Page 1

DFR 1250

PAPERLESS RECORDER

USER’S GUIDE

www.cooperinstruments.com

PH: (540) 349-4746 • FAX: (540) 347-4755

Page 2

CONTENTS

1.0 INTRODUCTION ....................................................................................................................1

1.1 Chart Speed to Sample Speed.......................................................................................................2

1.2 Reviewing Data ...............................................................................................................................2

1.3 Zooming and Conditioning Data....................................................................................................2

1.4 Customizing ....................................................................................................................................2

1.5 Triggering ........................................................................................................................................3

1.6 The Graphics LCD Display.............................................................................................................3

1.7 Other Graphic Modes .....................................................................................................................4

2.0 INSTALLATION AND SETUP................................................................................................5

2.1 Unpacking........................................................................................................................................ 5

2.1.1 Initial Inspection.......................................................................................................................5

2.1.2 Unpacking Procedure ..............................................................................................................5

2.1.3 Detected Damage ..................................................................................................................... 5

2.1.4 Equipment Return .................................................................................................................... 5

2.1.5 Storage......................................................................................................................................6

2.2 Installation ....................................................................................................................................... 6

2.2.1 Panel Mounting.........................................................................................................................6

2.3 Connection ......................................................................................................................................7

2.3.1 Power Connections.................................................................................................................. 7

2.3.2 Input Signal Connections ........................................................................................................8

2.3.3 Relay Output Connections ......................................................................................................9

2.3.4 Digital Input...............................................................................................................................9

2.3.5 USB Port (Option)...................................................................................................................10

2.3.6 ETHERNET Port (Option).......................................................................................................10

2.3.7 Isolated DC input (Option).....................................................................................................10

2.3.8 Cleaning .................................................................................................................................. 10

2.4 Input Scaling .................................................................................................................................10

2.5 Alarms............................................................................................................................................11

2.5.1 Alarm Types............................................................................................................................ 11

2.5.2 Setting ..................................................................................................................................... 11

2.5.3 Alarm Indication ..................................................................................................................... 12

2.6 Memory Cards ............................................................................................................................... 12

2.6.1 Care of the Data Cards...........................................................................................................12

2.6.2 Card Storage Capacity and Data Type .................................................................................12

3.0 BASIC OPERATING INSTRUCTIONS ................................................................................13

3.1 Basic Mode of Operation.............................................................................................................. 13

3.2 Viewing Historic Data ...................................................................................................................13

3.3 Compressing and Expanding Data (Trend Viewing)..................................................................13

3.4 Zooming Data (Amplification)......................................................................................................14

3.5 Menu Mode ....................................................................................................................................14

3.5.1 Exit! .........................................................................................................................................14

3.5.2 Alarm Reset! ........................................................................................................................... 15

3.5.3 Record Mode...........................................................................................................................15

3.5.4 Cursor ID!................................................................................................................................ 15

3.5.5 View File..................................................................................................................................15

3.5.6 Card Status!............................................................................................................................16

3.5.7 Sample Rate............................................................................................................................ 16

3.5.8 Password (Protection) ...........................................................................................................16

3.5.9 Adv. Setup (Advanced Setup) ...............................................................................................16

CF 151 ii AJW 10306 REV 1.0 05/07

Page 3

3.5.10 Display Adj (Adjust) .............................................................................................................16

3.6 Event Triggering ...........................................................................................................................17

3.7 Status Line Indicators ..................................................................................................................17

3.8 Entering Data................................................................................................................................. 17

3.9 Top Level Menu Overview............................................................................................................19

4.0 ADVANCED SETUP ............................................................................................................20

4.1 Channel Setup...............................................................................................................................20

4.2 Alarms............................................................................................................................................21

4.3 Relays ............................................................................................................................................22

4.4 Display ...........................................................................................................................................22

4.5 Data Card ....................................................................................................................................... 23

4.6 Clock ..............................................................................................................................................24

4.7 Beeper............................................................................................................................................24

4.8 Sample Trigger..............................................................................................................................25

4.9 Record Trigger ..............................................................................................................................25

4.10 External Input .............................................................................................................................. 25

4.11 Unit Tag........................................................................................................................................25

4.12 Comms.........................................................................................................................................25

5.0 MISCELLANEOUS...............................................................................................................26

5.1 Battery Backup Option ................................................................................................................. 26

5.2 Ethernet Option.............................................................................................................................26

5.3 Calibration .....................................................................................................................................27

5.3.1 Basic Calibration....................................................................................................................27

5.3.2 Examples ................................................................................................................................28

5.4 Specifications................................................................................................................................ 29

APPENDIX A - UNITS LABEL CHARACTERS.........................................................................31

APPENDIX B - ERROR AND INFORMATION MESSAGES .....................................................31

APPENDIX C - MASTER RESET...............................................................................................31

APPENDIX D – RE-PROGRAMMING FIRMWARE...................................................................32

WARRANTY REPAIR POLICY..................................................................................................32

CF 151 iii AJW 10306 REV 1.0 05/07

Page 4

SAFEGUARDS AND PRECAUTIONS

Read and follow all instructions in this manual carefully, and retain this manual for future reference.

Do not use this instrument in any manner inconsistent with these operating instructions or under any conditions that

exceed the environmental specifications stated.

This instrument is not user serviceable. For technical assistance, contact Cooper Instruments (800-344-3921).

WEEE NOTICE

In order to comply with EU Directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE):

This product may contain material which could be hazardous to human health and the environment. DO

NOT DISPOSE of this product as unsorted municipal waste. This product needs to be RECYCLED in

accordance with local regulations, contact your local authorities for more information. This product may

be returnable to your distributor for recycling - contact the distributor for details.

Para obedecer con EU Directiva 2002/96/EC en el Desecho el Equipo Eléctrico y Electrónico :

Este producto puede contener la materia que podría ser la salud humana perjudicial para y el ambiente. NO se

DESHAGA de este producto el desecho municipal como no clasificado. Estas necesidades del producto para SER

RECICLADAS de acuerdo con las regulaciones locales, contactan su administración local para más información.

Este producto puede ser retornable a su distribuidor para reciclar - contacta el distribuidor para detalles.

Afin de respecter la directive européenne 2002/96/EC sur l’Equipement Electronique et les Déchets

Electriques :

Ce produit pourrait contenir des matières qui peuvent être dangereuses pour la santé de l’homme et de

l’environnement. Ne pas jetter ce produit dans un container municipal inapproprié. Ce produit doit être recyclé en

accord avec les arrêtés locaux; contacter les autorités locales pour plus de renseignements. Ce produit peut être

renvoyé au distributeur pour recyclage - Contacter votre distributeur pour plus de details.

Um den Vorschriften der EU-Direktive 2002/96/EC bezueglich elektrischer und elektronischer Abfallstoffe

nachzukommen:

Dieses Produkt kann Materialien enthalten, welche gesundheitsgefaehrdend und umweltschädlich sind. Dieses

Produkt DARF NICHT wie unsortierter Hausmuell entsorgt werden. Dieses Produkt muss gemaess den oertlichen

Bestimmungen recycled werden, bitte kontaktieren Sie die lokalen Behoerden fuer weitere Informationen. Sie

koennen dieses Produkt zum Recycling an Ihren Haendler zurueckgeben, bitte kontaktieren Sie den Haendler fuer

weitere Details.

1.0 INTRODUCTION

This instrument is a versatile Solid State Data Recorder / Panel Indicator. It has all the capability of a traditional

paper recorder - variable chart speeds, the ability to review historic data, see trends and more, with a number of

specific exceptions - NO PAPER to jam, no ink to smudge and no pens to clog or break. The data is stored in a

Compact Flash memory card, which can be easily transported.

