Page 1

XAA 911 FOUR-CHANNEL SIGNAL TRIM SUMMING BOX

1.0 INTRODUCTION

The XAA 911 is an excitation or signal trim junction box that can accommodate two, three or four cells and are

used primarily in floor and hopper scales. Each model also has the capability to extend to more than four load

cells using an expansion connector. All models have a new Prevent® breather vent which inhibits the buildup of

pressure caused by sudden temperature or environmental changes. When correctly installed, all models can

withstand 900 PSI water pressure.

All terminals will function properly without modification. However, load cell output can be individually trimmed

with potentiometers, which is further explained in Section 4.0.

1.1 Model Designations

The XAA 911 junction box comes in several different models including stainless steel for the small junction box

and a FRP enclosure for the mid-range junction box. Applications vary from use in floor scales to hoppers so

selection can vary from a light capacity junction box to a mid-range capacity junction box. XAA 911 models

include:

• 4-Channel Excitation Junction Box w/ Expansion in SST Enclosure

• 4-Channel Signal Trim Junction Box w/ Expansion in SST Enclosure

• 4-Channel Excitation Junction Box w/ Expansion in a FRP Enclosure

• 4-Channel Signal Trim Junction Box w/ Expansion in a FRP Enclosure

2.0 XAA 911 JUNCTION BOX MOUNTING PROCEDURE

The XAA 911 junction boxes include tow different sizes:

• 4-Channel small enclosure

• 4-Channel mid-range FRP enclosure

The following sections describe the correct mounting procedure used for each.

