Page 1

PS, FB, PSH, ESH

MECHANICAL FORCE GAUGES

USER’S GUIDE

www.cooperinstruments.com

PH: 540-349-4746 • FAX: 540-347-4755

Page 2

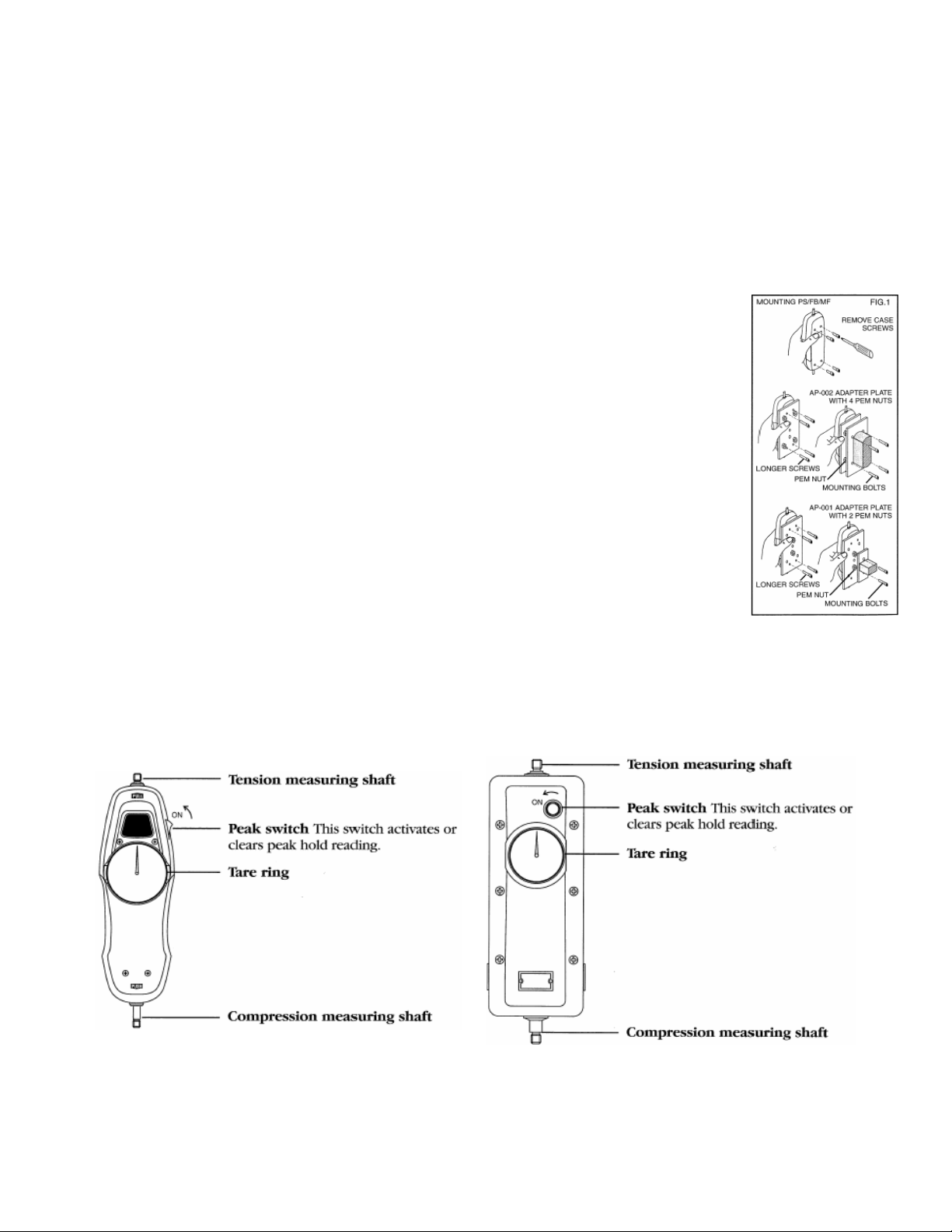

GENERAL OPERATION

1. Press (or rotate for Model PSH/ESH) Peak Switch OFF.

2. Hand tighten (no tool!) selected attachment to the measuring shaft.

3. Rotate Tare Ring to read “0” to tare the weight of attachment and measuring shaft orientation.

4. Begin measuring.

Real Time Mode: the Peak Switch is OFF and the gauge displays force as it changes. During Real Time Mode,

you can hold a critical reading by turning the Peak Switch to the ON position.

