Page 1

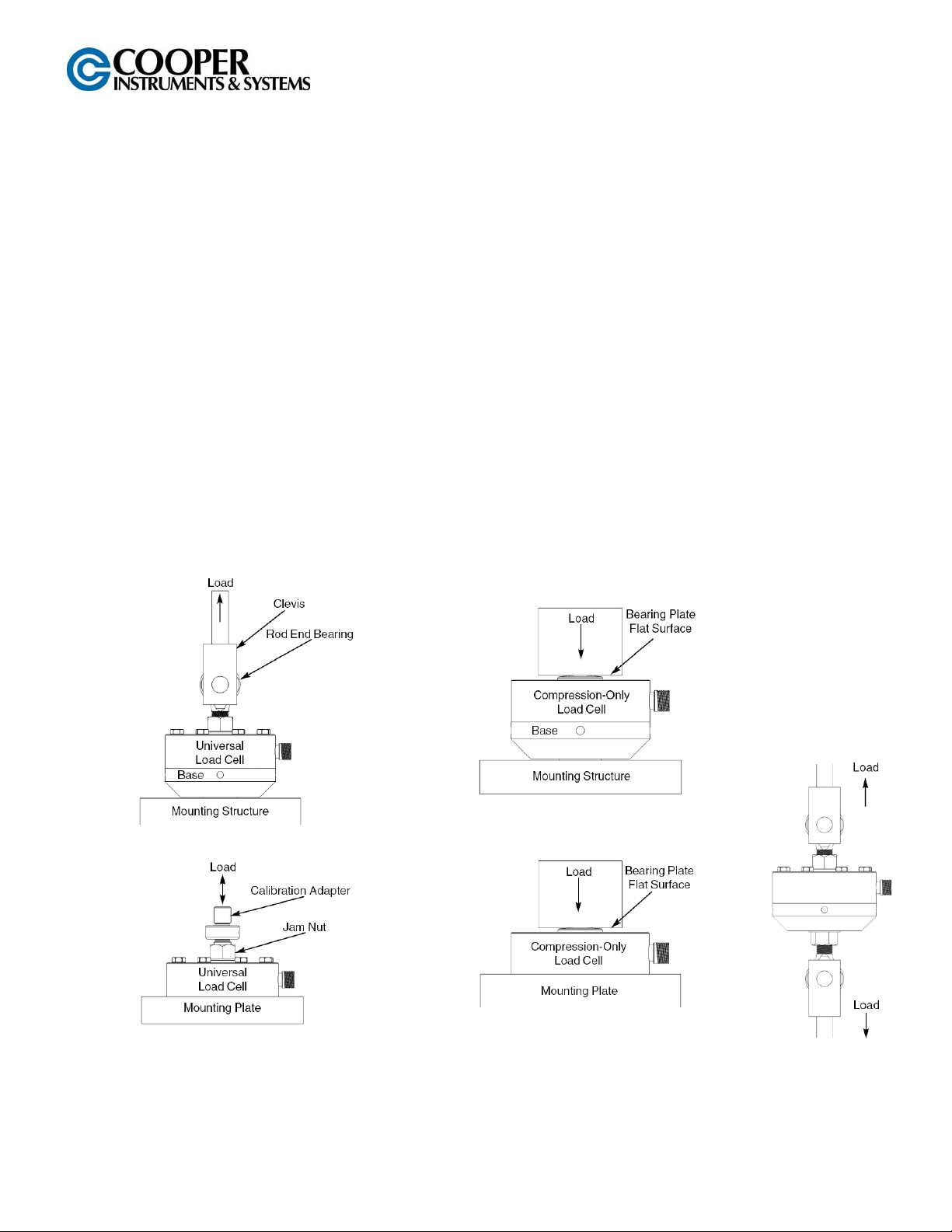

LGP 380/382 INSTALLATION INFORMATION

1. Cooper Instruments LGP 380 and LGP 382 Load Cells must be mounted on a surface that is flat and rigid enough so

as not to deform appreciably under load. An easy way to obtain the flat rigid surface is by using a Cooper supplied

base or mounting plate. Where this is not practical, a rigid surface equivalent to the appropriate Cooper base or

mounting plate will suffice. Cooper load cells respond to forces in the axis perpendicular to the mounting surface.

Load cell response to a non-axial force is proportional to that force times the cosine of the angle it makes with the

loading axis.

2. When installing these load cells on any surface other than on a Cooper base or mounting plate, the Grade 8 cap

screws holding the cell to the mounting surface must be tightened to the value shown in the torque chart.

