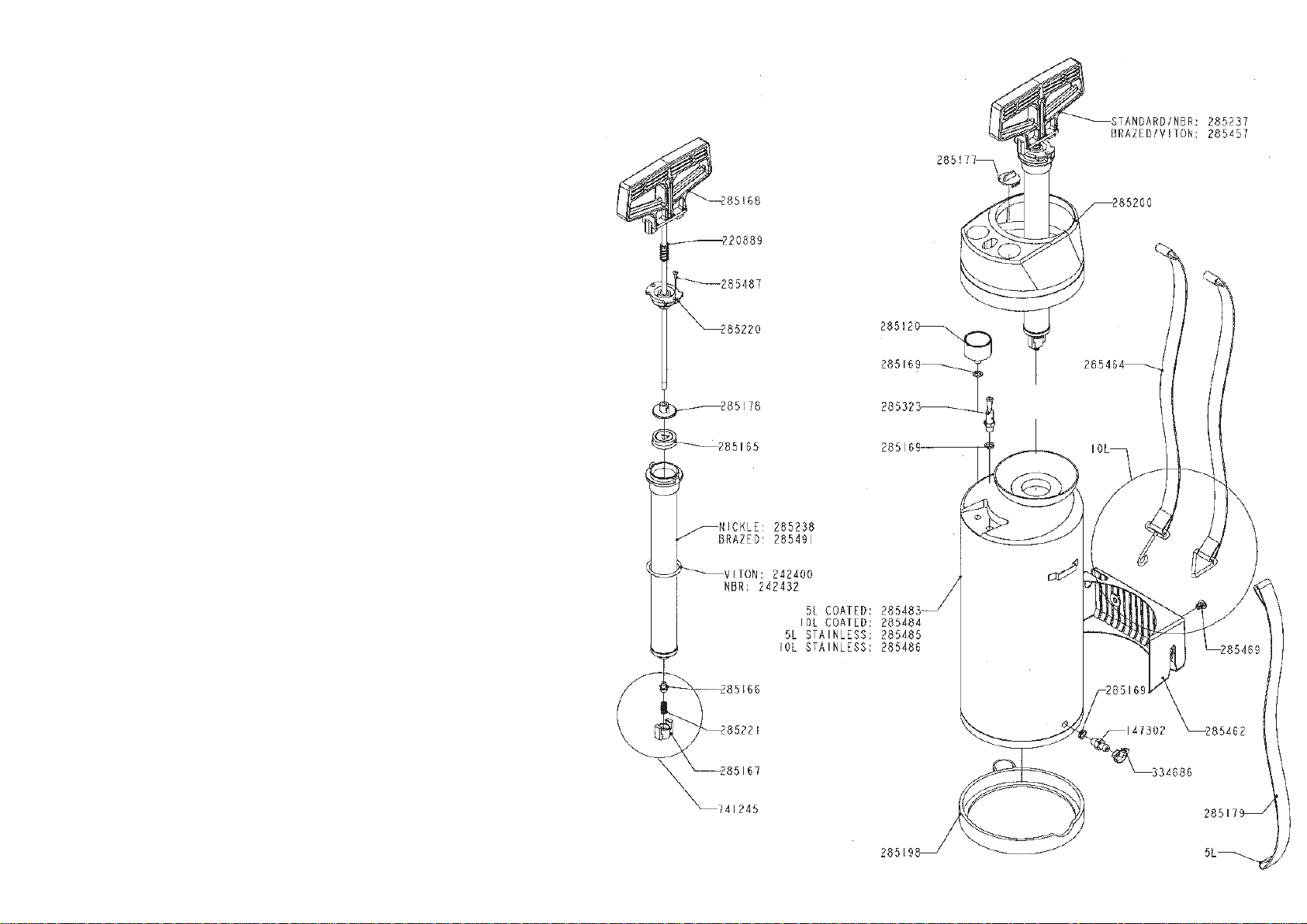

The containers incorporate a charge pump, pressure gauge,

and pressure relief valve which is set to operate above 6 bar

(85psi).

