Page 1

WSC 4329

WIRELESS CELLMITE SYSTEM

USER’S GUIDE

www.cooperinstruments.com

PH: (540) 349-4746 • FAX: (540) 347-4755

Page 2

CONTENTS

1.0 INTRODUCTION ....................................................................................................................1

2.0 M4329/4329M WIRELESS CELLMITE® SYSTEM QUICKSTART........................................1

2.1 M4329M Master CellMite® .................................................................................................................................2

2.2 M4329 Remote Slave CellMite®.........................................................................................................................2

3.0 INSTALLATION AND START UP..........................................................................................4

4.0 RUN MODE ............................................................................................................................4

4.1 Data Measurement .............................................................................................................................................4

4.2 Tare and Reset ...................................................................................................................................................4

4.3 CellMite Setup Options .......................................................................................................................................4

4.3.1 TEDS Tag™/Auto ID....................................................................................................................................4

4.3.2 Temperature Compensation ........................................................................................................................4

4.4 Sensor Setup Options.........................................................................................................................................4

4.4.1 Filtering ........................................................................................................................................................5

4.4.2 Analog Output ..............................................................................................................................................5

5.0 CALIBRATION MODE ...........................................................................................................5

6.0 TECHNICAL INFORMATION/CUSTOMER SUPPORT .........................................................5

7.0 WARRANTY REPAIR POLICY ..............................................................................................5

APPENDIX A – WIRELESS CELLMITE® SPECIFICATIONS.....................................................7

Excitation (M4329) ................................................................................................................................................ 7

Operation (M4329)................................................................................................................................................7

Outputs (M4329) ................................................................................................................................................... 7

Power (M4329/4329M) .........................................................................................................................................7

Mechanical (M4329/4329M) .................................................................................................................................7

Wireless Operation (M4329/4329M)..................................................................................................................... 7

APPENDIX B – M4329/4329M CABLES AND CONNECTORS ..................................................8

APPENDIX C – BRIDGE CONNECTION DIAGRAMS ................................................................9

CF 152 ii Pub. 3775-02

Page 3

1.0 INTRODUCTION

The WSC 4329 and WSC 4329M comprise the Wireless CellMite® System, a versatile precision system of instruments intended for the digital readout of strain gage sensors, such as load cells and extensometers, using wireless

communications between the CellMite® and the host PC. The Wireless CellMite® System can be used with any

member of the CellView family of graphical user interface software including CellView LITE, CellView Multi-

Display, and the CellView Driver, a C-Based API that programmers can use to write their own user interface.

CellMites™ can also be used optionally with an analog digital display that connects directly to the unit and/or the

M4340 CellMite® Battery Pack (ESL p/n 306340).

Here is a quick listing of its features:

• Communications to and from the remote, wireless slave CellMite® (M4329), via the wireless Master CellMite®

(M4329M) connected to the host PC RS232 serial port. The wireless slave CellMite® also allows for direct serial connection to the host PC.

• Remote, wireless slave CellMite® can be powered by the optional M4340 CellMite® Battery Pack (ESL p/n

306340).

• Shunt button can be used to close the shunt relay and take a reading when connected to an analog display.

• Tare button can tare readings when connected to an analog display.

• CellView family of software allows for the measurement load, peak, and valley in various English and metric

units. User-defined units are also supported in the GUI software.

• CellView family of software allows data storage directly to PC that is compatible with Excel spreadsheets

• CellView graphical user interfaces allow the user to Tare readings at any point when data is streaming from

the unit.

• This unit supports the calibration of up to three sensors. Calibration data is stored in the unit. The CellView

family of software allows the user to calibrate various types of strain-gage sensors.

• Calibration for load cells can be done using manufacturer’s milli-volt per volt calibration factor, 2 or 6 point

known mass/extension, or internal precision shunt calibration.

• Two latching solid state relay switches are available to for use through the CellView family of software.

• Automatic identification of calibrated load cells with TEDS Tag.

