Page 1

INSTALLATION INSTRUCTIONS AND OPERATING MANUAL

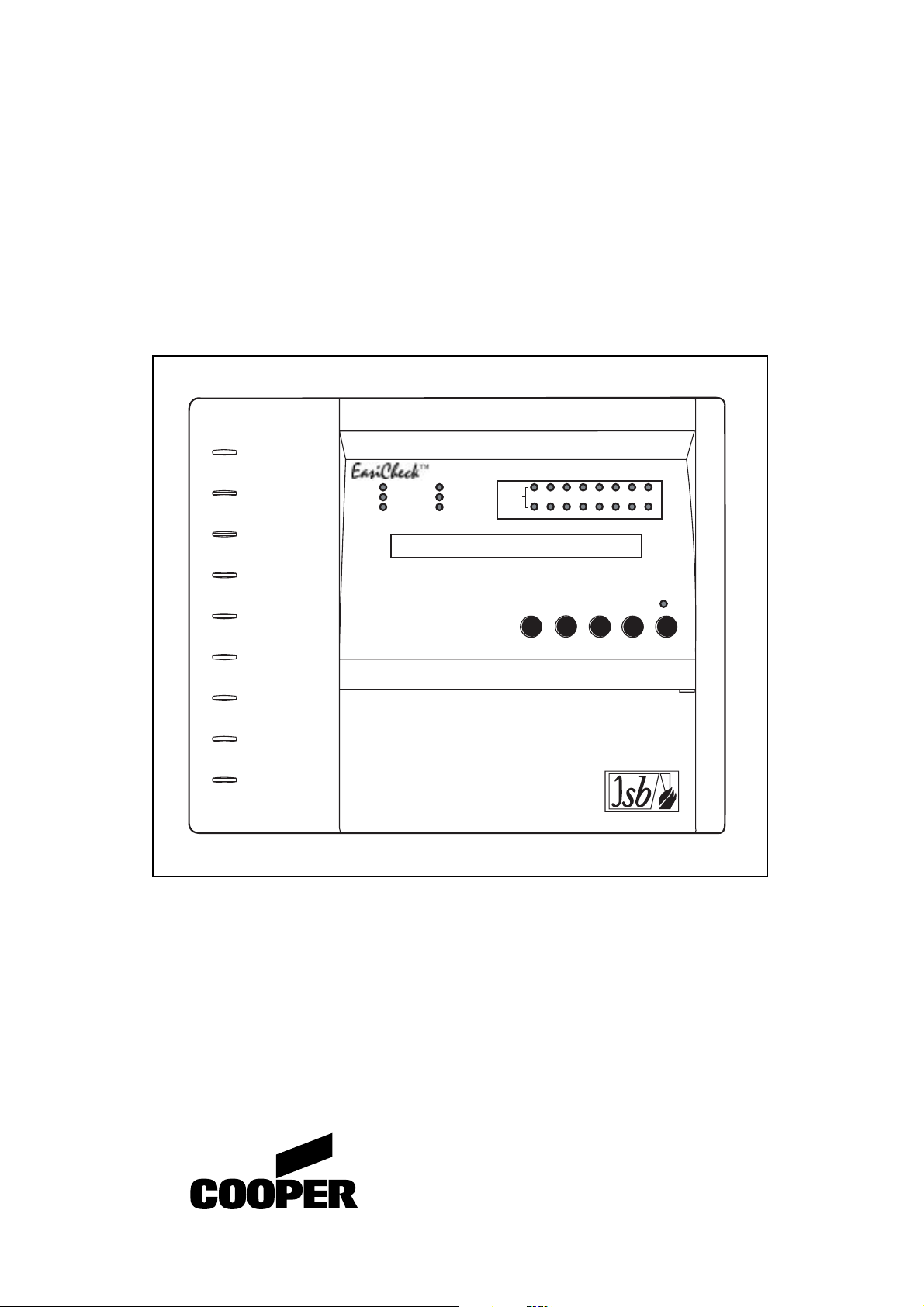

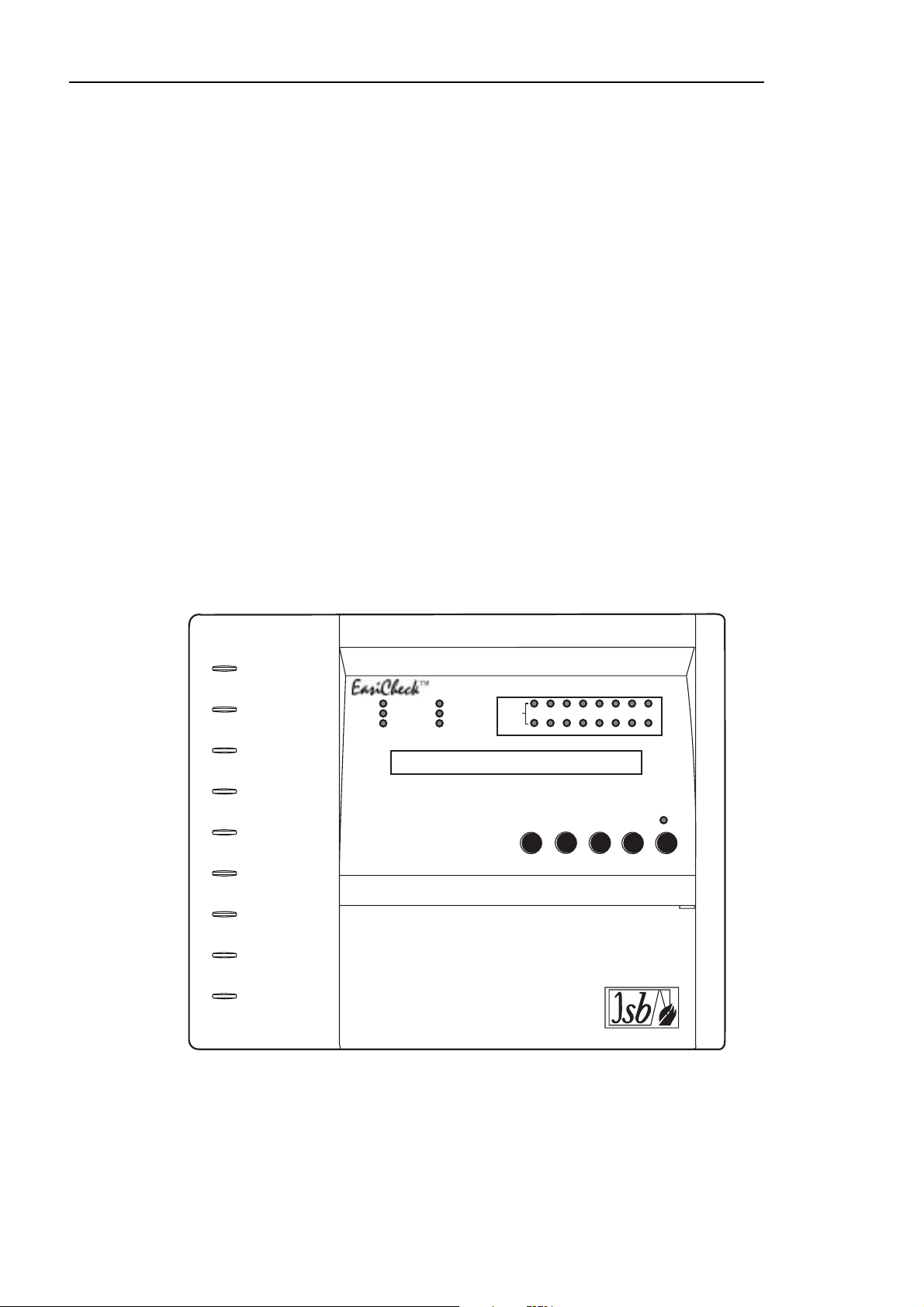

EASICHECK™ 1001

Self Contained

POWER ON

EMERGENCY

MODE

GENERAL FAULT

ADDRESSABLE EMERGENCY LIGHTING CONTROL PANEL

SYSTEM FAULT

TEST IN PROGRESS

DISABLE

LUMINAIRE

GROUPS

12345678

910111213141516

BUZZER

2

1

3

4 5

SCROLLMUTE

Lighting and Security

Page 2

CONTENTS

Introduction

Specification

The SCAEL Interface

Wiring

Powering Up

Commissioning

Setting Date/Time

User Menu

Networking

PC Software

2

EASICHECK™

Page 3

INDEX

Page

Contents 2

Index 3

1.0 Introduction 4

1.1 Specification 5

1.2 Features 6

SCAEL Interface

2.0 Programming 7

2.1 Installation 7

EasiCheck Panel

3.0 Installation 8

3.1 Installation guide 8

4.0 Loop Circuits 9

4.1 Isolators 9

4.2 Loop connection diagrams 10

5.0 Cable Requirement 11

5.1 Cable length - Volt drop 11

5.1.1 Spur circuit 11

5.1.2 Loop circuit 12

5.1.3 Loop with spurs 12

6.0 Mains Connection 14

6.1 Battery Connection 15

7.0 System Wiring 16

Optional Accessories

8.0 Network Diagram 17

8.1 Printer Connections 18

Panel Menu

9.0 Main Panel operations 19

9.1 Initial Power Up (Autolearn Mode)19

9.2 Commissioning 19

9.3 Setting Time and Date 20

9.4 Test Schedule 21

9.4.1 Weekly Test 21

9.4.2 Network Address 21

9.4.3 View Group Test 21

9.5 Menu Options 22

9.5.1 Enable/Disable All 22

9.5.2 Reset the Panel 23

9.5.3 Print Options 23

9.5.4 Discharge Test 24

9.5.5 Led Test (on the fitting) 25

9.5.6 V(Voltage) / I(Current) Display 25

9.6 User menu flowchart 26

Up/Downloading using PC Software

10.0 Description 27

10.1 Connection information 27

Miscellaneous

11.0 Site Configuration Forms 28

12.0 Group Testing 34

13.0 Weekly Test 34

14.0 Commissioning Request Form 35

3

EASICHECK™

Page 4

1.0 Introduction

The EASICHECK™ Panel is designed to periodically test the functionality of your installed

emergency. Once a week, once a month or 6 monthly, the EASICHECK™ will carry out tests

to determine whether your emergency lighting is fully functional.

For testing purposes, the luminaires can be designated to groups. The information for each

group is loaded at the commissioning stage via a PC. Groups can include luminaires in diverse

locations so as to prevent effective loss of emergency cover following test routines.

Manual tests with duration from 5 minutes to 3 hours can easily be instigated. Any faults that

are found are displayed at the panel. Multiple faults can be scrolled through the display by

pressing the scroll button. A permanent or intermittent fault will be detected by the panel. The

display will show the fault, address and location. The fitting will show flashing Amber LED

instead of the flashing green LED. The panel can test a single luminaire at any time if required.

This is done by use of the test mode menu option. A printer may be attached to record all test