Peak Mode: the Peak Switch is ON and the gauge will retain highest reading taken which will not change until a

higher value is measured. Turn the Peak Switch OFF to zero the gauge and turn it ON again to measure Peak

values.

MOUNTING

When mounting mechanical gauges to test stands, hold the gauge firmly and unscrew the 4 screws

in back, making sure the case does not separate. (FIG. 1)

AP-002 adapter plate mounts mechanical gauges to test stands. Align plate and gauge holes and

insert the 4 long screws supplied to attach gauge. Then utilize the 4 PEM nuts on the adapter plate

to mount to test stands with the mounting bolts supplied.

AP-001 adapter plate mounts low capacity gauges to most other brands of test stands. Use the 4

screws (supplied) to mount the gauge to the AP-001 adapter plate. Then utilize the 2 PEM nuts on

the AP-001 adapter plate to mount to other brands of test stand.

IMPORTANT

1. Do not exceed capacity of unit and avoid shock loading.

2. Failure to allow for sufficient overload capacity in the load, structure and mounting

elements, may result in property damage, serious injury, and death. For applications

involving suspension of equipment, additional safeguards are also a necessity.

3. Do not use the tension shaft to measure compression or the compression shaft to measure

tension.

4. Accuracy may be affected if unit is exposed to high humidity, dust or extreme shock.

5. Do not apply oil or chemical soap, which causes corrosion or dust adhesion.

6. Do not remove warranty seal or disassemble gauge. Disassembly voids warranty.

7. Recommended recalibration cycle is one year.

8. Specifications subject to change without notice.

Model FB/PS Model ESH/PSH

CF 22 2 PS, FB,PSH,ESH (V-4/06)