• Analog output of either a set voltage or a voltage tied to the sensor reading with user defined scale factor and

offset. Wide range, buffered ± 10.00 volt output.

• Other functions available as custom programmed options.

2.0 M4329/4329M WIRELESS CELLMITE® SYSTEM QUICKSTART

This section will help you get your Wireless CellMite® System set up and operating in just a couple of minutes.

The Wireless CellMite® M4329 Hardware provides DC excitation that is suitable for strain gage and resistive

bridges. It is highly recommended that you calibrate sensors and set the system settings while the remote slave

M4329 unit is visible to the user. This can even be done via direct serial connection between the remote slave

M4329 and the host PC. Then the unit can be placed remotely for operation. This is so that the user can see the

status of the remote slave’s LED while setup and calibration are performed.

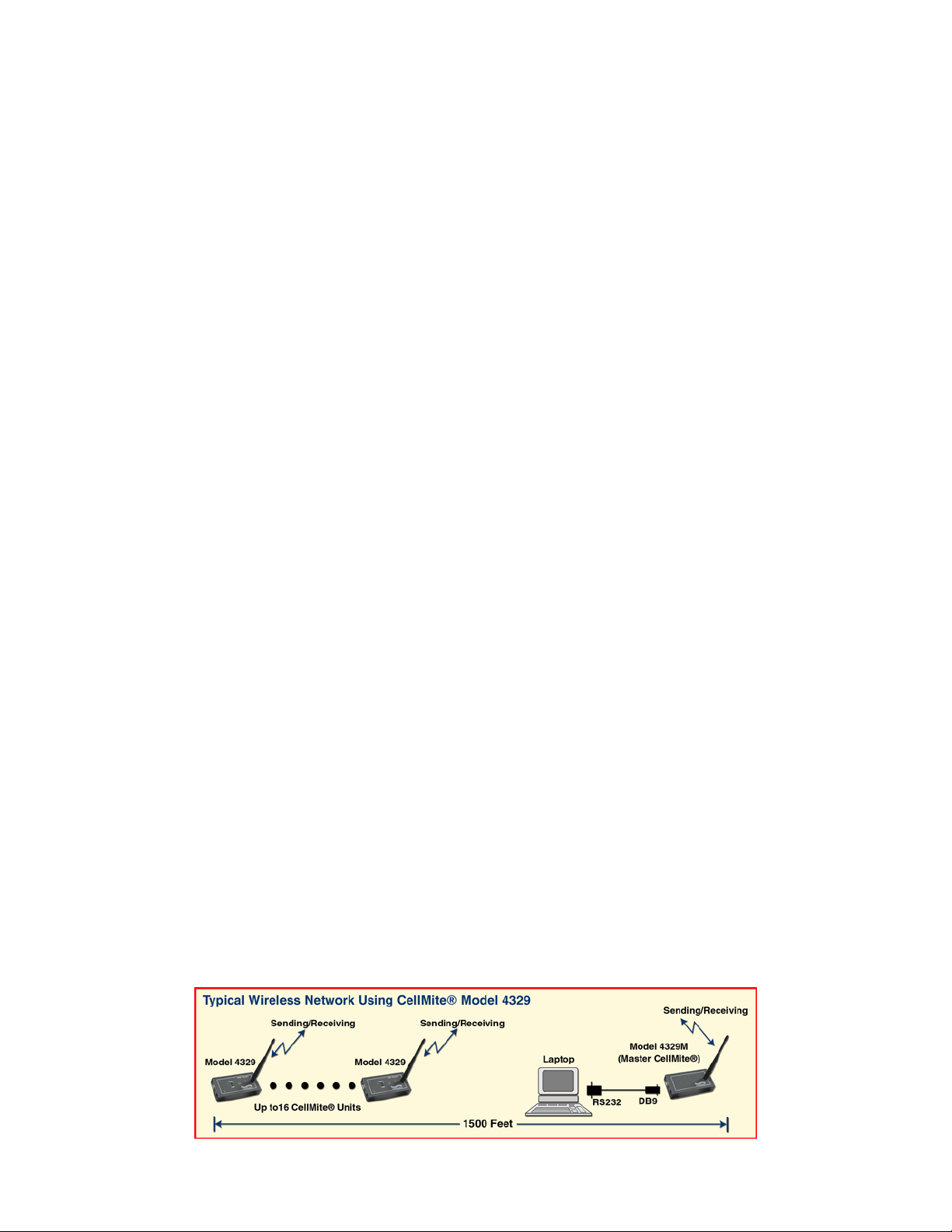

The typical setup of the system is illustrated below. The remote slave M4329 unit is attached to the load sensors or

extensometers in a remote area (and optionally powered by the M4340 CellMite® Battery Pack) while the M4329M

Master unit is connected by serial cable to the host PC. These two units communicate wirelessly. The commands

sent out by the host PC go to the Master M4329M unit and are sent to the remote slave M4329 unit for processing.

The data received by the M4329 remote unit is sent to the M4329M Master unit, which then sends it into the serial

port of the host PC. The communications have been tested out to a range of 1500 feet.

