Page 1

These instructions do not claim to cover all details or variations in the equipment, procedure, or process described, nor to provide directions for meeting every possible

contingency during installation, operation or maintenance. When additional information is desired to satisfy a problem not covered sufficiently for user’s purpose, please

contact your nearest representative.

ANCHOR BOLTS

1. Only bolt and nut kits supplied by Cooper Lighting should be used.

2. Existing anchor bolts or bolt adapters supplied by other than Cooper Lighting should not be used. If they are, Cooper Lighting assumes no

responsibility in case of bolt or adapter failure.

3. Anchor bolt and nuts from other sources should be used only on the advice of a Structural Engineer. Fasteners not suitable for this application can

result in bolt and/or thread failure and consequent collapse of the pole.

CAUTION: Use of nuts from other manufacturers with Cooper Lighting bolts may result in thread failure caused by improper thread fit.

4. In addition to electrical conduit and other equipment necessary to the installation, the foundation bolts should be cast into concrete, in

conformance with the template drawing supplied with the anchor bolts for each particular pole.

CAUTION:

A. Check all templates for dimensional accuracy before using them to locate bolt position in the foundation.

B. Be certain that anchor bolts are properly located to provide the desired directional orientation of the pole.

C. Be certain that the anchor bolts are plumbed vertically, and they extend above the finished surface of the foundation to the extent called for on the

bolt template drawing.

FOUNDATIONS

Since local soil and frost conditions vary widely a Civil Engineer familiar with these conditions should be consulted regarding dimensions and depths of

foundations.

POLE ERECTION AND FIXTURE INSTALLATION

1. All Cooper Lighting steel poles are to be installed using two nuts on each anchor bolt. The first nuts are to be run down on the thread to the top of

the foundation and be checked using a hand level to ensure that the top surfaces of all these nuts are the same height. The pole should then be

installed with its base plate holes over the bolts and the second nut screwed down to a moderate degree of tightness. The pole then should be

checked and adjustments made to ensure that the pole is plumb. When this is satisfactory, tighten the top nuts to the proper torque values as

shown using torque wrench.

2. When the installation is complete and confimred to be correct, the void that appears between the base plate and concrete foundation is to be

filled using a non-shrinking mortar grout. Then shape and finish to a neat appearance.

3. With the exception of the instructions presented on this page, the procedures for fixture installation and pole erection are the responsibility of the

installation contractor

Customer First Center • 1121 Hwy 74 South • Peachtree City, GA 30269

IMI-484 ACF080468

Poles

Sheet 1 of 3

2/15/08 IMI-484

INSTALLATION INSTRUCTIONS

IMPORTANT: READ CAREFULLY BEFORE INSTALLING LUMINAIRE.

RETAIN FOR FUTURE REFERENCE.

General: Upon receipt of pole thoroughly inspect for any freight

damage, which should be brought to the attention of the delivery

carrier. Compare the catalog description listed on the packing slip

with the label on the pole to be sure the correct merchandise has

been received.

Safety: This pole must be grounded in accordance with the

National Electrical Safety Code and applicable local codes and

ordinances. Proper grounding is required to insure personal safety.

Carefully observe grounding procedure under installation section.

This pole is not suitable for Hazardous or Classified Locations. This

product must be installed in accordance with the applicable installation code by a person familiar with the construction and operation

of the product and the hazards involved. Consult a qualified electrician to ensure correct branch circuit conductor.

