Page 1

INSTALLATION INSTRUCTIONS FOR THE LPM 560

PERFORMANCE CHARACTERISTICS @ 10 ± 0.01 VDC, 25°c

(Preliminary, based on limited test data)

Parameter Min. Typ. Max. Units Excitation* ----- 10 12 VDC Null shift, 25 to 0°, 25 to 50°C ----- ±0.5 ---- mV Null offset -30 0 +30 mV Linearity (BFSL)** ---- ±0.5 ---- %Span Sensitivity shift 25 to 0°, 25 to 50°C ---- ±5.0 --- %Span Sensitivity ---- 0.24 ---- mV/grf Repeatability ---- ±0.2 ---- %Span Response time ---- ---- 1.0 msec Input resistance ---- 5.0K ---- ohms Output resistance ---- 5.0K ---- ohms Plunger deflection ---- 30 ---- microns Weight ---- 2.0 ---- Grams ESD (direct contact – terminals and plunger)

*Non-compensated force sensors, excited by constant current (1.5 mA) instead of voltage, exhibit partial temperature compensation of

Span.

**BFSL: Best Fit Straight Line.

ENVIRONMENTAL SPECIFICATIONS

Operating temperature -40 to 85°C (-40 to +185°F)

Storage temperature -55 to 105°C (-67 to +221°F)

Shock Qualification tested to 150 g

Vibration Qualification tested to 0 to 2 kHz, 20 g sine

Note: All force related specifications are established using dead weight of compliant force.

DESCRIPTION

Catalog Listing Force Range(grams) Min Sapn* mV Typ Max Overforce grams Max

LPM 560 1,500 290 360 430 5,500

* Span: the algebraic difference between the output end points.

SOLDERING

Soldering temperature should not exceed 2.5 seconds per not exceed 315°.

Soldering duration should not exceed 2.5 seconds per lead. When PC board

mounting, provide terminal stand-off clearance of at least 0.040” from the soldering

surface. Heat sinking is also recommended.

EXCITATION SCHEMATIC

10 --- --- kVolts

CLEANING

Proper cleaning fluids should be selected,

based on the contaminants to be removed.

Alcohols are recommended.