CF 152 1 Pub. 3775-02

Page 4

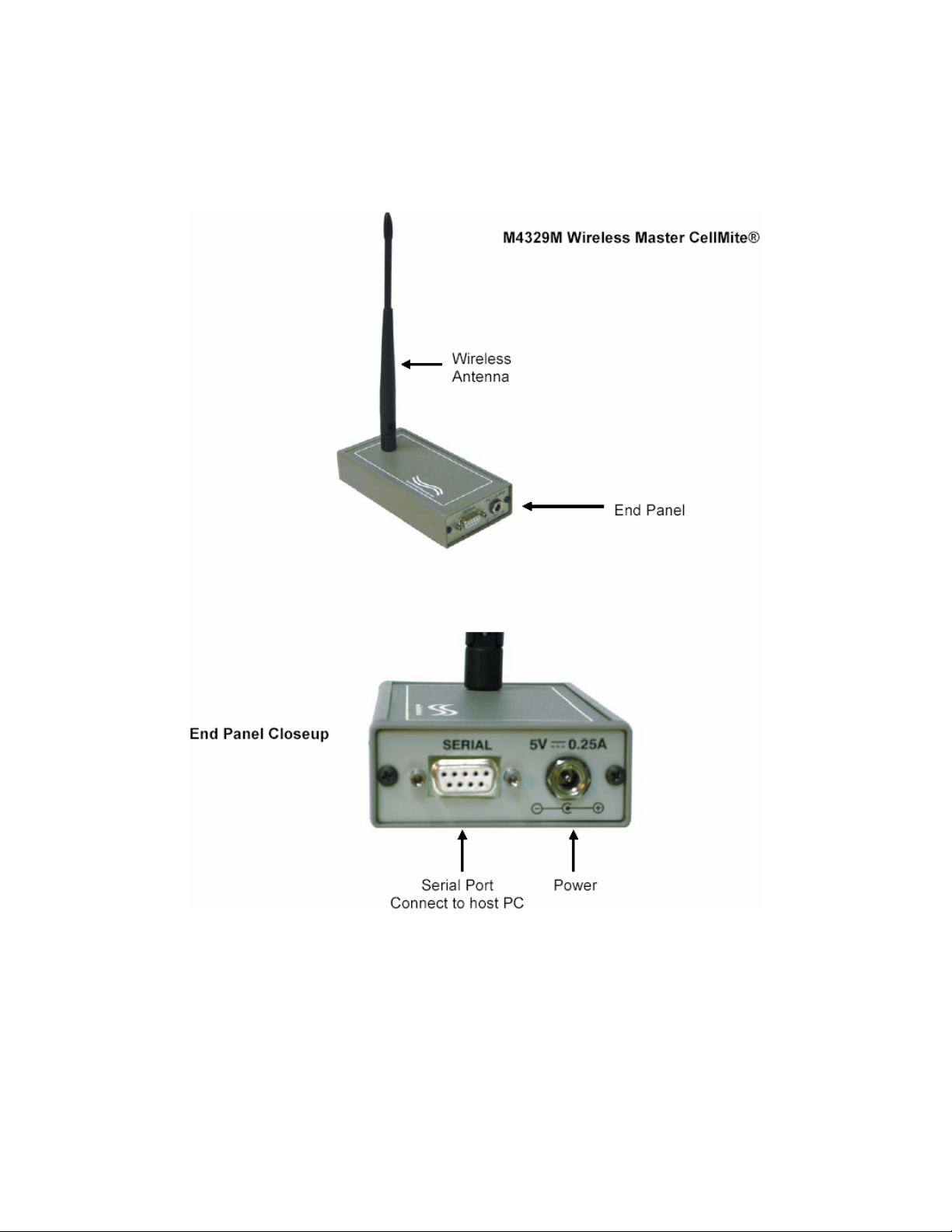

2.1 M4329M Master CellMite®

The M4329M Master CellMite®, in addition to having an antenna, has two connectors on its end panel. One is the

power connector that must be attached to the included 110/240V AC, 60/50 Hz power supply that can then be

plugged into a wall socket. The other connector is a female DB9 serial connector and must be connected to the

host PC via serial cable. The host PC must be running one of the CellView family of software to connect properly

to the M4329M Wireless System.

2.2 M4329 Remote Slave CellMite®

The M4329 Remote Slave CellMite® has two buttons and four connectors available. The connectors are on the

end panels, front and back, and the buttons are on the top panel along with the wireless communications antenna.

• Power – the Power connector must be connected to either a 110/240V AC, 60/50 Hz power supply, or the

M4340 CellMite® Remote Battery Pack (ESL p/n 306340).

• Sensor – DB9 Male connector that connects to the load cell or extensometer taking data readings.

CF 152 2 Pub. 3775-02

Page 5

• Serial – The M4329 can use wireless communications or, optionally, be connected directly to the host PC from

this port by serial cable.

• I/O – Analog Output connector. The M4329 may be programmed to output over this port either a set voltage or

voltage that is tied to sensor readings.

The top panel of the M4329 Remote Slave CellMite®, in addition to having the wireless communications antenna,

has one LED that informs the user of the state of the unit and two buttons, shunt and tare.

• Shunt Button - Pressing on the Shunt Button closes the shunt switch, connecting 60KΩ resistor in the unit in

parallel with the strain gauge. Re-pressing the Shunt Button will open up the shunt switch. The position of the

