Page 1

Catalog #

Project

Comments

Prepared by

Type

Date

SPECIFICATION FEATURES

04/04/2007 2:45:37 PM

Consult your representative for additional options and finishes.

Specifications and Dimensions subject to change without notice.

ADC040912

LAMP CONFIGURATIONS

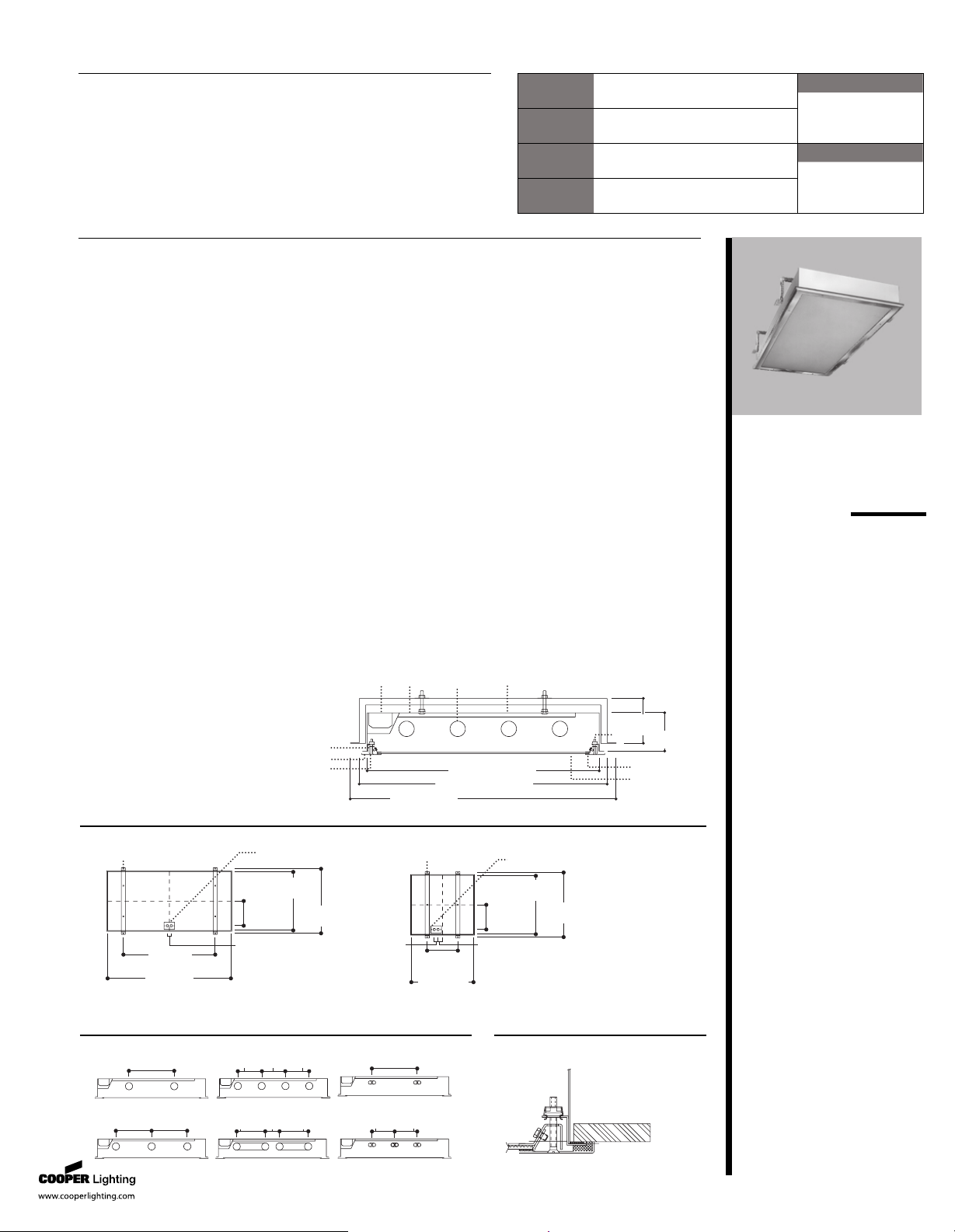

DOOR FRAME

MOUNTING DIMENSIONS

DESCRIPTION

The Fail-Safe CFF Series is designed for use in horizontal or non-laminar air

flow clean rooms. The enclosed and gasketed housing and one-piece, out-

side flanged door protect against infiltration of airborne bacteria. The die

formed edges on the door frame and the hole-free design of the housing

prevent air exchange between the fixture and plenum, allowing relamping

without contamination of the clean areas. These luminaires are U.L. listed

and C.S.A. certified for wet locations and are manufactured in accordance

with U.S.D.A., F.D.A., N.S.F. and Federal Standard 209E. 200 PSI Hose Down

Rating standard.

Application

The CFF Series is suitable for use

in I.E.S. Class 100, 1,000, 10,000

and 100,000 clean room environ-

ments. Applications include clean

rooms, technical and biomedical

labs, food processing/testing

centers and pharmaceutical labs.

A ... Lens

Lens is clear extruded with prisms

positioned inside fixture and

smooth surface on the outside for

easy cleaning.

B ... Fasteners

Flush mounted, stainless steel

machine screws secure through

captive cage nuts in housing and

are evenly spaced to compress

gasketing on all sides.

C ... Housing

Die-formed, 20 ga. CRS with tightly

butted and seam welded, sealed

end caps. Contains no holes that

would allow air passage. Standard

white high reflectance polyester

powder coat finish. Gloss: 85%;

Reflectance: 93%; Hardness: 2H;

Salt Spray: 500 Hours.

D ... Lamps

(By Others)

E ... Lens Retention

Unique, Particulock(TM) lens

retention system utilizes con-

tinuous, 18 ga. media clampdowns

to sandwich gasketing and

