Page 1

Warning

that all sources of power are turned off. All

work must meet local/national codes and be

performed by a certified electrician.

mount fixtures vertically.

: Before starting any work ensure

Do not

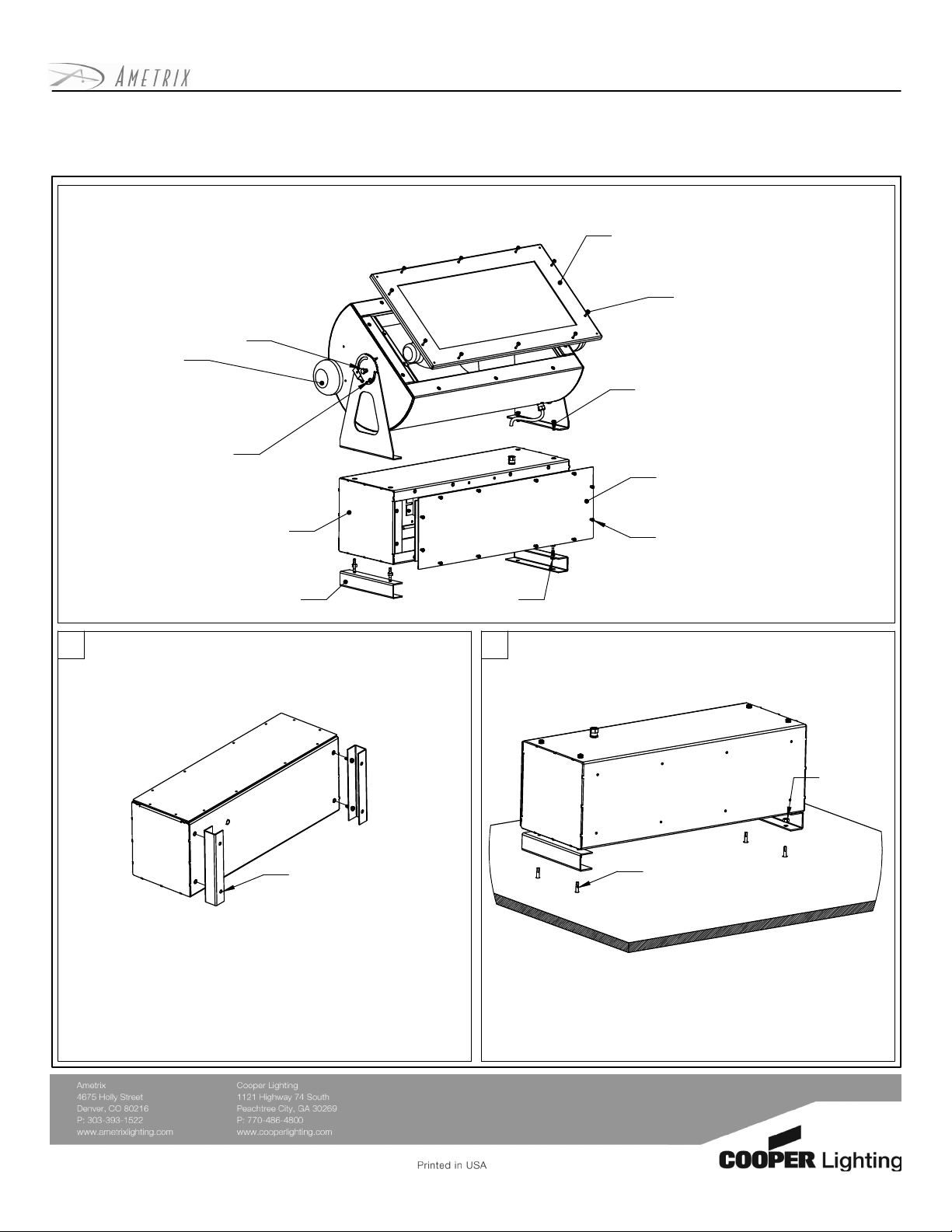

3/8-16 x1"

Hex End bolt

(2x)

End cap

1/4-20 x1"

Aiming screw

(2x)

Exploded View and Part Call-Out

Fixture door

Captive door

screws

(x10)

1/4-20 x1"

Screw

(4x)

Ballast enclosure

cover plate

Installation Instructions

Sheet 1 of 3

Roundel, XL

IN/OUTDOOR

BI

(Base, Integral)

Visor and Non-Visor

1.