Page 3

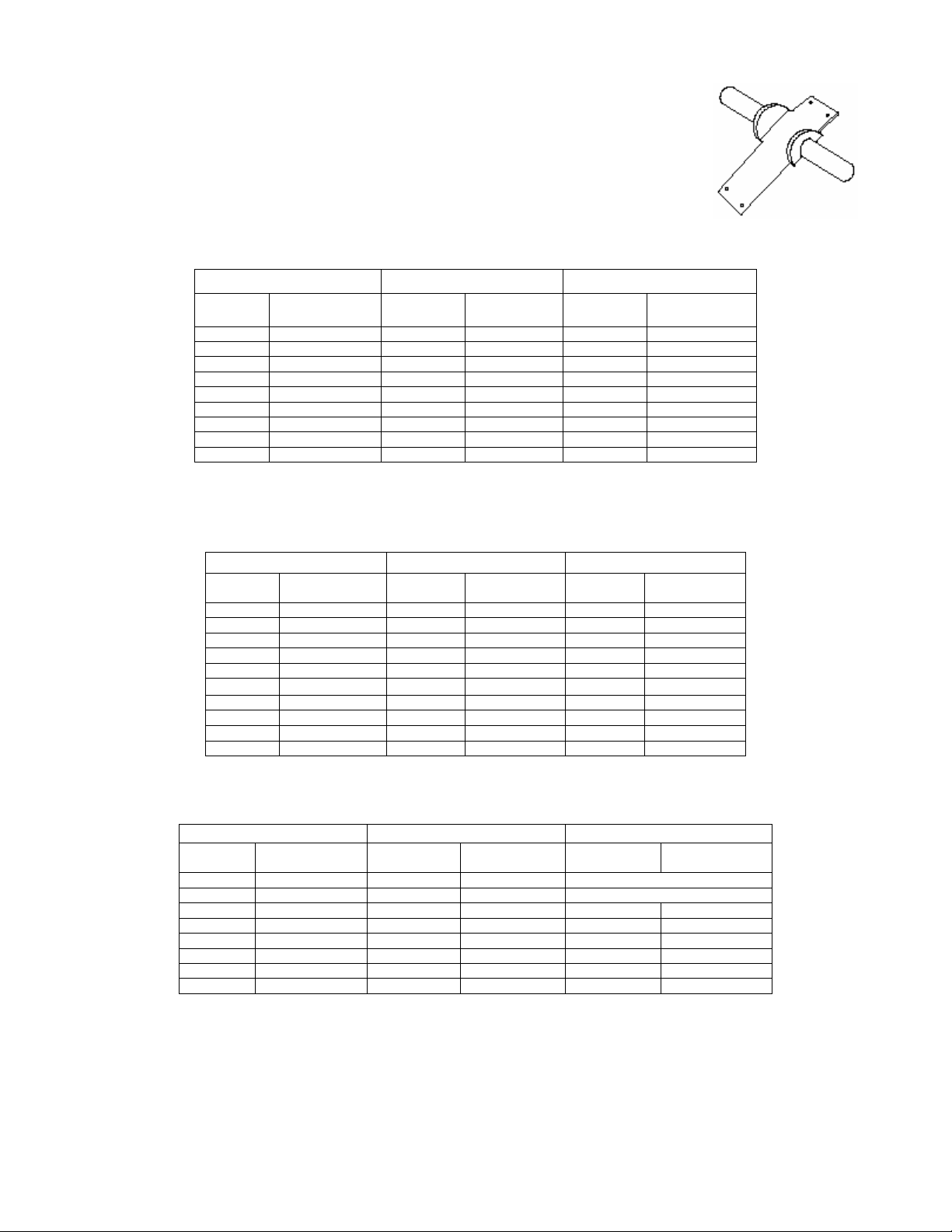

OPTIONAL HANDLE

The OH-1/MOH-1 fits PS, MF and FB series.

Constructed of high quality steel for rugged use, the handle facilitates measurements of

heavy loads. Complete with mounting screws, the OH-1 handle ensures safe and consistent

measuring conditions.

PS/MF Ranges (Resolution) Accuracy: PS±0.1% F.S. MF±0.3% F.S.

Pounds Kilograms Newtons

Model

PS-32 oz 32 ozf (0.25ozf) PS-0.5 kg 500 gf (2.5 gf) PS-10N 10 N (0.05 N)

PS-80oz 80 ozf (1ozf) PS-1 kg 1 kgf (5gf) PS-20 N 20 N (0.1 N)

PS-2 2lb (0.01 lb) PS-2kg 1kg (10 g) PS-30 N 30 N (0.2 N)

PS-5 5 lb (0.025 lb) PS-3 kg 3 kg (20 g) PS-50 N 50 N (0.25 N)

PS-10 10 lb (0.05 lb) PS-5 kg 5 kg (25 g) PS-100 N 100 N (0.52 N)

PS-20 20 lb (0.1 lb) PS-10 kg 10 kg (50 g) PS-200 N 200 N (1 N)

PS-30 30 lb (0.2 lb) PS-20 kg 20 kg (100 g) PS-200 N 200 N (1 N)

PS-50 50 lb (0.25 lb) PS-30 kg 30 kg (200 g) PS-500 N 500 N (2.5 N)

PS-100 100 lb (0.5 lb) PS-50 kg 50 kg (250 g)

Capacity

(Resolution)

Model

Capacity

(Resolution)

Model

Capacity

(Resolution)

Overload capacity: 165 lbs. For all ranges Stroke: 10 mm F.S.

FB Ranges (Resolution) Accuracy: FB ±0.3% F.S.

