Page 1

WFC 900

WELD FORCE PROBE

USER’S GUIDE

www.cooperinstruments.com

PH: 540-349-4746 FAX: 540-347-4755

Page 2

TABLE OF CONTENTS

1.0 INTRODUCTION ...................................................................................................................1

1.1 Overview.......................................................................................................................................... 1

1.2 Quick Operation Guide................................................................................................................... 1

1.3 Instrument Layout .......................................................................................................................... 1

1.3.1 LCD Display.............................................................................................................................. 1

1.3.2 Low Battery Indicator .............................................................................................................. 1

1.3.3 Decimal Point Position ............................................................................................................ 2

1.3.4 Incremental Display Step ........................................................................................................ 2

1.3.5 Load Cell................................................................................................................................... 2

1.4 Maximum Safe Overload ................................................................................................................ 2

1.5 Front and Side Views ..................................................................................................................... 2

1.6 Dimensions ..................................................................................................................................... 3

1.7 Specifications ................................................................................................................................. 3

2.0 OPERATION ..........................................................................................................................4

2.1 Battery Replacement...................................................................................................................... 4

2.2 Turning the Instrument On and Off............................................................................................... 4

2.3 Zeroing the Display ........................................................................................................................ 4

2.4 Restoring the Calibrated Zero ....................................................................................................... 4

2.5 Reading the High/Low Values ....................................................................................................... 5

2.6 Clearing the High/Low Values ....................................................................................................... 5

3.0 FIELD SELECTABLE FEATURES ........................................................................................5

3.1 Introduction..................................................................................................................................... 5

3.2 Setup Menu Operation ................................................................................................................... 5

3.3 Enable Options (“ ”) Description ............................................................................................... 6

3.3.1 Auto-off Feature ....................................................................................................................... 6

3.3.2 Always-On Feature .................................................................................................................. 6

3.3.3 [Zero] Button Disable Feature ................................................................................................ 7

3.3.4 [Hi/Lo] Button Disable Feature ............................................................................................... 7

3.3.5 [Clear] Button Disable Feature ............................................................................................... 7

3.4 Enable Options (“ ”) Menu Item ................................................................................................. 7

3.5 Engineering Units (“ ”) Menu Item ......................................................................................... 7

3.6 Auto-off time (“ “) Menu Item.................................................................................................. 8

3.7 Update Rate (“ ”) Menu Item .................................................................................................. 8

3.8 Internal Software Version (“ ”) Menu Item .............................................................................. 8

4.0 CALIBRATION.......................................................................................................................9

4.1 Calibration Considerations............................................................................................................ 9

4.2 Required Forces ............................................................................................................................. 9

4.3 Calibration Procedure .................................................................................................................... 9

4.3.1 Enter Forces to be Applied ..................................................................................................... 9

4.3.2 Apply Forces .......................................................................................................................... 11

4.4 Rear View of Front Face Panel .................................................................................................... 12

4.5 Calibration Error Messages ......................................................................................................... 12

5.0 TROUBLESHOOTING .........................................................................................................12

5.1 Introduction................................................................................................................................... 12

5.2 Help Message Codes.................................................................................................................... 13

5.3 Troubleshooting Hints ................................................................................................................. 13

WARRANTY REPAIR POLICY..................................................................................................13

WFC 900 ii Rev. D: 3/03

Page 3

Limited Warranty On Products.......................................................................................................... 13

Obtaining Service Under Warranty ................................................................................................... 14

Repair Warranty.................................................................................................................................. 14

WFC 900 iii Rev. D: 3/03

Page 4

1.0 INTRODUCTION

1.1 Overview

The WFC 900 is a rugged, hand-held instrument for accurately calibrating weld electrode force on resistance

welding machines. This device helps ensure compliance with ISO 9000 or QS 9000 quality requirements by taking

the guesswork out of setup. Measuring accurate force levels at the electrode tips helps eliminate inaccuracies of

the line-pressure readings, air cylinder friction, and mechanical wear.

The WFC 900 is designed for long life in the harsh welding environment by using Cooper’s standard fully-welded

load cell construction and NEMA 4 electronics packaging. The easy-to-use design includes a simple push-button

format and a large LCD display that provides both continuous and peak (maximum) force values in keypadselectable engineering units.

High-speed digital electronics sample readings during the squeeze-weld-hold sequence and capture the peak force

for display. A simple, one-button CLEAR prepares the instrument for the next reading. Two standard 9-volt alkaline

batteries provide 80 hours of continuous use. Battery life is maximized with a programmable power-off feature.

1.2 Quick Operation Guide

1. Depress the [On/Off] button to power up the instrument. Wait about 5 seconds for the instrument to warm up.

2. If a non-zero value appears on the display, press and hold the [Zero] button until the display reads “

takes about three seconds).