Integral ballast

enclosure

Mounting

brackets (2x)

Securing Mounting Brackets

Insert driver through

mounting holes in bracket

to secure brackets to ballast

enclosure.

1/4-20 x1"

Screw

(4x)

2.

#10-32 x 1/2"

Pan head screws

(x12)

Securing Ballast Enclosure to Surface

1/4-20 nut

(x4)

Pre-installed

1/4-20 bolts

(x4)

1.

Using 1/4-20 x1" screws, secure mounting brackets to bottom

of ballast enclosure.

2.

Brackets can be attached as shown or reversed allowing

access to bolts from side of fixture.

ADY080863 REV A(ECN080377)

1.

After securing mounting brackets to ballast enclosure, slide

brackets over pre-installed 1/4-20 bolts in mounting

surface.(Refer to page 3 for mounting dimensions)

2.

Using appropriate nuts, secure ballast enclosure to surface.

Page 2

Warning

that all sources of power are turned off. All

work must meet local/national codes and be

performed by a certified electrician.

mount fixtures vertically.

: Before starting any work ensure

Do not

Installation Instructions

Sheet 2 of 3

Roundel, XL

IN/OUTDOOR

BI

(Base, Integral)

Visor and Non-Visor

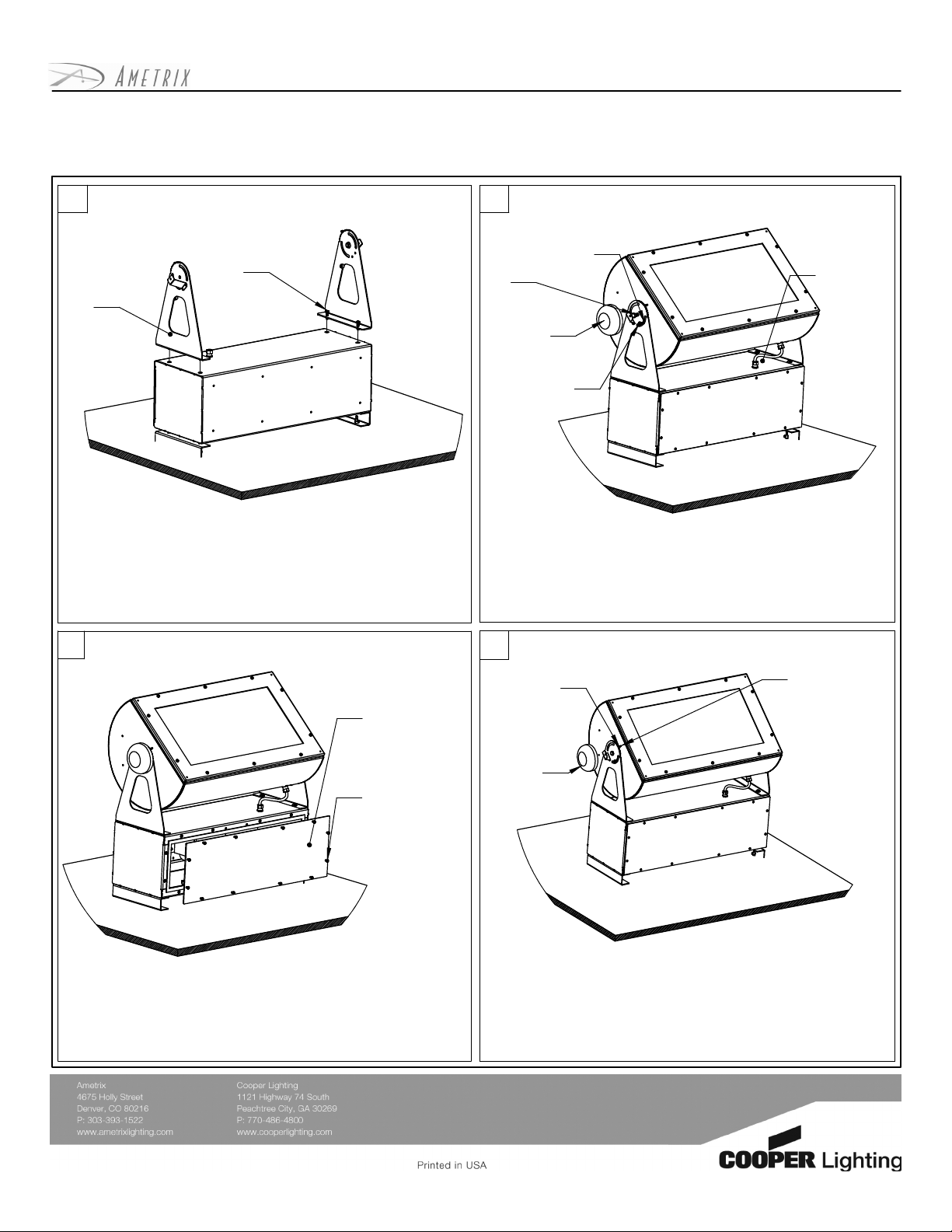

Securing Yoke Arms to Ballast Enclosure

3

1/4-20 x 1"

Pan head screws

(4x)

Yoke arms

(2x)

1.

Attach yoke arms to ballast enclosure using all four 1/4-20x

1" Pan head screws.

5

Wiring the Fixture

4

3/8-16 x 1"

Hex end bolt

(x2)

End Cap

1/4-20 x1"

Aiming screw