integrate lens and door frame for

even environmental seal.

F ... Hinge

Two braided, stainless steel cables

on one side of door provide

hinging.

G ... Door

One piece, 18 ga. door with baked

white polyester powder coat, fully

gasketed, outside door with die-

formed edges eliminates seams

which could entrap microscopic

contaminants. Optional doors

available.

H ... Ballast

Standard Class P, CBM/ETL ballast.

I ... Gasket

White, closed cell, Flexiseal(TM)

gasketing surrounds perimeter of

lens to seal lens to door frame and

around perimeter of door to seal

door to housing. Another layer

seals fixture to ceiling system after

installation.

J ... Access

A gasketed access plate on top of

the housing with two flattened,

7/8" diameter knockouts allows

connection of vapor tight conduit

fitting. Optional, above ceiling, top

access door for luminaire main-

tenance is available and ideal for

food processing and cleanroom

applications.

Labels

U.L. listed, C.S.A. certified,

standard wet label.

CFF

34W - 160W

Fluorescent

2' X 2'

2' X 4'

FLUORESCENT FLANGE

One-Piece Door

C

B

D

H

J

A

F

I

G

E

4 3/8"

[111mm]

3 3/4"

[95mm]

22 11/16"

[576mm]

24 1/4" [616mm]

26" [660mm]

E N E R G Y D A T A

Input Watts:

STD Ballasts & STD Lamps

(2) 20W T12 Fluorescents: 53W

(3) 20W T12 Fluorescents: 85W

(4) 20W T12 Fluorescents: 106W

(2) 40W Biaxial Fluorescents: 82W

(3) 40W Biaxial Fluorescents: 127W

ES Ballasts & STD Lamps

(2) 17W T8 Fluorescents: 45W

(3) 17W T8 Fluorescents: 68W

(4) 17W T8 Fluorescents: 90W

(2) 32W T8 Fluorescents: 71W

(3) 32W T8 Fluorescents: 108W

(4) 32W T8 Fluorescents: 142W

(2) 40W T12 Fluorescents: 86W

(3) 40W T12 Fluorescents: 136W

(4) 40W T12 Fluorescents: 172W

(2) 40W U-Lamps: 86W

ES Ballasts & ES Lamps

(2) 40W T12 Fluorescents: 76W

(3) 40W T12 Fluorescents: 120W

(4) 40W T12 Fluorescents: 152W

(2) 40W U-Lamps: 76W

Electronic Ballast Data

Consult Cooper Lighting Representative.