3. Insert probe, initiate welder, and take reading.

4. Press and hold the [Hi/Lo] button until the display reads “

5. Press [Clear] to clear the maximum value in preparation for the next reading.

6. As shipped from the factory, the instrument will automatically shut itself off if no buttons have been pressed in

four minutes.

Note: The WFC 900 is a force calibration device designed to measure the force between electrodes on resistance

welders. It can withstand passing current through the force transducer.

It is recommended for the safety of the operator and the WFC 900 to disable current before

operation. Many repeated current firings may damage the weld force indicator.

” to read the maximum (or peak) force value.

” (this

1.3 Instrument Layout

1.3.1 LCD Display

The 4½-digit liquid crystal display (LCD) readout displays the load applied to the instrument, interacts with the user

when the instrument is being set up or calibrated, and indicates if there is a problem with the instrument.

When a WFC 900 instrument is turned on, it illuminates all LCD segments. Then, the engineering units the gauge

will be using appears on the display. Most WFC 900 instruments are calibrated in pounds (“

instrument has conversion factors for many standard engineering units built in. However, if the instrument displays

(special) it has been specially calibrated to another engineering unit at the factory. In that case, the serial

number tag on the top of the instrument will indicate the engineering units being used and the capability to select

other engineering units should not be used.

After the display of the engineering units, the force applied to the load cell is shown on the display. If the load

applied to the load cell is above the instrument's ability to measure, the display will indicate this overrange condition

by showing a "

" on the far left hand side of the display. The display will read " " if the instrument is underranged.

”) and the

1.3.2 Low Battery Indicator

On the left side of the display, just above the minus sign, is the low battery indicator (in the shape of an arrow).

When the battery voltage is less than 5 volts, the display will be blanked and the low battery indicator will illuminate

to indicate that the batteries should be replaced. The low battery indicator can be seen when the instrument is

turned on and all segments of the display are momentarily lighted.

WFC 900 1 Rev. D: 3/03

Page 5

When the low battery indicator is illuminated, change the batteries as soon as possible. The instrument will not

function if the battery voltage falls below approximately 4 volts.

1.3.3 Decimal Point Position

The decimal point position automatically changes depending upon:

• the user selected engineering units

• the load range of the instrument.

The decimal point position cannot be changed manually.

1.3.4 Incremental Display Step

The incremental display step is the value by which the last digit of the display will change. This value will be 1, 2, or

5 display counts. It automatically changes depending upon:

• the user selected engineering units

• the load range of the instrument

The incremental display step cannot be changed manually.

1.3.5 Load Cell

The WFC 900 instrument can be ordered with one of two types of load cells: those with a load sensing button, and

those with a load sensing indentation. The load sensing button is useful when the unit is used with projection

welders. The load sensing indentation is useful for most spot welding applications.

1.4 Maximum Safe Overload

Maximum safe overload is the force that the instrument can experience occasionally without loss of accuracy or

permanent damage.

Force Range (lbs.)

0 - 500 = 500 750

0 - 1000 = 1K 1500

0 - 2000 = 2K 3000

0 - 5000 = 5K 7500

0 - 10000 = 10K 15000

Table 1: Maximum Safe Overload

Maximum Safe Overload

(lbs.)