shunt switch can also be determined by the LED color in run mode. If the shunt switch is closed, the LED will

CF 152 3 Pub. 3775-02

Page 6

be red. Otherwise, it will be green. In calibration mode, the Shunt Button should not be used. If depressed, it

will be ignored.

• Tare Button - Pressing on the Tare Button will tare the sensor reading in run mode. The Tare Button is not

used in calibration. If pressed, it will be ignored.

Once these connections are made, you are set up to use the any of the CellView family of GUI software to add,

calibrate and read data from strain gage extensometers or load sensors.

3.0 INSTALLATION AND START UP

When the Models 4329 and 4329M are powered, the LED on the M4329 remote slave’s top panel will first turn orange, and then green. Green means the unit has finished initialization and is in run mode.

4.0 RUN MODE

The WSC 4329 has two modes of operation, each discernable by looking at the color of the LED on the top of the

unit, Run mode, and System Calibration mode. At power-on it will be in Run mode. The LED is green when the

unit is in Run Mode and blue when the unit is in Calibration Mode.

With the use of one of the family of CellView software, the user can perform various tasks when the unit is in Run

Mode:

4.1 Data Measurement

Measure track, peak and valley from a given, calibrated sensor. The Model 4329 supports load units of Lbs and

Kg, as well as extension units of In, cm, and mm. Either sensor type can also send data as a percentage of a given

base load/extension. The various CellView GUI software packages add to these units and can be customized to

meet user needs. They also have a user-defined unit option that allows the user to create their own unit of measurement by applying a 5

th

order polynomial to the data.