9 1/2"

[241mm]

5"

[127mm]5"[127mm]5"[127mm]

9 1/2"

[241mm]

7 1/2"

[190mm]

7 1/2"

[190mm]

6"

[152mm]3"[76mm]6"[152mm]

4 3/4"

[121mm]

4 3/4"

[121mm]

Flange Type-One-piece Door

1 1/2"

[38mm]

9 11/16"

[246mm]

23 1/16" [586mm]

Ceiling Cut-Out

25 1/4"

[641mm]

(2) 7/8" [22mm] KO

Gasketed Access Plate

(4) 3/16" [5mm] Dia.

Yoke Mounting Hole

36"

[914mm]

48 5/16"

[1227mm]

1 3/4"

[44mm]

1 1/2"

[38mm]

9 11/16"

[246mm]

23 1/16" [586mm]

Ceiling Cut-Out

25 1/4"

[641mm]

(2) 7/8" [22mm] KO

Gasketed Access Plate

(4) 3/16" [5mm] Dia.

Yoke Mounting Hole

12"

[305mm]

24 5/16"

[617mm]

FAIL-SAFE

®

Page 2

Specifications and Dimensions subject to change without notice.

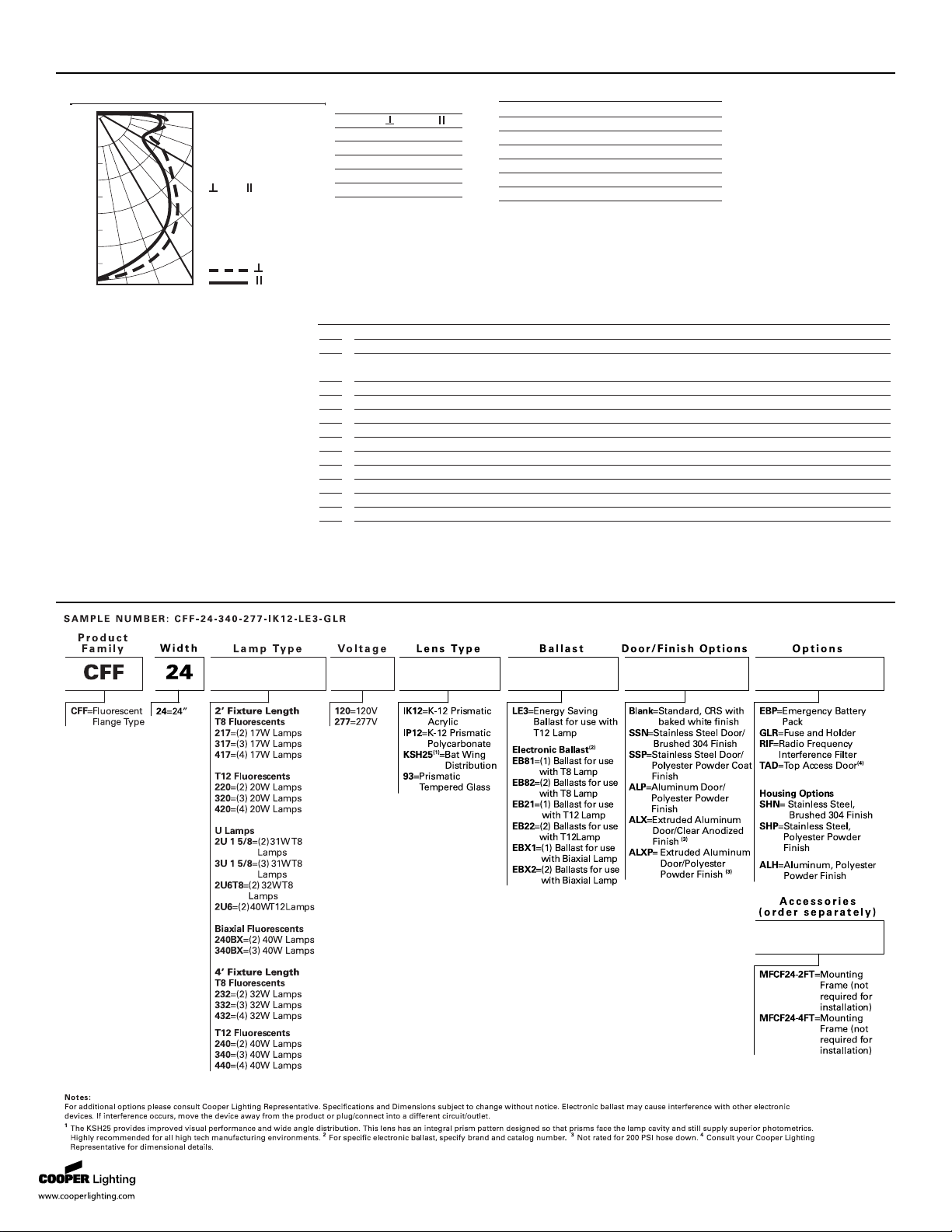

PHOTOMETRICS

ORDERING INFORMATION

CFF

C a ndl e p o w e r Dis t r i b u t ion

Z o nal L u m e n Sum m a r y

Zone Lumens %Lamp %Luminaire

0-30 2728 21.7 32.0

0-40 4499 35.7 52.8

0-60 7316 58.1 85.8

0-90 8526 67.7 100.0

90-180 0 0.0 0.0

0-180 8526 67.7 100.0

80% 70% 50% 30% 10% 0%

70 50 30 10 50 30 10 50 10 50 10 50 10 0