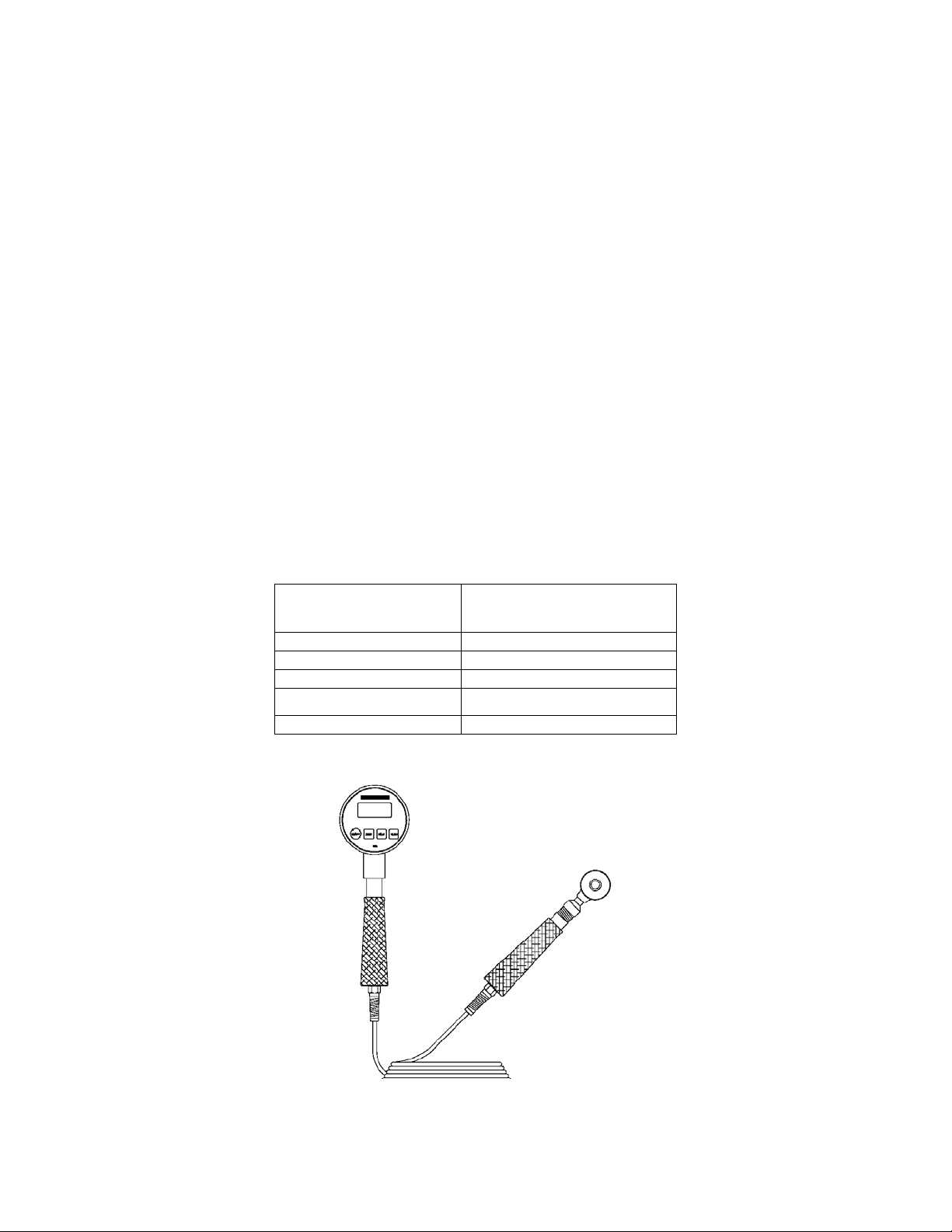

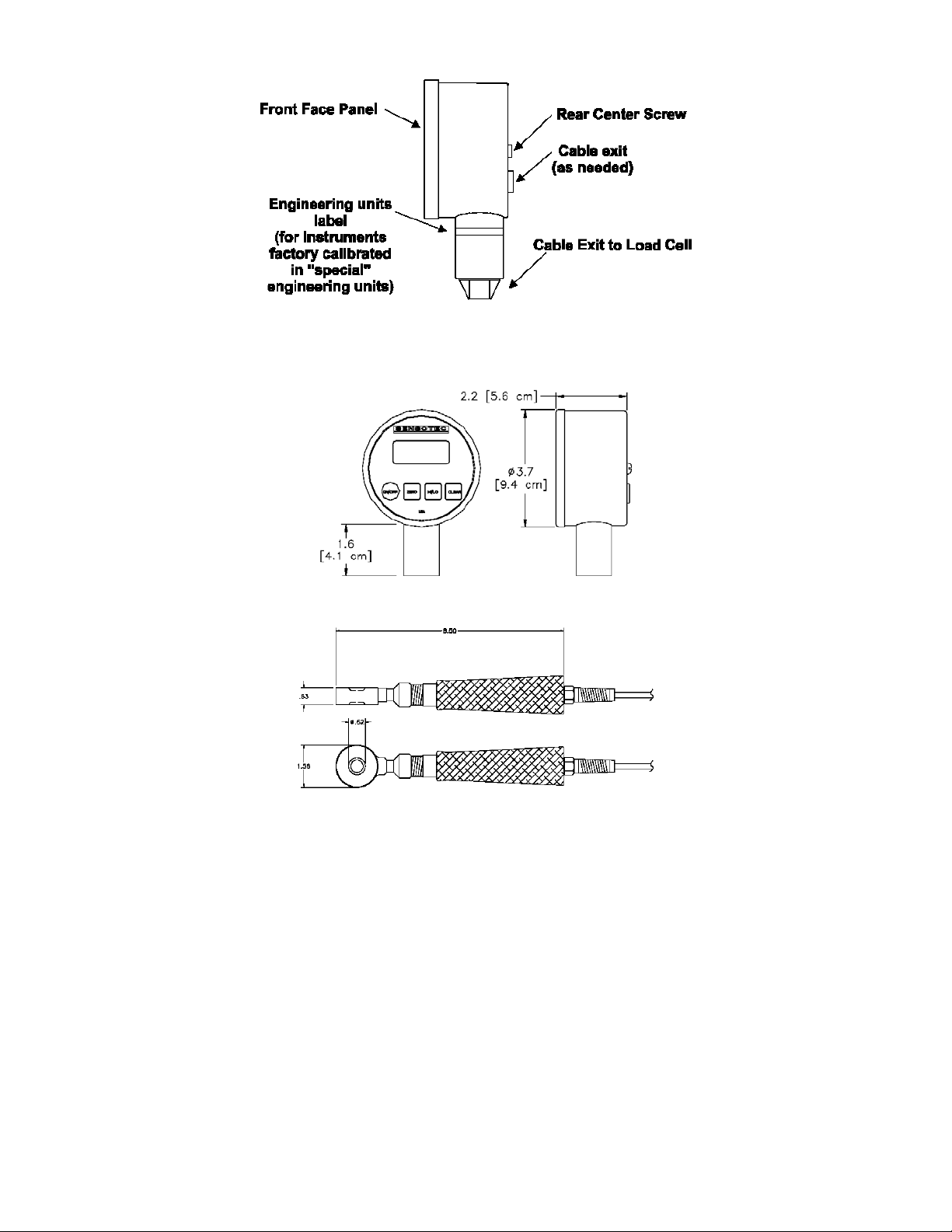

1.5 Front and Side Views

Figure 1-1. Model WFC 900 Front View (2-handed version)

WFC 900 2 Rev. D: 3/03

Page 6

Figure 1-2. Model WFC 900 Display Side View

1.6 Dimensions

Figure 1-4. Model WFC 900 Load Cell Dimensions (2000 lbs. Range with Sensing Indentation)

1.7 Specifications

Figure 1-3. Model WFC 900 Display Dimensions

Cooper continually improves its products, and thus these specifications are subject to change without notice.

Display Diameter: 3.7 inches

Accuracy: 0.5%

Operating Temperature: 30 to 180 ºF

Force Ranges 0 to: 1000, 2000, 5000, 10000 lbs.

Overload Capability: 150% of full-scale range

Calibration Engineering Units: lbs

Built-in Engineering Unit Conversion: lbs, Kg, kN, N, g (field selectable)

Sampling Rate: 19.2kHz internal; 24Hz display update

Power Requirements: two 9 Volt alkaline batteries provide approximately 80 hrs continuous life

Load Cell Material: BeCu

Housing Material: Stainless steel

High and Low Capture: Standard, same update rate as display

Zero and Span Adjustment: Standard

WFC 900 3 Rev. D: 3/03

Page 7

Front Panel Membrane Tactile feedback, raised buttons

Calibration Data: Stored on non-volatile memory chip

Package: All-welded load cell; NEMA 4 rated display unit

Weld Current: Survives accidental current discharge

2.0 OPERATION

2.1 Battery Replacement

Two nine-volt alkaline batteries (NEDA 1604) are recommended for use in the Model WFC 900. This is a common

type of battery that is available at many stores. With two alkaline batteries, a Model WFC 900 instrument will

operate continuously on for approximately 80 hours. Carbon-zinc batteries (sometimes labeled as “general

