Page 1

LXT 970/971 Non-Contact Torque Sensor

1.0 INTRODUCTION

The LXT 970/971 sensor has been designed to measure torque on static or rotating shafts bi-directional and in

real time. The sensor is delivered as a set including the connecting cable, shaft keys (if appropriate) and user

manual. The torque sensing shaft, the non-contact signal detector, and analog signal conditioning electronics

are integrated into the sensor housing. The torque sensor is characterized by very low power consumption,

internally amplified output voltage signal, long-term stability and a very good price-performance ratio.

2.0 CHARACTERISTICS

LXT 970 Series Model Number

Square Drive Round Drive

LXT 970-2.5 LXT 971-2.5

LXT 970-5.0 LXT 971-5.0

LXT 970-7.5 LXT 971-7.5

LXT 970-17.5 LXT 971-17.5

LXT 970-75 LXT 971-75

LXT 970-175 LXT 971-175

LXT 970-250 LXT 971-250

LXT 970-500 LXT 971-500

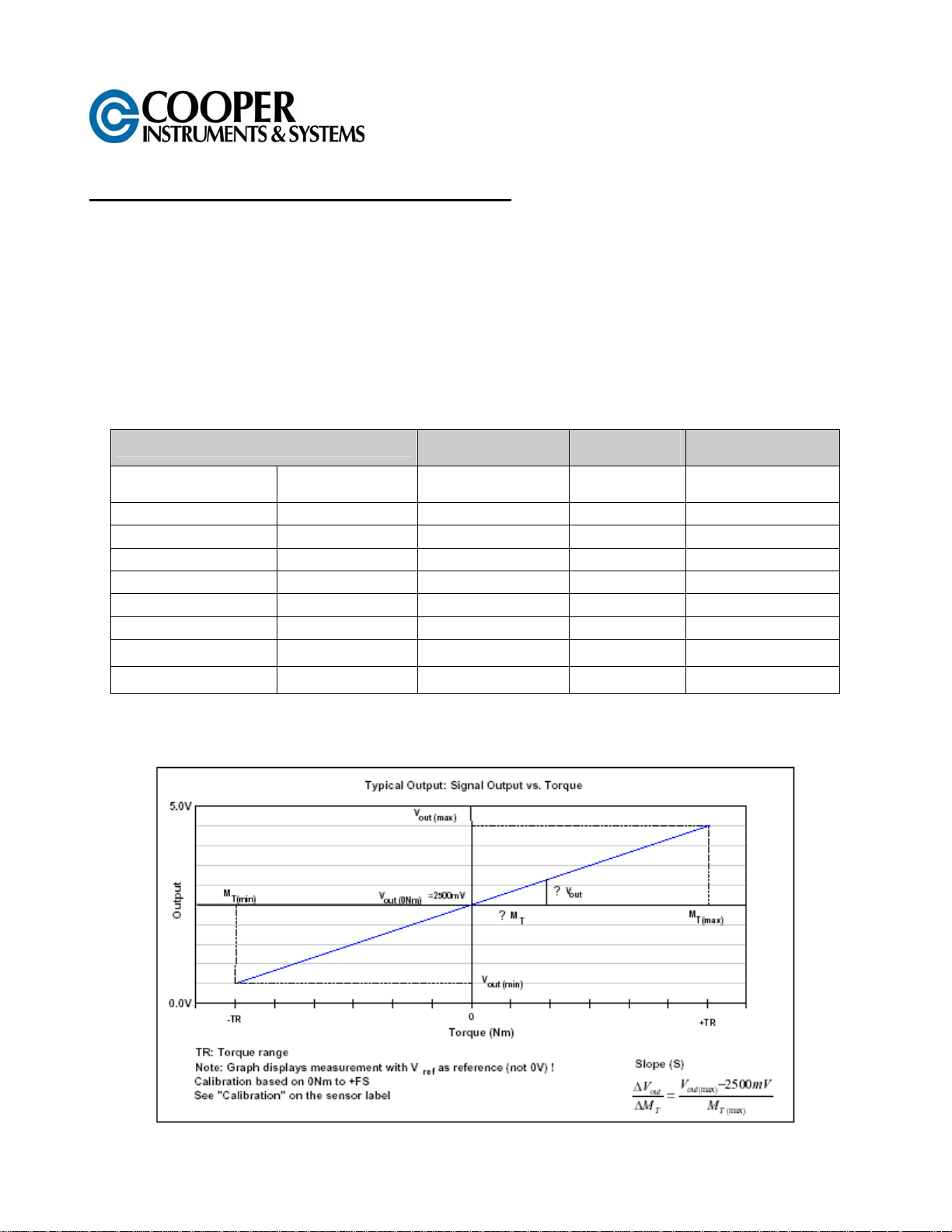

3.0 TYPICAL SENSOR OUTPUT

Max Rated Torque

[Nm (ft-lb)]

bidirectional (+/-)

2.5 (1.8)

5.0 (3.7)

7.5 (5.5)

17.5 (12.9)

75 (55.3)

175 (129)

250 (184.3)

500 (368.6)

Max Overload

[Nm (ft-lb)]

Ft-Lbs

5 (3.6) 5000 / 1000

10 (7.4) 5000 / 1000

15 (11) 5000 / 1000

35 (25.8) 5000 / 1000

150 (110.6) 5000 / 1000

350 (258) 5000 / 1000

350 (258) 5000 / 1000

750 (552.9) 5000 / 1000

Max Rotational

[rpm]

Round / Square

CF 59 1 V-11/18/02

Page 2

V

out(max)

between 0.5V and 4.5V; the actual signal output range depends on the calibraton value and the torque range.

and V

out(min)

are defined by the slope of each sensor. This means, the output is capable to be

LXT 971

(Round Shaft with

Keyway)

LXT 970

(Square Drive)