Pounds Kilograms Newtons

Model

FB-32 oz 32 ozf (0.25 zf) FB-1 kg 1kgf (10 gf) FB-10 N 10 N ( 0.1 N)

FB-80 oz 80 ozf (1 ozf) FB-2 kg 2 kgf (20 gf) FB-20 N 20 N (0.2 N)

FB-2 2 lb (0.02 lb) FB-3 kg 3 kg (25 g) FB-30 N 30 N (0.25 N)

FB-5 5 lb (0.05 lb) FB-5 kg 5 kg (50 g) FB-50 N 50 N (0.5 N)

FB-10 10 lb (0.1 lb) FB-10 kg 10 kg (100 g) FB-100 N 100 N (1 N)

FB-20 20 lb (0.2 lb) FB-20 kg 20 kg (200 g) FB-200 N 200 N (2 N)

FB-30 30 lb (0.25 FB-30 kg 30 kg (250 G) FB-300 N 100 N (2.5 N)

FB-50 50 lb (0.5 lb) FB-50 kg 50 kg (500 g) FB-500 N 500 N (5 N)

FB-100 100 lb (1 lb) FB-30 kg

FB-150 150 lbf (1 lbf)

Capacity

(Resolution)

Model

Capacity

(Resolution)

Model

Capacity

(Resolution)

Overload capacity: 165 lbs. For all ranges Stroke: 10mm F.S.

ESH and PSH Ranges (Resolution) Accuracy: ESH±0.5% F.S. PSH±0.3% F.S.

Pounds Kilograms Newtons

Model

ESH-200 200 lb (2 lb) ESH-50 kg 50 kg (0.5 kg)

PSH-200 200 lb (1 lb) PSH-50 kg 50 kg (0.25 kg)

ESH-300 300 lbf (2.5 lbf) ESH-100 kg 100 kg (1 kg) ESH-1000 N 1000 N (10 N)

PSH-300 300 lb (2 lbf) PSH-100 kg 100 kg (0.5 kg) PSH-1000 N 1000 N (5 N)

ESH-400 400 lb (4 lb) ESH-200 kg 200 kg (2 kg) ESH-2000 N 2000 N (20 N)

PSH-400 400 lb (2lb) PSH-200 kg 200 kg (1kg) PSH-2000 N 2000 N (10 N)

ESH-500 500 lb (5 lb) ESH-300 kg 300 kg (2.5 kg) ESH-3000 N 3000 N (25 N)

PSH-500 500 lb (2.5 lb) PSH-300 kg 300 kg (2kg) PSH-3000 N 3000 N (20N)

Capacity

(Resolution)

Model

Capacity

(Resolution)

Model

(Resolution)

Overload capacity: 135% of rated capacity Stroke 10mm F.S.

Capacity

CF 22 3 PS, FB,PSH,ESH (V-4/06)