AssembAssemb

Assemb

AssembAssemb

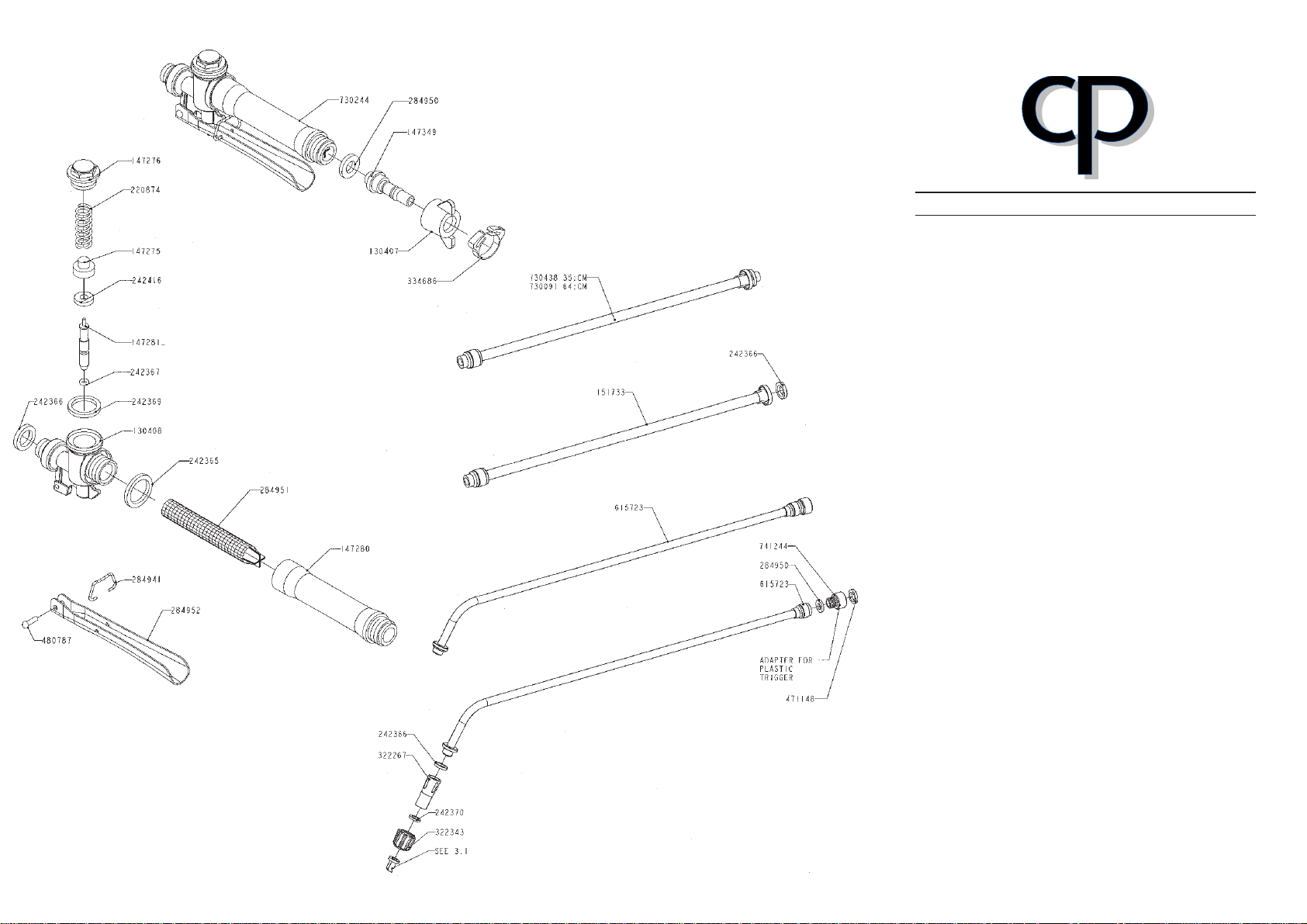

Fit lance to trigger valve and connect hose to the outlet of

container, ensuring that all washers are in place. Following

the operating instructions below, test the machine with water

to ensure that it is in correct working order.

OperOper

Oper

OperOper

Remove the pump assembly by pressing down on the pump

handle to disengage the lugs; then continue to turn handle

anti-clockwise to unscrew the pump assembly from the

container.

Pour in up to, but not more than, 5 litres or 10 litres of liquid.

Replace pump assembly, screwing home firmly. Charge with

air until pointer of pressure gauge reaches the red line (6

bar). Lower pressures can be used if desired. The sprayer is

now ready for use.

aa

tiontion

a

tion

aa

tiontion

icaica

ica

icaica

lyly

ly

lyly

tiontion

tion

tiontion

In order to depressurise the container, pull up the pressure

relief valve. When no more air is heard to escape, it is safe

to remove the pump assembly.

679029-GB-2002/11

Page 2

If in doubt, or if the machine does not give complete

satisfaction, please contact us.

NozzlesNozzles

Nozzles

NozzlesNozzles

The standard machine is provided with a variable spray

nozzle, which provides a fine mist spray, adjustable from a

wide cone to a straight jet of 6 metres (20’) or more by

turning the cap.

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

THIS SPRAYER MUST BE WASHED OUT THOROUGHLY

IMMEDIATELY AFTER USE with warm water and a little

soda, shaking the machine well and spraying the water out.

Remove the nozzles to save time. After using creosote,

wash out with a weak solution of detergent. The piston

washer (285165) should be oiled from time to time. To

withdraw piston rod with plunger, remove both screws

holding cylinder cap. When reassembling care should be

taken to avoid bending or damaging the piston washer. If the

piston washer has to be replaced, the open side of the

washer must face downwards.

The foot valve (285166) at the bottom of the cylinder

prevents liquid from entering the pump. If liquid leaks into

the pump, the valve should be inspected and cleaned. The

plastic cover of the tank is easily detachable for servicing

pressure gauge and safety valve. To remove cover, give a

sharp, upward pull. When replacing, be careful that catches

on plastic cover engage with outer rim of filling funnel and

push down.

SafSaf

ety vety v

alvalv

Saf

ety v

SafSaf

ety vety v

Valve should be checked every three months if the machine

is used continuously, or every six months if only used

periodically. The test should be

conducted as follows:

1. Ensure that the

trigger valve is

closed.

2. Fill machine

completely with clean

water to exclude all air.

3. Pressurise the container

using the hand pump

until the relief valve

opens. This should occur

between 6 and 7 bar (85

and 100psi). If the valve

does not operate

between these

pressures, it must be

replaced before the

machine is used.

e testinge testing

alv

e testing

alvalv

e testinge testing

SparSpar

Spar

SparSpar

e pare par

e par

e pare par

tsts

ts

tsts

PP

ossibossib

P

ossib

PP

ossibossib

Loss of pressure – Check sealing washers (285169).

Check ‘0’ Seal (242400) and its seating. If any parts are

damaged or worn, replace immediately.

Piston rises after pumping – Renew foot valve (285166)

by removing parts (285221) and (285167).

Difficulty in pumping – Check foot valve (285166) as

above. Examine piston washer (285165). If damaged,

replace.

le causes ofle causes of

le causes of

le causes ofle causes of

tr tr

tr

tr tr

ouboub

oub

ouboub

lele

le

lele

Loading...

Loading...