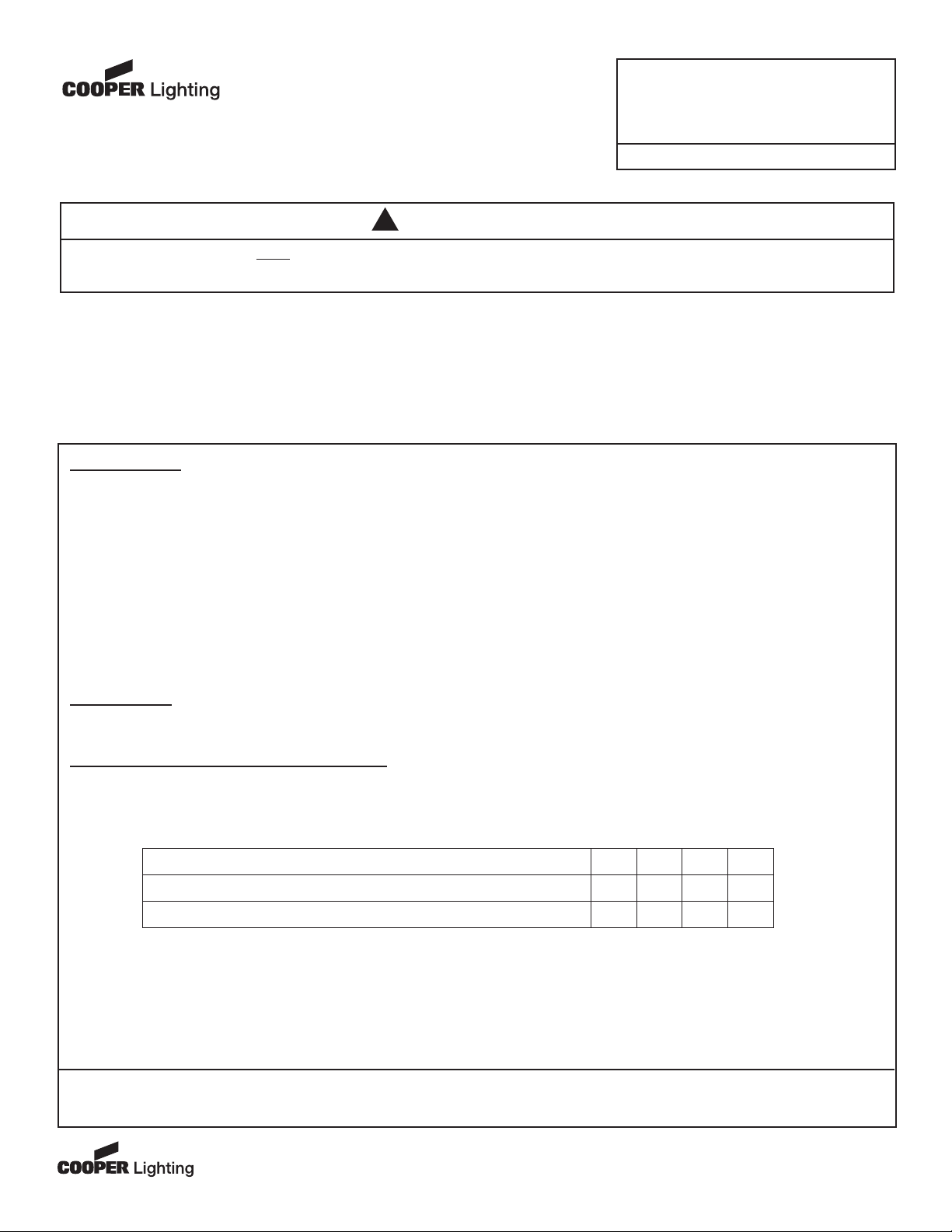

Bolt Diameter in Inches 3/4 1 1 3/4 1 1/2

Recommended Ft. lbs. of torque when nuts are not lubricated 105 250 500 870

Fecommended Ft. lbs. of torque when nuts are lubricated 78 190 380 650

WARNING

• Make certain power is OFF before starting installation or attempting any maintenance.

• FAILURE TO FOLLOW INSTRUCTIONS MAY RESULT IN SERIOUS INJURY OR DEATH.

!

Page 2

These instructions do not claim to cover all details or variations in the equipment, procedure, or process described, nor to provide directions for meeting every possible

contingency during installation, operation or maintenance. When additional information is desired to satisfy a problem not covered sufficiently for user’s purpose, please

contact your nearest representative.

CAUTIONS:

Cooper Lighting poles have been designed to support only the luminaires and equipment originally intended. miscellaneous items such as pennants

signs and decorations may cause pole failure because of overloading. Addition of these items voids cooper lighting’s warranty. Cooper Lighting will,

however, supply information on total loading EPA on request. Cooper Lighting’s poles are guaranteed only when used in a pole/ luminaire or floodlight

combination. any other application of poles, including application without a luminaire or floodlight, voids Cooper Lighting’s warranty.

