Page 1

INS #

Brand Logo

reversed out of

black

INS #

IB500018EN

Installation Instructions – Prevail XL / USSL XL

Instructions d’installation – PrevailXL / USSLXL

Instrucciones de instalación – Prevail XL / USSL XL

WARNINGWARNING

Risk of Fire, Electrical Shock, Cuts or other Casualty Hazards- Installation and maintenance of this

product must be performed by a qualified electrician. This product must be installed in accordance

with the applicable installation code by a person familiar with the construction and operation of the

product and hazards involved.

Risk of Fire and Electric Shock- Make certain power is OFF before starting installation or attempting

any maintenance. Disconnect power at fuse or circuit breaker.

Risk of Fire- Refer to product label for specific minimum supply conductor requirements.

Risk of Burn- Disconnect power and allow fixture to cool before handling or servicing.

Risk of Personal Injury- Fixture may become damaged and/or unstable if not installed properly.

Failure to comply with these instructions may result in death, serious bodily injury and property damage.

DISCLAIMER OF LIABILITY: Cooper Lighting Solutions assumes no liability for damages or losses of any kind

that may arise from the improper, careless, or negligent installation, handling or use of this product.

NOTICE: Green ground wire provided in proper location. Do not relocate.

ATTENTION Receiving Department: Note actual fixture description of any shortage or noticeable damage on

delivery receipt. File claim for common carrier (LTL) directly with carrier. Claims for concealed damage must be

filed within 15 days of delivery. All damaged material, complete with original packing must be retained.

Safety: This fixture must be wired in accordance with the National Electrical Code and applicable local codes and

ordinances. Proper grounding is required to insure personal safety. Carefully observe grounding procedure under

installation section.

APPLICATIONS: This lighting fixture is designed for outdoor lighting services, and should not be used in area

of limited ventilation or inside high ambient temperature enclosures. It must be stored in a dry location prior to

installation. Do not expose lighting fixture to rain, dust or other environmental conditions prior to installation

and insertion of photo control or shorting cap (if so equipped). Best results will be obtained if installed and

maintained according to the following recommendations.

Regulatory Information:

device, pursuant to part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been test and found to comply with the limits of a Class A digital

Page 2

COOPER LIGHTING SOLUTIONS IB500018EN Installation instructions

Installation Instruc tions – Prevail XL / USSL XL

INSTALLATION

This lighting fixture has been shipped complete with one

of several mounting options. Please follow the installation

instructions specific to the catalog part that you ordered.

Care must be taken not to set lighting fixture down on

optical lenses.

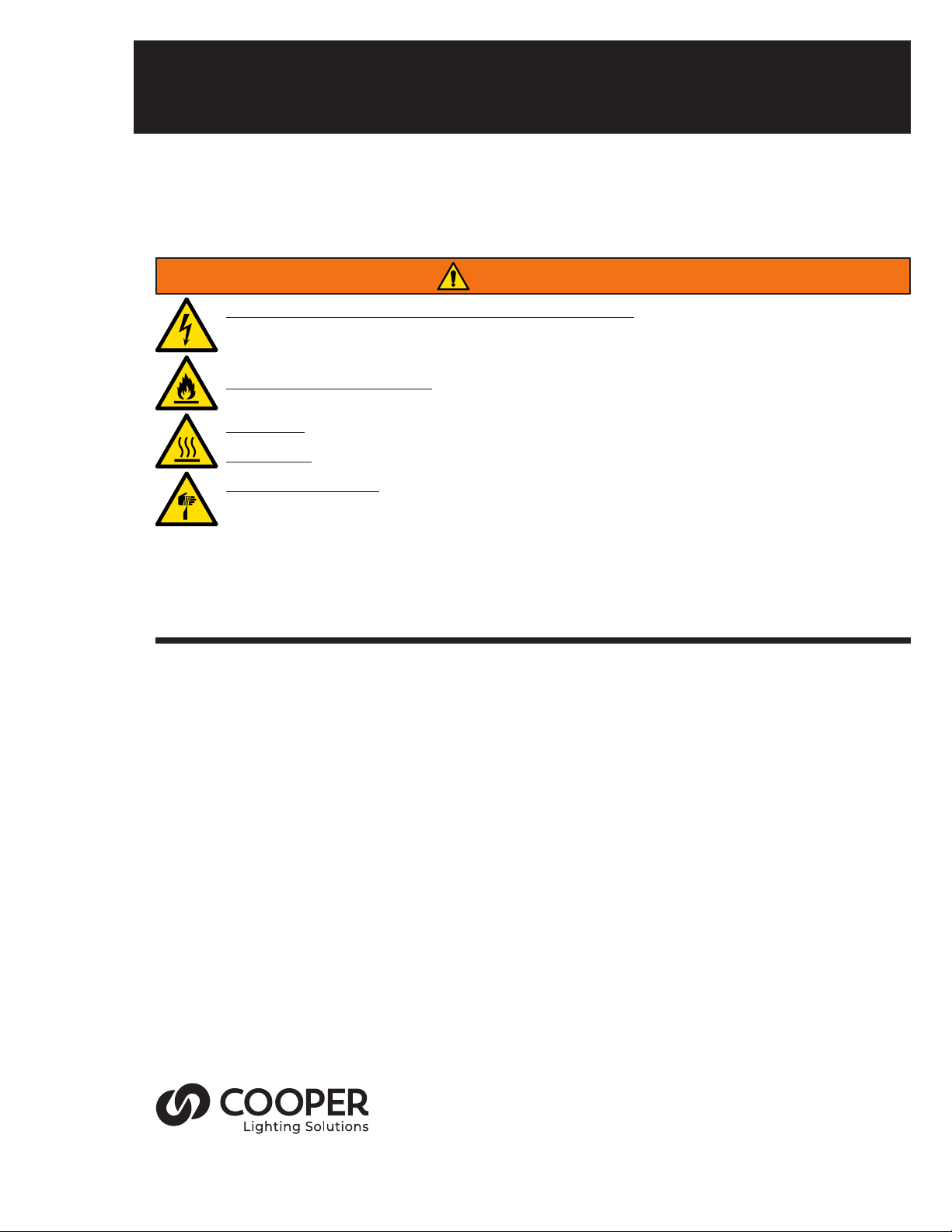

Pole Mount Arm

Tools Required

Ratchet, 3/4” socket, 3/4” wrench, 3/8” socket, #2 Phillips

head screw driver and torque wrench, drill.

1. Pole mounting arm is designed for a square or round

pole. Round pole installation will require the mounting

arm break-away tabs to be removed. Grab tabs with

pliers and break-away as shown in (Figure 1). The

minimum pole diameter shall be: 3”. No isolators or

gasketing permissible between mounting surfaces.