Page 4

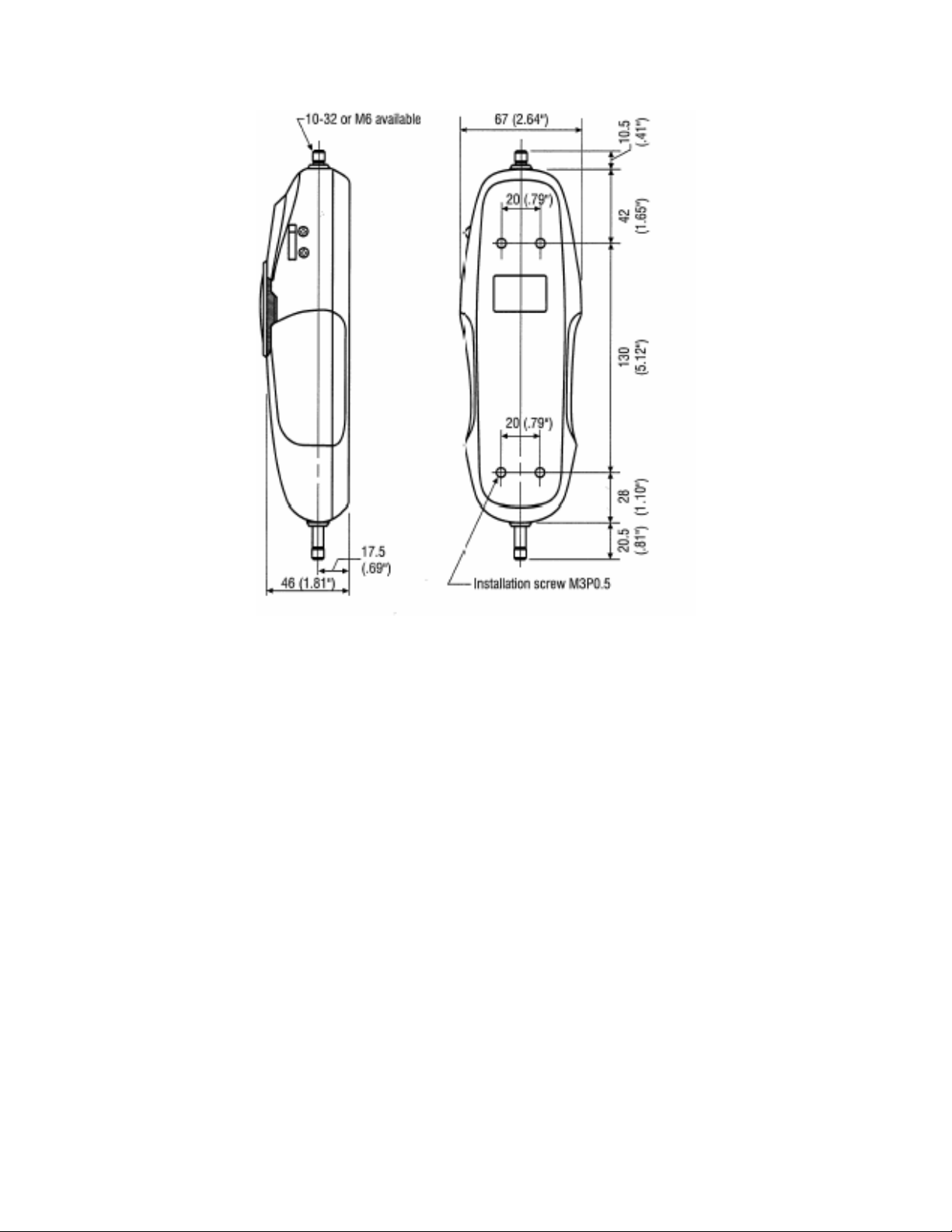

DIMENSIONS

When installing be sure to keep the depth to 8mm.

CF 22 4 PS, FB,PSH,ESH (V-4/06)

Page 5

DIMENSIONS

CF 22 5 PS, FB,PSH,ESH (V-4/06)

Page 6

WARRANTY REPAIR POLICY

Limited Warranty On Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in

workmanship within one year of the date of shipment by Cooper will be repaired or replaced free of charge provided that a

return material authorization is obtained from Cooper and the defective product is sent, transportation charges prepaid,

with notice of the defect, and it is established that the product has been properly installed, maintained, and operated

within the limits of rated and normal usage. Replacement or repaired product will be shipped F.O.B. from our plant. The

terms of this warranty do not extend to any product or part thereof which, under normal usage, has an inherently shorter

useful life than one year. The replacement warranty detailed here is the buyer’s exclusive remedy, and will satisfy all

obligations of Cooper whether based on contract, negligence, or otherwise. Cooper is not responsible for any incidental

or consequential loss or damage which might result from a failure of any and all other warranties, express or implied,

including implied warranty of merchantability or fitness for particular purpose. Any unauthorized disassembly or attempt to

repair voids this warranty.

Obtaining Service Under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact the Repair

Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number. Shipment to Cooper

shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from our plant in Warrenton,

Virginia. Non-verified problems or defects may be subject to a $100 evaluation charge. Please return the original

calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty applies only to

those items that were found defective and repaired; it does not apply to products in which no defect was found and

returned as is or merely recalibrated. It may be possible for out-of-warranty products to be returned to the exact original

specifications or dimensions.

* Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper to receive

information specifying the reason the product is being returned. Specific test data, written observations on the failure and

the specific corrective action you require are needed.

CF 22 6 PS, FB,PSH,ESH (V-4/06)

Loading...

Loading...