sFt

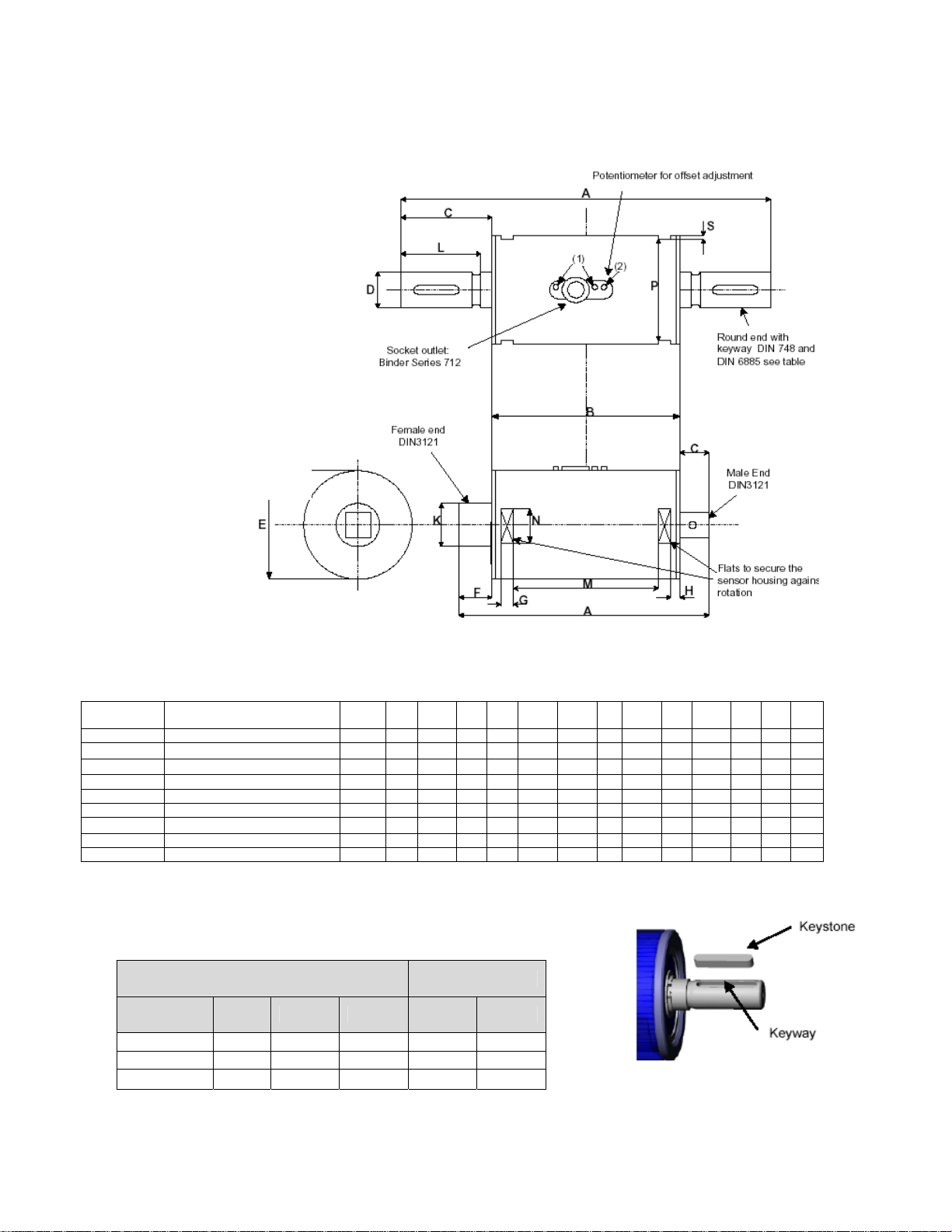

(1) Do not loosen or tighten the mounting screws.

(2) See 8.4 – Offset adjustment

Dimensions Nominal Torque Capacity

LXT 970

¼ inch

3/8 inch

½ inch 175-250 123.5 70 18.5 - 50 35 8 5 24 - 43.9 18 47 1.5

¾ inch 500 146 87 29.6 - 60 29.6 10.5 2 33.5 - 61.4 19 57 1.5

LXT 971

Ø 9 mm

Ø 14 mm 75 139 70 34.5 14 50 - 8 5 - 30 43.9 18 47 1.5

Ø 19 mm 175-250 179 70 54.5 19 50 - 8 5 - 50 43.9 18 47 1.5

[Nm]

2.5 - 5.0 - 7.5 - 17.5 95.5 70 9.5 - 40 16

75

2.5 - 5.0 - 7.5 - 17.5

A B C D E F G H K L M N P S

8 5 12 - 43.9 15 37 1.5

107 70 13 - 50 24 8 5 18 - 43.9 18 47 1.5

125 70 27.5 9 40 - 8 5 - 23 43.9 15 37 1.5

4.0 KEYWAY DIMENSIONS (ROUND SHAFT

SENSORS ONLY)

Dimensions Keyway [mm] Keystones

Shaft

Diameter

Width Depth Length Height Length

Ø 9 mm 3 1.8 18.5 3

Ø 14 mm 5 3 25.5 5

Ø 19 mm 6 3.5 45.5 6

18

25

45

CF 59 2 V-11/18/02

Page 3

5.0 TERMINAL DIAGRAM

Terminal diagram of socket-outlet: View looking at sensor socket.

Pin Color Description

1 White Supply Voltage Vcc

2 Brown Signal Output Vout

3 Black Ground

4 Blue (Not Used)

5 Grey Reference Voltage 2.5V

The output V

represents the virtual zero point for direct +/- torque

measurement (See below “Sensor cable and

connection” section B).

Use connector with proper shielding termination (360 deg). Otherwise maintain shield as close to cable

ends as possible and connect to earth ground.

Sensor Cable Connection

A) This circuit is recommended for absolute torque

measurement, e.g. 2.5V equals to approx. 0 Nm

Grey and blue wires are not in use.

is a constant 2.5V output and

ref

B) This circuit is recommended for relative torque

measurement, e.g. 0V equals to approx. 0 Nm

Blue wire is not in use.

