Page 1

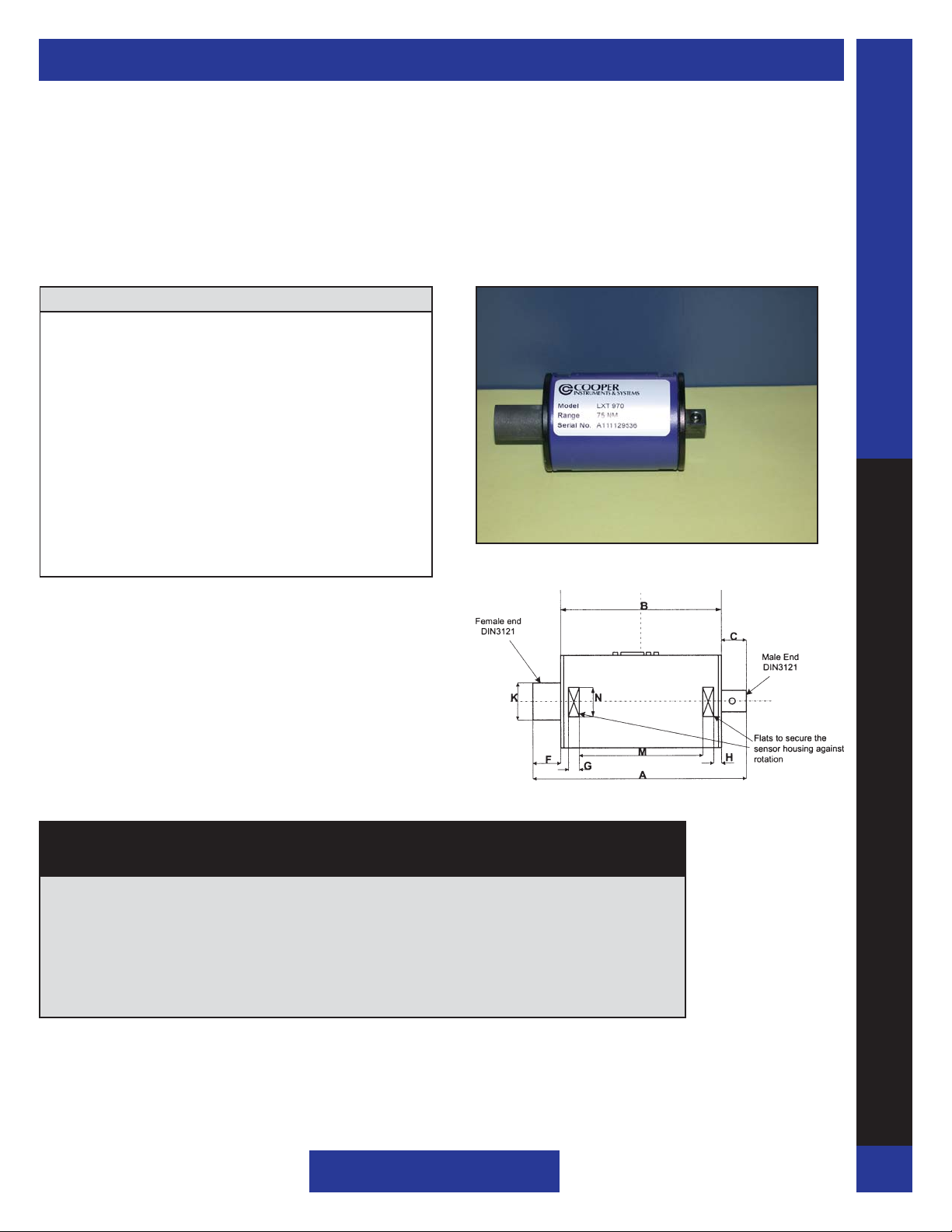

LXT 970 ROTATING TORQUE LOAD CELL

he LXT 970 torque transducer operates on the principle of

magnetoelasticity. The sensors output signal is caused by a

T

change in the magnetic field created by an applied torque on the

sensor’s shaft. Non-contact detectors, in close proximity to the shaft,

detect changes in the magnetic field and provide an electrical signal

proportional to the torque. The electronics in the sensor provide signal

conditioning suitable for use in industrial and process applications. The

zero output is 2.5v. The output span can range from 10mv/v to 2.5v in

either direction.

SPECIFICATIONS

LOAD RANGES:

ACCURACY:

LINEARITY:

HYSTERESIS:

REPEATABILITY:

MATERIAL:

TEMPERATURE RANGE:

OUTPUT:

BRIDGE RESISTANCE:

EXCITATION:

SAFE OVERLOAD:

RPM:

CABLE:

2.5 Nm to 500 Nm

(1.8 ft.lb to 368 ft.lb)

±1% F.S.

<1% F.S.

<1% F.S.

0.2% F.S.

Steel

32° to 158°F

0.5 - 4.5 Vdc

N/A

9-12 Vdc

200 % of F.S.

5000 Max Round Shaft

1000 Max Square Shaft

3 Ft with Mating Connector

• LOW COST

• COMPACT SIZE

• FAST DELIVERY

• <1% ACCURACY

TORQUE CELLS

AVAILABLE RANGES

LXT 970 Square Drives - Male/Female

Drive A B C E F G H K M N P

2.5 Nm 1/4 3.76 2.75 0.38 1.56 0.63 0.31 0.19 0.50 1.75 0.56 1.44

5.0 Nm 1/4 3.76 2.75 0.38 1.56 0.63 0.31 0.19 0.50 1.75 0.56 1.44

7.5 Nm 1/4 3.76 2.75 0.38 1.56 0.63 0.31 0.19 0.50 1.75 0.56 1.44

17.5 Nm 1/4 3.76 2.75 0.38 1.56 0.63 0.31 0.19 0.50 1.75 0.56 1.44

75 Nm 3/8 4.19 2.75 0.50 1.94 0.94 0.31 0.19 0.69 1.75 0.69 1.88

175 Nm 1/2 4.88 2.75 0.75 1.94 1.38 0.31 0.19 0.94 1.75 0.69 1.88

250 Nm 1/2 4.88 2.75 0.75 1.94 1.38 0.31 0.19 0.94 1.75 0.69 1.88

500 Nm 3/4 5.75 3.44 1.19 1.96 1.38 0.44 0.06 1.31 2.44 0.75 2.25

COOPER INSTRUMENTS & SYSTEMS

www.cooperinstruments.com sales@cooperinstruments.com

1-800-344-3921

10/10/06

Loading...

Loading...