results.

If the system communication fails, loop voltage is incorrect, or if there is a Mains failure, any

test that is in progress is terminated and the luminaire states are returned to normal mode.

4

EASICHECK™

POWER ON

EMERGENCY

MODE

GENERAL FAULT

ADDRESSABLE EMERGENCY LIGHTING CONTROL PANEL

SYSTEM FAULT

TEST IN PROGRESS

DISABLE

LUMINAIRE

GROUPS

12345678

910111213141516

BUZZER

2

1

3

4 5

SCROLLMUTE

Page 5

1.1 Specification

" User Text Display Address, location and fault description.

" Dimensions H x W x D (mm) 270 x 332 x 90

" Maximum System Capacity 250 self contained luminaires depending on system type

" Weight (Including Battery) 6 Kg

" LED Indicators/LC Display LEDs are;

Power On, Emergency Mode, General

Fault, System Fault, Test In Progress, Disable,

Scroll and Luminaire Groups

LCD is 2 lines x 40 characters

" User Controls Soft touch five button keypad

" User Function Menu Enable/Disable Units/SCAEL Interface LED Test, Test Mode,

Voltage/Current Display and Print options using RS232

Portable Printer

" Remote Signal Volt free change over Contact (1A 24V DC Relay)

" Communications Port RS232 (Printer) and RS485 (Repeater)

" Sealed Lead Acid Batteries 24V system comprising of 2 x 12V @ 3.2Ah each

" Battery Charger 800mA, constant voltage, temperature compensated

" Loop Output 26V Stabilised

" Loop Communication 9V pulses superimposed on the 26V line

" Temperature Range Battery charger compensated 0° to 40°(C

" Commissioning Site Software Download at initialisation from a PC

" Memory life(without power) 10 Years

" Working Memory 1 week for test result information

" Number of Loops 1

5

EASICHECK™

Page 6

1.2 Features

" 80 Character display showing the exact address and location of any fault identified.

" 16 group capability with individual group indicators in addition to text display.

" One loop giving a total of 250 address capacity.

" Two self contained 12 volt rechargeable batteries for 6 hour standby with a fully loaded loop.

" Full text downloading in seconds using PC compatible computer (i.e. Laptop).

" Self learning of SCAEL Interfaces addresses to aid commissioning

" In the event of Fault, display shows location text, address, charge current and battery voltage.

" Stabilised 24V output independent of Battery voltage during Mains fail.

Fault Relay

Volt free change over contact is provided (see section 7.0), it is rated at 1A / 24V DC

The relay operates upon any Fault condition.

Loop Wiring

Electrical insulation test should not be carried out if the loop cables are connected to the

EasiCheck panel, or to the fittings or to any electronic circuitry.

Before connecting the wiring to the EasiCheck panel, the wiring should be tested for continuity,

polarity, short circuit and earth faults.

Networking

A maximum of 64 EasiCheck Panels can be networked by fitting of additional network cards.