2. Mount the arm to the round or square pole using the

provided 1/2” x 1-3/4” long bolts, washers and nuts as

shown in (Figure 2). Torque bolts to 40 ft-lbs. (55 N-M).

3. Fold fixture wire leads tightly towards fixture door when

sliding fixture on to mounting arm. Install the (3) 1/4-20

x 1” screws and tighten to 6 ft-lbs. Tighten the center

screw first as shown in (Figure 3).

4. Make wire connections inside the mounting arm. Refer

to wire diagram for power connections. Connect the

supply wires to appropriate luminaire leads: (Figure 4)

• Supply side ground wire to green luminaire lead.

• Supply side neutral wire to white luminaire lead.

• Supply side line voltage wire to black luminaire

lead.

5. Install arm cover and tighten (2) Philips head screws to

20 in-lbs. (2.3 N-M). As shown in (Figure 5).

ote:N Ensure the luminaire supply leads do not get pinched

between cover and mounting arm as shown in

(Figure 3 & 5).

6. If applicable, Install pole cap after completion of

luminaire installation and wiring.

9/16” (14.3mm)

Diameter Hole

And Slot

4-7/8˝

(124mm)

7/8˝

(22mm)

Washer

1/2” Bolt

Washer

Figure 2.

Figure 3.

Figure 4.

Cover Plate

Screws.

Tighten To 20

in-lbs (2.3N-M)

Split Washer

1/2” Nut

Install (3) 1/4-20 Screws And

Line (Black) Black

White

White Common

(Black 480V)

Green Ground

(Black

480V)

Green

Ground

Tighten to 72 in-lbs.

Fixture

For Round Pole Installations,

Break Away Tabs

Figure 1.

2

Figure 5.

Align Cover Tabs

With Arm Slots

Page 3

COOPER LIGHTING SOLUTIONS IB500018EN Installation instructions

Installation Instruc tions – Prevail XL / USSL XL

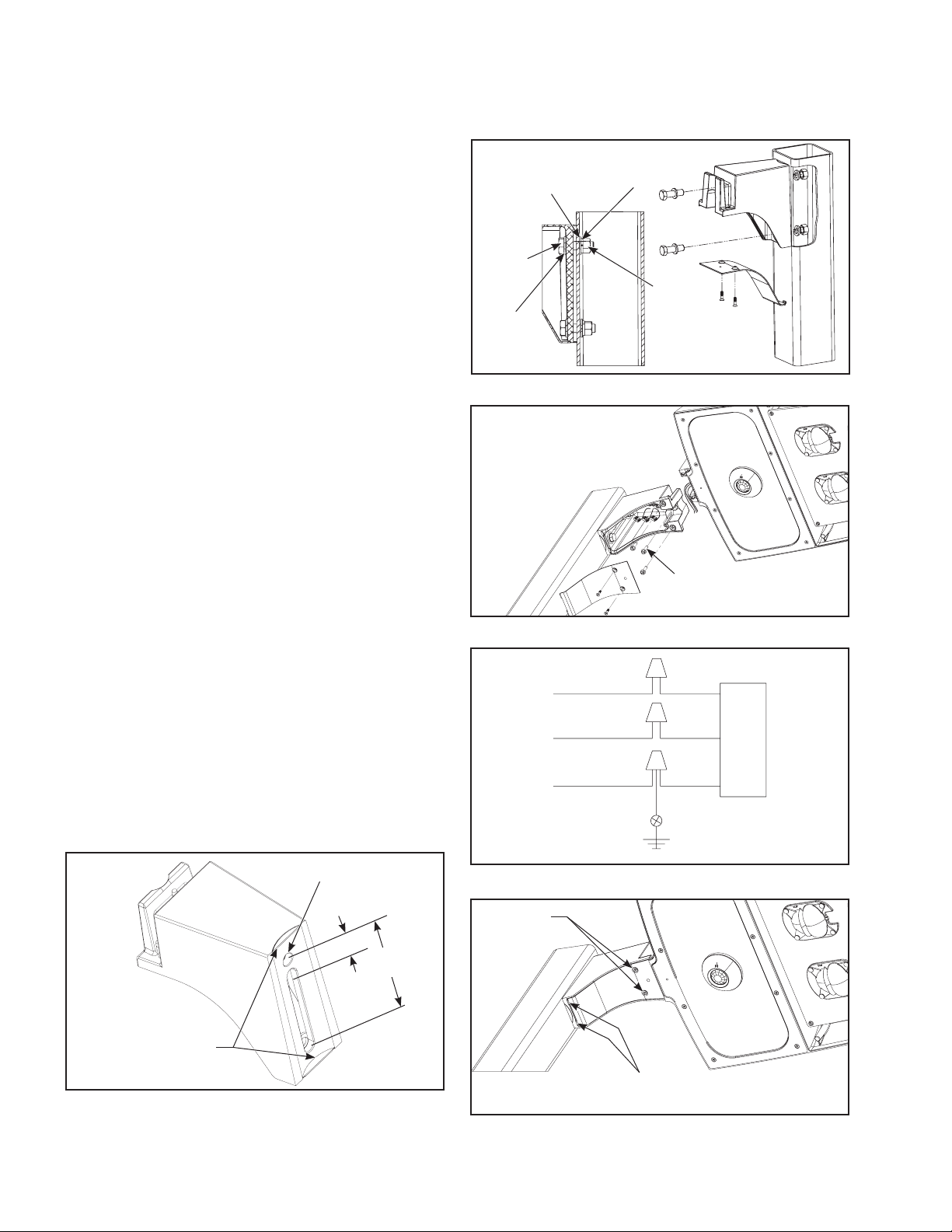

Wall Mount

Tools required

#2 Phillips head screw driver, torque wrench.

ote:N Hardware and tools to mount wall plate to wall not

supplied.

1. Pull the supply wires out of junction box (not supplied)

and through the large hole in the center of the wall

plate.

2. Secure attachment plate to the wall using four bolts

(not included).

3. Follow instructions step 3 through 5 from pole mount

arm configuration as shown in (Figure 6).

6. Install the (3) 1/4-20 x 1” screws and tighten to

6(Ft-lbs). Tighten the center screw first as shown in

(Figure 3.) and install the plastic plug over the center

screw. (Figure 3.)

7. Tuck wires into the fixture and install fixture door.

Tighten the (8) fixture door screws to 20 in-lbs. (or

tighten door thumb screws).

8.0

8.0

[203]

[203]

[178]

7. 0

Mast Arm Mount (Figure 7)

Tools required

1/4” Allen wrench, #2 Phillips head screw driver, torque

wrench, drill and 7/16” drill bit.

1. Determine wire connection method whether inside the

mast arm or inside a separate junction box. Lead wires

are provided exiting the mast arm for connections.

