Page 1

Quick-Check notes

What size sheaves should be purchased?

It makes sense to take advantage of the range for the sheaves. Most customers can make do with one set

of sheaves for the entire assortment of wires they tension by installing the sheave set that matches the largest

diameter cable being used. If a customer checks tension in both 3/4” and 3/16” rope, then they should order

two sheave sets of sheaves. The operator must use the appropriate sheave set for the wire size and

calibration stored. Changing sheave sets takes about two minutes with included wrench.

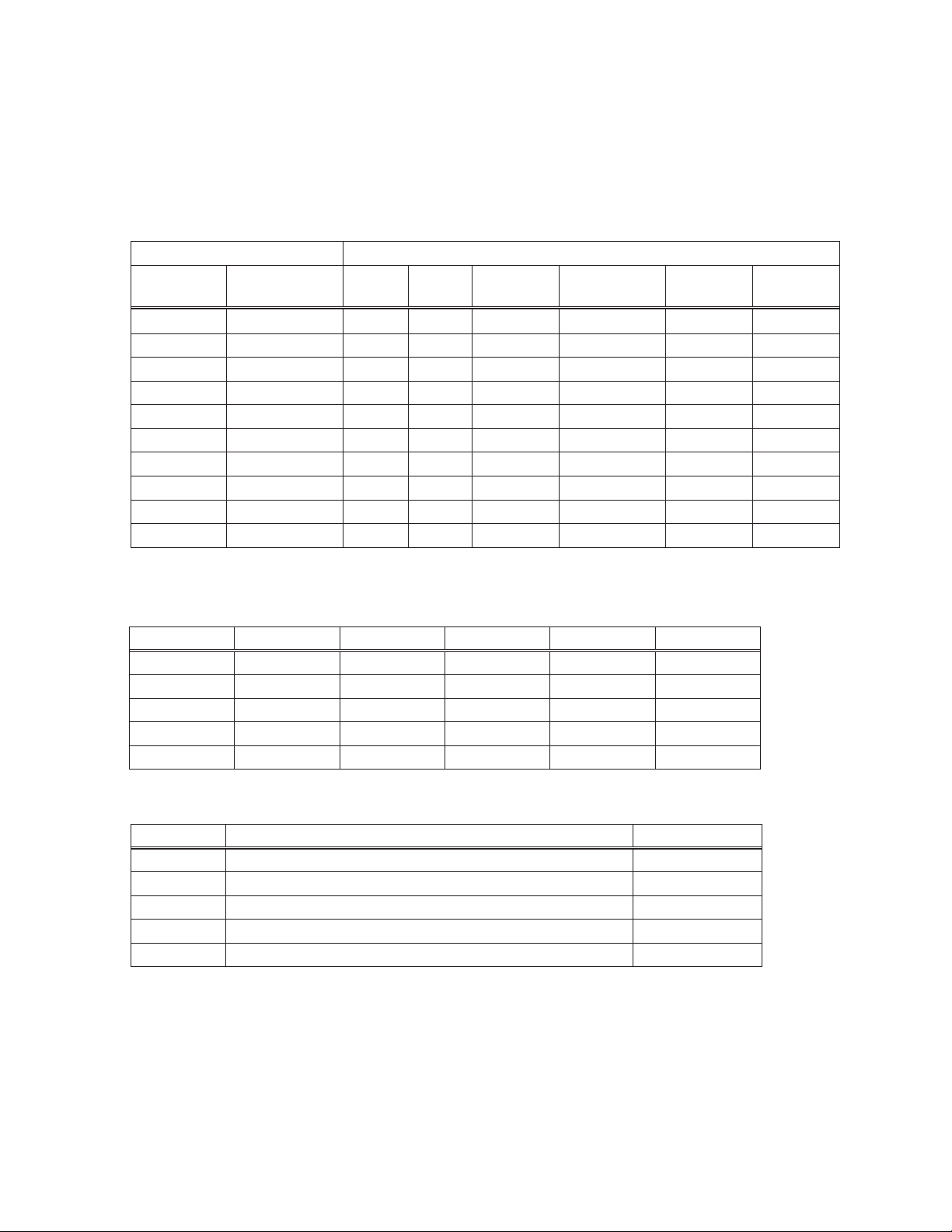

Wire rope calibration slings on hand:

Popular Stranded Wire Wire type

Wire size

Default load*

3/16” 1000 lbf

1 x 7

EHS

YY Y

1/4” 2000 lbf Y Y Y Y Y

5/16” 3000 lbf Y Y Y

3/8” 3500 lbf Y Y Y Y Y

7/16” 4000 lbf Y Y

1/2” 5000 lbf Y Y Y Y

9/16” 6000 lbf Y Y

5/8” 7000 lbf Y Y Y Y Y

3/4” 8000 lbf Y Y Y Y

7/8” 9000 lbf Y

1 x 19

EHS

6 x 19

Fiber Core

6 x 19 IWRC

Wire Core

7 x 19

Wire Core

8 x 19

Fiber Core

* or maximum capacity of Quick-Check / whichever is lower

Electric Conductors

Name Size Dia. Type Sheathing Max Load

Sparrow 2 AWG 0.316 ACSR No 1710 lbf

Raven 1/0 0.398 ACSR No 2628 lbf

Penguin 4/0 0.563 ASCR No 3636 lbf

Chickadee 397.5 0.743 ACSR No 3636 lbf

Petunia 750 0.997 AAC No 3636 lbf

Individual Applications

Wire Size Description Default Load

1/2” 6 x 26 wire core 5000 lbf

3/4” 3 x 7 standard safety (unstretched) 6000 lbf

3/4” 3 x 7 pre-stretched safety 8000 lbf

5 mm 1 x 7 stainless steel 1000 lbf

3 /16” solid steel (pre-stressed concrete) 7000 lbf

Calibration load may be changed if desired. Higher calibration loads are limited by max. capacity of the sling.

If the desired wire size/type does not appear, customer may supply 15 feet of wire to determine if a custom

calibration sling can be created. Extra charges may apply. Consult factory for details.

As wire slings are added, the most current listing of the available wire slings can be found on the Quick-Check

price list on the dillonforce.com website.

Loading...

Loading...