The Panels are inter connected in a network loop (two in, two out). Any EasiCheck Panel

reporting a fault in the system will be shown on all Panels. The Fault may be viewed and reset

from any Panel. See page 11 for cable type

6

EASICHECK™

Page 7

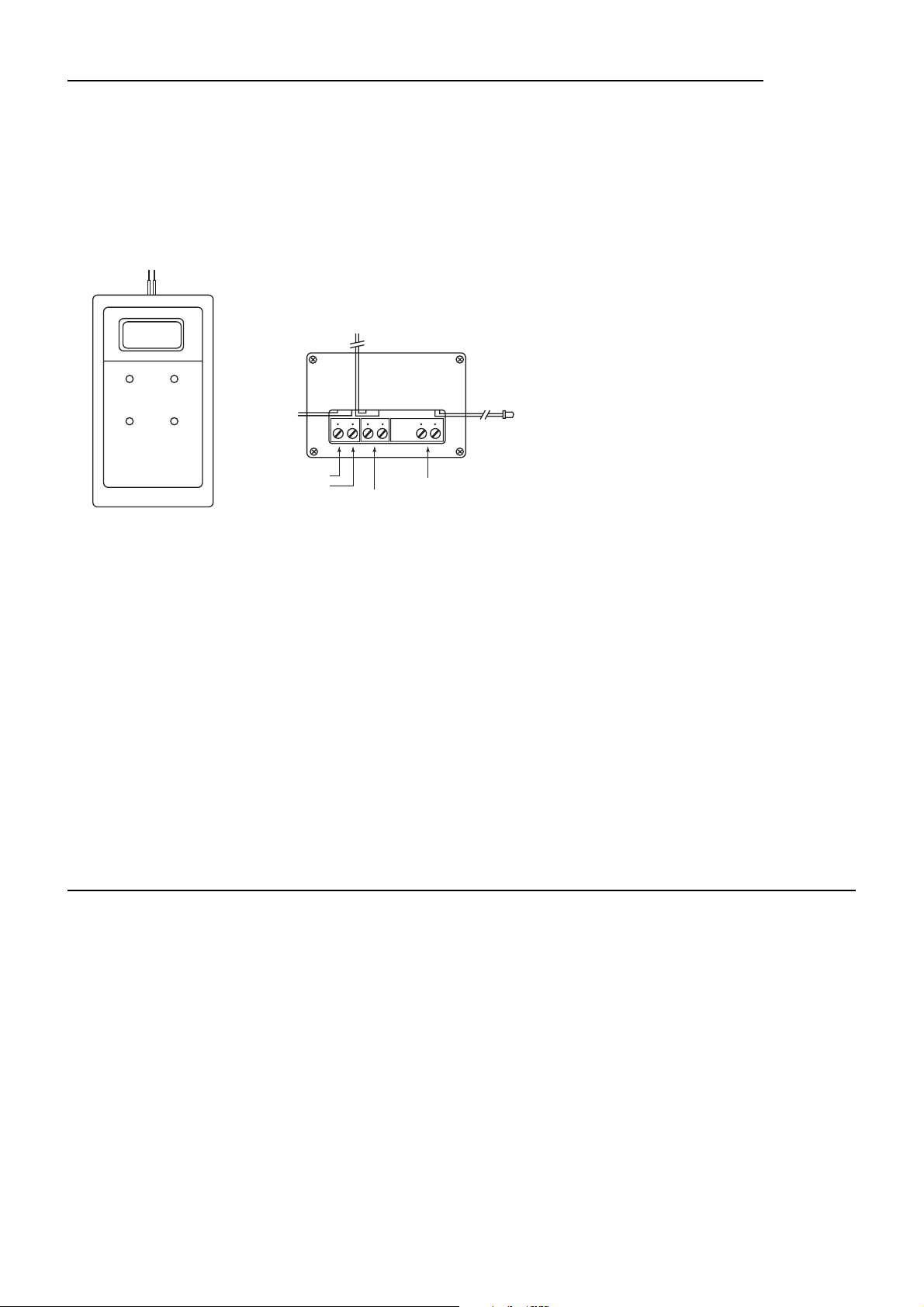

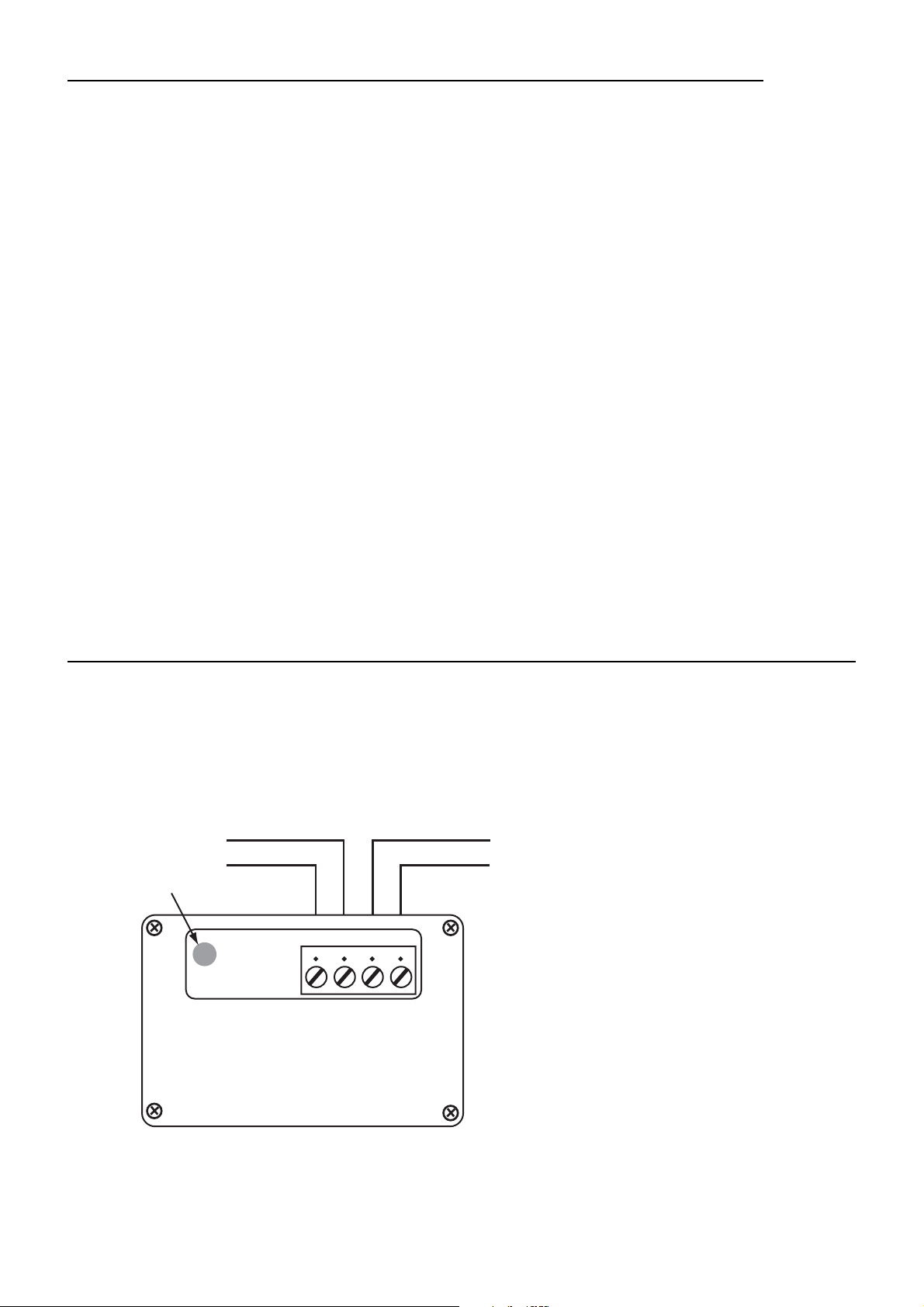

2.0 Programming the EASICHECK™ SCAEL Interface.

Before the SCAEL Interface is connected it must be programmed in order for the

EASICHECK™ Panel to recognise it as part of the system. This is done with an

EASICHECK™ hand held programming unit. The programming unit has two spring loaded

connections which are to be held briefly on to the SCAEL Interface ‘TELE/LOOP’ connections.

