Page 1

ES 10 & ES 20 TEST STAND

UNPACKING AND SETTING UP

A. Carefully unpack the stand and inspect for any damage. Inspect the contents to ensure that you have received a

test stand complete with all accessories – see “ List of included items” section.

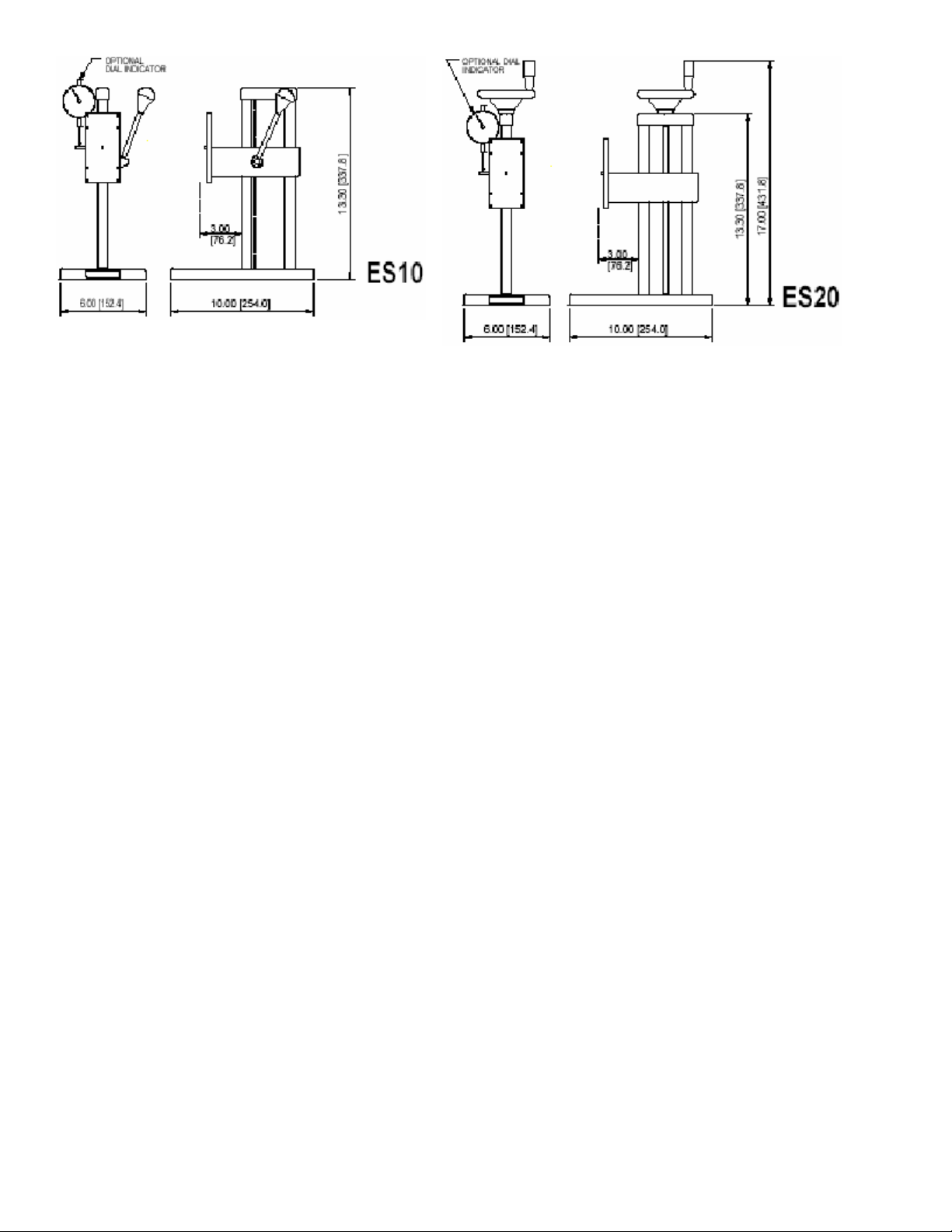

B. Install the loading lever into the hub on the ES10 stand or install the handwheel on the ES20 stand.

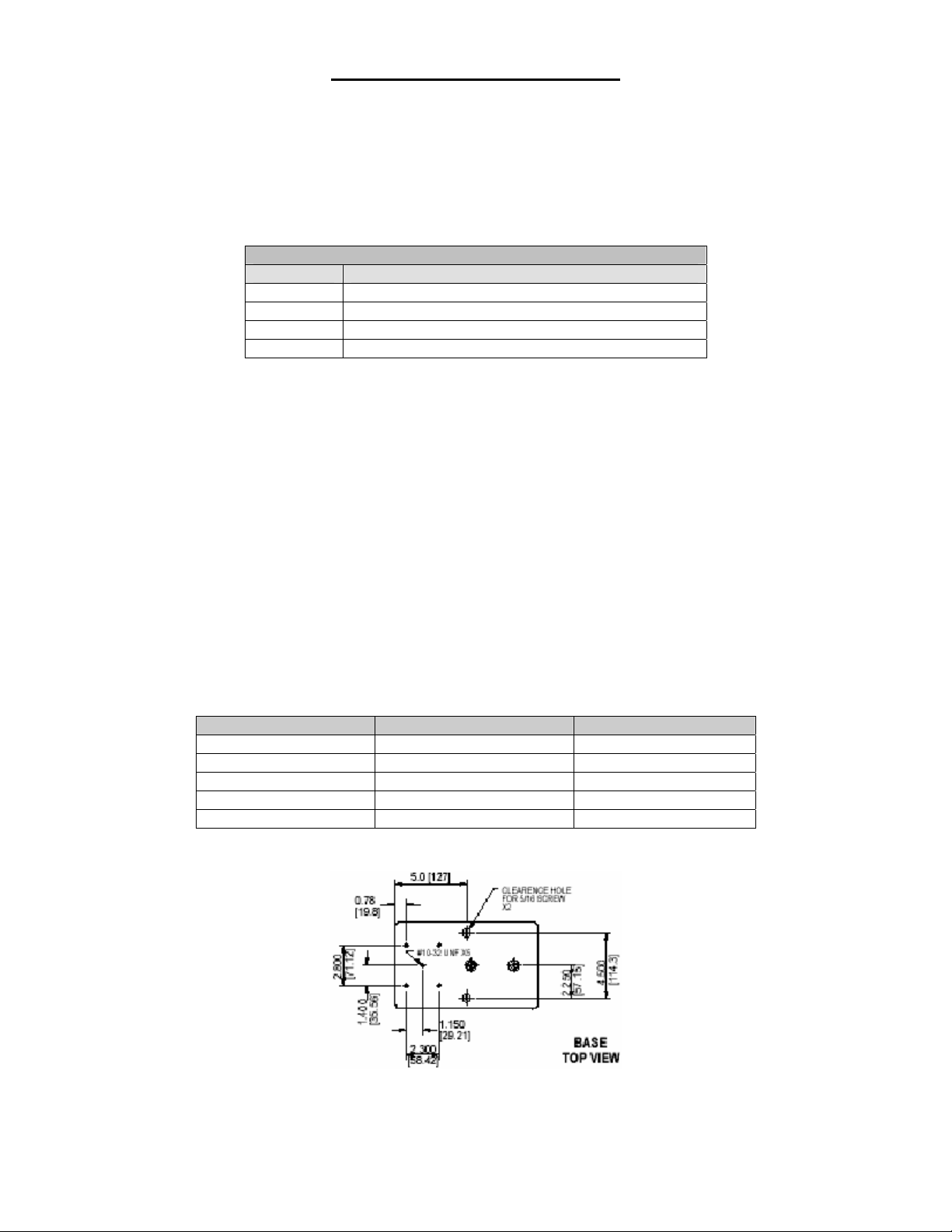

C. Place the stand on a firm, flat and level working surface free from vibration to ensure accurate readings. If

preferred, the test stand can be secured to a work bench with two screws or bolts through the two clearance holes

in the base – see “Operation” section for further details.

LIST OF INCLUDED ITEMS

Quantity Item

1 Force measurement stand, ES10 or ES20

1 User’s Guide (this booklet)

4 Gauge mounting hardware (thumb screws)

1 Mounting hole drill template

Optional dial indicator kit ES001

The dial indicator kit, ES001, clamps onto the column of the stand. The dial can be repositioned along the length of the

column.

It allows for 1.0” travel and provides a resolution of 0.001”.

OPERATION

The test stand can be mounted to a workbench using the clearance holes in the base – see drawing for hole location.

The included mounting-hole drill template can be used to locate holes in work area.

Cooper force gauges can be mounted directly to the stand without adapters. Mount gauge using the gauge hardware

provided.

The loading lever on the ES10 can be adjusted to allow for ease of operation. Reposition the lever using one of the three

tapped holes in the hub – refer to the dimensional drawing.

If the optional dial Indicator kit (ES0001) is purchased separately, it can be easily installed using the hardware provided.

SPECIFICATIONS

ES10 ES20

Load Capacity 100 lbs (500 N) 100 lbs (500 N)

Maximum travel 9” (228.6 mm) 9” (228.6 mm)

Loading method Rack & pinion Hand wheel

Rate 1.05”/rev (26.67 mm) 0.06”/rev (1.52 mm)

Weight 10 lbs (4.5 kg) 10 lbs (94.5 kg)

CF 78 1 (32-1021 0805 Rev. 2)

Page 2

WARRANTY REPAIR POLICY

Limited Warranty On Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in