Of course it does all the regular functions a lot better, and the data can be transferred directly into reports,

spreadsheets or analysis programs. Data can be examined and archived on any Windows XPTM compatible

machine and can be printed out in various formats as required.

This instrument has two universal inputs so it can measure voltage, current, thermocouples and RTDs by simply

selecting them from the menu. It also has two potential free alarm output contacts and an isolated digital input. The

display can be user configured to graphics, digital or a combination. Maximum data storage is 2 Gigabytes.

Communication options include USB and Ethernet ports.

Things are done a little differently in a paperless recorder and there are a few new concepts that you may need to

become familiar with. There are more features and functions in this unit than you will probably use. It is

recommended that you read this manual in its entirety before attempting to use the instrument.

CF 151 1 AJW 10306 REV 1.0 05/07

Page 5

The balance of this introduction will attempt to introduce some of the more unique features of this paperless

recorder.

1.1 Chart Speed to Sample Speed

A major difference between paper and paperless is SAMPLE SPEED, which is analogous to CHART SPEED in the

paper recorder. There is an apparent chart speed, the rate at which the samples appear to move across the

Graphics Display, but unlike paper recorders the display is made up of discrete data points, each of which is a

distinct sample of the data being measured. The rate of movement across the screen is thus a direct function of the

sample rate. The major factor in deciding what sample rate to select is knowing how much data is enough. In a

paper recorder a chart speed of 1 inch per hour is fine for a process that does not vary very quickly but would result

in a thick blur if trying to record a 1Hz sine wave. Unlike a paper recorder, every point recorded by the paperless

recorder is uniquely identifiable, no matter how dense it appears on the screen. It is always better to have too much

data than to have too little. The only consideration is the amount of space used in the memory card.

To relate chart speed to sample rate we need to consider how we plan to reproduce the data. The graphic LCD

display has a density of 70 pixels (data points) per inch; a typical dot matrix printer has 180 pixels per inch and a

laser printer 300 pixels per inch. Thus to fill one inch of the display in one hour we need to sample at a rate of 70

samples per hour, a little over once per minute, however if this is now printed on a laser printer it will fill less than

1/3 of an inch. It is the amount and quality of the data that counts. Another advantage of the paperless recorder is

that it can sample internally at 100 samples per second (one every 0.01 seconds). These samples can be averaged

or peaks or valleys can be detected and then this data can be stored at the chosen sample rate.

Trial and experience will yield the best sample speeds for the application. Start with a faster sampling rate than you

think you will need; you can always slow it down in the future. As a rule of thumb, one sample every 10 seconds

should give the equivalent information that 1 inch per hour of chart paper would.

1.2 Reviewing Data

One of the biggest features of this recorder is its ability to show historic data and trends. The data on the graphics

screen can be rewound like a tape recorder, scrolling back in time, displaying past data on the screen while still

recording data in real time.

The data can also be compressed on screen, showing a whole day or week's worth of recording on one screen,

enabling trends or irregularities to be spotted easily. A data cursor can be moved around the screen to uniquely

identify samples in both time and amplitude.

Refer to the Section 3 for the specifics on reviewing data.

1.3 Zooming and Conditioning Data

The recorder acquires data with greater resolution than can be displayed on the screen. The user has the ability to

ZOOM in to amplify the data either 2 or 4 times, equivalent to using a magnifying glass on the display. These

ZOOM windows can be scrolled up or down to cover the entire data spectrum. The vertical scale automatically

adjusts to the zoom level and position to enable resolution of minor changes in input signal.

The recorder also acquires data at a rate faster than what may be displayed on the screen. The user can set the

sampling rate from 100 samples per second down to 1 sample every 10 minutes. When sampling slower than 100

samples per second, the recorder can be programmed to record the average, maximum or minimum values. Thus if

a sample rate of 1 sample per minute is chosen, the recorder will still sample internally at 100 samples per second

while computing the average or detect and store either the maximum (peak) value or minimum (valley) value,

depending on the mode programmed. It will then store this value when the minute is up. Unless required otherwise,

it is recommended that the average value be used for recording since this will tend to filter or smooth the data. See

Advanced Setup Menu for details.

1.4 Customizing

There are many operating features and parameters that the user can program. All settings are stored in nonvolatile

memory and are recalled each time the unit is powered on. The display can be scaled to read in engineering units,

and the trace can be labeled accordingly with up to three alphanumeric characters. Four alarms are fully user

CF 151 2 AJW 10306 REV 1.0 05/07

Page 6

programmable and can be associated with either channel or the external input. The Alarm levels can be set in the

engineering units of the display, the sense of the alarm, the type and the deadband or hysteresis can be individually

set for each alarm. Optional relay outputs can be assigned independently to each alarm. A reset delay feature is

also available.

There are other features which may be programmed by the user including the time stamping mode, either real time

or elapsed time, clock update rates, file names, beeper operation etc. (Refer to – Advanced Setup)

1.5 Triggering

The recorder has the ability to change sampling speeds and stop or start recording as a result of a triggered event.

This event may be tied to any of the four internal alarms or optionally to an external signal. This enables the unit to

monitor a process without recording or to record at a slow speed to conserve card space. When an external event

or internal alarm condition occurs, the unit will begin recording or change to a higher sample rate for the data of

interest.

