Page 1

S-BEAM LOAD CELL MOUNTING GUIDE

CAUTIONS:

1. Do not pull or carry sensor by cable.

2. Any tampering or removal of cover, cable and/or connector will void warranty.

3. Always have sensor plugged in during installation to monitor output to avoid permanent zero shift

or overload

4. The threaded ends of the hardware should never come in contact with the middle portion of the sbeam. The center of the s-beam is a non -contact area and a sizable gap should be left between it

and the ends of the hardware.

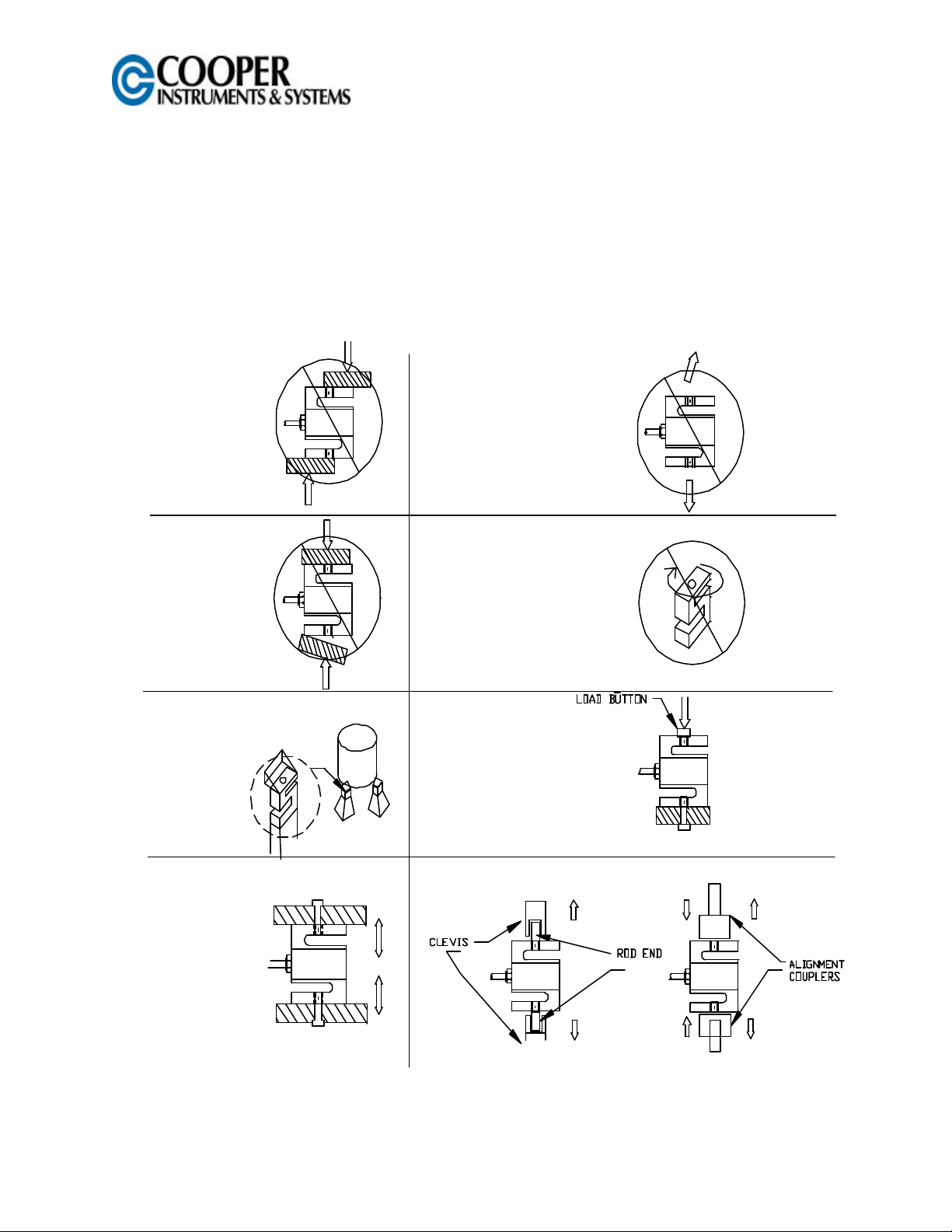

MOUNTING:

LOAD MUST BE

EVEN AND

CENTERED

LOAD MUST BE

FLAT AND

PARALLEL WHEN

COMPENSATING

LINKAGES ARE

NOT USED

SENSOR CAN BE

USED TO

MONITOR

VOLUME IN A

HOLDING TANK

APPLICATION.

TENSION LOADING MUST

BE INLINE WHEN

COMPENSATING

LINKAGES ARE USED

THREAD THE FIXTURE TO

THE LOAD CELL THREADING

THE LOAD CELL TO THE

FIXTURE CAN APPLY

TORQUE THAT MAY

DAMAGE THE UNIT

A LOAD BUTTON MAY

BE USED WHILE THE

BOTTOM OF THE

SENSOR IS

SECURED TO A BASE

PLATE.

ROD END BEARINGS WITH CLEVISES OR

ALIGNMENT COUPLERS MAY BE USED TO MAKE UP

SENSOR CAN BE

USED

SANDWICHED

WITH MORE THAN

ONE UNIT

BETWEEN

PLATES.

FOR MISALIGNMENT.

CF 32 S-Beam Mounting Guide REV. 11/9/05

Loading...

Loading...