(x2)

1.

While firmly supporting fixture head, secure to yoke arms using

both 3/8-16 x1" hex end bolts.

2.

Slide spacers between fixture head and yoke and secure

fixture head position using both 1/4-20 x1" aiming screws.

3.

Insert fixture wire into compression fitting in ballast enclosure.

4.

Replace end cap.

6

Securing Fixture Head

Aiming screw

spacer

(x2)

Fixture Wire

Aiming the Fixture

Ballast

cover plate

#10-32 x1/2"

Pan head screws

(x12)

1.

Loosen all 12 screws and remove ballast box cover plate.

2.

Attach appropriate wires ensuring all connections are properly

matched.

3.

Secure ballast box cover plate using all twelve screws.

Yoke arm

indicator

End cap

(x2)

1. To aim fixture, unscrew end caps from fixture. Loosen both

1/4-20 x1" aiming screws on both sides of fixture. When yoke

indicator and fixture head indicator are lined up, the slope of

the lens face is 40-degrees. Each subsequent notch is an

additional 10-degrees.

2. When fixture is rotated to desired angle, re-tighten set screws

and replace end caps.

Fixture head

indicator

ADY080863 REV A(ECN080377)

Page 3

Warning

LAMP

that all sources of power are turned off. All

work must meet local/national codes and be

performed by a certified electrician.

mount fixtures vertically.

: Before starting any work ensure

Do not

Installation Instructions

Sheet 3 of 3

Roundel, XL

IN/OUTDOOR

BI

(Base, Integral)

