Page 1

B

A

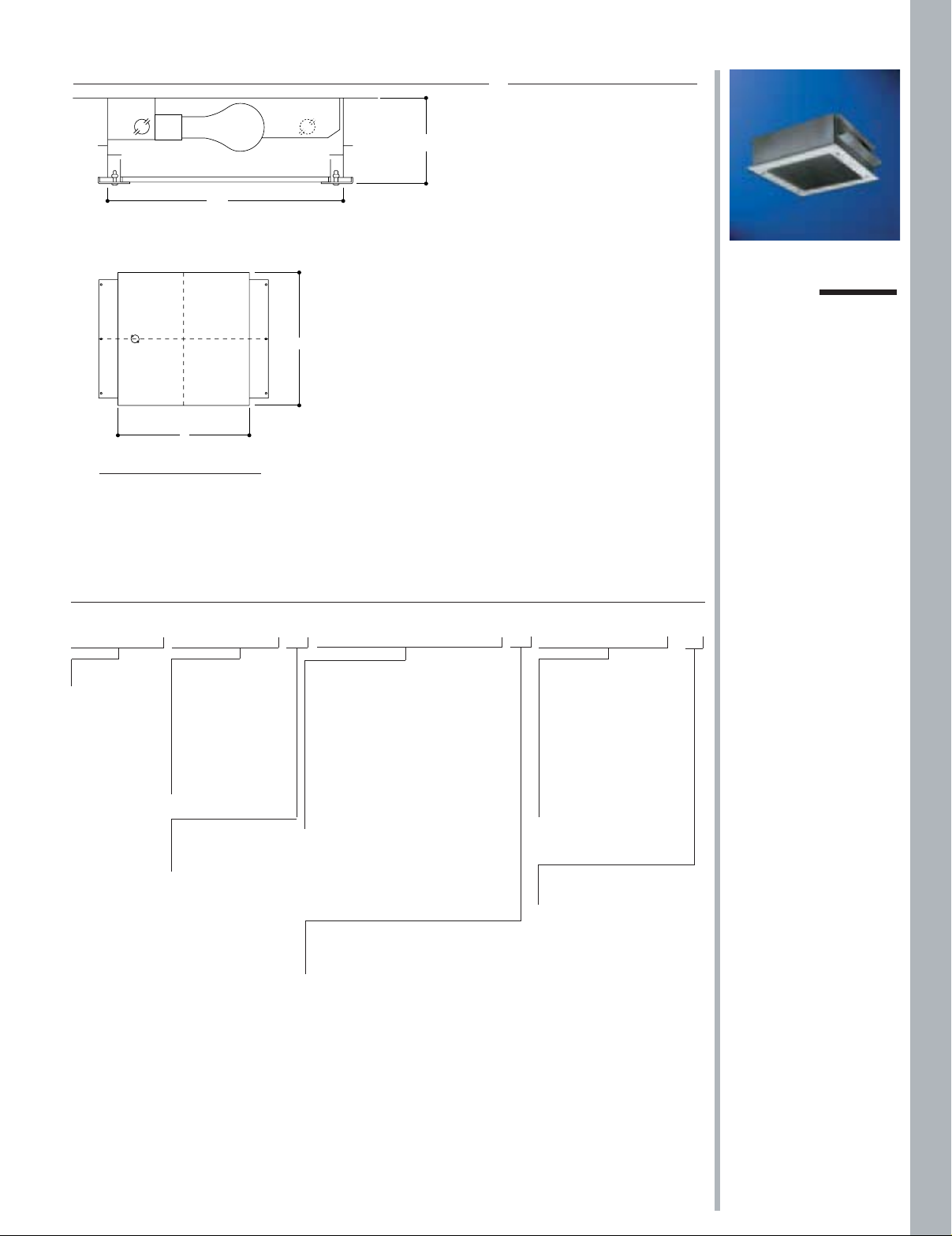

DIMENSIONS

B

C

B

MOUNTING

AB C

4 7/8" 14 3/8" 14 3/8"