workmanship within one year of the date of shipment by Cooper will be repaired or replaced free of charge provided that a

return material authorization is obtained from Cooper and the defective product is sent, transportation ch arges prepaid,

with notice of the defect, and it is established that the product has been properly installed, maintained, and operated

within the limits of rated and normal usage. Replacement or repaired product will be shipped F.O.B. from our plant. The

terms of this warranty do not extend to any product or part thereof which, under normal usage, has an inherently shorter

useful life than one year. The replacement warranty detailed here is the buyer’s exclusive remedy, and will satisfy all

obligations of Cooper whether based on contract, negligence, or otherwise. Cooper is not responsible for any incidental

or consequential loss or damage which might result from a failure of any and all other warranties, express or implied,

including implied warranty of merchantability or fitness for particular purpose. Any unauthorized disassembly or attempt to

repair voids this warranty.

Obtaining Service Under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact the Repair

Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number. Shipment to Coop er

shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from our plant in Warrenton,

Virginia. Non-verified problems or defects may be subject to a $150 evaluation charge. Please return the original

calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty applies only to

those items that were found defective and repaired; it does not apply to products in which no defect was found and

returned as is or merely recalibrated. It may be possible for out-of-warranty products to be returned to the exact original

specifications or dimensions.

* Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper to receive

information specifying the reason the product is being returned. Specific test data, written observations on the failure and

the specific corrective action you require are needed.

CF 78 2 (32-1021 0805 Rev. 2)

Loading...

Loading...