Refer to wire diagram for power connections. Connect

the supply wires to appropriate luminaire leads as

shown in (Figure 4).

2. Slip the fixture with attached mast arm assembly over

the customer mounting arm (making sure not to pinch

any supply leads while routing). Make sure the mast

arm is fully seated into the mast arm adapter as it

should bottom out against the adapter.

3. Secure the mast arm to the mounting arm with the

(4) 3/8-16 x 3/8” set screws. Level the fixture while

tightening the set screws. Torque to 168 in-lbs.

4. Drill a 7/16” hole through the mast arm and install the

3/8” bolt and nut. Use care when drilling to prevent

wire damage. Torque to 120 in-lbs.

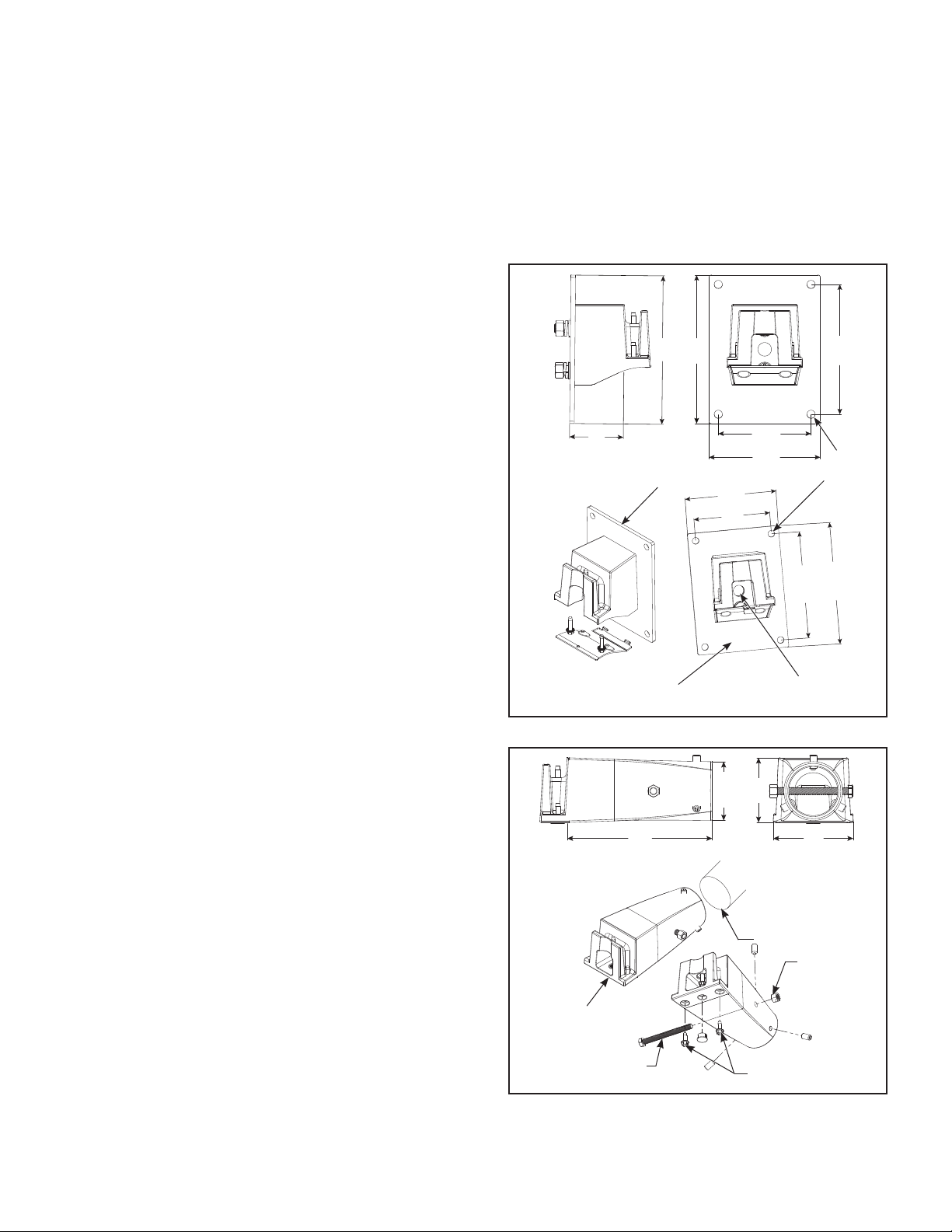

Mast Arm Optional Accessory Wiring

1. Install the mast arm from steps 2-4.

2. Fold wire leads tightly towards fixture door when sliding

fixture on to mounting arm. If using fixture supplied

lead, use the wiring steps from the Mast Arm Mount

above or proceed with the following steps 3-7.

3. Open fixture door by loosening the (8) Phillips head

screws (or thumb screws if supplied) on the door as

shown in (Figure 8).

4. Remove wire grommet for fixture wires at the back

of the fixture as shown in (Figure 8). Once removed,

fixture is no longer IP rated.

5. Insert customer lead wires into fixture through

grommet hole and slide fixture on to the mast arm

adapter. Manage wire routing during this process.

Figure 6.

Level Surface

2.9

[74]

Wall Plate

[188]

3/8” Bolt

7. 4

6.0

[152]

5.0

[127]

6X8 Plate Size

3.0

[76]

O.D.

5.0

[127]

6.0

[152]

7. 0

[178]

Wire Way

(Center Hole)

3.3

[84]

4.1

[104]

Mast Arm Pole

(2” Tenon Arm)

Set Screws (Torque

To 168 In-Lbs)

Tighten To 72 In-Lbs.

ø.44

[11]

Dia. Hole

8.0

[203]

Figure 7.