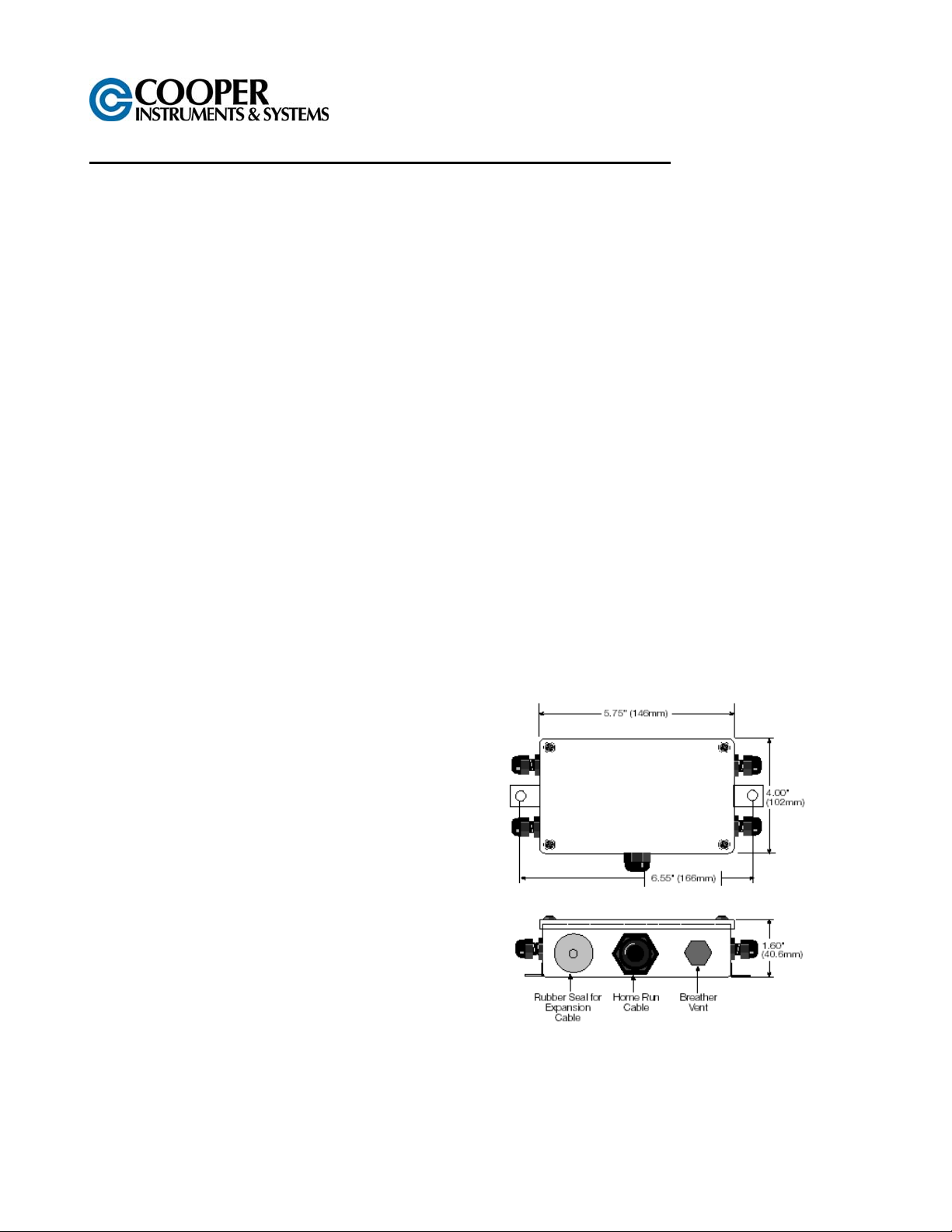

2.1 Mounting the Small Junction Box

The junction box should be mounted in a location

that is convenient for servicing and away from

standing water. Try to mount the enclosure in a

location so that the load cell cables need not be

cut nor length added. Load cell output is

temperature compensated for the supplied cable

length. Altering that length can change the cell’s

signal output.

Depending on the mounting surface, the

enclosure is attached using four pan-head

screws, bolts, or other suitable fasteners. Figure

1 (right) shows dimensions for mounting the

enclosure.