See Diagram;

Programmer SCAEL INTERFACE

Switch on the programming unit by pressing the top right button marked On/Off. After a few

seconds the programming unit display will show the next address number due to be

programmed. Hold the spring terminal against the SCAEL Interface and press Program. The

programmer will show ‘Pro’ to register address acceptance and then the address number will

increment by one ready for the next interface. The interface is now ready to be fitted. Repeat

this until all of the interfaces have been programmed.

Note: If you are unsure as to which address the SCAEL Interface has been programmed for,

then with the programmer switched off, hold the spring terminals against the SCAEL Interface

and switch on the programmer. After a short delay the programmer display will flash the

number of the SCAEL Interface address and then return to the next address number to be

programmed.

The SCAEL unit contains a latching relay. During transit it is possible for the relay to change

state, even though it is not powered up. During programming the programmer will

automatically restore the relay to its correct position.

2.1 Installation of the SCAEL Interface.

The SCAEL Interface should be connected into the Luminaire by following the instructions

supplied.

Attach the address label to the Luminaire. Sets of address labels are available separately.

The interface is connected in series with the existing battery pack and the LED is fitted through

a hole in the gear tray to display healthy or fault status. The incoming mains live charge and

live switched (maintained luminaires only) should be wired into the screw terminal block and

the corresponding flying wires for each should be connected into the luminaires in the usual

manner.

The interface continually monitors the battery voltage and charge current which is interrogated

by the EASICHECK™ Control Panel and checked for correctness. Any luminaire found to be

incorrect will have it’s Green LED switched to Amber and the Control Panel will display the

Address number, location and a fault description.

7

EASICHECK™

BATTERY OUT

RED = +VE

001

BLACK = -VE

PROGRAM ON / OFF

TENS

UNITS

LIVE SWITCH (OUT)

LIVE CHARGE (OUT)

BROWN

LIVE SWITCH (IN)

LIVE CHARGE (IN)

SCAEL INTERFACE

RED

LED

TELE/LOOP

BATTERY IN

Page 8

3.0 Installation

In common with all electronic equipment the panel should be installed in a clean, dry,

reasonably well ventilated place, and not in direct sunlight. Temperatures in excess of 40°(C

and below 5°(C may cause problems, if in doubt consult Cooper Lighting and Security Ltd. The

panel should be located away from any potential hazard, in a position where it is readily

accessible to authorised staff. Mount the panel to the wall using the drill template provided. Do

not drill through the panel to the wall as dust will contaminate the circuitry, and prevent correct

operation.

A metal back box is available for semi-recessing the control panel. Dimensions 327mm wide x

265mm high x 77mm deep.

When using 20mm conduit entry direct to the top of the housing, use a flanged coupler to

ensure a wide distribution of pressure when tightening the coupling.

3.1 Installation Guide

Never Use oversized conductors or connect more conductors into termination

points than it can safely contain.

Never Carry out insulation tests on cables connected to electronic equipment.

Always Use the correct gauge of cables.

Always Adhere to volt drop limitation for loop cables

8

EASICHECK™

Page 9

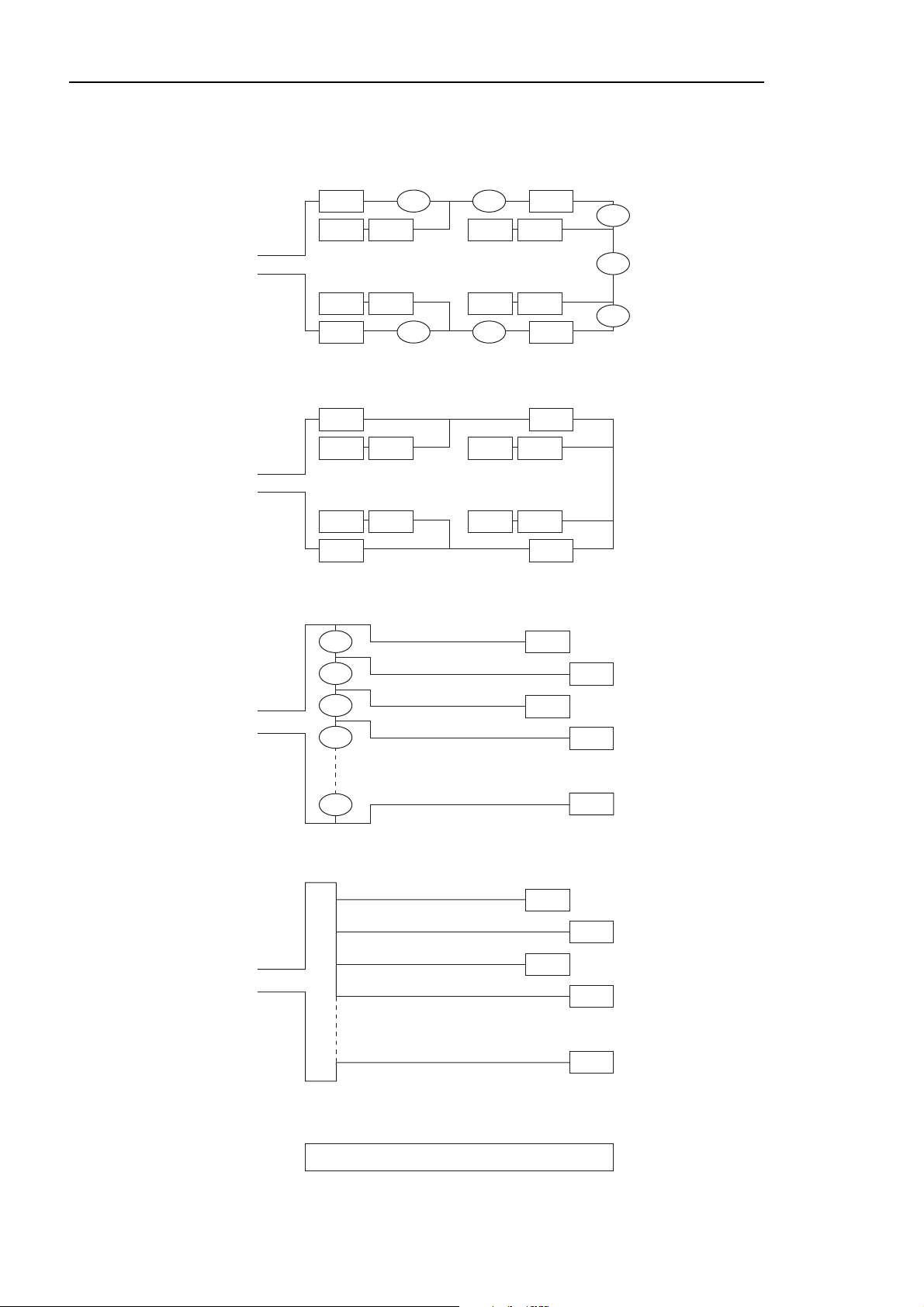

4.0 Loop Circuits

The following recommendations apply specifically to EASICHECK™ loop circuits:

" The EASICHECK™ Panel is a one loop Addressable emergency lighting test system.