3. LGP 380 and LGP 382 Load Cells must have jam nuts tightened to the value shown in the table below, to avoid

thread damage.

4. For best performance of the LGP 380 and LGP 382 Load Cells, the use of jam nuts is recommended. The jam nuts

should be installed as indicated in the table below.

5. Rod end bearings, or threaded adapters, should have smooth threads and class 3 fit.* They should be installed hand

tight and backed off 1 turn prior to tightening jam nut as indicated in the table below.

6. Bearing Plates should be hardened steel (Rc 45 or higher) when mating with a load button or steel load cells. For

aluminum compression-only load cells, mild steel bearing plate may be used.

7. To eliminate potential reading errors, the outer rim or base of the load cell and its connecting electrical cable should

be mounted on the fixed or non-moving structure.

*Class 6g Metric.

TENSION

COMPRESSION

INSTALLATION ON IRREGULAR SURFACE USING COOPER-SUPPLIED BASE

INSTALLATION ON FLAT PLATE PER TABLE BELOW, PERPENDICULAR TO LOAD AXIS

WITHIN 1 DEGREE. FLEXURE MOUNTING SCREWS TO BE TIGHTENED TO THE VALUE

SHOWN IN THE TORQUE CHART.

ROD END

MOUNTING

CF36 06212010 (V-FORM 15-5J0506)

Page 2

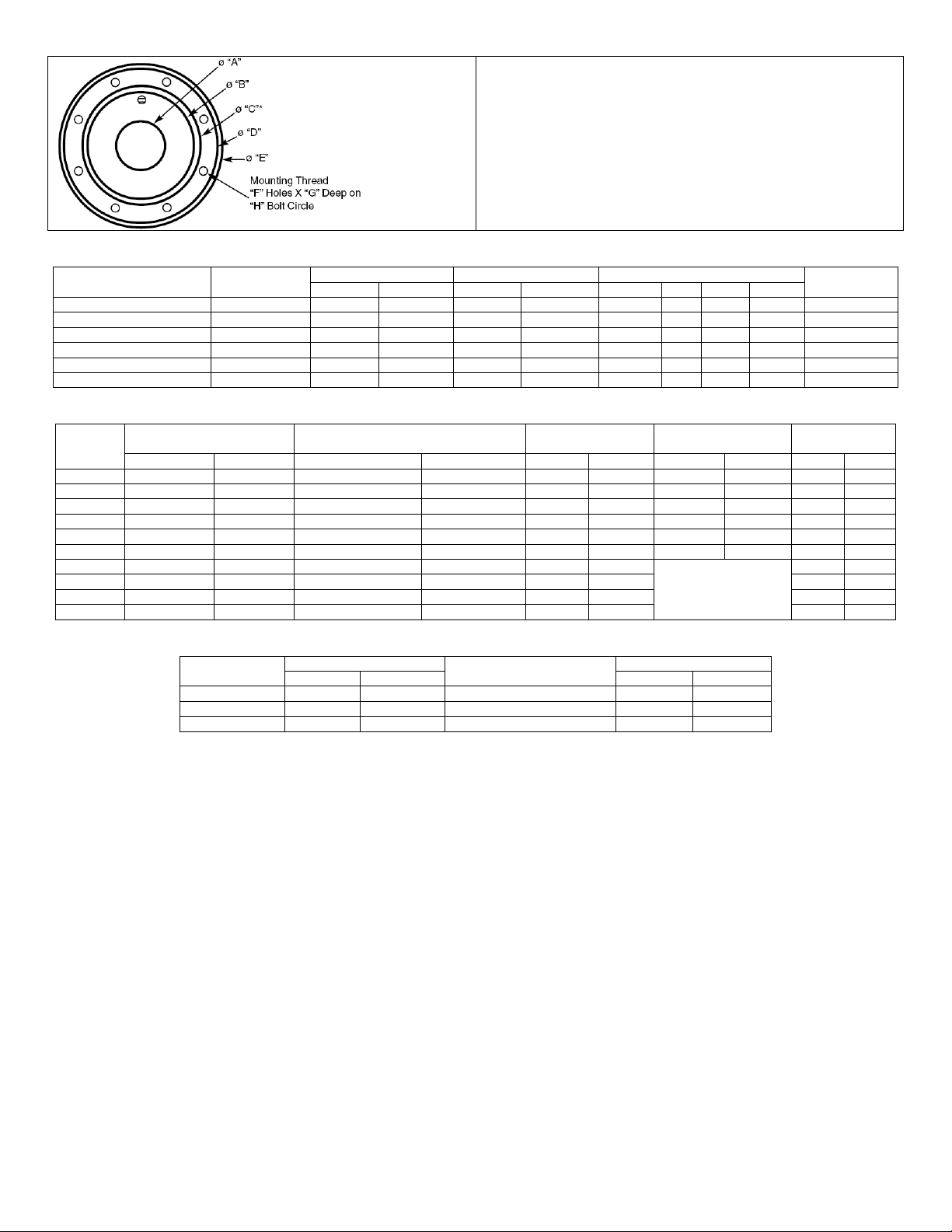

1. Cooper-supplied bases are heat-treated to a Rockwell

hardness of 30-33.