CF39 06/21/02

Page 2

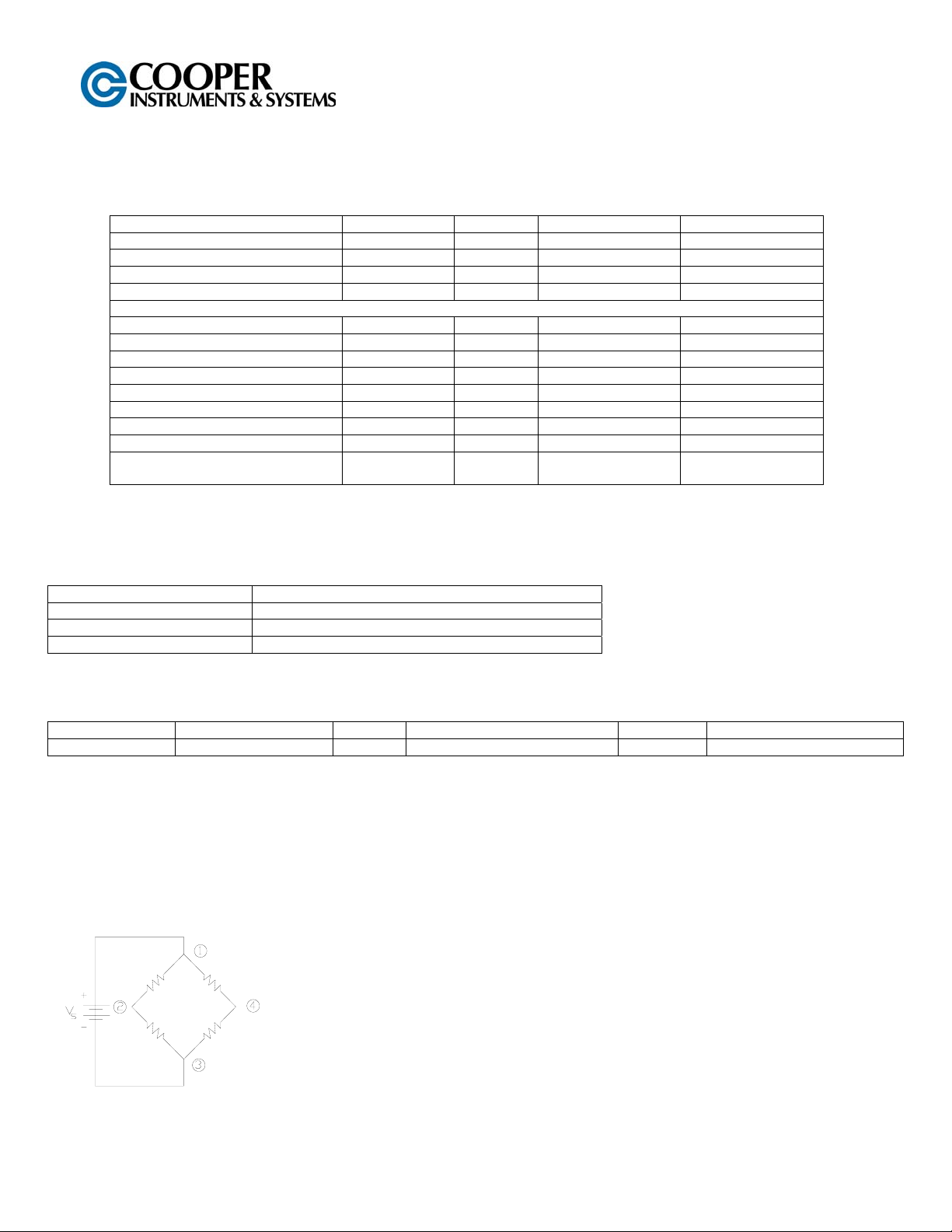

LPM 560 CIRCUIT

1. Circled numbers refer to sensor terminals (pins). Pin 1 is designated with a notch. The color designation is in reference to use

of the optional cable supplied as part number 560-1.

Pin 1 = Supply Vs(+) = Red

Pin 2 = Output, (+) = White

Pin 3 = Ground, (-) = Black

Pin 4 = Output, (-) = Green

2. The force sensor may be powered by voltage or current. Maximum supply voltage is not to exceed 12 volts. Maximum supply

current is not to exceed 1.6 mA. Power is applied across Pin 1 and Pin 3.

3. The sensor output should be measured as a differential voltage across Pin 2 and Pin 4 (V

ratiometric to the supply voltage. Shifts in supply voltage will cause shifts in output. Neither Pin 2 nor Pin 4 should be tied to

ground or voltage supply.