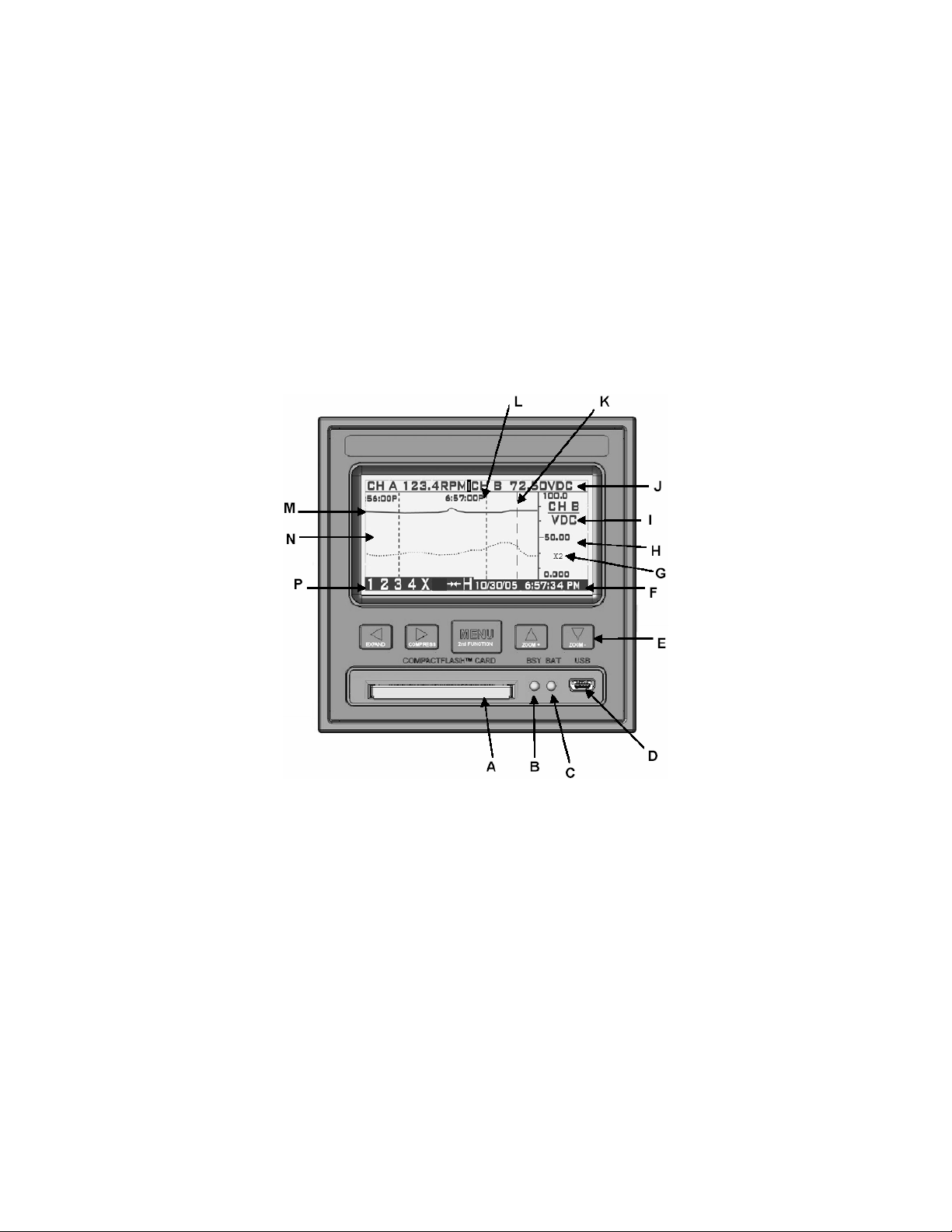

1.6 The Graphics LCD Display

Recorder Front View showing TREND Display

The above diagram is a representation of the recorder in the TREND mode. The alpha characters around the

border point to various features of the unit and are described below. Not shown are the MENUS which pop up over

the display. The menus are in the form of those shown in Sections 4 and 5. The numbers in parenthesis below refer

to the section that covers the topic in detail.

A CompactFlash™ card slot – manually insert a card into the unit to store data and configuration information. Can

also be used as a means of updating the firmware in the unit. Cards up to 2 Gigabytes in size can be used.

B Busy LED (Red) – on when the unit is recording and blinks rapidly whenever the unit is accessing the

CompactFlash™ card. Blinks at 1 second rate if unit is triggered but not recording. Do not attempt to remove

the card when this light is on.

C Power LED (Green) – on during normal operation. If the optional internal battery pack is present, this LED will

blink during power failure to indicate the unit is running off internal batteries.

D Optional USB interface – enables connection to a Windows XP compatible PC.

CF 151 3 AJW 10306 REV 1.0 05/07

Page 7

E Navigation buttons – used to set up and navigate around the display. The buttons are all dual function; the

second function is initiated by holding down the MENU button while pressing one of the other buttons. The

second function is printed on each button.

F Date and Time – shows the actual time of day (real time). The time is displayed user selectable in 12 or 24 hour

format. The user can also select European or American formats and auto daylight savings adjustment. See

Clock setup.

G Zoom Scale Indicator – shows the zoom scale for the channel indicated if > x1. Separate scale for each

channel. See zooming.

H Right hand edge of the graphics area in which the traces are displayed. This is the vertical scale area

designated by the scale values at the top, center and bottom of the scale. The most recent data that is

displayed in digital form at the top of the display (J) is against the right edge of this scale and moves left with

time - the most recent data is to the right and the oldest data is to the extreme left. New data appears against

this margin and the oldest data disappears off the screen at the extreme left. The graphic cursor (K) will start

against this right edge.

I Vertical Scale Identifier – this display alternates between Channel A and Channel B. It displays the Channel

Tag and the Engineering units. See Channel setup.

J Digital Window – the top of the screen displays the values for each Channel including the Channel identifier,

the current value and the engineering units. Channel A is displayed on the left and Channel B on the right. This

window displays the absolute digital value of the instantaneous (last) reading for the channel, and is the right

most sample value on the trend display (G), unless the cursor is active. In that case it shows the value at the

point the cursor intersects the trend line.

K Cursor – is displayed when activated in the cursor ID mode. This cursor can be moved using the left ◄ and

right ► arrow buttons. The values in the digital window (J) are the values at the point where the cursor

intersects the trend line.

L Date/Time Axis Delimiter – the dotted vertical lines placed at equal increments along the Horizontal axes

(Time). The Date/Time stamp beside the line indicates the exact position of the line. Both date and time may be

shut off or relocated vertically. These lines move with the trace at a speed dependent on the sampling speed.

This is configurable in Display Setup.

M Channel B Trace – the trend line is the graphic representation of Time (horizontal) versus Amplitude (vertical)

and is shown solid to distinguish it from the Channel A trace, which is shown as a dotted trend line. This is

configurable in Display Setup.

N Graphic TREND Window – shows the channel traces, which may be compressed, expanded, zoomed, scrolled

and halted.

P Status Icons – these icons appear at various times to indicate the status of the unit and the display. From left to

right they are:

• The numbers 1,2,3 and 4 are the ALARM indicators - one for each alarm. The numbers are present when the

alarm is enabled and will blink if the alarm is in an alarm condition.

• The X indicates the status of the EXTERNAL INPUT and is present when the external input is present.

• The

icon indicates the display is compressed. The horizontal time stamps indicate the current

compressed values. The display can function normally in compressed mode, may be paused or the user can

scroll back and forth using the left ◄ and right ► arrow buttons.

• The H indicates the display is in the HOLD condition. While in HOLD, the trends do not update. The display

enters the HOLD condition when the ID Cursor (K) is present or the user scrolls in the horizontal direction

using the left ◄ and right ► arrow buttons. Exit the HOLD mode by pressing the MENU button.

DO NOT INSERT OR REMOVE THE COMPACT FLASH CARD WHILE THE BUSY LED IS ON!

1.7 Other Graphic Modes

In addition to the full screen trend mode shown section 1.6, there are two additional graphic display modes.

CF 151 4 AJW 10306 REV 1.0 05/07

Page 8

The Dual Digital mode, as shown below, enables both channels to be shown as Digital values similar to a digital

panel meter. The user has the option of showing the displays in normal or reverse video (shown) modes, and the

display can be set to blink on Alarm Condition.

The other Graphic mode is a split screen with the trend in the top half and the digital display in the lower half as

shown below. When selecting this mode, Channel B is the default digital value, but can be switched in the

Advanced Setup menu.

2.0 INSTALLATION AND SETUP

2.1 Unpacking

2.1.1 Initial Inspection

Exercise care when unpacking the instrument from the shipping carton. The instrument is packed in a custom

cardboard box to prevent damage during normal transit. If damage to the shipping carton is evident, ask the

carrier’s representative to be present when the instrument is unpacked.

2.1.2 Unpacking Procedure

To unpack your Recorder, first remove the cardboard retainer and instrument from the shipping carton. Check the

box for the following contents - The Recorder, two locking bars, two 6-32 x ½" screws, AC power supply wall unit

(unless the unit is the isolated DC model) and this manual.

2.1.3 Detected Damage

Remove the instrument from the plastic bag and check for damage if any. Also check that the unit is as ordered. If

damage is detected after unpacking the instrument, immediately report any damage to the shipping agent and repack the instrument for return it to the factory as described in the following section.

2.1.4 Equipment Return

Before returning a damaged or malfunctioning instrument to the factory for repair, contact the sales organization

from which you purchased the instrument. A Return Merchandise Authorization (RMA) number must be obtained

from the factory before returning an instrument for any reason.

CF 151 5 AJW 10306 REV 1.0 05/07

Page 9

2.1.5 Storage

For prolonged storage before installation, re-pack the Recorder in the shipping container and store in a cool, dry

area. We do not recommend storage of the Recorder for more than one year. If longer storage time is required,

contact the factory for additional storage information.