6.0 OPERATING INSTRUCTIONS

6.1 Field of Application

The torque sensor is intended for use in an industrial environment (e.g. in test stands).

6.2 Scope of Delivery

The torque sensor set consists of the sensor unit (signal detector and signal conditioning electronics integrated

into sensor housing); one connecting cable (length 1.5 m) with soldered plug connector; and one installation and

instruction manual.

6.3 Sensor Installation and Removal

The shafts connected to the torque sensor must be properly aligned. A shaft coupling should be selected to

eliminate or minimize backlash, angular misalignment, end-float, or other mechanical situations that would affect

the performance or operation of the torque sensor. Secure the sensor utilizing the 8mm guides located on the

sensor body (optional sensor holder). A maximum cable length of 3 m must not be exceeded. Using a cable or

connector other than supplied by Cooper Instruments, or a cable supplied by Cooper that is of a different length

may affect the overall performance of the sensor. *Prior to removing the sensor from operation, remove all

lateral forces or torque stored in the mechanical assembly. Remove the keys from the shafts before loosening

the mounting screws. *

DO NOT REMOVE THE SHAFT WITH TORQUE APPLIED TO THE SENSOR.

CF 59 3 V-11/18/02

Page 4

6.4 Offset Adjustment

The sensor is preset at the factory to indicate an output signal at 0 Nm of 2.5 volts. The output voltage signal

can be adjusted via a potentiometer (2) (Refer to Section on Mechanical Dimensions). Remove the headless

screw; and using a plastic screwdriver, set the potentiometer to 2.5 V using a plastic screwdriver. Replace the

headless screw until flush with the surface of the housing.

Factory setting is 2.5V.

6.5 Interface Description

Mechanical Interface:

For transmission on both ends of the shafts are keyway adapter or square ends (male/female) available.

Electrical Interface:

On the sensor outside is a 5 pole plug for power supply and signal lines (see Terminal diagram).

6.6 Operation (Normal, Optimization)

For optimal measurement results, do not exceed the rated torque when using the sensor. Do not operate the

sensor at the maximum rotational speed for extended periods of time. Observe the prescribed operating

conditions to ensure trouble free and maintenance free operation of the sensor.

6.7 Operation Outside Specified Conditions, Corrective Action

External magnetic fields may have an adverse effect on the measurement results. Excessive mechanical stress

on the sensor (e. g. longitudinal forces / loads outside the specified limits, strong vibrations) may cause damage

to the sensor and thus lead to incorrect signal outputs. Should these conditions be experienced, readjusting the

sensor may improve the performance (see Section 7.4 - Offset Adjustment). If the problem persists, do not

open the sensor housing. Contact Cooper Instruments for assistance.

6.8 Commissioning

After sensor installation, observe the following procedure:

• Switch on the power supply unit and check the supply voltage. Peak voltages to the sensor must be avoided!

Be sure to verify the power supply voltage prior to connecting the sensor!

• Using the supplied sensor cable, connect the sensor to the power supply unit.

• Connect the sensor output to a high-resistance device such as an A/D converter, oscilloscope, PLC analog

board, PC measurement board, etc.

• With the sensor under no mechanical load (zero torque condition), determine the output signal voltage.

• If required: Adjust the signal output to read 2.5 V (0 Nm); see 7.4 - Offset Adjustment.

6.9 Service and Maintenance

There are no required maintenance operations for the sensor.

6.10 Disposal

Please return the device to the manufacturer for disposal.

6.11 Handling and Transportation

During sensor handling, storage and transportation, it is important to ensure that the sensor is not exposed to

any magnetic or electromagnetic fields higher than specified by the electromagnetic compatibility. Static or

dynamic loads on the sensor must be avoided.