Figure 1. Enclosure Dimensions

CF 60 1 91909 ©2006

Page 2

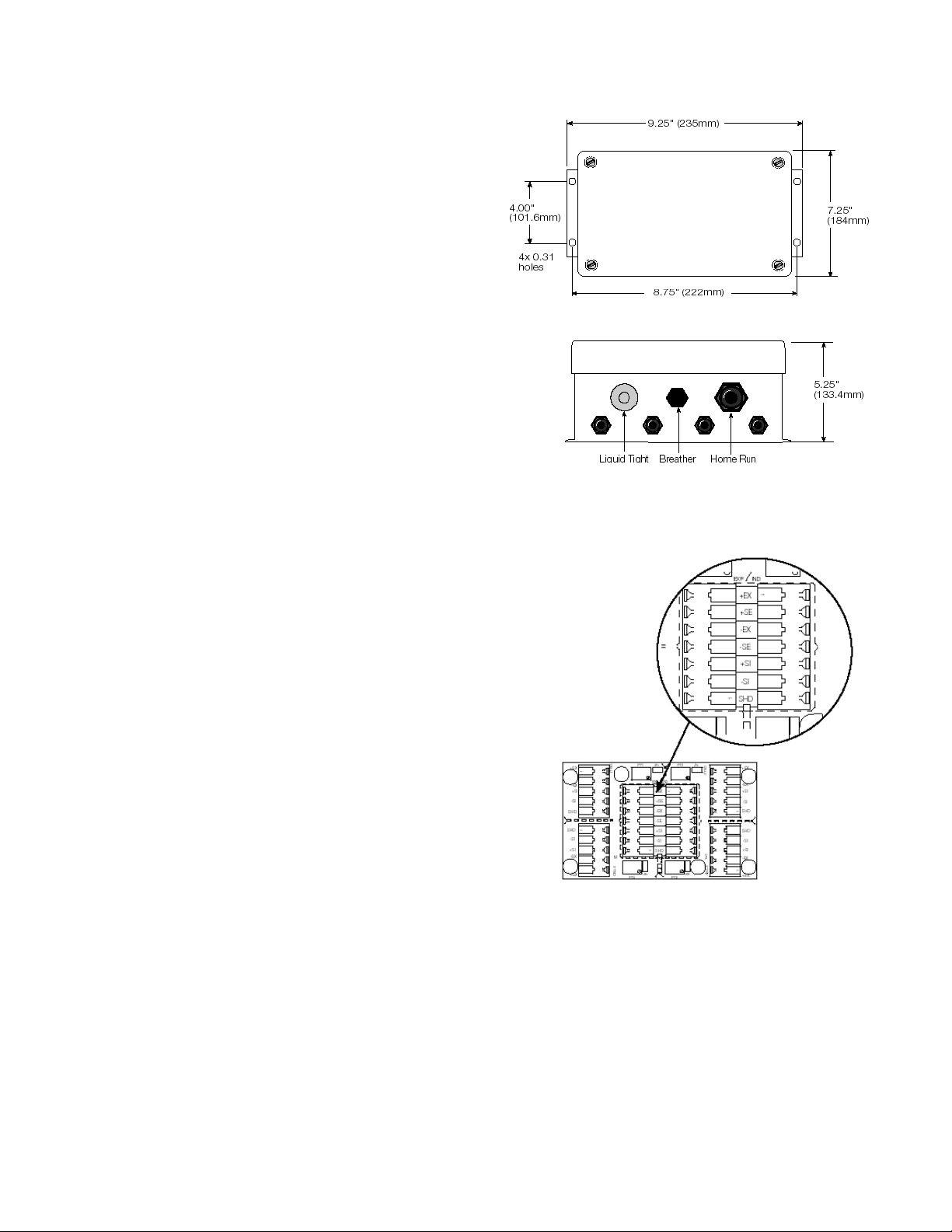

2.2 Mounting the Mid-Range Junction Box

The junction box should be mounted in a location that is

convenient for servicing and away from standing water. Try

to mount the j-box in a location so that the load cell cables

need not be cut, nor length added. Load cell output is

temperature compensated for the supplied cable length.

Altering the length can change the cell’s signal output.

Depending on the mounting surface, the enclosure can be

attached using four pan-head screws, bolts or other

suitable masonry fasteners. Figure 2 (right) shows the

dimensions for mounting the enclosure.

Figure 2. Enclosure Dimensions

3.0 WIRING THE JUNCTION BOX

The XAA 911 has been designed to connect and trim up to

four load cells per board. However, it is possible to use this

box with other combinations. Use the expansion port on the

main board (shown below) to connect multiple junction

boxed in series to accommodate application that have

more that four load cells.

After determining the wiring pattern, route the load cell

cables through the nylon cord grip assemblies and leave

the grips loose until final closure. Before connecting load

cell wires to the terminals, strip the wire insulation back ¼”

to expose the wire. The spring-loaded terminals will

accommodate 12 to 28 gauge wire. To connect the load

cell and indicator wires to the appropriate connectors, push

in the quick-connect lever with a small screwdriver. While

holding in the lever, insert the appropriate wire into the

exposed wire opening. Release the screwdriver to allow

the spring-loaded gate to close and lock the wire in place.

The indicator terminal strip is used to connect the main cable to the indicator. Determine the indicator’s load cell

input connections from the operating manual. Run a cable from your indicator terminal into the junction box through

the larger cord grip and make the connections on the indicator terminal using the same procedure a s inserting load

cell cables to the appropriate connectors.

Figure 3. Expansion Port Wiring Location

4.0 TRIMMING PROCEDURE

Trimming is a process of equalizing the output from multiple individual load cells. If needed, load cell output can

be individually trimmed with potentiometers.

CF60 2 91909 ©2006

Page 3

Whenever a substantial amount of trim (more than 5% of normal output) seems necessary to equalize output,

check for other possible problems. The best trim is always the least amount of trim. When all errors except cell

mismatch and cable extension or reduction have been corrected, continue with the trimming.

Please refer to the appropriate trimming section depending on whether you’ve got an excitation board or a

signal trip board.

4.1 Signal Board Trimming Procedure

Use the following steps to properly trim the junction boxes.

1. Determine the number of load cells needed.

2. Make sure jumpers are in place to enable trimming of the cells corresponding to each load cell. See

Figure 5 for the location of jumpers JP1, JP2, JP3 and JP4. Note that jumpers must be removed to enable

trimming on the excitation board.

3. Set all potentiometers fully clockwise to give maximum signal output from each cell (see below for location

of potentiometers).

4. Zero the indicator and place calibrated test weights over each load cell in turn. The amount of test weight to

be used will depend on the scale configuration; for specific recommendations, refer to Handbook 44 Field

Manual, published by the Institute for Weights and Measures. For a four-cell platform, it’s recommended

using 25% of scale capacity.

5. Record the value displayed on the indicator after the rest weight is placed in turn on each corner (di re ctly

over the load cell) without allowing the weight to overhang the sides. Allow the scale to return to zero each

time to check for friction or other mechanical problems. Select the load cell that has the lowest value as your

reference point. This cell will not be trimmed.

6. Replace the same test load over each cell in turn. Using the corresponding potentiometer, trim each cell

down to equal the reference load cell. As corner corrections are somewhat interactive, check all cells again

for repeatability. If necessary, repeat steps 4 and 5.