2.2 Installation

The instrument is intended to operate in the following environment:

Indoor Use Only

Installation Category II per IEC 664

Pollution Degree Level II per IEC61010-1

Temperature -10 °C to 50 °C operating per IEC61010-1

Humidity Maximum relative humidity 80% for temperatures up to 31 °C decreasing linearly to 50% relative humidity

at 40 °C

Recorder Power 9.0 +0.5V dc @ 5VA (unless indicated otherwise on the unit)

AC Power Requirement (External adapter) 100 - 240 Vac ~ 50/60 Hz

NOTE: The recorder is designed to be panel mounted and as such should be considered as permanently

connected. Disconnection from the supply must be possible via a customer supplied switch or circuit breaker. This

disconnection device must be included in the panel installation and should be clearly marked, it must be in close

proximity to the Recorder and easily accessible to the operator.

NOTE: In order to fully comply with the CE EMC Directive 89/336/EEC, connections to the recorder should not

exceed 3m (9.8ft) without adding additional filtering.

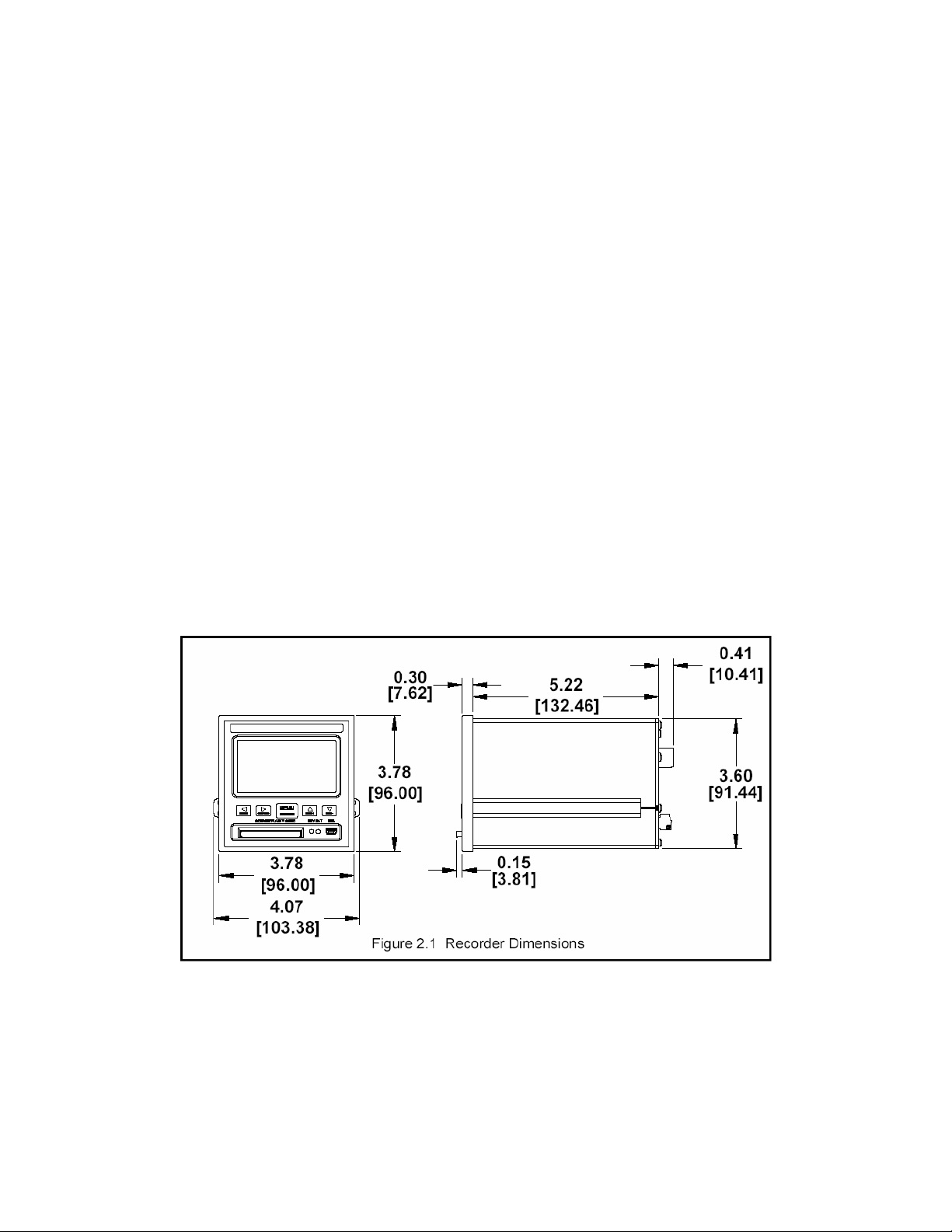

The Recorder fits in a standard ¼ DIN panel cutout of 92 x 92 mm (3.62 x 3.62 in.) and requires 140mm (7.5

inches) panel depth not including space for power and input source cable. The thickness of the panel is immaterial,

but panels thicker than .125 inch will require that the locking bars be cut down. Actual dimensions are shown below

in Figure 2.1:

WARNING: Do not use this instrument in any manner inconsistent with these operating instructions or

under any conditions that exceed the environmental specifications stated.

2.2.1 Panel Mounting

The Recorder should be mounted in a vertical panel to ensure proper operation. Ensure you have the proper

clearances and proceed as follows:

2.2.1.1 Cut a panel opening 96 mm x 96 mm (3.62 x 3.62 in.).

CF 151 6 AJW 10306 REV 1.0 05/07

Page 10

2.2.1.2 Remove any packaging material from the Recorder. Always handle the unit carefully to avoid damaging

the LCD display or scratching the display surface.