Visor and Non-Visor

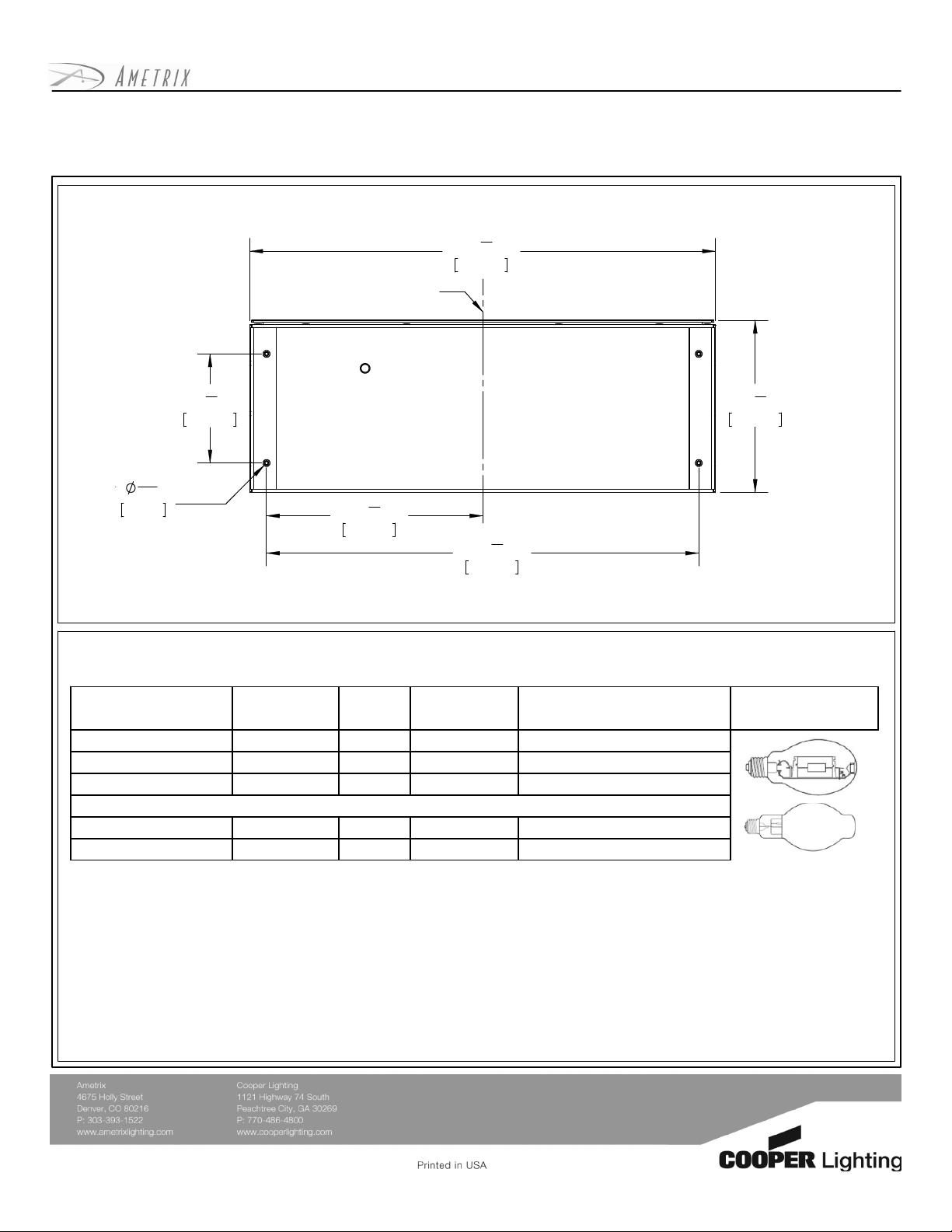

13

32

10.32

(4x)

"

1

6

"

2

165.10

Mounting Plate Dimensions

3

"27

4

704.85

C

L

7

12

"

8

327.03

3

25 "

4

654.05

Lamping Size Chart

(lamps provided by others)

In[mm]

1

10

4

260.35

"

FIXTURE SIZE

(inche s/ mm )

WATTAGE

# OF

LAMPS

LAMP TYPE LAMP DESCRIPTION

27/ 685.8 250W 1 ED28 Metal Halide

27/ 685.8 400W 1 ED28/BT37 Metal Halide

27/ 685.8 400W 2 ED28/BT37 Metal Halide

27/ 685.8 750W 1 BT37 Metal Halide

27/ 685.8 1000W 1 BT37 Metal Halide

(not to scale)

ADY080863 REV A(ECN080377)

Loading...

Loading...