3

Page 4

COOPER LIGHTING SOLUTIONS IB500018EN Installation instructions

Installation Instruc tions – Prevail XL / USSL XL

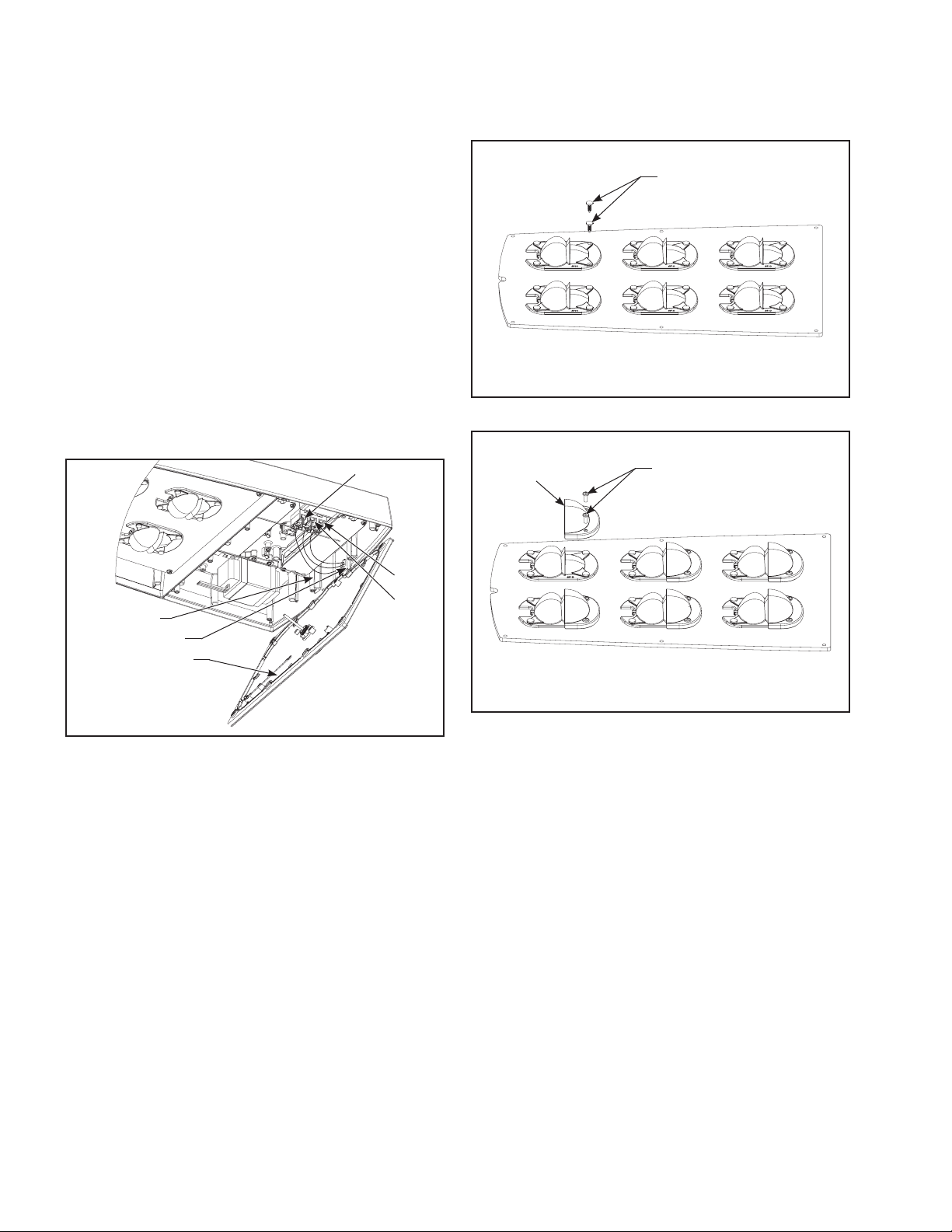

House Side Shield

Tools required

#2 Phillips head screw driver and pliers.

1. Carefully remove plastic push pins on optics as shown

in (Figure 9).

ote:N The optics are permanently secured to the fixture.

DO NOT try to remove the optics. The optics are not

field-rotatable.

2. Install house side shield with provided #10 x 1/2”

Phillips screws. Tighten until house side shield is snug.

Do not over tighten.

3. For factory installed rotated optics, reuse the existing

#8-32 Phillips screw for attaching the house side shield.

ote:N House side shield must ONLY be installed on the

back side of the optics as shown in (Figure 10). DO

NOT install on the other side of the optic.

Wire Leads

Wire Grommet

Open Fixture Door

Neutral

Hot

Ground

Front Of Fixture

Figure 9.

House Side

Shield

Front Of Fixture

Plastic Pins

Screws #10 X 1/2” Or

#8 X 1/2” (As Required)

Pole Side Of Fixture Pole Side Of Fixture

Figure 8.

4

Figure 10.

Page 5

Instructions d’installation – PrevailXL/USSLXL

AVERTISSEMENTAVERTISSEMENT

Risque d’incendie, de décharge électrique, de coupure ou d’autres accidents de personne – L’installation

et l’entretien de ce produit doivent être effectués par un électricien qualifié. Ce produit doit être installé

conformément aux règles d’installation en vigueur par une personne familière avec la construction et le

fonctionnement du produit, ainsi qu’avec les risques inhérents.

Risque d’incendie et de décharge électrique – Assurez-vous que l’alimentation électrique est HORS

TENSION avant de commencer l’installation ou de tenter d’en faire l’entretien. Mettez l’alimentation

électrique hors tension depuis le fusible ou le disjoncteur.

Risque d’incendie – Consultez l’étiquette du produit pour connaître les exigences minimums du

conducteur d’alimentation.

Risque de brûlure– Débranchez la source d’alimentation et laissez refroidir le luminaire avant de procéder

à son entretien ou à sa manipulation.

Risques de blessures – Le luminaire peut être endommagé et/ou instable s’il n’est pas installé

correctement.

La désobéissance aux instructions suivantes représente un risque de blessures graves ou mortelles et de

dommages matériels.

EXONÉRATION DE

dommages ou pertes de quelque nature que ce soit pouvant découler d’une installation, d’une manipulation ou

d’une utilisation inappropriée, imprudente ou négligente de ce produit.

AVIS: Le fil de mise à la terre vert se trouve au bon endroit. Ne le déplacez pas.

ATTENTION Service de réception: Veuillez fournir une description réelle de tout manque ou de tout dommage

constaté à la réception du luminaire. Les réclamations contre le transporteur (chargement partiel) doivent être

déposées directement auprès dudit transporteur. Les réclamations d’avaries occultes doivent être faites dans les

15jours suivant la réception. Tout matériel endommagé doit être entièrement conservé avec son emballage d’origine.

RESPONSABILITÉ: Cooper Lighting Solutions n’assume aucune responsabilité pour les

Sécurité: Le câblage du luminaire doit être conforme au Code national de l’électricité, aux lois et ordonnances

locales en vigueur. Une mise à la terre adéquate est requise afin d’assurer votre sécurité. Respectez soigneusement

la procédure de mise à la terre du chapitre d’installation.

APPLICATIONS: ce luminaire a été conçu pour l’éclairage extérieur et ne doit pas être utilisé dans un endroit peu

ventilé ou dans des enceintes à haute température ambiante. Il doit être rangé dans un endroit sec en attendant

son installation. N’exposez pas le luminaire à la pluie, à la poussière ou à d’autres conditions ambiantes avant

l’installation et l’insertion de l’interrupteur photo-électrique ou de la fiche de mise en court-circuit (si équipés). Pour

de meilleurs résultats, respectez les recommandations d’installation et d’entretien suivantes.