purpose” or “heavy duty”) should not be used. Please note that the temperature specifications of the batteries you

purchase may not be the same as those of the Model WFC 900.

If two batteries are not available, the instrument will operate with only one alkaline battery installed in either clip.

However, this will reduce the continuous operation time to approximately 40 hours. The use of two lithium batteries

will allow your Model WFC 900 instrument to operate continuously for over 160 hours.

To install the batteries:

1) Remove the center screw on the back of the instrument.

2) Remove the front face panel from the case.

3) The colored ribbon cable extending from the sensor to the electronics may be disconnected to make the battery

installation more convenient.

4) Replace the batteries one at a time, making sure of the correct polarity.

5) Reconnect the sensor cable to the electronics.

ÎImportant note: The correct orientation of the sensor cable is shown in Section 4.4. If you connect the sensor

cable backwards, the instrument will not operate correctly.

6) Replace the front face panel.

7) Carefully replace the rear center screw.

Note: Calibration and setup values are stored in a nonvolatile memory, and are not lost during battery replacement.

2.2 Turning the Instrument On and Off

Push the [On/Off] button to turn the instrument on or off.

As the instrument turns on, every segment on the display is momentarily lighted. The high/low data values are

cleared.

2.3 Zeroing the Display

Hold the [Zero] button until the display shows “

The instrument will retain this zero value even after the instrument has been turned off.