2. Mounting surface should be perpendicular to the load

axis within 1 degree.

3. Mounting screws should be Grade 8 (10.9) or better.

4. Torque, lightly lubricated, mounting screws per Table 3

or 4 below.

5. Inner and outer rings identify the critical area over which

flatness specification applies.

Table 1 – Base or Mounting Plate Dimensions, LGP 380 Universal and LGP 382 Compression-O nly Load Cells

Model Number

LGP 380, 300 to 10K lbf 1.34 2.87 3.14 3.98 4.13 1/4-28 8 0.30 3.500 0.0002

LGP 380, 25K to 50K lbf 2.65 3.99 4.54 5.84 6.06 3/8-24 12 0.63 5.125 0.0002

LGP 380, 100K lbf 3.76 5.47 5.75 7.80 8.00 1/2-20 16 1.00 6.500 0.0002

LGP 380, 200K lbf 4.81 6.76 7.472 10.58 11.00 5/8-18 16 1.12 9.000 0.0002

LGP 382, 1K to 10K lbf 1.34 2.87 3.14 3.98 4.13 ¼-28 8 0.30 3.500 0.0002

LGP 382, 25K to 50K lbf 2.65 3.99 4.54 5.84 6.06 3/8-24 12 0.63 5.125 0.0002

Hub Diameter

“A”

Inner Mounting Ring Outer Mounting Ring Mounting Threads

“B” “C” “D” “E” Thread “F” “G” “H”

Mtg Surface

Flatness

Table 2 – Mounting Parameters, LGP 380 Load Cells

Model

Number

LGP 380 300 1.5 1/4-28 UNF X 1.50 M6 X 40mm 5 7 10 14 10 14

LGP 380 250, 500 1.25, 2.50 1/4-28 UNF X 1.50 M6 X 40mm 5 7 15 20 16 20

LGP 380 500, 1K 2.5, 5 1/4-28 UNF X 1.50 M6 X 40mm 5 7 25 34 32 43

LGP 380 1K, 2K 5, 10 1/4-28 UNF X 1.50 M6 X 40mm 5 7 50 68 65 88

LGP 380 2.5K, 5K 12.5, 25 1/4-28 UNF X 1.50 M6 X 40mm 10 14 100 136 165 224

LGP 380 5K, 10K 25, 50 1/4-28 UNF X 1.50 M6 X 40mm 10 14 100 136 330 445

LGP 380 12.5K, 25K 50, 100 3/8-24 UNF X 2.25 M10 X 60mm 55 75 830 1130

LGP 380 25K, 50K 125, 250 3/8-24 UNF X 2.25 M10 X 60mm 55 75 1660 2250

LGP 380 50K, 100K 225, 450 ½-20 UNF X 3.00 M12 X 75mm 120 160 3320 4500

LGP 380 100K, 200K 450, 900 5/8-18 UNF X 4.00 M16 X 100mm 250 340

Capacity Mounting Screw Size

US (lbf) Metric kN) Fractional Metric (lb-ft) (Nm) (lf-ft) (Nm) (lb-ft) (Nm)

Mounting Screw

Torque

Thread Adapter

Torque

Pull thread adapter

to 110-140% of

capacity and tighten

jam nut.

Max. Hub

Torque

6640 9000

Table 3 – Mounting Parameters, LGP 382 Load Cells

Model Number

LGP 382 1K, 2K 5, 10 1/4-28 UNF X 1.25 5 7

LGP 382 5K, 10K 25, 50 1/4-28 UNF X 1.25 10 14

LGP 382 25K, 50K 125, 250 3/8-24 UNF X 1.75 55 75

Capacity Mounting Screw Torque

US (lbf) Metric (kN)

Mounting Screw Size

(Socket Head Capt Screw)

(lb-ft) (Nm)

CF36 06212010 (V-FORM 15-5J0506)

Loading...

Loading...