Renseignements légaux:

Cet équipement a été mis à l’essai et déclaré conforme aux limites établies pour un

dispositif numérique de catégorieA en vertu de la section15 des règlements de la FCC. Son fonctionnement est

assujetti aux deux conditions suivantes: 1)cet appareil ne doit pas provoquer d’interférences nuisibles et 2)cet

appareil doit accepter toutes les interférences reçues, même celles qui pourraient provoquer un fonctionnement

indésirable.

INSTALLATION

Ce luminaire est livré avec toutes ses pièces et l’une des

Diamètre du trou

et de fente de

14,3mm (9/16 po)

différentes options de montage. Suivez les instructions

d’installation correspondant à la pièce commandée dans le

catalogue. Prenez soin de ne pas déposer le luminaire sur

22mm

(7/8 po)

124mm

(4 7/8 po)

les lentilles.

Bras de montage de poteau

Outils requis

Cliquet, douille de 19,1mm (3/4 po), clé de 19,1mm (3/4

po), douille de 9,5mm (3/8 po), tournevis à tête cruciforme

no2, clé dynamométrique et perceuse.

Séparez les languettes

lorsque vous effectuez

l’installation d’un poteau rond

Figure 1.

COOPER LIGHTING SOLUTIONS IB500018EN Instructions d’installation

5

Page 6

Instructions d’installation – PrevailXL/USSLXL

1. Le bras de montage de poteau est conçu pour un

poteau carré ou rond. L’installation d’un poteau rond

requiert le détachement des languettes du bras de

montage. Tenez les languettes avec des pinces et

séparez-les, comme montré à la Figure1. Le diamètre

minimum du poteau doit être de: 76,2mm (3po).

Aucun isolateur ou joint d’étanchéité n’est autorisé

entre les surfaces de montage.

2. Montez le bras au poteau rond ou carré en utilisant les

boulons longs de 12,7 x 44,5mm (1/2 x 1 3/4 po), les

rondelles et les écrous fournis, comme montré à la

Figure2. Serrez les boulons à un couple de 54,2Nm

(40pi-lb).

3. Pliez les fils du luminaire devant la porte du luminaire

lorsque vous glissez le luminaire sur le bras de

montage. Installez les trois (3) vis de 6-20 x 25mm

(1/4-20 x 1po) et serrez-les à un couple de 8,1Nm

(6pi-lb). Serrez d’abord la vis centrale, comme montré

à la Figure3.

4. Effectuez le raccord des fils à l’intérieur du bras de

montage. Consultez le schéma de câblage pour

effectuer les raccords. Raccordez les fils d’alimentation

aux fils appropriés du luminaire: (Figure4).

• Raccordez le fil de mise à la terre latéral au fil de

sortie vert du luminaire.

• Raccordez le fil neutre latéral au fil de sortie blanc

du luminaire.

• Raccordez le fil de tension secteur au fil noir du

luminaire.

5. Installez le couvercle du bras et serrez les deux (2) vis

à tête cruciforme à un couple de 2,3Nm (20po-lb).

Comme montré à la Figure5.

ote:N Assurez-vous que les fils d’alimentation du luminaire

ne sont pas coincés entre le couvercle et le bras de

montage, comme montré aux Figures3 et 5.

6. Si requis, installez le capuchon du poteau après avoir

effectué l’installation et le câblage du luminaire.

Figure 3.

Figure 4.

Vis du couvre-

joint. Serrez

à un couple

de 2,3Nm

(20po-lb)

Fil (noir) Noir

Blanc commun

(noir 480V)

Vert – mise à la terre

Alignez les languettes du

couvercle avec les fentes du bras

Installez les trois (3) vis 1/4-20 et serrez

à un couple de 3,4Nm (72po-lb).

Blanc

(noir

480V)

Luminaire

Vert – mise

à la terre

Rondelle élastique

Rondelle

Boulon de

12,7mm

(1/2 po)

Rondelle

Écrou de

12,7mm (1/2

po)

Figure 2.

6

COOPER LIGHTING SOLUTIONS IB500018EN Instructions d’installation

Figure 5.

Page 7

Instructions d’installation – PrevailXL/USSLXL

Montage mural

Outils requis

Tournevis à tête cruciforme no2, clé dynamométrique.

ote:N La quincaillerie et les outils nécessaires au montage

de la plaque murale ne sont pas fournis.

1. Tirez les fils d’alimentation hors de la boite de jonction

(non fournie) et par le grand trou situé au centre de la

plaque murale.

2. Fixez cette dernière au mur en utilisant quatre (4)

boulons (non fournis).

3. Suivez les étapes3 à 5 de la configuration du bras de

montage du poteau comme montré à la Figure6.

Montage de la crosse (Figure7)

Outils requis

Clé hexagonale de 6mm (1/4 po), tournevis à tête

cruciforme no2, clé dynamométrique, perceuse et mèche

de 11mm (7/16 po).

1. Déterminez la méthode de câblage des fils selon qu’ils

se trouvent à l’intérieur de la crosse ou à l’intérieur

d’une boite de jonction distincte. Des fils d’alimentation

sont prévus à la sortie du bras du poteau pour effectuer

les raccords. Consultez le schéma de câblage pour

effectuer les raccords. Raccordez les fils d’alimentation

aux fils appropriés du luminaire, comme montré à la

Figure4.

2. Glissez le luminaire et l’ensemble de la crosse sur le

bras de montage du client (en vous assurant de ne pas

coincer les fils d’alimentation pendant l’acheminement).

Assurez-vous que la crosse est complètement

enfoncée dans l’adaptateur de crosse et qu’elle repose

fermement contre l’adaptateur.

3. Fixez fermement la crosse au bras de montage en

utilisant les trois (4) quatre de serrage de 9-16 x 9mm

(3/8-16x 3/8 po). Mettez le luminaire à niveau pendant

que vous serrez les vis de serrage. Serrez à un couple

de 13,6Nm (168po-lb).

4. Percez un trou de 11mm (7/16 po) dans la crosse et

installez le boulon de 9mm (3/8 po) et l’écrou. Percez

soigneusement le trou afin d’éviter tout dommage au

fil. Serrez à un couple de 13,6Nm (120po-lb).

4. Retirez le passe-fil sur les fils du luminaire situés à

l’arrière du luminaire comme montré à la Figure8. Une

fois retiré, le luminaire ne possède plus son indice de

protection.

5. Insérez les fils d’alimentation du client par le trou du

passe-fil et glissez le luminaire sur l’adaptateur de

crosse. Effectuez l’acheminement du fil pendant cette

procédure.