" The loop circuit has provision for a maximum of 250 SCAEL Interfaces.

" Each SCAEL Interface has it’s own individual address which can be programmed by

using the EASICHECK™ programmer.

" The recommended cable should be used for the loop circuit.

(see Cable Types section)

" The total length of cable in the loop circuit should not exceed 2km (including all spurs)

" Since SCAEL Interfaces receive/send signals in either direction, a complete loop or

ring circuit is preferred (see diagram) so they continue to function if an open circuit

occurs.

" Isolator units can be installed at intervals throughout the circuit to prevent a short circuit

fault disabling the complete loop.

" It is important to check the voltage drop to ensure the supply to any SCAEL Interface

does not fall below 15V DC.

4.1 Isolators

For spur circuits, it is preferable for circuit integrity to fit an isolator at each spur. For loop

circuits it is preferable to fit an isolator every 15 to 20 fittings

9

EASICHECK™

Note: Unlike the SCAEL Interfaces,

the loop polarity must be observed.

TELE/LOOP

+

-

Fault Indicator

LOOP WIRING

+

-

+

-

-

+

ISOLATOR

PART No: 7466-0005

4063.100.000

Page 10

4.2 Loop connection diagrams

10

EASICHECK™

Mixed Loops with Spurs (+ Isolators)

Loop

Loop

S S

S S S S

S S S S

S S

Mixed Loops with Spurs (No Isolators)

S S

S S S S

S S S S

S S

I

I I

I

Radial (+ Isolators)

I

S

I

I

I

Loop

Loop

I

I

I

I

Radial (No Isolators)

S

S

S

S

S

S

S

S

S

I = Isolator, S = SCAEL Interface

Page 11

5.0 Cable Requirement

Cable type : Two core or screened

Recommended size : 1.0 to 2.5mm2(see Volt drop calculation)

Maximum Resistance : 40 Ohms

Maximum Capacitance : 2.0 µF / km

Maximum cable length : 2 km (see Volt drop calculation)

5.1 Cable Length - Voltage drop

5.1.1 Spur Circuit.

Make sure that the minimum voltage at the furthest point of the spur exceeds 15 Volts

alternatively the maximum voltage drop on the cable should be less than 10 Volts.

Calculation for Voltage Drop

Vdrop = R x I x n (Volts) (1)

Re-arranged equation (1)

R = Vdrop/I x n Ω (2)

n= Number of fittings or addressable interfaces on the spur

I = Average Current of an addressable interface in the fitting = 0.0012 Amps

R = Cable cold resistance ( go and return) Ω

Vdrop not to exceed 10 Volts

This resistance will vary depending on the size of the cable as shown below;

Table 1.0

Therefore for worst case condition, the maximum cable resistance R (max) is;

R(max) = 10/ I x n = 10/0.0012 x n = 8333.33/n Ω (3)

Example 1 If a spur has 250 fittings , using equation (3) the maximum cable resistance is.

R(max) = 8333.33/250 = 33.3 Ω

11

EASICHECK™

Size Cold Resistance Cold Resistance

Single Core Go and Return

1.0 mm

2

18.1 Ω/km 36.2 Ω/km

1.5 mm

2

12.1 Ω/km 24.2 Ω/km

2.5 mm

2

7.4 Ω/km 14.8 Ω/km

Page 12

Example 2 If the spur is wired with 1.0 mm

2

cable, using the go and return column of

table 1, the Max cable length will be 33.3/36.2= 0.9 Km , for 1.5 mm2the Max

cable length is 33.3/24.2 = 1.38 Km and finally for 2.5 mm2the cable length is

33.3/14.8= 2.25 Km.

5.1.2 Loop Circuit;

Calculation as above but assume the loop is broken at one end.

5.1.3 Loop with spurs;

Calculate all individual spurs including maximum return to Panel.

Example 3

As the above example with 250 fittings and using 10 spurs, each having 25

fittings with a main loop length of 100 Metres as shown in Fig1.

Assuming worse case with all load lumped in one place, the maximum

distance of each spur using (Equation 1) will be;

Vdrop = [ RL x n x I ] x [ Rspur x ns x nfs I ] (4)

Where RL = Main Loop cable resistance as shown on Fig 1.

n= Total number of fittings on the loop.

I= Average current of an addressable interface = 0.0012 A

Rspur = Spur resistance

ns = Total number of spurs

nfs = Total number of fittings per spur

Re-arrange (Equation 4) so that the spur resistance is;

Rspur = [ Vdrop - [ RL x n x I ] ] Ω (5)

ns x nfs x I

12

EASICHECK™

Page 13

a) If the loop and spurs are wired with 1.0mm2cable and allowing for maximum permissible

voltage drop with reference to table 1;

Rspur = [ 10 - [ 3.62 x 250 x 0.0012 ] ] (6)

10 x 25 x 0.0012

This corresponds to a maximum spur cable length of 0.820 km

Hence, the total system cable length is 8.3km compared to 0.9 km for a loop system

(see example 2)

b) Similarly, if the system is wired using 1.5mm

2

cable and following the above rules;

Rspur = 30.9Ω , This corresponds to a maximum spur cable length of 1.27km

Hence, the total system cable length is 12.8 km compared to 1.38 km for a loop system

(see example 2)

13

EASICHECK™

= 29.7Ω

Fig. 1

Panel

RI = Cable resistance of main loop

nfs

Loop

of

100m

Number of spurs (ns)

Fitting

Page 14

6.0 Mains Connection

" Normal supply for the system should be derived from the public supply system.

" When no public supply is available, privately generated power may be used.

" The standby battery provides 3.2Ah which will maintain the system in operation for at

least 6 hours upon a Mains failure.

The EASICHECK™ draws a maximum of 1 Amp from the 230V mains supply, wiring used

should be adequate for this load, and should be marked

‘EMERGENCY LIGHT SYSTEM, DO NOT SWITCH OFF’.

A plug and socket is not satisfactory. The mains supply should be connected only to the

terminal block marked ‘230V’, this can be found on the top left hand side of the power supply

board.

14

EASICHECK™

Note: Using a switched DPST spur provides a method of isolating the Mains supply for

maintenance purposes.

230-240 VAC

Mains

LNE

Page 15

6.1 Battery Connection

The two 12V Batteries are connected together in series. The Red wire from the EasiCheck is

connected to the Red terminal of one of the Batteries, the link wire is then fitted to the Black

terminal of that Battery, the other end of the link wire is fitted to the Red terminal of the other

Battery, then finally the Black wire from the EasiCheck is connected to the unconnected Black

Battery terminal.