4.2 Tare and Reset

CellView software allows the user to command the unit to tare track data and reset peak and valley measurements.

4.3 CellMite Setup Options

While the CellMite® is in Run Mode, the user can, with the use of CellView software, name the unit with four characters that the unit stores, enable and disable TEDS Tag/Auto ID of sensors, and enable or disable the unit’s internal temperature compensation.

4.3.1 TEDS Tag™/Auto ID

The CellMite® unit is capable of recognizing a sensor that has been calibrated on the unit when that sensor is

plugged into the unit. This is true only if the sensor has been calibrated in one of the three sensor “slots” within the

unit and has not been overwritten with another sensor calibration. This feature is only available in the CellView

LITE software and only valid when a single CellMite® is attached to the system. It cannot work when multiple

CellMites® are attached.

4.3.2 Temperature Compensation

The unit has the ability to compensate for temperature that may affect data readings. By default, temperature

compensation is set ON in the factory unless otherwise requested.

4.4 Sensor Setup Options

Each of the three sensor “slots” within the CellMite® can store calibration data, but they can store sensor-specific

settings in the CellMite® via CellView software. This includes filtering, display decimal points (the unit will use this

to output data to an attached digital display if that option has been purchased), analog output settings if analog output is tied to the sensor output, and the base value to use when track data is in units of %.

CF 152 4 Pub. 3775-02

Page 7

4.4.1 Filtering

The CellMite® can perform moving average filtering of data using up to 128 data points.

4.4.2 Analog Output

The user can set the range of voltage the unit outputs in response to the sensor stimulus. This allows the user to

set any maximum and minimum voltage and offset so that the analog output can be scaled to match the input requirements of nearly any data acquisition system. This includes single ended and bipolar outputs.

5.0 CALIBRATION MODE

The remote slave M4329 unit’s LED turns blue when the unit is placed in calibration mode OR when an address

check is sent to it via the CellView software. If the unit is in calibration mode, the LED will stay blue. If an address

check was sent, as is done by the GUIs to monitor the connection to the unit, the LED will flash blue and return to

green for run mode.

Once in calibration mode, sensors can be calibrated using their manufacturer’s mV/V constant, two or five point

Mass, or precision shunt calibration. The CellView family of software steps the user through the calibration process

for each sensor.

There are three sensor “slots” within the CellMite® unit that can hold these calibrations. Calibration data is maintained in the unit through power cycle.

Once a sensor has been calibrated, the unit must be commanded to stream data to the CellView software. Streaming data, test conditions, and storing of test data are all handled by one or more of the family of CellView software.

Speak to your Cooper Instruments sales representative for more information on CellView software.

6.0 TECHNICAL INFORMATION/CUSTOMER SUPPORT

For technical information or support on any Cooper Instruments product or to order cables and other products that

you may need, please call Cooper Instruments at 800-344-3921.

You can also visit our web site at http://www.cooperinstruments.com

.

7.0 WARRANTY REPAIR POLICY

Limited Warranty on Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in

workmanship within one year of the date of shipment by Cooper will be repaired or replaced free of charge provided that a return material authorization is obtained from Cooper and the defective product is sent, transportation

charges prepaid, with notice of the defect, and it is established that the product has been properly installed, maintained, and operated within the limits of rated and normal usage. Replacement or repaired product will be shipped

F.O.B. from our plant. The terms of this warranty do not extend to any product or part thereof which, under normal

usage, has an inherently shorter useful life than one year. The replacement warranty detailed here is the buyer’s

exclusive remedy, and will satisfy all obligations of Cooper whether based on contract, negligence, or otherwise.

Cooper is not responsible for any incidental or consequential loss or damage which might result from a failure of

any and all other warranties, express or implied, including implied warranty of merchantability or fitness for particular purpose. Any unauthorized disassembly or attempt to repair voids this warranty.