GROUNDING:

Poles must be grounded in accordance with requirements in the National Electrical Code and applicable Local Electrical Codes.

VIBRATION:

Many isolated wind conditions exist that can be davasting to poles and luminaires. Although rare, vibrations severe enough to cause damage can

occur in structures of all types influenced by many interacting variables. Vibrations are generally unpredictable. constant winds in the 10-30 mph range

can severely damage certain poles by vibration and there is no single cure that will assure the prevention of all modes of vibration. Many factors may

contribute to the development of a vibration problem. It is not however the result of defective material or workmanship and therefore not covered by

the Cooper Lighting warranty. Vibration dampers that can help alleviate this condition can be supplied by Cooper Lighting either factory installed or for

field installation. Cooper Lighting recommends that vibration dampers be considered when any of the following conditions exist:

1. Poles installed on a bridge structure, overpass, or parking ramp structure.

2. Pole having a fixture epa load of less than 0.5.

3. Camera support poles.

4. Locations that experience prevailing constand winds in the 10 to 30 mph range.

5. Any site that has history of vibration problems.

6. Areas specificed as special wind zones (consult local authorities).

7. Locations near an airport, mountain foothills, great lakes, large open areas of flat ground or any other unique locations that may experience

abnormal wind conditions.

The user’s maintenance program should include observation for excessive vibration and examination for any structural damage or bolt loosening.

Failure to do so could result in structural failure.

Customer First Center • 1121 Hwy 74 South • Peachtree City, GA 30269

IMI-484 ACF080468

Poles

Sheet 2 of 3

2/15/08 IMI-484

INSTALLATION INSTRUCTIONS

IMPORTANT: READ CAREFULLY BEFORE INSTALLING FIXTURE.

RETAIN FOR FUTURE REFERENCE.

WARNING

• Make certain power is OFF before starting installation or attempting any maintenance.

• FAILURE TO FOLLOW INSTRUCTIONS MAY RESULT IN SERIOUS INJURY OR DEATH.

!

Tribute Galleria Vision Site

Single

Dual -

2 @ 180

Triple -

3 @ 90

Quad -

4 @ 90

Single

Dual -

2 @ 180

Triple -

3 @ 90

Quad -

4 @ 90

Single

Dual -

2 @ 180

Triple -

3 @ 90

Quad -

4 @ 90

POLSS4APSA15

100 MPH 100 MPH 100 MPH 100 MPH - - - - - - - -

POLSS4APSA20

100 MPH 100 MPH 100 MPH 90 MPH 100 MPH 90 MPH - - 100 MPH 100 MPH 100 MPH 90 MPH

POLSS4APSA25

100 MPH 90 MPH 80 MPH 80 MPH 90 MPH - - - 100 MPH 90 MPH 80 MPH 80 MPH

POLSS5APSA30

90 MPH 80 MPH 80 MPH - 80 MPH - - - 90 MPH 80 MPH 80 MPH -

Page 3

These instructions do not claim to cover all details or variations in the equipment, procedure, or process described, nor to provide directions for meeting every possible

contingency during installation, operation or maintenance. When additional information is desired to satisfy a problem not covered sufficiently for user’s purpose, please

contact your nearest representative.

WARRANTY AND OBLIGATIONS

THE FOLLOWING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES. WHETHER EXPRESS, IMPLIED OR STATUTORY

INCLUDING, BUT NOT BY WAY OF LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

Cooper Lighting warrants to the customer for resale only that Cooper Lighting’s products are free from defects in materials and workmanship. The

obligation of Cooper Lighting under this warranty is expressly limited to repair or replacement without charge, at the sole option of Cooper LIghting of

defective products within a period of one year from the date of shipment of products and only after Cooper Lighting has issued a Return Materials

Authorization to customer for the products.

This warranty does not apply to Cooper Lighting products which have been altered or repaired or which have been subjected to neglect, abuse, misuse or accident (including shipping damages). THIS WARRANTY ALSO DOES NOT APPLY TO PRODUCTS NOT MANUFACTURED BY COOPER

LIGHTING WHICH HAVE BEEN INSTALLED AND USED IN CONJUNCTION WITH COOPER LIGHTING PRODUCTS. This warranty specifically

excludes fatigue or similar failure resulting from induced vibration, harmonic osciliation, or resonance associated with the movement of air currents

around the pole.