15

EASICHECK™

(+VE)

+-

Black(-VE)

Red

BlackRed

(+VE)

(-VE)

Page 16

7.0 System Wiring

Connect all SCAEL Interfaces to the EASICHECK™ Panel by means of the TELE/LOOP

connections. There are two connections (loop in & out on +). Interfaces are not polarity

sensitive;

16

EASICHECK™

230 VAC

Mains

LNE

PG

I/P

REPEATER

CONNECTION

Tx- Tx+

FAULT

RELAY

N/O N/CC0V TxD

26V

RS232

RS232 PRINTER

0V

RxDTxD

F+ S-

F-

LOOP

S+

Page 17

Optional Accessories

8.0 Networking

The EASICHECK™ can be fitted with an optional Network card for which there is already a

reserved socket. This is a PCB that simply plugs on to the Power Supply Board and has four

connections. These four connections wire to other Panels fitted with Network cards in a loop

configuration (two in, two out). All Panels connected in this manner will be fully operational and

any Panel will control the system from its keypad. Once a network card has been fitted it’s

address number must be set.

17

EASICHECK™

Network interconnections;

Network Card;

Network sample wiring;

JP1

IN OUT

+ - + -

JP2

Panel 1 Panel 2 Panel 3

NETWORK CARD

+ - + -

IN OUT

+ - + -

IN OUT

EasiCheck™

Panel

EasiCheck™

Panel

2 Core

+ - + -

IN OUT

EasiCheck™

Panel

EasiCheck™

Panel

Page 18

8.1 Printer Connections.

18

EASICHECK™

The Printer enables the user to printout Weekly test reports, Full Reports and the Event Log as needed.

Printer

PSU

Connection

Black wire

FAULT

RELAY

N/CCN/O

RS485

Tx-

Tx+0VTxD

RS232 RS232

PRTR

TxD

RxD

0V

Panel connections

Page 19

9.0 Main Panel Operation

There are two modes of operation;

1. Autolearn mode; System automatically searches for all SCAEL Interfaces connected to

the loop.

No text is available in this mode. This mode can be used for initial checking.

(Note: SCAEL Interfaces must be programmed)

2. Commissioned Mode; The Panel is re-commissioned using a PC to download Address,

Group, type of luminaire, Number of Cells, Duration, Descriptive address text for each

fitting and Test times.

9.1 Initial Power Up (Autolearn Mode)

Switch Mains power on and connect Batteries

After an initial test the display will show;

At this point the system is checking to see how many SCAEL Interfaces are connected.

After a short period the display will show for example;

The system is now ready for limited use without descriptive text for the location.

9.2 Commissioning

In order for the display to show user chosen specific text, the Panel must be Commissioned by

a Cooper Lighting and Security Service Engineer using a PC to download the required

descriptive text;

To Re-Commission, enter the Engineer Passcode.

The display will show;

Press (, the display shows;

Press &, the display shows;

Press &.

The display will light all LEDs in turn and then the display will show;

Press &, the display will show;

See Downloading section (Page 25)

19

EASICHECK™

WAITING FOR THE MASTER TO TRANSMIT THE

NUMBER OF FITTINGS INSTALLED

SYSTEM HEALTHY ! No of FITTINGS= 198

DATE : dd/mm/yy TIME : 10:07:58

1: TIME 2: DATE 3:TEST SCHEDULE

4: RE-COMMISSION 5: QUIT

ARE YOU SURE YOU WANT TO RE-COMMISSION ?

PRESS 1 FOR YES PRESS 5 FOR NO

ATTENTION !!! THIS WILL ERASE ALL DATA !

PRESS 1 FOR CONTINUE PRESS 5 FOR ABORT

TRANSMIT TEXT WITH PC PRESS 1

NO TEXT AVAILABLE PRESS 2

PLUG PC INTERFACE UNIT INTO THE EASICHECK

WITH PC READY TO TRANSMIT

Page 20

9.3 Setting the Time & Date

Setting The Time;

Enter the Engineer Passcode.

The display will show;

Press &, the display will show;

Press &,%,$ or ( to adjust the current time.

Upon completion, press ' to exit the menu.

Setting The Date;

Enter the Engineer Passcode.

The display will show;

Press %, the display will show;

Press &,%,$ or ( to adjust the current date.

Upon completion, press ' to exit the menu.

20

EASICHECK™

1:TIME 2:DATE 3:TEST SCHEDULE

4:RE-COMMISSION 5: QUIT

TIME = HH:MM:SS TO UPDATE PRESS

1:SECS 2:MIN 3:HOUR 4:TENS 5:QUIT

1:TIME 2:DATE 3:TEST SCHEDULE

4:RE-COMMISSION 5: QUIT

DATE = DD/MM/YY DAY OF WEEK: THURSDAY

1:DAY 2:MONTH 3:YEAR 4:D.O.W 5:QUIT

Page 21

21

9.4 Test Schedule

Enter the Engineer Passcode.

The display will show;

Press $, the display will show;

Note: After each menu has been accessed, the passcode will have to be re-entered

9.4.1 Weekly Test;

Press &, the display will show;

Press &,%,$ or ( to adjust the test day and time.

Once the time has been corrected, press ' to exit the menu.

9.4.2 Network Address;

Press %, the display will show;

Press & or % to adjust the network address. (Set to 000 if No Network card is fitted)

Once the address has been selected, press ' to exit the menu.

9.4.3 View Group Test;

Press $, the display will show;

Press ' to exit the menu.

1:TIME 2:DATE 3:TEST SCHEDULE

4:RE-COMMISSION 5: QUIT

1:WEEKLY TEST 2:NETWORK ADDRESS

3:VIEW GROUP TEST 5:QUIT

NETWORK ADDRESS IS : 032

1:TENS 2:UNITS 5:QUIT

WEEKLY TEST SET : TUESDAY AT 22.00 HRS

1:DATE 2:HOUR 3:TENS 4:UNITS 5:QUIT

SYSTEM IN AUTO-LEARN MODE!! ALLTESTING

IS INITIATED MANUALLY 5:QUIT

Page 22

22

9.5 User Menu Options

Enable/Disable (Fittings);

Enter the User Passcode.

The display shows;

Press &, the display shows;

Press & or %, the display shows;

Press % and $ to select the required fitting then press & to enable/disable it.

The display shows;

Repeat pressing % and $ if further fittings require enabling/disabling.

Press ' to exit the menu.

9.5.1 Enable / Disable All;

Enter the User Passcode.

The display will show;

Press &, the display shows;

Press % or $, the display shows;

Note: If Disable is selected, the disable LED illuminates and buzzer sounds once.

CODE ACCEPTED. 1:ENABLE/DISABLE

2:RESET 3:OTHERS 4:TEST 5:QUIT

1:ENABLE 2:DISABLE 3:DISABLE ALL

4:ENABLE ALL 5: QUIT

TO ENABLE/DISABLE FITTING ### (PRESS 1)

2:HUNDREDS 3:UNITS 4:UNITS 5:QUIT

FITTING ### IS ENABLED/DISABLED

2:HUNDREDS 3:TENS 4:UNITS 5:QUIT

CODE ACCEPTED. 1:ENABLE/DISABLE

2:RESET 3:OTHERS 4:TEST 5:QUIT

1:ENABLE/DISABLE 2:ENABLE ALL

3:DISABLE ALL 5:QUIT

ALL FITTINGS IN THE LOOP ARE ENABLED/DISABLED

EXIT (PRESS 5)

Page 23

23

User Menu Options continued...