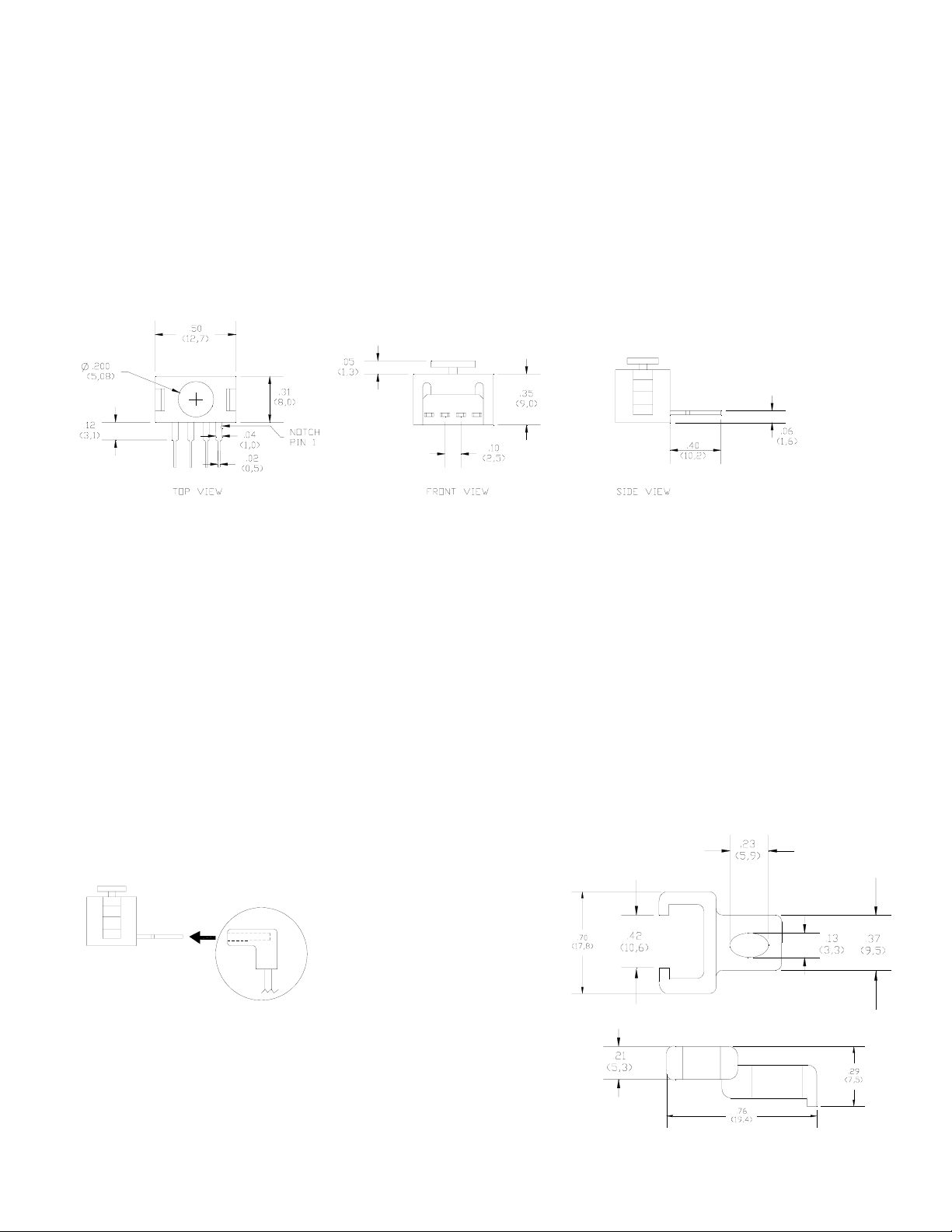

MOUNTING DEMINSIONS

(for reference only)

MOUNTING

Sensor output characteristics do not change with respect to mounting orientation. Care should be taken not to obstruct the vent hole in

bottom of housing. Improper venting may result in unstable output.

Mounting bracket mounting torque: 2-5 in.lb. (0,21-0,56 Nm).

APPLYING FORCE

Evaluation of the sensor is to be performed using dead-weight or compliant force. Application of a rigid, immobile force will result in

output drift (decrease) as elastometric seals relax. Off-center plunger loading has minimal effect on sensor performance and maintains

operation within design specifications.

Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this printing.

However, we assume no responsibility for its use.

ACCESSORIES Catalog Listing Description

560-1 Optional cable assembly

560-2 Plastic mounting bracket

Optional Cable: Part 560-1

The “L” connector must always be plugged with the orientation described

below. Plugging in the connector in a different way will align the pin sockets in

a wrong configuration and would change the wire code.

= V2 – V4). The output is

o

Optional Clip: Part 560-2

CF39 06/21/02

Loading...

Loading...