81 81 81 81 79 79 79 75 75 72 72 69 69 68

75 72 69 67 70 68 66 67 64 65 62 62 60 59

69 64 60 57 63 59 56 61 55 58 54 56 52 51

64 58 53 49 57 52 48 55 48 53 47 51 46 45

59 52 46 42 51 46 42 49 42 48 41 46 40 39

54 46 41 37 46 40 36 44 36 43 36 42 35 34

50 42 36 32 41 36 32 40 32 39 31 38 31 30

46 38 32 28 37 32 28 36 28 35 28 34 28 26

43 34 28 25 33 28 24 33 24 32 24 31 24 23

39 30 25 21 30 25 21 29 21 29 21 28 21 20

37 28 22 19 27 22 19 27 19 26 19 25 19 17

rc=Ceiling reflectance, rw=Wall reflectance, RCR=Room cavity ratio

CU Data Based on 20% Effective Floor Cavity Reflectance.

Test No. ITL36036

CFF-24-440-IK12

Lamp=(4) 40WT12

Lumens=8526

Spacing Criteria

=1.4 =1.2

Efficiency=67.7%

rc

rw

RCR

0

1

2

3

4

5

6

7

8

9

10

C o eff i c i e n t of U t i l i z ati o n

Av e r a g e

L u min a n c e

Deg.

45 1595 1323

55 1154 980

65 822 779

75 871 857

85 1018 933

500

1000

1500

2000

2500

Fail-Safe • Customer First Center • 1121 Highway 74 South • Peachtree City, GA 30269 • TEL 770.486.4800 • FAX 770.486.4801

04/04/2007 2:45:37 PM

ADC040912

Loading...

Loading...