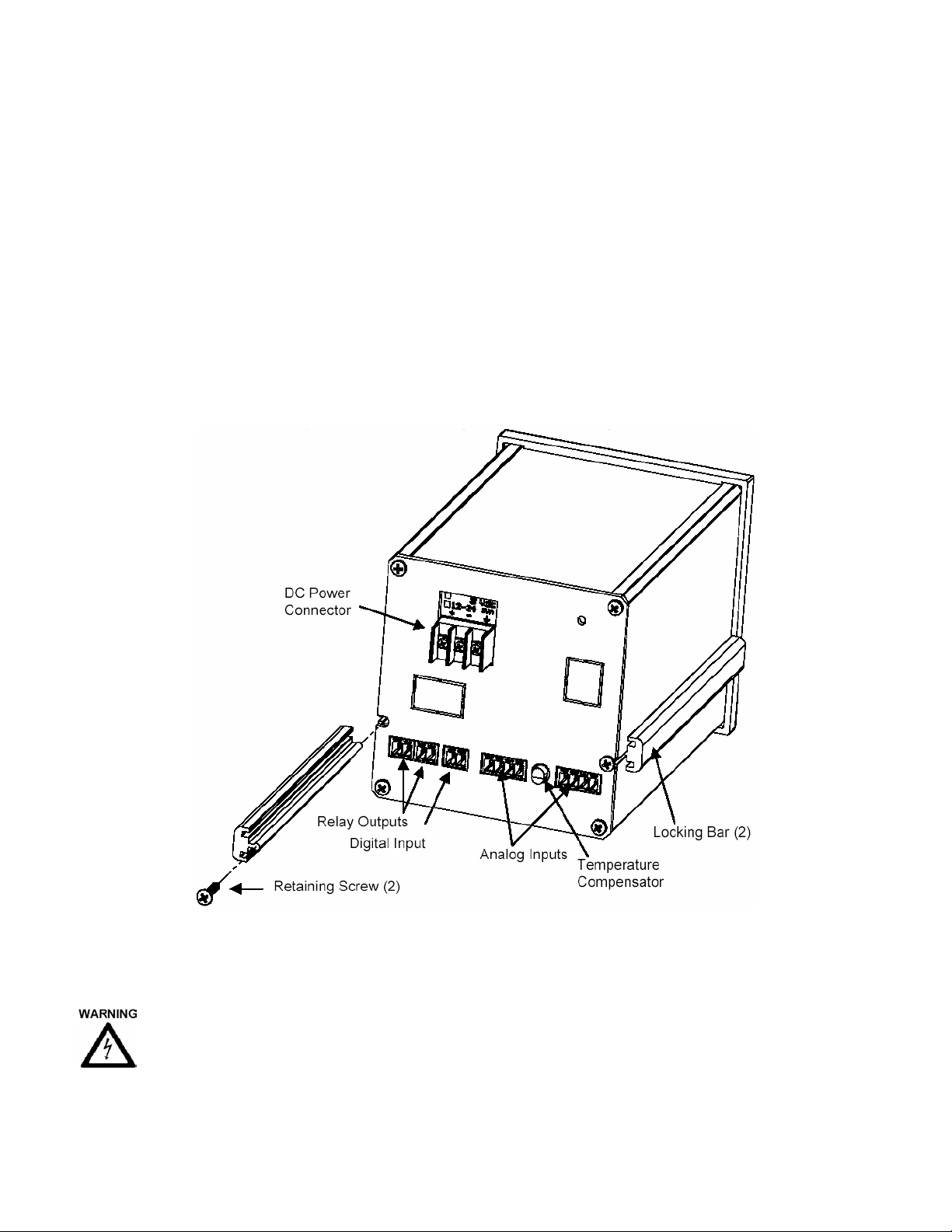

2.2.1.3 Remove the locking bars from the Recorder enclosure by removing the captivating screws

2.2.1.4 Insert the Recorder, rear end first, through to front of the panel opening.

2.2.1.5 With the Recorder held firmly in place against the panel, install one of the locking bar assemblies from

the rear, by sliding the locking bar tongue into the groove on the side of the Recorder enclosure as

shown in Figure 2.2.

2.2.1.6 Insert the retaining screw into the rear of the groove. Using a Phillips screwdriver, tighten the screw

until the locking bar is just pressing against the panel.

2.2.1.7 Install the other locking bar assembly into the groove on the opposite side of the Recorder enclosure

and tighten as before.

2.2.1.8 Using the screwdriver, tighten both screws so that the Recorder is held firmly in place. Do not over

tighten, to avoid stripping the threads.

Figure 2.2 Rear View - Installation

2.3 Connection

2.3.1 Power Connections

NOTE: The Recorder is designed to be panel mounted and power should be considered to be

permanently connected. Disconnection from the supply must be possible via a customer supplied switch

or circuit breaker. This disconnection device must be included in the panel installation and should be

clearly marked, in close proximity to the Recorder and easily accessible to the operator.

THE RECORDER IS DESIGNED TO OPERATE ON 9 Vdc. DO NOT CONNECT AC POWER DIRECTLY TO THE

UNIT AT ANY TIME.

CF 151 7 AJW 10306 REV 1.0 05/07

Page 11

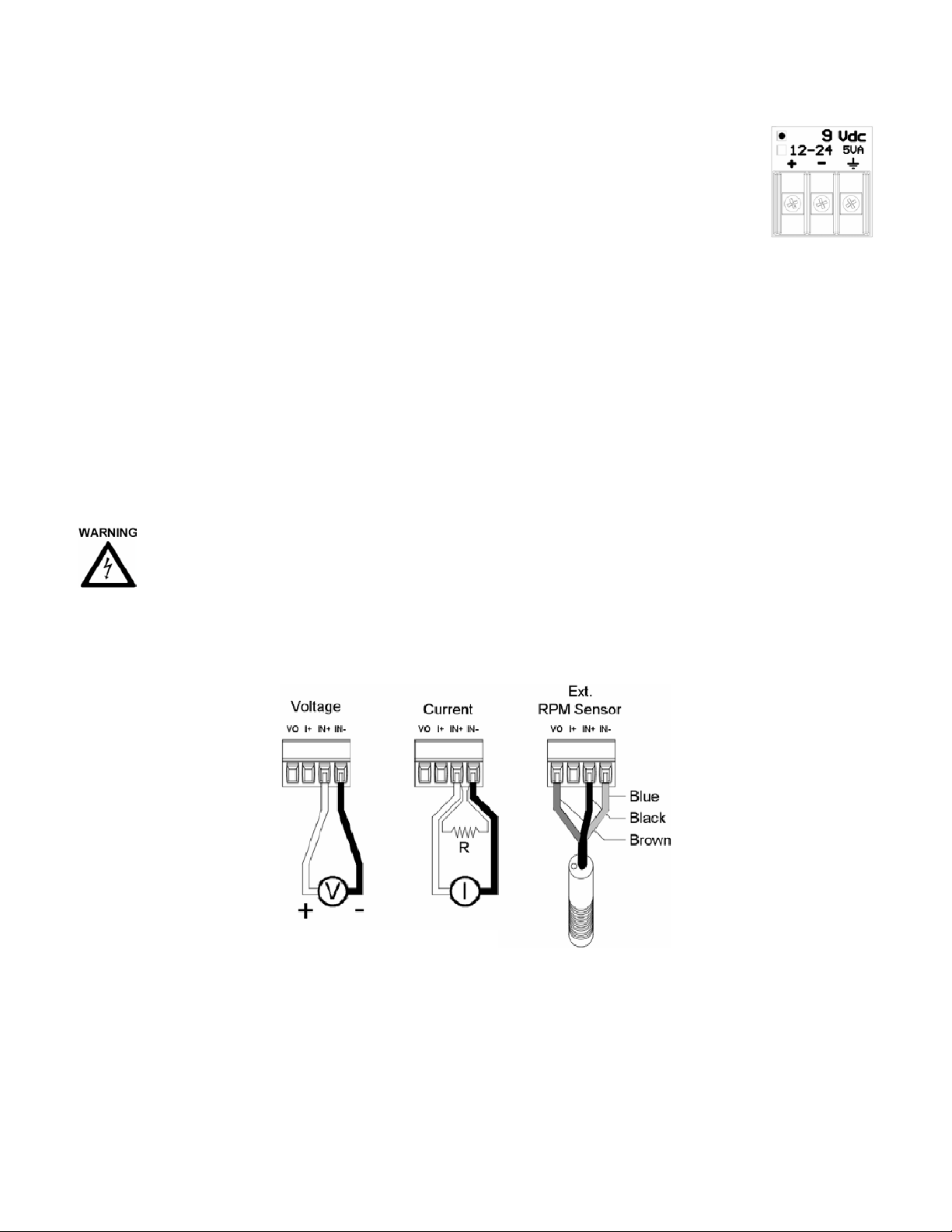

The power connector is located on the rear panel in the top left corner. There are two voltage

options available for the recorder – the standard is 9Vdc, which is used with an external universal

AC Mains power supply. The external wall power supply is a high efficiency switcher that will work

from 100 to 240 Volts AC 50/60 Hz. The other power option is an isolated 12 to 24Vdc input for

use with an external DC power supply. The power supply option is marked with a dot in a square

on a label above the power connector as shown in Figure 2.3. Check the unit to ensure that the

power and inputs are as expected.

Figure 2.3

Before connecting any power or inputs to the unit, ensure that all signal wires and power cables are at zero voltage.