178

(7,0)

Diam. du

trou11(0,44)

203

178

(8,0)

(7,0)

Chemin de câble

(trou central)

74

(2,9)

Plaque murale

203

203

(8,0)

(8,0)

152

(6,0)

127

(5,0)

Dimension de la plaque

152,4 x 203,2mm (6 x 8po)

127

(5,0)

152

(6,0)

Figure 6.

Diam.

84

ext. de

3,3

3,0 (76)

188

7, 4

104

4,1

Câblage de la crosse facultative

1. Installez la crosse selon les étapes2 à 4.

2. Pliez les fils du luminaire contre la porte du luminaire

lorsque vous glissez le luminaire sur le bras de

montage. Si vous utilisez le fil fourni, effectuez les

étapes de câblage du montage de la crosse ci-dessus

ou effectuez les étapes3 à 7suivantes.

3. Ouvrez la porte du luminaire en desserrant les huit (8)

vis à tête cruciforme (ou les vis à serrage à main, le cas

échéant) de la porte, comme montré à la Figure8.

Poteau de crosse

(tenon de bras de 50,8mm [2])

Vis de serrage

(serrez à un couple

de 13,6Nm

[168po-lb])

Surface de niveau

Boulon de 9,5mm (3/8 po)

Serrez à un couple

de 8,1Nm (72po-lb)

Figure 7.

COOPER LIGHTING SOLUTIONS IB500018EN Instructions d’installation

7

Page 8

Instructions d’installation – PrevailXL/USSLXL

6. Installez les trois (3) vis de 6-20 x 25mm (1/4-20 x

1po) et serrez-les à un couple de 8,1Nm (6pi-lb).

Serrez d’abord la vis centrale, comme montré à la

Figure3, puis installez le bouchon de plastique sur la

vis centrale (Figure3).

7. Rassemblez les fils dans le luminaire et installez la

porte du luminaire. Serrez les huit (8) vis de la porte du

luminaire à un couple de 2,2Nm (20po-lb) (ou serrez

les vis de serrage à main de la porte).

Tiges en plastique

Protecteur latéral pour maison

Outils requis

Tournevis à tête cruciforme no2 et pinces.

1. Retirez soigneusement les goupilles-poussoirs en

plastique des optiques comme montré à la Figure9.

ote:N Les optiques sont fixées de manière permanente au

luminaire. N’essayez PAS de retirer les optiques. Les

optiques ne peuvent pas être tournées sur place.

2. Installez protecteur latéral pour maison en utilisant les

vis à tête cruciforme no 10 x 13mm (1/2 po) fournies.

Serrez jusqu’à ce que le protecteur latéral de maison

repose fermement contre le mur. Évitez le serrage

excessif.

3. Pour les optiques installées en usine, réutilisez les

vis à tête cruciforme no8-32 existantes pour fixer le

protecteur latéral de maison.

ote:N Le protecteur latéral de maison s’installe

SEULEMENT derrière les optiques, comme montré

à la Figure10. NE l’installez PAS de l’autre côté de

l’optique.

Neutre

Devant du luminaire

Figure 9.

Protecteur latéral

pour maison

Devant du luminaire

Figure 10.

Vis no 10 x 12,7mm (1/2 po) ou

no 8 x 12,7mm (1/2 po) (tel que requis)

Côté du poteau du luminaire

Côté du poteau du luminaire

Fils d’alimentation

Passe-fil

Ouvrez la porte du luminaire

Figure 8.

8

COOPER LIGHTING SOLUTIONS IB500018EN Instructions d’installation

Sous

tension

Mise à la

terre

Page 9

Instrucciones de instalación

Instrucciones de instalación – Prevail XL/USSL XL

Riesgo de incendio, descarga eléctrica, cortes u otros riesgos de accidentes: la instalación y el

mantenimiento de este producto deben ser realizados por un electricista calificado. Una persona con

conocimientos sobre la construcción y el funcionamiento del producto y los riesgos implicados debe

instalar este producto de conformidad con el código de instalación aplicable.

Riesgo de incendio y descarga eléctrica: asegúrese de que la alimentación eléctrica esté APAGADA

antes de comenzar la instalación o intentar realizar cualquier tipo de mantenimiento. Desconecte la

alimentación eléctrica en el fusible o cortacircuitos.

Riesgo de incendio: consulte la etiqueta del producto para conocer los requisitos mínimos específicos del

conductor de suministro.

Riesgo de quemadura: desconecte la alimentación y permita que la luminaria se refresque antes de

manipularla o repararla.

Riesgo de lesiones personales: la luminaria puede dañarse o desestabilizarse de no instalarla

correctamente.

El incumplimiento de estas instrucciones puede provocar la muerte, lesiones corporales graves y daños

materiales.

RENUNCIA DE RESPONSABILIDAD: Cooper Lighting Solutions no asume ninguna responsabilidad por daños o

pérdidas de ningún tipo que puedan derivarse de la instalación, manipulación o uso incorrecto, descuidado o

negligente

AVISO: El tornillo de puesta a tierra verde ya está ubicado correctamente. No lo cambie de ubicación.

ATENCIÓN Departamento de Recepción: Observe que la descripción real de la luminaria no carezca de piezas ni

presente daños notorios al momento de su entrega. Presente el reclamo directamente al transportista de carga por

envíos de carga ligera (LTL). Los reclamos por daños ocultos deben presentarse dentro de los 15 días posteriores a

la entrega del producto. Se debe guardar todo el material dañado, junto con el embalaje original.

de este producto.

ADVERTENCIAADVERTENCIA

Seguridad: Esta luminaria debe cablearse de acuerdo con el Código Eléctrico Nacional y los códigos y ordenanzas

locales aplicables. Se requiere una conexión a tierra adecuada para garantizar la seguridad personal. Observe

cuidadosamente el procedimiento de conexión a tierra en la sección de instalación.

APLICACIONES: Este accesorio de iluminación está diseñado para servicios de iluminación al aire libre y no debe

utilizarse en áreas de ventilación limitada o en lugares cerrados a alta temperatura ambiente. Debe almacenarse en

un lugar seco antes de la instalación. No exponga el accesorio de iluminación a la lluvia, el polvo u otras condiciones

ambientales antes de la instalación e inserción del control fotográfico o la tapa de cortocircuito (si está equipado).

Los mejores resultados se obtendrán si se instala y se mantiene de acuerdo con las siguientes recomendaciones.

Información reglamentaria:

Este equipo ha sido probado y cumple con los límites de un dispositivo digital de

Clase A, de conformidad con la parte 15 de las Normas de la FCC. La operación está sujeta a las siguientes dos

condiciones: (1) Que este dispositivo no produzca interferencia dañina y (2) que este dispositivo debe aceptar

cualquier interferencia recibida, incluida aquella que pueda provocar un funcionamiento no deseado.