LIMITATION OF LIABILITY

IN NO EVENT SHALL COOPER LIGHTING BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES (REGARDLESS OF

THE FORM OF ACTION, WHETHER IN CONTRACT, STRICT LIABILITY, OR IN TORT INCLUDING NEGLIGENCE) NOR FOR LOST PROFITS; NOR

SHALL THE LIABILITY OF COOPER LIGHTING FOR ANY CLAIMS OR DAMAGE ARISING OUT OF OR CONNECTED WITH THIS AGREEMENT OR

THE MANUFACTURE, SALE, DELIVERY, USE, MAINTENANCE, REPAIR OR MODIFICATION OF THE PRODUCTS, OR SUPPLY OF ANY REPLACEMENT PARTS THEREFORE, EXCEED THE PURCHASE PRICE OF THE PRODUCTS.

THIS LIMITATION OF LIABILITY SHALL APPLY TO ANY LIABILITY FOR DEFAULT UNDER OR IN CONNECTION WITH THE PRODUCTS, PARTS, OR

SERVICES DELIVERED HEREUNDER WHETHER BASED ON WARRANTY. FAILURE OF OR DELAY IN DELIVERY, OR OTHERWISE NO LABOR

CHARGES WILL BE ACCEPTED WITHOUT PRIOR WRITTEN APPROVAL OF COOPER LIGHTING. THIS CLAUSE SHALL SURVIVE FAILURE OF AN

EXCLUSIVE REMEDY.

Customer First Center • 1121 Hwy 74 South • Peachtree City, GA 30269 IMI-484 ACF080468

Poles

Sheet 3 of 3

2/15/08 IMI-484

INSTALLATION INSTRUCTIONS

IMPORTANT: READ CAREFULLY BEFORE INSTALLING FIXTURE.

RETAIN FOR FUTURE REFERENCE.

WARNING

• Make certain power is OFF before starting installation or attempting any maintenance.

• FAILURE TO FOLLOW INSTRUCTIONS MAY RESULT IN SERIOUS INJURY OR DEATH.

!

Hawaii

Puerto Rico

Alaska

Spokane

Boise

Pocatello

Portland

Roseburg

Missoula

Great Falls

Havre

Billings

Lander

Eureka

Fresno

Reno

Tonopah

Salt Lake City

Milford

Phoenix

Fairbanks

Barrow

Nome

San Antonio

Houston

Abilene

Fort Worth

Albuquerque

Oklahoma City

Jackson

Grand Junction

Denver

Dodge City

Lincoln

Huron

Bismark

Des Moines

Springfield

Knoxville

Atlanta

Columbia

Raleigh

Columbus

Pittsburgh

Harrisburg

Albany

Portland

Boston

Hartford

New York

Washington D.C.

Richmond

Hatteras

Wilmington

Charleston

Jacksonville

Miami

Tampa

Birmingham

St. Louis

Kansas City

Dubuque

Buffalo

Duluth

Fargo

Cheyenne

Seattle

Sacramento

San Francisco

Los Angeles

San Diego

Yuma

Las

Vegas

Juneau

Anchorage

Philadelphia

Pensacola

Caribou

El Paso

Minneapolis/

St. Paul

Lansing

Detroit

International Falls

Sault Sainte Marie

Kodiak

Green Bay

Indianapolis

Norfolk

Little Rock

Lexington

Nashville

Brownsville

Shreveport

Memphis

Charleston

New Orleans

Chicago

Special Wind Region

(Per ASCE)