9.5.2 Reset the Panel;

Enter the User Passcode.

The display will show;

Press %, the display shows;

All LEDs light up in turn and then switch off.

The Panel returns to normal.

9.5.3 Print Options;

Enter the User Passcode.

The display will show;

Press $ the display shows;

Press $ the display shows;

Ensure that the printer is connected and switched on.

press &,%,$ or (, the selected printout will be generated.

CODE ACCEPTED. 1:ENABLE/DISABLE

2:RESET 3:OTHERS 4:TEST 5:QUIT

RESET ACTIVATED

CODE ACCEPTED. 1:ENABLE/DISABLE

2:RESET 3:OTHERS 4:TEST 5:QUIT

1:V/I READINGS 2:LED TEST

3:PRINT 5:QUIT

1:FITTING STATUS 2:WEEKLY TEST RESULT

3:FULL DISCHARGE TEST 4:EVENT 5:QUIT

Example Event Log

--------------------------------

COOPER LIGHTING !! EASICHECK

DATE : 07/05/02

TIME : 10:07:58

--------------------------------

EVENT LOG

-----FAULT EASICHECK PANEL------

CHARGER !!! CHECK BATTERY/MAINS

DATE : 07/05/02 TIME : 10:06:00

--------------------------------

-------------FAULT--------------

LAMP ADD:001 V=03.82 I=0.11

DATE : 07/05/02 TIME : 10:04:33

-----FAULT EASICHECK PANEL------

SYSTEM REBOOT !!

DATE : 07/05/02 TIME : 09:59:43

--------------------------------

Weekly Test Result

-------------------------------COOPER LIGHTING !! EASICHECK

DATE : 07/05/02

TIME : 10:07:58

-------------------------------TEST RESULT !!! WEEKLY TEST AT

DATE : 07/05/02 TIME : 09:55:59

-------------------------------ADD GP CELLS DUR V I

001 01 --- -- 03.65 -1.07

--------------------------------

Page 24

User Menu Options continued...

9.5.4 Discharge Test;

Enter the User Passcode.

The display will show;

Press (, the display shows;

Press &, the display shows;

Press &, % or $, the display shows;

If & is selected, the panel returns to normal display and starts test.

If % is selected, the display shows;

Press % or $ to select the required address number.

Press &, the display shows;

Press % or $ to select another fitting then press & to test.

Press ' to return to normal.

If $ is selected, the display shows;

Press % or $ to select the required group.

Press &, the display shows;

Press % or $ to select another group.

Press ' to return to normal.

24

EASICHECK™

CODE ACCEPTED. 1:ENABLE/DISABLE

2:RESET 3:OTHERS 4:TEST 5:QUIT

1:DISCHARGE TEST 2:ALL IN CHARGE

5:QUIT

DURATION OF TEST !! 1: FIVE MINUTES

2: ONE HOUR 3: THREE HOURS 5:QUIT

DO YOU WANT TO TEST 1: ALLFITTINGS

2: SINGLE FITTING 3: GROUPS 5:QUIT

TO TEST FITTING ### (PRESS 1)

2: HUNDREDS 3:TENS 4:UNITS 5:QUIT

TESTING FITTING ### FOR MORE PRESS

2: HUNDREDS 3:TENS 4:UNITS 5:QUIT

TESTING GROUP ### FOR MORE PRESS

UP: 2 DOWN: 3 QUIT : 5

TO TEST GROUP # !! PRESS 1 FOR YES

UP: 2 DOWN: 3 QUIT : 5

Page 25

User Menu Options continued...

9.5.5 LED Test (on the fitting)

Enter the User Passcode.

The display will show;

Press $, the display shows;

Press %, the display shows;

Press & or % the LED changes colour.

Press ' to return to normal.

9.5.6 V(Voltage) / I(Current) Display;

Enter the User Passcode.

The display will show;

Press $, the display shows;

Press &, the display shows;

Press % or $, to select;

Press &, the display shows;

After a short while, the display shows;

Press ' to return to normal.

25

EASICHECK™

CODE ACCEPTED. 1:ENABLE/DISABLE

2:RESET 3:OTHERS 4:TEST 5:QUIT

1:V/I READINGS 2:LED TEST

3:PRINT 5: QUIT

1:TEST LED AMBER

2:LED NORMAL GREEN 5:QUIT

CODE ACCEPTED. 1:ENABLE/DISABLE

2:RESET 3:OTHERS 4:TEST 5:QUIT

1:V/I READINGS 2:LED TEST

3:PRINT 5: QUIT

TO SELECT FITTING ### (PRESS 1)

2:HUNDREDS 3:TENS 4:UNITS 5:QUIT

THE BATTERY V AND I OF ADD: ###

WILL BE DISPLAYED IN AMOMENT

BATTERY VOLTAGE AND CURRENT OF ADD: ###

VOLT = 04.04 CURR = +0.21 QUIT (PRESS 5)