INSTALACIÓN

Esta luminaria se ha enviado completa, con una de varias

Orificio y ranura de

9/16" (14.3mm) de

diámetro

opciones de instalación. Siga las instrucciones de instalación

específicas para la pieza del catálogo que solicitó. Se debe

tener cuidado de no colocar la luminaria sobre los lentes

ópticos.

Brazo de montaje en poste

Herramientas necesarias

7/8˝

(22 mm)

4-7/8˝

(124mm)

Trinquete, enchufe de 3/4", llave de 3/4", enchufe de 3/8",

destornillador Phillips No. 2 y llave dinamométrica, taladro.

Para instalaciones de postes

redondos, separar pestañas

1. El brazo de montaje en poste está diseñado para un

poste cuadrado o redondo. La instalación de los postes

redondos requerirá que se quiten las pestañas de

separación del brazo de montaje. Agarre las pestañas

Figura 1.

con unas pinzas y sepárelas como se muestra en

(Figura 1). El diámetro mínimo del poste debe ser

de: 3”. No se permiten aisladores ni juntas entre las

superficies de montaje.

COOPER LIGHTING SOLUTIONS IB500018EN

9

Page 10

Instrucciones de instalación – Prevail XL/USSL XL

2. Monte el brazo en el poste redondo o cuadrado

utilizando los pernos largos de 1/2" x 1-3/4", arandelas

y tuercas provistos como se muestra en la (Figura 2).

Apriete los pernos a 40 pies-libras (55 N-M).

3. Doble los cables de la luminaria firmemente hacia la

puerta de la luminaria cuando deslice la luminaria sobre

el brazo de montaje. Instale los (3) tornillos de 1/4-20

x 1” y apriételos a 6 ft-lbs. Apriete primero el tornillo

central como se muestra en (Figura 3).

4. Haga las conexiones de cables dentro del brazo de

montaje. Consulte los diagramas de cableado para ver

las conexiones de alimentación. Conecte los cables de

alimentación a los terminales correspondientes de la

luminaria: (Figura 4)

• El cable de conexión a tierra del lado de la

alimentación con el terminal verde de la

luminaria.

• El cable neutro del lado de la alimentación con el

terminal blanco de la luminaria.

• El cable de tensión de línea del lado de la

alimentación con el terminal negro de la

luminaria.

5. Instale la cubierta del brazo y apriete los (2) tornillos de

cabeza Philips a 20 in-lbs. (2,3 N-M). Como se muestra

en (Figura 5).

ota:N Asegúrese de que los cables de suministro de la

luminaria no queden atrapados entre la cubierta y el

brazo de montaje como se muestra en (Figura 3 y 5).

6. Si corresponde, instale la tapa del poste después de

completar la instalación de la luminaria y el cableado.

Figura 3.

Figura 4.

Tornillos de la

placa de cubierta.

Apriete a 20 in-lbs

(2.3N-M)

Línea (negro)

Blanco Común

(Negro 480V)

Verde Conexión a tierra

Instale (3) tornillos de 1/4-20 y

apriételos a 72 in-lbs.

Negro

Blanco

(Negro

480V)

Verde

Conexión a

tierra

Luminaria

Arandela

Perno de 1/2"

Arandela

Figura 2.

10

Arandela de

seguridad

Tuerca de 1/2"

Figura 5.

COOPER LIGHTING SOLUTIONS IB500018EN Instrucciones de instalación

Alinee las pestañas de la

tapa con las ranuras del brazo

Page 11

Instrucciones de instalación

Instrucciones de instalación – Prevail XL/USSL XL

Montaje en paredes

Herramientas necesarias

Destornillador Phillips No. 2, llave dinamométrica.

ota:N No se proveen la tornillería y herramientas para

montar la placa de pared a la pared.

1. Extraiga los cables de alimentación de la caja de

conexiones (no suministrados) y páselo por el orificio

grande en el centro de la placa de pared.

2. Asegure la placa de fijación a la pared usando cuatro

pernos (no incluidos).

3. Siga las instrucciones de los pasos 3 a 5 de la

configuración del brazo de montaje en poste como se

muestra en (Figura 6).

Montaje del brazo del mástil (Figura 7)

Herramientas necesarias

Llave Allen de 1/4", destornillador Phillips No. 2, llave

dinamométrica, taladro y broca de 7/16".

1. Determine el método de conexión del cable ya sea

dentro del brazo del mástil o dentro de una caja

de conexiones separada. Se suministran cables

conductores que salen del brazo del mástil para las

conexiones. Consulte los diagramas de cableado para

ver las conexiones de alimentación. Conecte los cables

de alimentación a los cables adecuados de la luminaria

como se muestra en (Figura 4).

2. Deslice la luminaria con el ensamblaje del brazo del

mástil fijado sobre el brazo de montaje del cliente

(asegurándose de no pellizcar ningún cable de

alimentación mientras se enruta). Asegúrese de que el

brazo del mástil esté completamente asentado en el

adaptador del brazo del mástil, ya que debe tocar fondo

contra el adaptador.

3. Asegure el brazo del mástil al brazo de montaje con los

(4) cuatro de fijación de 3/8-16 x 3/8”. Nivele la luminaria

mientras aprieta los tornillos de fijación. Apriete a 168

in-lbs.

4. Perfore un orificio de 7/16" a través del brazo del mástil

e instale el perno de 3/8" y la tuerca. Tenga cuidado al

perforar para evitar dañar el cable. Apriete a 120 in-lbs.

4. Retire la arandela del cable para los cables de la

luminaria en la parte posterior de la luminaria como se

muestra en (Figura 8). Una vez retirada, la luminaria ya

no tendrá la clasificación IP.

5. Inserte los cables de conducción del cliente en la

luminaria a través del orificio de la arandela y deslice

la luminaria sobre el adaptador del brazo del mástil.

Administre el enrutamiento de cables durante este

proceso.

8.0

2.9

[74]

Placa de pared

8.0

[203]

[203]

Tamaño de la placa 6X8

6.0

[152]

5.0

[127]

5.0

[127]

6.0

[152]

[178]

Diámetro del

orificio ø.44

[11]

8.0

7. 0

[203]

[178]

Canaletas

(agujero central)

Figura 6.

3.0

3.3

[76]

[84]

O.D.

7. 4

[188]

4.1

[104]

7. 0

Cableado de accesorios opcionales del brazo del

mástil

1. Instale el brazo del mástil de los pasos 2-4.

2. Doble bien los cables hacia la puerta de la luminaria

cuando deslice la luminaria sobre el brazo de montaje.

Si usa el cable provisto por la luminaria, use los pasos

de cableado del montaje del brazo del mástil antes

mencionados o continúe con los siguientes pasos 3-7.