The DC power is applied to the unit via a three-way screw terminal connector. The power supply is supplied with

two tinned leads, the positive lead is identified by the RED shroud over the wire. The third connection is for system

GROUND. You will require a small flat-head screwdriver. Connect the power and signal wires accordingly, noting

carefully all polarities. Ensure that the unit is properly grounded to a suitable ground within the cabinet.

Loosen the screws on the terminal block and insert the exposed conductor cable from the power supply below the

screws, under the metal plate. Ensure that the insulation is flush with the terminal block. If it is too long, remove the

cable, trim and reinsert. Tighten the screw to firmly hold the cable. Ensure the ground wire is connected and

properly grounded at the other end. If you are not using the supplied wall power supply, follow the same procedure

carefully identifying the positive supply line. The unit is protected against reverse polarity but not against substantial

over voltage.

2.3.2 Input Signal Connections

The maximum input on any input channel is 25 Volts DC. Voltages higher than this may permanently

damage the unit.

Ensure the unit is powered down before connecting any inputs.

There are two universal analog inputs – Channel A and Channel B. Each is programmed independently of the

other. Inputs can be voltage or current (50mA max using an external shunt), thermocouples, RTDs or TTL

compatible pulse inputs. Isolation is provided between inputs and the rest of the system. The channels are not

isolated from each other. Connection detail for the various inputs is shown in Figure 2.4.

CF 151 8 AJW 10306 REV 1.0 05/07

Page 12

Figure 2.4 - Connection Detail

When connecting the signal wires, keep polarities correct. The screw terminals are marked on the rear panel - there

are four connections per channel. The high or positive signal marked IN+, and a low or common signal marked IN-.

The terminal marked Vo is the Auxiliary voltage output used to drive external sensors at +5Vdc and a maximum of

50mA. The terminal marked I+ is the 1mA current required for RTDs or resistors. Any screen or shield (often the

braided wire) should connect directly to the system ground and is used to shield the low level input signals from

induced noise pick up.

Connect the signal wires to the terminal block in the manner described above. Use wire of adequate gauge to carry

the signal. The mA input requires the use of an external 250 ohm shunt (Check with supplier). Thermocouples

should be connected with thermocouple wire of the same type as the input; the terminal block is the reference

junction. Connect any sheath or braid to the GROUND connection. RTDs have an additional wire, the current

source, which is connected to the terminal marked I+. See Figure 2.4.

WARNING: Unused inputs must have IN+ and IN- commoned together.

CAUTION: Never run signal and power or control wiring together in the same conduit. This practice will

prevent possible recording error due to induced signals between lines. Route signal wires away from

power wires at the rear panel.

NOTE: Ground cable shields at one end only to eliminate the possibility of interference due to ground loop

currents. When grounded transducers are used, the shield should be grounded at the sensor end only.

2.3.3 Relay Output Connections

To prevent the possibility of electrical shock, use extreme caution when wiring contact output

connections. Hazardous potentials may exist on contact output terminals that are floating with

respect to instrument ground. WIRES FROM REMOTE SOURCES MAY CONTAIN DANGEROUS

POTENTIALS. ENSURE ALL POWER SOURCES ARE DISCONNECTED BEFORE WIRING RELAY

CONTACTS.

The relay contacts are rated for AC or DC operation (Maximum recommended voltage - 30 Volts.) Each relay has a

set of potential free contacts. There is no polarity to the terminals; it is a normally open contact that closes in alarm

condition. These contacts are internally suppressed for EMI/RFI and High Voltage transients resulting from

inductive loads. The relays may be programmed as fail safe, which means they are energized in the “off” condition.

This way if the power should fail the relays will open into the alarm condition. See note below.

2.3.4 Digital Input

The digital input is optically isolated and is activated by an external dc supply of 5 to 12Vdc at 20mA. The input is

via the DIGITAL INPUT + and – terminals. The - connection is the COMMON for the external input, while the + is

the input for the positive voltage.

CF 151 9 AJW 10306 REV 1.0 05/07

Page 13

The digital input may be used as an External Trigger to stop or start recording, or may be used to change the

sampling speed. Thus the unit can be set to record only when a conveyor is running for example. The External

Trigger may also be linked internally to the optional Relay Output. This could be used as a remote "record active"

indicator. Refer to Sections on Relay setup and External Input setup.

Note: In order to fully comply with the CE EMC Directive 89/336/EEC cables to the relay output and digital input

should be looped through a ferrite (Type Steward 28R2025-0R0 or similar) close to the terminals.

2.3.5 USB Port (Option)

The USB Port is an option and will be installed only if specifically ordered. It is a serial connection to a PC that

allows the user to program the recorder remotely, start or stop recording and download real time data.

Refer to the separate manual that is supplied with the USB interface option.

2.3.6 ETHERNET Port (Option)

The Ethernet Port is an option and will be installed only if specifically ordered. It allows the user to program the

recorder remotely, start or stop recording and download real time data. The IP address is set in the Advanced

SETUP Menu Refer to the separate manual that is supplied with the Ethernet interface option.

2.3.7 Isolated DC input (Option)

The unit may be powered by an external DC source with the isolated DC to DC option. Connect the unit to the

external DC source and observe the voltage and polarity of the inputs. In order to fully comply with the CE EMC

Directive 89/336/EEC the power cable should be looped through the ferrite bead provided, close to the terminals.

2.3.8 Cleaning

The unit may be cleaned by wiping with a soft cloth. The front panel and display / keypad may be wiped with a

slightly damp soft cloth containing soapy solution or a mild detergent. Do not use any lemon based (citric acid)

product to clean the display / keypad. NOTE: THE UNIT IS NOT WATERTIGHT.

2.4 Input Scaling

The input to the recorder is often a standard process variable (e.g. voltage) rather than the actual units being

measured (e.g. pressure).

There are a number of custom conversions available in the unit to take care of special inputs such as

thermocouples and RTDs, which need special scaling and linearization. These are preset in the unit and require no

modification. There is also the capability to customize any input variable that has a linear relationship to the

measured variable. The relationship between the required variable and the input variable must satisfy the equation

for a straight line: y = mx + b

where y is the output value to be displayed and recorded, x is the input variable (typically volts or milliamps DC), m

is the scale factor (slope of the line) which defines the relationship between the input and the displayed variable

and is a constant (linear relationship), and the factor b (known as the y intercept) is a constant offset variable that

may be positive or negative.

This facility to scale the input is found in the ADVANCED SETUP menu and is available to each channel

independently. Here the user can easily scale the input and set the displayed units using three alphanumeric

characters.

The scaling is achieved in the unit in the CHANnel X SETUP option (X = A or B) in the ADVanced SETUP menu.

First set the displayed LO SCALE, which may be positive, negative or zero. Then set the displayed HI SCALE for

the full-scale input. The unit will then automatically compute the scale factor and offset.

Setting the engineering units is done in the same menu location using the CHAN UNITS option to set the three

alphanumeric characters.

Let us assume we have an input from a pressure transducer of 1 to 5 volts DC, corresponding to real world units of

zero to 250 PSI (Pounds per Square Inch of pressure). Assume we choose the 0 to 5 volt input. The actual output

span of the transducer is 4 volts, with 1 volt = 0 PSI and 5 volts = 250 PSI. This is equivalent to 62.5 PSI per volt.

The LO SCALE which is the "0" volt value is equivalent to -62.5 PSI and should be set to this value, and the HI

CF 151 10 AJW 10306 REV 1.0 05/07

Page 14

SCALE is set to "250". The engineering units are set to "PSI". The display will

now show zero to 250 PSI for 1 to 5 Volts input. The linear scaling is shown in

Figure 2.5.

2.5 Alarms

The Recorder has four programmable internal alarms with dual relay output.