6.12 Safety Precautions

1. Do not open the sensor housing under any circumstances.

2. Do not remove or loosen the locating rings on the shaft ends.

3. Do not loosen or tighten the nut of the flange-mounting socket-connector (1) (see Mechanical dimensions).

CF 59 4 V-11/18/02

Page 5

*Carrying out any of the above operations (1-3) results in loss of sensor calibration. The sensor does no

longer operate regularly and must be returned to Cooper for calibration and certification.

4. Use only power supplies that are properly isolated from the electrical mains.

5. Observe the specifications regarding maximum electrical and mechanical loads on the sensor, as shown on

the sensor label and in section 4 - Technical Features.

6. Protect the sensor from exposure to any electric or magnetic fields.

7.0 WARRANTY REPAIR POLICY

Limited Warranty On Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in

workmanship within one year of the date of shipment by Cooper will be repaired or replaced free of charge

provided that a return material authorization is obtained from Cooper and the defective product is sent,

transportation charges prepaid, with notice of the defect, and it is established that the product has been properly

installed, maintained, and operated within the limits of rated and normal usage. Replacement or repaired

product will be shipped F.O.B. from our plant. The terms of this warranty do not extend to any product or part

thereof which, under normal usage, has an inherently shorter useful life than one year. The replacement

warranty detailed here is the buyer’s exclusive remedy, and will satisfy all obligations of Cooper whether based

on contract, negligence, or otherwise. Cooper is not responsible for any incidental or consequential loss or

damage which might result from a failure of any and all other warranties, express or implied, including implied

warranty of merchantability or fitness for particular purpose. Any unauthorized disassembly or attempt to repair

voids this warranty.

Obtaining Service Under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact

the Repair Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number.

Shipment to Cooper shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from

our plant in Warrenton, Virginia. Non-verified problems or defects may be subject to a $100 evaluation charge.

Please return the original calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty

applies only to those items that were found defective and repaired; it does not apply to products in which no

defect was found and returned as is or merely recalibrated. It may be possible for out-of-warranty products to

be returned to the exact original specifications or dimensions.

* Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper

to receive information specifying the reason the product is being returned. Specific test data, written

observations on the failure and the specific corrective action you require are needed.

CF 59 5 V-11/18/02

Page 6

8.0 TECHNICAL FEATURES

Description Symbol

LXT 970-971 Series

Unit Remarks

Torque Range

Maximum rated torque - bi-directional M 2.5 5.0 7.5 17.5 75 175 250 500

Analog signal output V

0.5 - 4.5 Vdc

out

Nm Full Scale = 0 to maximum rated torque

Degree of protection IP 50 Per EN60529

Supply voltage Vcc 9.0 .. 12.0 Vdc

Signal output at 0 Nm (adj. via offset Pot.) V

out (0)

2.5 V Adjustable via potentiometer

Signal output resistance 50 Ω

Signal band width BW 1000 Hz

RD=round shaft 0 ... 5000 (RD)

Rotational speed

SQ=square drive

n

0 ... 1000 (SQ)

Rpm

Repeatability < ±0.1 %FS DKD-R 3-5

Hysteresis and linearity failure and signal

variation during rotation

< 1 <2 % FS

Operating temperature range Top 0 ... +70 °C Reference temperature: 21°C

Maximum longitudinal force between shaft and

housing

40 N Influence on measurement signal <1%FS

F

l

Maximal lateral force Fq 50 N Influence on measurement signal <1%FS

Zero drift (temperature-related) < ±0.1 % FS / K

Resistance to magnetic fields (distance 70mm)

4000 Oe

318 kA/m

Minimal distance from sensor housing:

70mm

EN 55011, EN 6100-4-3,EN 6100-4-6, EN

Electromagnetic compatibility

6100-4-4, EN 6100-4-2, EN 50204, EN

50081-3, EN 50082-2

Not intended for medical use

Storage temperature T -20...+100 °C

Weight

Round 383 386 392 400 685 856 861 XX

Square 395 397 401 386 652 754 749 1385

g

CF 59 6 V-11/18/02

Loading...

Loading...