Page 26

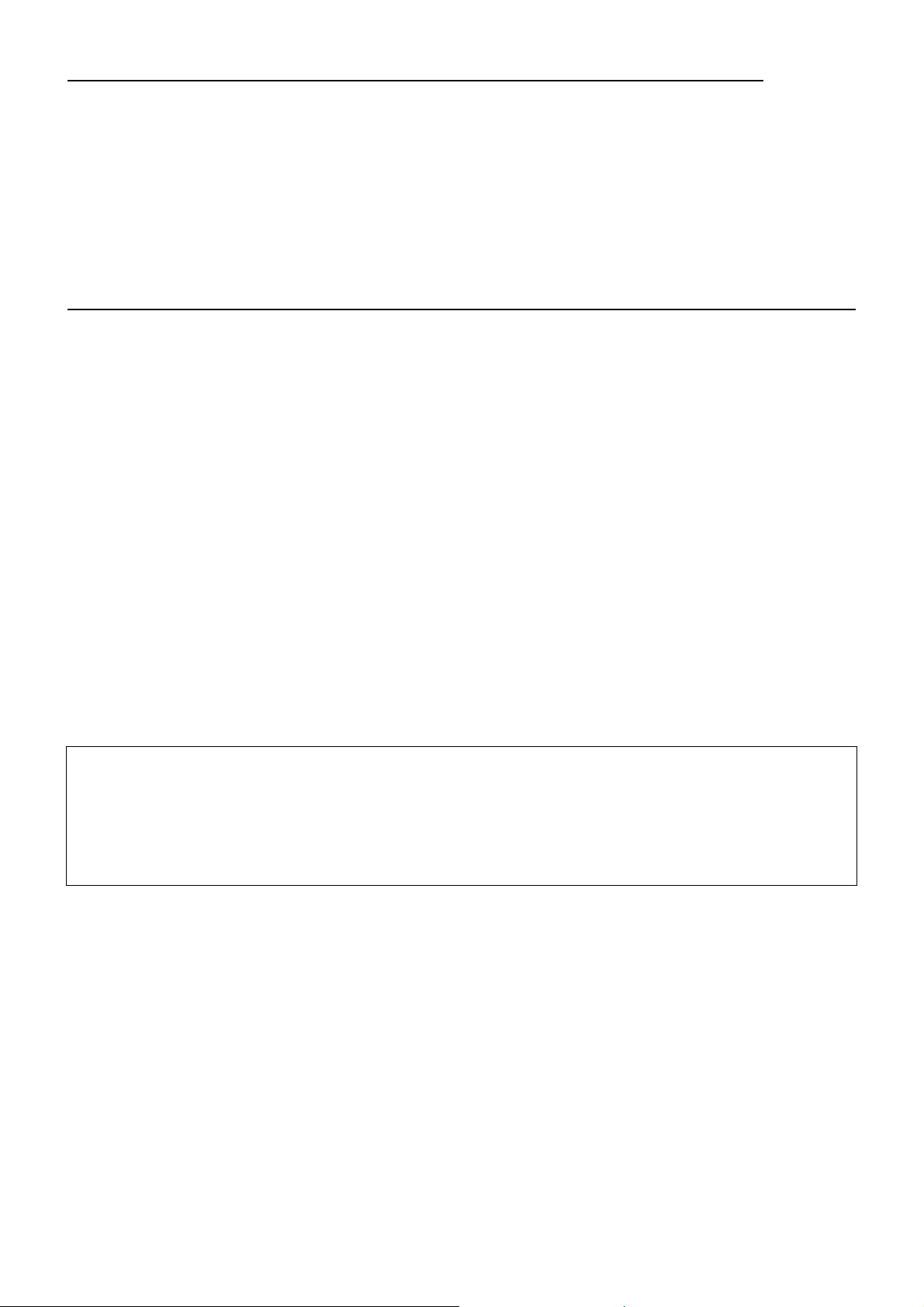

9.6 User menu flowchart

EASICHECK™ Control Panel

User Menu Structure

Self-Contained

26

EASICHECK™

NOTE: During fault conditions the buzzer

may be muted by pressing button 4>

Multiple faults may be viewed by pressing

button 5 only when the scroll Led is flashing.

1 ENABLE

2 DISABLE

3 DISABLE ALL

4 ENABLE ALL

5 QUIT

1 ENABLE

2 HUNDREDS

3 TENS

4 UNITS

5 QUIT

1 DISABLE

2 HUNDREDS

3 TENS

4 UNITS

5 QUIT

USER

PASSCODE

1 ENABLE/DIS

2 RESET

3 OTHER

4 TEST

5 QUIT

1V/I READINGS

2 LED TEST

3 PRINT

5 QUIT

1 DISCHARGE

2 ALL CHARGE

5 QUIT

1 SELECT

2 HUNDREDS

3 TENS

4 UNITS

5 QUIT

1 AMBER

2 GREEN

5 QUIT

1 FIT STATUS

2 WEEKLY TEST

3 FULL DIS

4 EVENT

5 QUIT

1 FIVE MINS

2 ONE HOUR

3 THREE HOUR

5 QUIT

1 LAST 10

2 ALL EVENTS

3 CLEAR LOG

5 QUIT

1 ALL FITTINGS

2 SINGLE

3 GROUPS

5 QUIT

1 TEST

2 HUNDREDS

3 TENS

4 UNITS

5 QUIT

1 TEST

2 UP

3 DOWN

5 QUIT

Page 27

10.0 Up/Downloading using PC Software (Commissioning Engineer Operation)

The PC software enables the address, location text, luminaire type and any comments to be

downloaded to the EASICHECK™ Panel. Each luminaire can be assigned to a group for

testing purposes.

The software can download to all 64 networkable Panels.

The PC is connected to each Panel on the network in turn. All data for that Panel is

downloaded.

The PC software allows copying of Group or Panel for cases where a floor or level has been

copied.

Site details on screen include full postal address, post code, telephone number etc. And any

additional remarks.

The testing schedule can be set from a pre-set menu or a custom setting.

For networked systems, panels are identified by panel number, P1, P2 etc.

10.1 Connection Information

27

#

POWER ON

EMERGENCY

MODE

GENERAL FAULT

ADDRESSABLE EMERGENCY LIGHTING CONTROL PANEL

SYSTEM FAULT

LUMINAIRE

TEST IN PROGRESS

GROUPS

DISABLE

PLUG PC INTERFACE UNIT INTO THE

EASICHECK WITH PC READY TO TRANSMIT

12345678

910111213141516

BUZZER

2

1

3

4 5

SCROLLMUTE

Page 28

28

Site Configuration.

Address Group Type Area/Location Comment

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Page 29

Site Configuration continued.

29

EASICHECK™

Address Group Type Area/Location Comment

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Page 30

30

Site Configuration continued.

Address Group Type Area/Location Comment

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

Page 31

Site Configuration continued.

31

EASICHECK™

Address Group Type Area/Location Comment

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

Page 32

Site Configuration continued.

32

EASICHECK™

Address Group Type Area/Location Comment

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

Page 33

Site Configuration continued.

33

EASICHECK™

Address Group Type Area/Location Comment

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

Page 34

Site Configuration continued.

12.0 Group Testing

13.0 Weekly Test

34

EASICHECK™

Address Group Type Area/Location Comment

241

242

243

244

245

246

247

248

249

250

Group Time Day Month

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Time

Day Of Week

Page 35

4.0 EasiCheck Commissioning Request Form

Project Title: ________________________________________

Prior to the commissioning being undertaken, it is necessary that the contractor completes the

following information so as to aid system commissioning.

With reference to the above project we confirm;

Dedicated Mains Supply Installed Yes / No

All Fittings Installed Yes / No

All Fittings Addressed Correctly Yes / No

Schematics and Drawings Available Yes / No

Wiring Fault Free Yes / No

Loop +ve to Earth _______MΩ -ve to Earth _______ M Ω

Note: Typical readings should show infinity to Earth with a minimum of 1 M Ω.

Please Schedule;

Installation/Address Inspection week commencing: ___ / ___ / ___

(1 weeks notice required)

System Commissioning week commencing: ___ / ___ / ___

(2 weeks notice required)

Reference should be made to the Project Plan Flowchart for timing of deliveries and

commissioning requests.

Upon receipt of this form, the confirmation requested for commissioning dates will be returned

to you. Failure to complete may delay system commissioning.

Signed on behalf of Contractor :

Above in Capitals :

Position :

Telephone Number :

Once completed, please return to;

Service Department

Cooper Lighting and Security Ltd

Wheatley Hall Road

Doncaster

South Yourkshire

DN2 4NB

TEL: 01302 321541

35

EASICHECK™

Page 36

www.cooper-ls.com

Cooper Lighting and Security Ltd.

Wheatley Hall Road, Doncaster, South Yorkshire, DN2 4NB, United Kingdom

Sales General Export

Tel: +44 (0)1302 - 303222 +44 (0)1302 - 321541 +44 (0)1302 - 303250

Fax: +44 (0)1302 - 367155 +44 (0)1302 - 303220 +44 (0)1302 - 303251

Email: sales@cooper-ls.com technical@cooper-ls.com export@cooper-ls.com

7702-4022/V1

Lighting and Security

Loading...

Loading...