” (about 5 seconds).

2.4 Restoring the Calibrated Zero

To restore the zero, first press and hold the [Clear] button, while holding

[Clear]...

... press the [Zero] button. Hold both buttons until the display shows “ ”,

then release.

The "calibrated zero" is the zero value of the instrument at the time it was last calibrated. Restoring the calibrated

zero can be used to “undo” an inadvertent press of the [Zero] button.

WFC 900 4 Rev. D: 3/03

Page 8

2.5 Reading the High/Low Values

The high and low values are updated at the same rate as the tracking value.

Press the [Hi/Lo] button once to read the highest value since the last time the

data was cleared.

The word “

instrument is not displaying the "live" tracking value of the applied force. However, the instrument is still monitoring

the applied force and updating the high and low values.

The word

instrument is not displaying the "live" tracking value of the applied force. However, the instrument is still monitoring

the applied force and updating the high and low values.

” and the corresponding value will flash intermittently on the display. This flashing indicates that the

and the corresponding value will flash intermittently on the display. This flashing indicates that the

Press the [Hi/Lo] button a second time to read the lowest value since the last

time the data was cleared.

Press the [Hi/Lo] button a third time to return to the “live” tracking mode. The

display will show “---“ to indicate that the instrument has returned to the “live”

tracking mode.

2.6 Clearing the High/Low Values

Press the [Clear] button to erase the high and low data values.

The high and low data values are also cleared when the instrument is turned off.

3.0 FIELD SELECTABLE FEATURES

3.1 Introduction

This Chapter discusses the field selectable features available on the model WFC 900 Force Gage. These features

can be activated, deactivated and modified via the Setup Menu accessed by the front panel. These field selectable

features include:

• enabling the automatic power off feature to conserve battery life

• disabling the front panel buttons

• changing the engineering units used to display the applied force.

• adjusting the automatic power off time

• changing the update rate

3.2 Setup Menu Operation

All of the field selectable features are accessed via the Setup Menu. This section discusses its operation. To

change a feature with the Setup Menu:

Make sure the instrument is turned off. Then, press the [On/Off] button.

While unit is checking the display (lighting all LCD segments simultaneously),

press and hold down the [Zero] button.

The display now reads “

”, which is the first item of the Setup Menu. Release the [Zero] button.

Pressing and releasing the [Zero] button will scroll down through the available

Setup Menu items.

WFC 900 5 Rev. D: 3/03

Page 9

The table below provides a list of the items available in the Setup Menu and a brief description of each.

Table 2: Setup Menu Items

Display Menu Item Purpose

Low Limit setpoint N/A

High Limit setpoint N/A

Enable Options Enable Auto-Off feature;

Engineering units Change engineering units used to display

Auto-off time Change Auto-Off power down time

Update rate Change update rate of force readings

Internal software

revision

Disable front panel buttons

force

Display internal software part number and

revision

When the menu item you wish to change is displayed, press [Clear].

The display now shows the present setting of that menu item. If you only wish to examine the present setting of the

menu item, you can use the [On/Off] button to turn the instrument off. Otherwise...

Use the [Hi/Lo] and [Clear] buttons to scroll up and down, respectively.

If you wish to abandon the changes you made to this setting, you can use the [On/Off] button to turn the instrument

off. Otherwise...

The next menu item will be displayed after the instrument stores the setting into memory.

Once the setting you want is displayed, press the [Zero] button to store this

setting into memory.

3.3 Enable Options (“ ”) Description

The Enable Options (“ “) menu item controls the features described in the sub-sections below.

3.3.1 Auto-off Feature

The unit will shut itself off if no buttons are pressed for the time duration specified with the Auto-off time (“ “)

menu item. The unit can also be shut off with the [On/Off] button. This feature is useful for conserving battery life.

The instrument is shipped with this feature enabled.

3.3.2 Always-On Feature

The [On/Off] button is disabled and will not shut the unit off. This mode is used so that the high and low capture

values, output signals, or limit alarms are not interrupted if an operator tries to shut the unit off during testing or

monitoring.

WFC 900 6 Rev. D: 3/03

Page 10

3.3.3 [Zero] Button Disable Feature

This feature disables the ability to zero the display of the instrument. The ability to restore the calibrated zero is also

disabled. When the [Zero] button is pressed, the display momentarily reads “ ” which indicates that the button

has been disabled via the Enable Options menu item.

3.3.4 [Hi/Lo] Button Disable Feature

This feature disables the ability to read the stored high and low values on the display. The display will always read

the “live” tracking value of the applied force. When the [Hi/Lo] button is pressed, the display will momentarily read

” which indicates that the button has been disabled via the Enable Options menu item.