The alarms can be associated with either analog input channel, can be set as

high or low, latching or non-latching with or without lockout capability. Each

relay has a set of potential free normally open contacts (Form A - SPNO) that

are accessible from the rear panel via screw terminal connections. Alternatively

the relays can be set to the failsafe mode, normally closed (Form B – SPNC). The relays can be assigned to any,

all or none of the alarms. Refer to section on Alarms and Relays in Advanced Setup Menu.

2.5.1 Alarm Types

A high alarm is active when the input is greater than the setpoint. A low alarm is active when the input is less than

the setpoint. A latching alarm will remain set once activated and must be reset by the operator. Note that the

alarm condition should be removed before resetting the alarm or the alarm will activate and latch again. A non-

latching alarm will set on alarm condition and automatically reset once the alarm condition is removed. A

differential, known as hysteresis or deadband can be introduced so that once an alarm is set (at the setpoint), the

input must go beyond the deadband before the alarm resets. This prevents the output relays from chattering in

borderline conditions. The deadband is set in absolute units and adds to the setpoint in a low alarm, or subtracts

from the setpoint in a high alarm. By way of example, if the setpoint is 100, the hysteresis (deadband) is set to 5,

and the alarm is a high type and non-latching, then the alarm will activate when the input exceeds 100 and will

remain active until the input drops below 95 (100 minus 5). Alternatively the user can set a reset delay from 1 to

255 seconds. This delay must time out once an alarm condition has been removed before the alarm will reset to

normal.

Lockout prevents an alarm from activating until the setpoint has been traversed in the opposite sense by the input.

For example, if we were measuring pressure and had a low alarm set at 100, we may not wish the alarm to be

active on start up when the pressure may be low or zero. We really wish to monitor a low-pressure situation once

our target pressure has been reached, say 150. The lockout prevents the alarm activating at startup. The alarm

remains deactivated until the input exceeds the setpoint. Now the alarm arms and any future time that the input

drops below the setpoint, the alarm will activate.

2.5.2 Setting

Setting and configuration is done in the Advanced Setup Menu.

The alarm setpoints are set in the same units as the input type and may be different for each channel. When setting

the actual setpoint value, the value may be incremented in steps other than what is expected (unit steps). This is

due to the fact that the input is converted into a digital value with a finite resolution. It is not possible to set a

setpoint value that cannot be resolved by the internal microprocessor. Select the closest value to the exact value

you require; it will always be with 0.5%. The same applies when setting the deadband.

Note that when configuring the alarms, there is no correlation between inputs, alarms and relay outputs. These are

user defined. Each alarm can be assigned to only one input channel.

When setting up each alarm channel, the user should DISABLE the alarm so that parameters may be changed

WITHOUT AFFECTING THE RELAYS. This is done in the ALARMS menu by selecting the ENABLE option so that

no √ appears to the left of this option. Once everything is set, select ENABLE once more to activate the alarm,

indicated by the presence of the √. (Refer to Section on Setting Alarms)

⇒ When setting up alarms, you may get unexpected results from the relays if they are enabled. Ensure there

is nothing connected to the relays that could result in an accident due to random closing of the relays

during setup and always DISABLE the alarm as described above. Make the changes and then re-enable

the alarm.

There are many different ways the alarms can be set up. All the alarms can be assigned to a single channel and

may be of the same type giving for example a various degrees of high warning and ultimately a high shutdown

CF 151 11 AJW 10306 REV 1.0 05/07

Page 15

indication. Also, the relays may be assigned to any combination of alarms. This would allow a single relay output to

indicate any alarm active. The combinations are endless.

2.5.3 Alarm Indication

There are three indications of alarm condition: the relay outputs, visual icons on the display and audible alarm.

When an alarm is armed and functioning, it is indicated by a small "1", "2", "3" or "4" in reverse video on the bottom

left hand side of the graphic display. These status indicators remain on as long as the alarm is enabled. If an alarm

is triggered (in alarm condition), the status indicator will blink and the internal beeper will sound. The beeper can be

permanently disabled from the Advanced Setup Menu - BEEPER - ALARMS - OFF.

The relays close on an alarm condition, assuming they have been set up correctly. The relays can be set as failsafe by reversing the logic of the alarms (Advanced Setup Menu - RELAYS - FAILSAFE).

2.6 Memory Cards

The memory cards used are standard CompactFlash™ cards. We recommend the use of Sandisk™

CompactFlash™ cards. The cards are keyed and can only go into the recorder right side up. The largest capacity

card that can be accommodated is 2 Gigabytes.

2.6.1 Care of the Data Cards

Do not expose the cards to direct sunlight or extremes of temperature for any length of time. Do not expose to

moisture. Do not bend or twist. Avoid high static discharge. Mail in suitable packaging to avoid postal damage.

When transporting, use an anti-static bag or the plastic enclosure in which the card is supplied.

2.6.2 Card Storage Capacity and Data Type

Depending on what else is stored on the card (e.g. configurations files, other data files), data storage capacity can

be roughly calculated by the following formulas:

Number of samples is card size divided by 4.4. The time that it will take to fill a card is roughly the number of

samples divided by the sample rate. For example, a 32MB card will hold roughly 32,000,000 divided by 4.4 =

7,272,727 samples. At 5 samples per second this is 1,454,545 seconds or 404 hours or approximately 16.8 days.

If you show the Card Status window (MENU - CARD STATUS), it will indicate how much time is left on the card. It

also displays the current Filename that is being used for recording.

The files on the card are in DOS standard format and can be managed on any Windows™ based machine with a

CompactFlash™ reader - internal or external. The content of the files is in proprietary binary format and requires

special software to read the data. All units are supplied with the Navigator Lite Software, which allows the data to

be exported to Excel.

This space intentionally left blank.

CF 151 12 AJW 10306 REV 1.0 05/07

Page 16

3.0 BASIC OPERATING INSTRUCTIONS

The Basic mode of operation encompasses those functions that would be done on a routine basis and relate

primarily to viewing and reviewing data with some use of the menu system. The advanced mode, while technically

still simple to operate, involves setting up the unit and would typically need to be done only once.

3.1 Basic Mode of Operation

Basic operations are all done using the five buttons on the front panel (shown below) and the first level menu.

Each arrow button has dual functions. The second function is activated by pressing and holding the MENU (2nd

Function) button and then pressing any of the other buttons. The 2nd function of each button is denoted by the text

under the arrow symbol. (EXPAND, COMPRESS, ZOOM + and ZOOM -).

The unit need not be recording to the memory card in order to manipulate data. The data available however is

dependent on how long the unit has been operating, the sample rate and the buffer or memory card size.

3.2 Viewing Historic Data

Any data that is not currently visible on the screen is historic data. To view past data, the left (◄) and right (►)

arrow buttons are used to rewind (◄) or fast forward (►) the data (scrolling). When rewinding, data will be retrieved

from the memory card or from the internal buffer and is available as far back as the start of recording. When fastforwarding, data is available up to real time. The time and date stamp on the screen indicates the relative time of

the samples being viewed. Depending on the amount of data to process there may be delays before the screen

reacts.

Historic viewing by scrolling is limited to the file (or files) created since recording was manually started via the

RECORD MODE Menu - ON. If NOT recording, scrolling back in time is limited to the content of the internal buffer.

The history buffered is dependent upon the sampling speed. Data is presented as latest data first.

It is possible to view data from other files of previously recorded data (or even data recorded on another machine)

using the View File menu.

⇒ At any stage during the rewind or fast forward process, the screen can be restored to current or real time

display by pressing the MENU button.

⇒ When the data on screen is not current, an

appears on the status line to indicate that the rewind or

compress mode is active and the data is on Hold.