7. Pull excess cable out of the enclosure.

8. Using a wrench, tighten nut until the rubber touches the cable completely.

9. Then tighten the nut an additional ½ turn. To be watertight, each cord grip must be tightened so the rubber

sleeve begins to protrude from the hub.

10. Unused hubs must be properly plugged to prevent moisture entry. Contact Cooper Instruments to order

extra hole plugs.

11. Remove the desiccant from the plastic bag, and insert the desi ccant bag into the junction box before

closing. Inspect the desiccant during normal service and change as needed.

12. Replace the cover and tighten the cover screws in an alternation pa ttern to 15 in/lb to be certain the gasket

is compressed equally in all locations.

Figure 4. Signal Trim Main Board

4.2 Signal Board Trimming Procedure

Use the following steps to properly trim the junction box.

1. Determine the number of load cells needed.

CF60 3 91909 ©2006

Page 4

2. Make sure jumpers are in place to enable trimming of the cells corresponding to each load cell. See Figure

4 for the location of jumpers JP1, JP2, JP3, and JP4. Note that you need to remove jumpers for any unused

cells.

3. Set all potentiometers fully clockwise to give maximum signal output from each cell (see above for location

of potentiometers).

4. Zero the indicator and place calibrated test weights over each load cell in turn. The amount of test weights

to be used will depend on the scale configuration; for specific recommendations, refer to Handbook 44 Field

Manual, published by the Institute for Weights and Measures. For a four-cell platform, it’s recommended

using 25% of scale capacity.

5. Record the value displayed on the indicator after the test weight is placed in turn on each corner (directly

over the load cell) without allowing the weight to overhand the sides. Allow the scale to return to zero each

time to check for friction or other mechanical problems. Select the load cell which has the lowest value as

your reference point. This cell will not be trimmed.

6. Replace the same test load over each cell in turn. Using the corresponding potentiometer, trim each cell

down to equal the reference load cell. As corner corrections are somewhat interactive, check all cells again

for repeatability. If necessary, repeat steps 4 and 5.

7. Pull excess cable out of the enclosure.

8. Using a wrench, tighten the nut until the rubber touches the cable completely.

9. Then tighten the nut an additional ½ turn (180º). To be watertight, each cord grip must be tightened so the

rubber sleeve begins to protrude from the hub.

10. Unused hubs must be properly plugged to prevent moisture entry. Contact Cooper Instruments to order

extra hole plugs.

11. Remove the desiccant from the plastic bag, and insert the desi ccant bag into the junction box before

closing. Inspect the desiccant during normal service and change the desiccant as needed.

12. Replace the cover and tighten the cover screw in an alternating p attern to 15 in/lb to be certain the gasket is

compressed equally in all locations.

5.0 WARRANTY REPAIR POLICY

Limited Warranty On Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in

workmanship within one year of the date of shipment by Cooper will be repaired or replaced free of charge

provided that a return material authorization is obtained from Cooper and the defective product is sent,

transportation charges prepaid, with notice of the defect, and it is established that the product has been properly

installed, maintained, and operated within the limits of rated and normal usage. Replacement or repaired

product will be shipped F.O.B. from our plant. The terms of this warranty do not extend to any product or part

thereof which, under normal usage, has an inherently shorter useful life than one year. The replacement

warranty detailed here is the buyer’s exclusive remedy, and will satisfy all obligations of Cooper whether based

on contract, negligence, or otherwise. Cooper is not responsible for any incidental or consequential loss or

damage which might result from a failure of any and all other warranties, express or implied, including implied

warranty of merchantability or fitness for particular purpose. Any unauthorized disassembly or attempt to repair

voids this warranty.

Obtaining Service Under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact

the Repair Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Autho r ization number.

Shipment to Cooper shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from

our plant in Warrenton, Virginia. Non-verified problems or defects may be subject to an evaluation charge.

Please return the original calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty

applies only to those items that were found defective and repaired; it does not apply to products in which no

defect was found and returned as is or merely recalibrated. It may be possible for out-of-warranty products to

be returned to the exact original specifications or dimensions.

CF60 4 91909 ©2006

Page 5

* Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper

to receive information specifying the reason the product is being returned. Specific test data, written

observations on the failure and the specific corrective action you require are needed.

CF60 5 91909 ©2006

Loading...

Loading...