“

3.3.5 [Clear] Button Disable Feature

This feature disables the ability to clear the high and low data values with the [Clear] button. The ability to restore

the calibrated zero is also disabled. When the [Clear] button is pressed, the display momentarily reads “ ” which

indicates that the button has been disabled via the Enable Options menu item. NOTE: The high and low data

values may also be cleared by turning the unit off and back on, unless the Always-on feature is used.

3.4 Enable Options (“

To activate or deactivate the features described in the previous section, the setting of the Enable Options (“ “)

menu item must be changed. The procedure to change the setting of a menu item is described in the “Setup Menu

Operation” section earlier in this Chapter. The setting value of the Enable Options (“ “) menu item is obtained by

adding together the values of the desired options according to the table below.

”) Menu Item

Table 3: Enable Options (“ “) settings

Feature Disabled Enabled

Auto-off 0 1

Always-on 0 2

[Zero] button 4 0

[Clear] button 16 0

[Hi/Lo] button 32 0

For example, to enable the Auto-off feature and disable the [Zero] button enter a setting value of “0005”. As another

example, to disable both the [Zero] and the [Clear] buttons enter a setting value of “0020”. If the Auto-off and

Always-on features are both activated, the unit will behave as follows: The [On/Off] button can turn the instrument

on but it cannot turn the instrument off. The only way to turn the instrument off is not to press any buttons for the

duration specified in the Auto-off time (“ “) menu item. Note that the Auto-off time (“ “) setting can be

several hours.

3.5 Engineering Units (“ ”) Menu Item

The Engineering Units (“ “) menu item determines which units-of-measure are used to display the force

readings. Most WFC 900 instruments are calibrated in lbs. and the instrument has conversion factors for many

WFC 900 7 Rev. D: 3/03

Page 11

standard engineering units built in. The procedure to change the setting of a menu item is described in the “Setup

Menu Operation” section earlier in this Chapter.

Note: If the instrument displays “ ” (special) when powering up, it has been specially calibrated to another

engineering unit. The ability to change the engineering units is not available. The table below gives a list of the

engineering units built into the instrument.

Table 4: Engineering Units (“ ”) Available Settings

Setting Engineering Unit / Comment

for factory use only

lbs

N

KN

g

kg

3.6 Auto-off time (“ “) Menu Item

The Auto-off time (“ “) menu item is only meaningful if the Auto-off feature is enabled in the Enable Options

(“ “) menu item. The procedure to change the setting of a menu item is described in the “Setup Menu Operation”

section earlier in this Chapter. The table below gives a list of the available settings for the Auto-off time (“

“).

Table 5: Auto-off time (“ “) Available Settings

Setting Time

0 4 minutes

1 1 hour

2 2 hours

3 3 hours

4 4hours

5 5 hours

6 6 hours

7 7 hours

8 8 hours

3.7 Update Rate (“ ”) Menu Item

The Update Rate (“ ”) menu item determines the number of times the force readings are updated per second.

The track, high and low values are all updated at this rate. The update rate can be varied from 5 to 24 updates per

second. As shipped from the factory, the update rate is set to 24 per second.

Important Note: To receive maximum accuracy in resistance welding applications, it is important to leave the

update rate set at 24 per second.

3.8 Internal Software Version (“ ”) Menu Item

The Internal Software Version (“ ”) menu item displays the part number and version number of instrument’s

operating software. The software part number and version number are of the form:

084-1087-02 1.19

Where the “084-1087-02” is the part number, and the “1.19” is the version number. Since this string is too long to fit

on the 4½ digit-display, pressing either the [Hi/Lo] or [Clear] buttons will scroll through this string 4 characters at a

time.

WFC 900 8 Rev. D: 3/03

Page 12

4.0 CALIBRATION

4.1 Calibration Considerations

In order to obtain optimum performance from the model WFC 900 instrument when testing or re-calibrating, Cooper

recommends the following:

• Allow a 5-minute warm-up period before testing or calibration.

• The force standard you use should be at least 4 times more accurate than the specification of the WFC 900

instrument.

4.2 Required Forces

In order to re-calibrate the instrument, you must have a precision force standard that can produce the zero-scale,

half-scale and full-scale forces for the instrument's range. For example, if your WFC 900 instrument has a range of

500 lbs, your force standard must be able to accurately produce forces of 0 lbs, 250 lbs, and 500 lbs.

If your force standard cannot produce these exact values, the instrument can be programmed in the field to expect

slightly different values during the re-calibration process. For example, if your calibrated weights are equal to 0 lbs,

251 lbs and 498 lbs, you can program the instrument to expect these weights during the re-calibration process.