80

95

110

100

90

80

70

Miles

Per

Hour

Basic

Wind

Speed

90

90

90

80

70

70

70

70

70

80

90

100

100

100

90

80

70

90

100

100

110

110

90

90

100

100

70

70

70

70

70

70

80

80

80

90

80

80

80

70

90

90

70

70

70

8

0

80

80

80

80

90

90

90

90

100

100

110

110

110

100

100

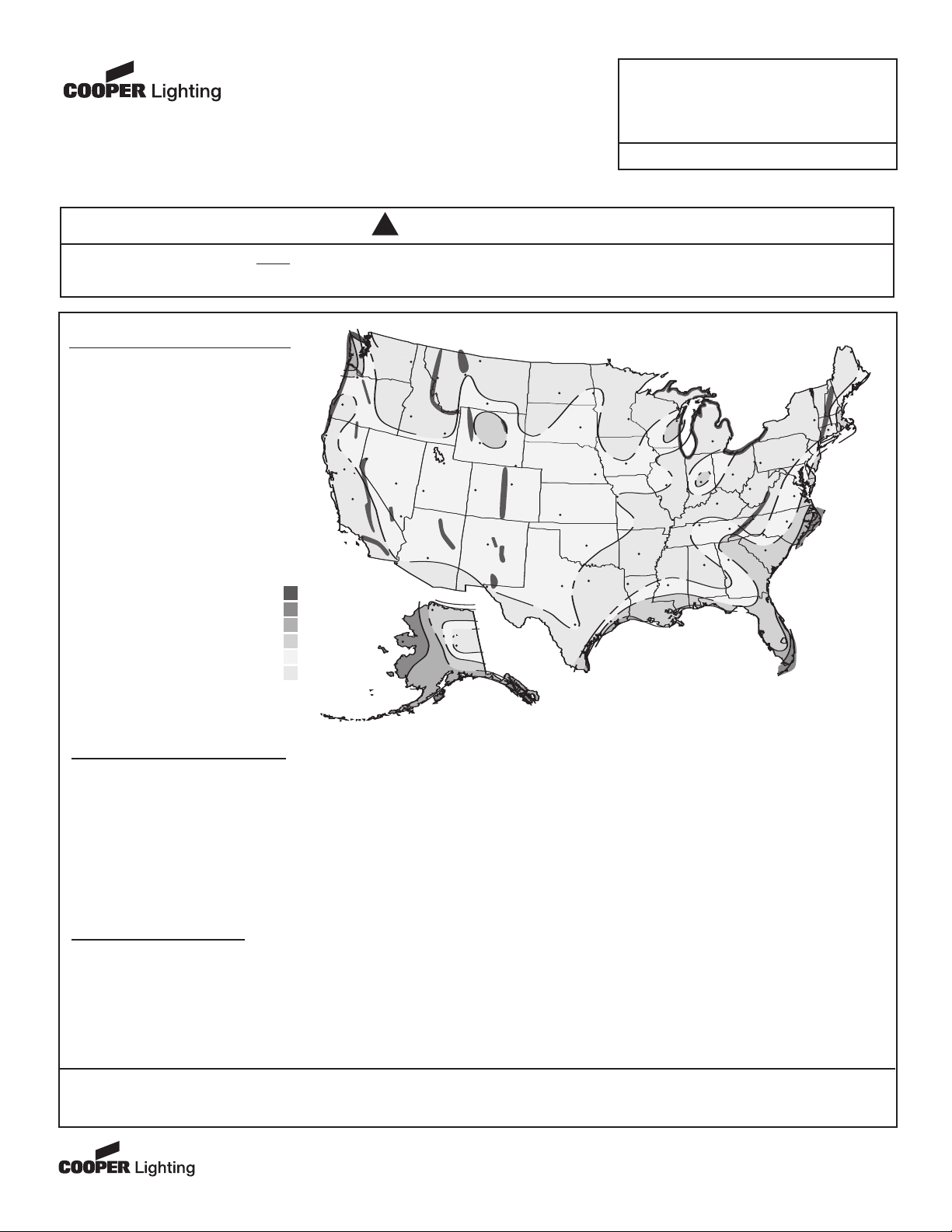

ISOTACH WIND MAP

This map has been included in this

catalog in order to aid in the selection

of a pole with regard to its geographic

location. Although a less stringent

25-year mean recurrence map is

sometimes used by other pole

suppliers, it is our belief that the

added measure of assurance offered

in the use of this map deems it more

desirable.

NOTE: This wind map is intended as a

general guideline only. Consult

local engineering standards

to determine the exact wind

loading conditions for your

application.

Loading...

Loading...