(124mm) (365mm) (365mm)

ORDERING INFORMATION

SAMPLE NUMBER: ICP-213-277-82/96-SSN-SF3

Product Family

ICP=Maximum

Security

Concrete Pour

Luminaire

Lamp Type

Compact Fluorescent

113=(1) 13W Lamp

213=(2) 13W Lamps

313=(3) 13W Quad

1

Lamps

226=(2) 26W Quad

Lamps

Incandescent

150I=(1) 150W Lamp

Voltage

120=120V

3

277=277V

347=347V

A

Lens Type /

Inner Layer

(optional)

90=.005 UV

Absorbing

2

Overlay

Fixture Side

80=.125 Prismatic

Acrylic

81=.156 Prismatic

Polycarbonate

82=.187 Prismatic

Polycarbonate

93=.156 Prismatic

Tempered Glass

3

Ballast

Blank=Magnetic Ballast (Standard)

EBT1=(1) Electronic Ballast

EBT2=(2) Electronic Ballast

Environmental Side

84=.125 Clear

Polycarbonate

85=.187 Clear

Polycarbonate

86=.250 Clear

Polycarbonate

87=.375 Clear

Polycarbonate

88=.500 Clear

Polycarbonate

94=.187 Clear

Tempered Glass

96=.250 Clear

Tempered Glass

97=.375 Clear

Tempered Glass

98=.500 Clear

Tempered Glass

DESCRIPTION

The Fail-Safe ICP Series

combines maximum security

construction features with

energy saving technology. This

recessed concrete pour

luminaire utilizes a one piece

heavy gauge housing, security

lensing and tamper resistant

fasteners to maximize impact

resistance and prevent

unauthorized fixture

penetration. U.L. listed for

concrete pour or recessed

applications, C.S.A. certified,

standard wet label.

Options

EBP=Emergency Battery

3

Pack

INL=Incandescent Night

Light-DC Bayonet Base

(Lamp by others)

Stainless Steel Door Frames

SSN=Natural Brushed Finish

SSP=Polyester Powder Coat

Finish

Fasteners

SF3=Allen-Head

(center pin reject)

Accessories (Order Separately)

9306=Allen-Head Wrench

VRSD=TORX

resistant Screwdriver

4, 5

®

-head Vandal

FAIL-SAFE

ICP

13W-52W

Compact Fluorescent

150W

Incandescent

MAXIMUM SECURITY

RECESSED OR CONCRETE

POUR LUMINAIRE

• Lens choice of prismatic

acrylic, prismatic

polycarbonate or prismatic

tempered glass on fixture

side, clear polycarbonate

or clear tempered glass on

environmental side

• Stainless steel tamperresistant TORX®screws

with center pin reject are

standard. Allen-head

screws with center pin

reject are optional

• Die formed 16 ga.

galvanized steel with die

formed, spot welded ends

• Lamps by others

• Continuous, 16 ga., "L"

angles, held with machine

screws provide secure lens

retention

• One-piece, 14 ga. CRS door

frame with die-formed

edges and tightly closed

corners increases rigidity

• Porcelain socket, copper

screwshell, silicone braid,

150˚C (for use with

incandescent lamps)

• Polyurethane gasketing

surrounds door frame and

prevents light leaks

CONFINEMENT

®

Notes: For additional options , consult Cooper Lighting Representative. Specifications and Dimensions subject to change without notice.

1

Available in electronic,quad-tube only. 290 not available in 313 or 226. 3Fluorescent only. 4Not available in 313. 5For use with Compact

Fluorescent, Biaxial, and 20W T12 lamps.

• Two 16 ga., galvanized

steel "L" angles attach to

sides of housing for

mounting to deck prior to

concrete pour

• U.L. listed for concrete

pour or recessed

applications, C.S.A.

certified, standard wet

label.

COOPER LIGHTING

1449

Loading...

Loading...