All WFC 900 instruments are calibrated in lbs regardless of the field-selected engineering units. However, if the

instrument displays the word “ ” (special) when it powers up, it has been specially calibrated to another

engineering unit. In that case, the serial number tag on the top of the instrument will indicate the engineering units

that will be used for re-calibration.

To maintain NIST traceability, Cooper can re-calibrate a WFC 900 instrument for you. NIST certificates may be

ordered as a separate accessory for a nominal fee.

Table 6: Required Forces (all in lbs)

Force Range

500 0 250 500

1K 0 500 1000

2K 0 1000 2000

5K 0 2500 5000

10K 0 5000 10000

4.3 Calibration Procedure

Calibration Point 0

(zero-scale force)

Calibration Point 1

(half-scale force)

Calibration Point

2 (full-scale force)

The calibration procedure consists of two parts, the first of which may not be necessary in all applications.

• First, the instrument is told exactly what zero-scale, half-scale and full-scale forces are to be applied during the

calibration procedure.

• Second, the forces are applied to the instrument.

The following two sections explain this procedure.

4.3.1 Enter Forces to be Applied

The expected force values to be applied during calibration are accessed via the Factory Configuration Menu. This

section discusses its operation.

To change a value with the Factory Configuration Menu:

Make certain the instrument is turned off.

WFC 900 9 Rev. D: 3/03

Page 13

Open up the instrument by removing the center screw on the back. Next, remove the front face panel. Take care

not to break the wires extending from the sensor to the electronics. As indicated on Figure 4-1, move the mode

jumper from the "park" position to the "configure" position.

Hold the [On/Off] button, then press the [Hi/Lo] button. The display will

momentarily read “

”.

Release the [Hi/Lo] button, and the display will read “

” which is the first item of the Factory Configuration

Menu.

Pressing and releasing the [Zero] button will scroll down through the available

Factory Configuration Menu items.

The table below provides a list of the items available in the Factory Configuration Menu and a brief description of

each.

Table 7: Factory Configuration Menu Items

Display Menu Item Purpose

Decimal Point How many decimal points are used

to edit the , and

Factory Configuration Menu items.

Zero-Scale Point The expected value in lbs of the

force to be applied at zero scale.

Half-Scale Point The expected value in lbs of the

force to be applied at half scale.

Full-Scale Point The expected value in lbs of the

force to be applied at full scale.

Input Range For factory use only. Do not

change this setting.

When the menu item you wish to change is displayed, press [Clear].

The display now shows the present setting of that menu item. If you only wish to examine the present setting of the

menu item, you can use the [On/Off] button to turn the instrument off. Otherwise...

Use the [Hi/Lo] and [Clear] buttons to scroll up and down, respectively.

If you wish to abandon the changes you made to this setting, you can use the [On/Off] button to turn the instrument

off. Otherwise...

Once the setting you want is displayed, press the [Zero] button to store this

setting into memory.

The next menu item will be displayed after the instrument stores the setting into memory.

WFC 900 10 Rev. D: 3/03

Page 14

After you have finished using the Factory Configuration Menu, the mode jumper must be moved from its

"configure" position to its "park" position as indicated in Figure 4-1. Close the unit up and replace the center

screw.

4.3.2 Apply Forces

Make certain the instrument is turned off.

Open up the instrument by removing the center screw on the back. Next, remove the front face panel. Take care

not to break the wires extending from the sensor to the electronics. As indicated on Figure 4-1, move the mode

jumper from the "park" position to the "calibration" position.

The display will begin to alternately flash between the force required for calibration point #0 (for example “

and “----“). If you wish to abandon the calibration procedure, press the [On/Off] button to turn the unit off.

Otherwise...

Next, the display will begin to alternately flash between the force required for calibration point #1 (for example,

“

”) and “----“.

Hold the [On/Off] button, then press the [Clear] button. The display will

momentarily read “

Apply the indicated force to the instrument. Press [Clear] until “ ” is

displayed, indicating that the reading is being stored.

”.

”

Apply the indicated force to the instrument. Press [Clear] until “

displayed, indicating that the reading is being stored.

Finally, the display will begin to alternately flash between the force required for calibration point #2 (for example,

” and “----“).

“

When the last force point has been entered, the instrument will turn itself off. At this time, the mode jumper must be

moved from its "calibration" position to its "park" position as indicated in Figure 4-1. Close the unit up and replace

the center screw.

Check that the instrument has been calibrated properly by turning it back on and using the force standard.

Apply the indicated force to the instrument. Press [Clear] until “

displayed, indicating that the reading is being stored.