3. Abra la puerta de la luminaria aflojando los (8) tornillos

de cabeza Phillips (o los tornillos de ajuste manual si se

suministran) en la puerta como se muestra en

(Figura 8).

COOPER LIGHTING SOLUTIONS IB500018EN

Nivel de

superficie

Figura 7.

Perno de 3/8"

Poste del brazo del mástil

(brazo de espiga de 2")

Tornillos de fijación

(apriete a 168

in-lbs)

Apriete a 72 in-lbs.

11

Page 12

Instrucciones de instalación – Prevail XL/USSL XL

6. Instale los (3) tornillos de 1/4-20 x 1” y apriételos a

6 (Ft-lbs). Primero apriete el tornillo central como se

muestra en (Figura 3.) e instale el tapón plástico sobre

el tornillo central. (Figura 3.)

7. Meta los cables en la luminaria e instale la puerta de

la luminaria. Apriete los (8) tornillos de la puerta de la

luminaria a 20 in-lbs. (o apriete los tornillos de ajuste

manual de la puerta).

Pines de plástico

Protector lateral

Herramientas necesarias

Destornillador Phillips No. 2 y pinzas.

1. Retire con cuidado los pines de presión plásticos en las

ópticas como se muestra en (Figura 9).

ota:N Las ópticas están aseguradas permanentemente a la

luminaria. NO intente quitar las ópticas. Las ópticas

están fijas.

2. Instale el protector lateral con los tornillos Phillips

No. 10 x 1/2” provistos. Apriete hasta que el protector

lateral esté ajustado. No lo ajuste demasiado.

3. Para las ópticas que giran, instaladas de fábrica,

reutilice el tornillo Phillips No. 8-32 existente para fijar

el protector lateral.

ota:N El protector lateral SOLAMENTE debe instalarse en

la parte posterior de las ópticas como se muestra

en (Figura 10). NO lo instale en el otro lado de las

ópticas.

Neutro

Frente de la luminaria

Figura 9.

Protector

lateral

Frente de la luminaria

Figura 10.

Tornillos No. 10 X 1/2" o

No. 8 X 1/2" (según sea necesario)

Lado del poste de la luminaria

Lado del poste de la luminaria

Cables

Arandela para cable

Abra la puerta de la luminaria

Figura 8.

12

COOPER LIGHTING SOLUTIONS IB500018EN Instrucciones de instalación

Caliente

Conexión

a tierra

Page 13

Cooper Lighting Solutions

is a registered

trademark. All trademarks are property

of their respective owners.

Cooper Lighting Solutions est une marque

de commerce déposée. Toutes les autres

marques de commerce sont la propriété

de leur propriétaire respectif.

Cooper Lighting Solutions es una marca

comercial registrada. Todas las marcas

comerciales son propiedad de sus

respectivos propietarios.

Product availability, specifications,

and compliances are subject to

change without notice

La disponibilité du produit, les

spécifications et les conformités

peuvent être modifiées sans préavis

La disponibilidad de productos, las

especificaciones y los cumplimientos

están sujetos a cambio sin previo aviso

FCC Statement

Note: This equipment has been tested and

found to comply with the limits for a Class

A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed

to provide reasonable protection against

harmful interference in a residential

installation. This equipment generates uses

and can radiate radio frequency energy

and, if not installed and used in accordance

with the instructions, may cause harmful

interference to radio communications.

However, there is no guarantee that

interference will not occur in a particular

installation. If this equipment does cause

harmful interference to radio or television

reception, which can be determined by

turning the equipment off an on, the user is

encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving

antenna.

• Increase the separation between the

equipment and receiver.

• Connect the equipment into an outlet

on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced

radio/TV technician for help.

Declaración de la FCC

Nota: El equipo ha sido probado y cumple

con los límites para un dispositivo digital de

Clase A, de conformidad con la parte 15 de

las Normas de la FCC. Estos límites están

diseñados para proporcionar una protección

razonable contra las interferencias dañinas

en una instalación residencial. Este equipo

genera usos y puede emitir energía de

radiofrecuencia y si no se instala y utiliza de

acuerdo con las instrucciones, puede causar

interferencia dañina en las comunicaciones de

radio. Sin embargo, no se puede garantizar

que dicha interferencia no ocurra en una

instalación determinada. Si este equipo causa

interferencia dañina en la recepción de radio

o televisión, lo que puede determinarse

apagando y encendiendo el equipo, se

recomienda al usuario que intente corregir

la interferencia mediante una o más de las

siguientes medidas:

• Reorientar o reubicar la antena receptora.

• Aumentar la separación entre el equipo y

el receptor.

• Conectar el equipo a una toma de

corriente en un circuito diferente al que

está conectado el receptor

• Consultar con el distribuidor o con un

técnico de radio/TV experimentado para

obtener ayuda.

Énoncé de la FCC

Remarque: Cet équipement a été mis à l’essai

et déclaré conforme aux limites établies

pour un dispositif numérique de catégorieA

en vertu de la section15 des règlements

de la FCC. Ces limites sont conçues pour

assurer une protection raisonnable contre

tout brouillage nuisible dans une installation

résidentielle. Cet équipement produit, utilise,

et peut émettre des ondes radioélectriques ;

s’il n’est pas installé et utilisé conformément

aux instructions, il peut créer des parasites

nuisibles aux communications radio.

Cependant, il n’existe aucune garantie que les

interférences ne se produiront pas avec une

installation particulière. Si ce matériel cause

des brouillages préjudiciables à la réception

de la radio ou de la télévision qui peuvent

être déterminés en mettant le matériel hors

tension et sous tension, l’utilisateur est

invité à essayer de corriger ce brouillage au

moyen de l’une ou de plusieurs des mesures

suivantes:

• Réorientez ou déplacez l’antenne

réceptrice.

• Augmentez la distance entre l’équipement

et le récepteur.

• Branchez l’équipement sur une prise de

courant d’un circuit différent de celui

auquel le récepteur est branché.

• Communiquez avec le détaillant ou un

technicien en radio/télé expérimenté pour

obtenir de l’aide.

Warranties and

Limitation of Liability

Please refer to www.cooperlighting.com for our terms and conditions.

Garanties et limitation de responsabilité

Veuillez consulter le site www.cooperlighting.com pour obtenir les conditions générales.

Garantías y Limitación de Responsabilidad

Visite www.cooperlighting.com para conocer nuestros términos y condiciones.

Cooper Lighting Solutions

121 Highway 74 South

1

Peachtree City, GA 30269

P: 770-486-4800

www.cooperlighting.com

© 2020 Cooper Lighting Solutions

All Rights Reserved

Printed in USA

Imprimé aux États-Unis

Impreso en los EE. UU.

Publication No. IB500018EN

December 12, 2019

Loading...

Loading...