Obtaining Service under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact the

Repair Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number. Shipment to Cooper shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from our

plant in Warrenton, Virginia. Non-verified problems or defects may be subject to a $100 evaluation charge. Please

return the original calibration data with the unit.

CF 152 5 Pub. 3775-02

Page 8

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty applies

only to those items that were found defective and repaired; it does not apply to products in which no defect was

found and returned as is or merely recalibrated. It may be possible for out-of-warranty products to be returned to

the exact original specifications or dimensions.

* Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper to

receive information specifying the reason the product is being returned. Specific test data, written observations on

the failure and the specific corrective action you require are needed.

This space intentionally left blank.

CF 152 6 Pub. 3775-02

Page 9

APPENDIX A – WIRELESS CELLMITE® SPECIFICATIONS

Excitation (M4329)

Voltage: 5 VDC

Nom. Load: 350 Ω

Operation (M4329)

Internal Resolution: 24-bit

Input Range: ±5.5 mV/V (Avail. to+200mV/V)

Conversion Rate: 60 per second

Error: 0.01%, ±1 count

Pushbuttons: Tare, Shunt

Precision Shunt: 60 Ω

Indicator: status LED

Outputs (M4329)

Analog: 16-bit, scalable, ±10V

Serial Data: multi-drop RS232

Switches: solid state

Power (M4329/4329M)

5 VDC, 230 mA

(included adapter) 110/240VAC, 60/50 Hz

Compatible with 4 x AA NiMH Rechargable Batteries

Mechanical (M4329/4329M)

Unit Size: 5.5” X 2.75” X1.2”

Unit Weight: 8.9 oz. (252 g)

Wireless Operation (M4329/4329M)

Nominal Frequency: 900 MHz

Classification: Mobile

Complies with Part 15 of the FCC Rules.

CF 152 7 Pub. 3775-02

Page 10

APPENDIX B – M4329/4329M CABLES AND CONNECTORS

The following are the pinouts of the connectors on the M4329/4329M units. The pins that are not listed below are

reserved and should not be connected to external equipment. Serial port pinouts apply to both units. I/O and Sensor pinouts apply only to the M4329 Remote Slave unit.

Serial Port Pins 2,3 and 5 are used for

RS232 communications

Sensor – DB9(M)

Pin # Signal Name

1 Excite - HI

2 Sense - HI

3 Channel “A” Cell Output - HI

4 Channel “A” Cell Output - LO

5 Sense – LO

6 Excite – LO

7 * Auto ID

8 Reserved

9 GND

Serial – DB9(F)

Pin # Signal Name

2 TXD

3 RXD

5 GND

Pins 6-15 Reserved

I/O – 8-Pin Mini-Din( F )

Pin # Signal Name

1-4 Reserved

5 Analog Output

6 GND

Pins 7 & 8 Reserved

Note: Items preceded by

an asterisk are optional.

CF 152 8 Pub. 3775-02

Page 11

APPENDIX C – BRIDGE CONNECTION DIAGRAMS

External

Excite HI

Sense HI

R1

R2

Strain

Gauge

R3

Shunt Switch

60KΩ shunt

Cell Output HI

Sense LO

Excite LO

Cell Output LO

Quarter Bridge Connection Diagram.

Three external resistors should be added as recommended by the

sensor manufacturer to complete the bridge circuit.

CF 152 9 Pub. 3775-02

Page 12

Excite HI

Sense HI

External

Shunt Switch

R1

60KΩ shunt

Cell Output HI

R2

Sense LO

Excite LO

Cell Output LO

Half Bridge Connection Diagram.

Two external resistors should be added as recommended by the sen-

sor manufacturer to complete the bridge circuit.

CF 152 10 Pub. 3775-02

Page 13

Excite HI

Sense HI

Shunt Switch

60KΩ shunt

Cell Output HI

Sense LO

Excite LO

Cell Output LO

Full Bridge Connection Diagram.

Complete circuit provided by the sensor manufacturer. No external resistors are required.

CF 152 11 Pub. 3775-02

Loading...

Loading...