” is

” is

WFC 900 11 Rev. D: 3/03

Page 15

4.4 Rear View of Front Face Panel

Figure 4-1. Front face panel (rear view), showing mode jumper positions

and orientation of sensor cable

4.5 Calibration Error Messages

If unexpected forces are encountered during the calibration procedure, the WFC 900 instrument will alert the user

by flashing the word “

cannot continue, and that you must turn the instrument off and recalibrate again when the error has been corrected.

A list of error message numbers and their causes is given in “TROUBLESHOOTING” in Chapter 5.

” and a message number on the display. This indicates that the calibration process

5.0 TROUBLESHOOTING

5.1 Introduction

This chapter provides information on correcting common problems that may be encountered operating and

calibrating the instrument.

WFC 900 12 Rev. D: 3/03

Page 16

5.2 Help Message Codes

If the instrument detects a problem during its power-on self-test, operation, or calibration, it will alert the user by

flashing the word “ ” and an error message code number on the display. The instrument cannot continue

operation and you must turn the instrument off and correct the error.

• “ ”: Calibration error.

Analog to digital converter overrange.

One of the force points is above the calibration range of the instrument. Or, the sensor cable is not connected

properly.

• “

Analog to digital converter underrange.

One of the force points is below the calibration range of the instrument. Or, the sensor cable is not connected

properly.

• “

The applied forces at any two calibration points did not differ enough.

• “

The engineering unit conversion that you selected cannot be rendered on a 4½-digit display. For

consider the case of an instrument with a range of 2000 lbs. If you were to select grams (“ ”) in the

Engineering Units (“ ”) menu item the instrument would signal this error. This is because 2000 lbs equals

907184 grams, which cannot be shown on a 4½-digit display.

• “

“ ”: Non-volatile memory read error.

“

“ ”: Non-volatile memory version mismatch.

“ ”: Analog-to-digital converter not ready.

Turn the instrument off and on again. If these problems persist, contact Cooper.

”: Calibration error.

”: Calibration error.

”: Self-test error.

example,

”: Non-volatile memory write error.

”: Non-volatile memory verify error.

5.3 Troubleshooting Hints

• Verify that the power source is operating correctly. Make sure the batteries are fresh or that the external supply

is wired correctly.

• Verify that you have set the instrument to read in the desired units-of-measure.

• Verify that the sensor cable is connected correctly. The figure on page 31 shows the correct orientation of the

sensor cable.

• If you have changed the display update rate from the factory default of 24 per second, it may now be set too

low for your application and this may be interpreted as the peak readings being too low. Try increasing the

display update rate.

• The sensor and the electronics are a matched set. Do not, under any circumstances, exchange sensor and

electronics on two different instruments.

• The [Zero] button must be held down for 5 seconds before the display will be zeroed. This is in order to prevent

unintentional zeroing of the display.

• As shipped from the factory, the instrument will shut itself off after four minutes unless any button is pressed.

You can adjust this Auto-off feature if you wish.

• Inspect the instrument for physical damage. If the instrument is physically damaged, consult the factory for

repair. Do not attempt repairs as this may void the warranty.

• When all else fails, disconnect the batteries for 5 seconds, then reinstall.

WARRANTY REPAIR POLICY

Limited Warranty On Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in

workmanship within one year of the date of shipment by Cooper will be repaired or replaced free of charge provided

that a return material authorization is obtained from Cooper and the defective product is sent, transportation

charges prepaid, with notice of the defect, and it is established that the product has been properly installed,

maintained, and operated within the limits of rated and normal usage. Replacement or repaired product will be

WFC 900 13 Rev. D: 3/03

Page 17

shipped F.O.B. from our plant. The terms of this warranty do not extend to any product or part thereof which, under

normal usage, has an inherently shorter useful life than one year. The replacement warranty detailed here is the

buyer’s exclusive remedy, and will satisfy all obligations of Cooper whether based on contract, negligence, or

otherwise. Cooper is not responsible for any incidental or consequential loss or damage which might result from a

failure of any and all other warranties, express or implied, including implied warranty of merchantability or fitness for

particular purpose. Any unauthorized disassembly or attempt to repair voids this warranty.

Obtaining Service Under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact the

Repair Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number.

Shipment to Cooper shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from our

plant in Warrenton, Virginia. Non-verified problems or defects may be subject to a $100 evaluation charge. Please

return the original calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty applies

only to those items that were found defective and repaired; it does not apply to products in which no defect was

found and returned as is or merely recalibrated. It may be possible for out-of-warranty products to be returned to

the exact original specifications or dimensions.

*Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper to

receive information specifying the reason the product is being returned. Specific test data, written observations on

the failure and the specific corrective action you require are needed.

WFC 900 14 Rev. D: 3/03

Loading...

Loading...