3.3 Compressing and Expanding Data (Trend Viewing)

In order to view data trends, it is often necessary to pack more data onto the screen than is normally visible in real

time. To compress the data, press and hold the MENU (2

nd

Function) key and then press the COMPRESS (.) key.

Each time this key is pressed the amount of data on the screen will double up to a maximum of 32 times

(equivalent to 5 sequential key presses). Once compressed, data can be rewound and fast-forwarded as described

in the previous section. The data can be expanded back after being compressed by pressing and holding the

MENU key and then pressing the EXPAND (◄) button.

Note that compression displays peak values (both high and low). Thus even though data is compressed, all

amplitude information is present on the display. At compressions of 16 times or greater, the redraw time of data on

the screen slows down due to the large amounts of data that must be manipulated.

⇒ At any stage during the compression or expansion process, the screen can be restored to current or real

time display by pressing the MENU button.

⇒ When the data on screen is compressed, a

appears on the status line to indicate that the compress

mode is active.

CF 151 13 AJW 10306 REV 1.0 05/07

Page 17

3.4 Zooming Data (Amplification)

As a result of the small display area available, it is not always possible to see small changes in amplitude of the

recorded signals even though the resolution of the internal converters can measure it. To overcome this problem

you can ZOOM in on a portion of the graph and get increased resolution.

ZOOM applies to each channel independently. The trace that will zoom is the one whose scale is shown to the

right. To adjust the other trace simply wait for its scale to appear.

To ZOOM in and amplify the graph, press and hold the MENU key, press the ZOOM+ (▲) button and then release

both buttons. The display will zoom in by 2. Note that the scale units change to reflect the increased zoom level.

There are three zoom levels available: x1, x2 and x4.

To decrease the zoom level (or zoom out), press and hold the MENU key, press the ZOOM- (▼) button and then

release both buttons.

While adjusting the zoom, scale flipping is suspended. Turning the other trace off will also suspend flipping.

Note that when zoomed in at any zoom level, the (▲) and (▼) buttons will move the graph relative to the window

enabling viewing of any part of the graph within the zoom window. When zooming, the trace expands or contracts

about the centerline. If zooming drives the trace off the screen, it will automatically reposition itself at the top or

bottom vertical edge of the chart. Once in a zoom level, all functions are operational on the zoomed display.

⇒ When in a zoom mode, the zoom level is indicated in the lower half of the scale for the associated channel

(X2, X4 etc.). No indication indicates normal scale (X1).

⇒ To exit the zoom mode, zoom out (MENU + ▼) as far as possible until the scale value disappears – x1

mode.

3.5 Menu Mode

At any time when in normal view mode, pressing the MENU button will bring up the user

menu as shown to the right. Note that the menu "pops up" over the graphics display. The unit

continues to record and will not lose data. There is also a time out option that will return a

menu display back to a graphic display after a period of inactivity. (Refer to Advanced Setup

DISPLAY - MENU TIMEOUT).

⇒ When the menu is active, the Left Arrow (◄) and Right Arrow (►) buttons act as

ESCAPE keys to return to a previous level without activating any function.

The user moves about the menu using the Up Arrow (▲) and Down Arrow (▼) buttons. The

current selection is always highlighted in reverse. To select a function, simply move to it with

the (▲) and (▼) buttons and then press the MENU button once. To go back a level without

activating any function, simply press the (◄) or (►) buttons. Note that the menu has more options than can be

displayed at once on the screen. When a selection gets to the top or bottom of the menu list, the list will scroll until

the last entry is reached then wrap around. Pressing and holding the (▲) and (▼) buttons will activate an Auto

Repeat function and cause the highlight bar to scroll automatically.

The menu has multiple levels. An option with a secondary level is indicated by .. after the name. Access to the

various levels can be controlled by a password (Refer below).

3.5.1 Exit!

When the menu is displayed, it defaults to the EXIT selection. At this point, pressing the MENU button will return to

the graphic display.

CF 151 14 AJW 10306 REV 1.0 05/07

Page 18

3.5.2 Alarm Reset!

Pressing the MENU button after selecting ALARM RESET! will reset any alarm that is active and latched and then

exit the Menu Mode. If the alarm is not latched but is still in alarm, selecting this option will briefly reset the alarm,

which will then activate again.

3.5.3 Record Mode..

To begin or end recording in the data card, press the MENU button, use the Up Arrow (▲) or Down Arrow (▼) button

to highlight RECORD MODE and then press the MENU button again. Several options appear in a sub window:

OFF, ON and TRIGGERED. To exit at this stage without changing the current setting, press either the Left (◄) or

Right (►) Arrow button. Otherwise, use the Up Arrow (▲) or Down Arrow (▼) button to make a selection and then

press the MENU button. The active selection is indicated by a √ to the left of the option. If you are using the alarms

or external input to control the recording, select TRIGGERED for triggered operation. OFF and ON will always stop

or start a recording irrespective of the state of any of the record triggers. (Refer to Event Triggering.)

⇒ The RECORD MODE menu option may be password protected.

⇒ Before selecting ON or TRIGGERED to begin a recording, ensure that a Memory Card is in place and that

there is sufficient space available to contain your new data. (Refer to CARD STATUS below.)

To return to the graphic screen, press either the Left (◄) or Right (►) Arrow button. For further details on other

options under RECORD MODE, refer to ADV. SETUP - DATA CARD.

Note: While recording, the recorder automatically switches to OFF when a card is removed, or if it is not present

when power is applied. This will require a manual restart of the recording when a new card is inserted. If the card

remains in the slot while power is removed the recorder restores the recording state it was in when the power was

interrupted.

3.5.4 Cursor ID!

The Cursor ID mode enables the user to accurately pinpoint the time and amplitude of any sample in the graphics

window. The unit has to be in the full graphic mode for this option to work.

To enable this function, press the MENU button, use the Up Arrow (▲) or Down Arrow (▼) button to highlight

CURSOR ID! and then press the MENU button again. The Menu will vanish revealing the Graphics screen and a

single data cursor against the right edge of the display area. Note: The Cursor ID mode will not activate if the

Trend is compressed. The screen will be in the HOLD mode and the data window at the top of the screen and

time/date stamp at the lower right will show the values of the samples under the data cursor. The status line will

show the highlighted

to indicate that the data and timestamp is that of the data under the cursor and not real

time data.

Using the Left (◄) or Right (►) buttons the user can move the data cursor to the point of interest. The data window

at the bottom of the screen will show the time and date of the sample and the digital readings at the top of the

screen - A (and B in dual channel units) show the absolute value. Note that at the extremities of the data, the cursor

hits an end point and then the data scrolls beneath it. This method can be used to accurately identify unique points

on the graphics display no matter how busy the traces appear.

To return to normal (real time) mode, press the MENU button. Note that entering the Cursor ID mode does not

affect the real time acquisition of data.

3.5.5 View File

The user can view data from files other than the one currently being recorded. The View File option allows the user

to view previously recorded data on the data card from the very first file through to the current data. The display

HAS TO BE IN THE FULL GRAPHIC MODE for this to work.

To view a file on the memory card, press the MENU button, use the Up Arrow (▲) or Down Arrow (▼) button to

highlight VIEW FILE and then press the MENU button again. The current filename will be displayed. To view

historic data from this file, simply press the MENU button. To choose a different file on the memory card, press the

CF 151 15 AJW 10306 REV 1.0 05/07

Page 19

Left Arrow (◄) button twice to display a directory listing of all files on the card. Then use the Up Arrow (▲) or Down

Arrow (▼) button to highlight the desired file and press the MENU button twice to select it.

When viewing from a file, the status line will show a highlighted

to indicate that the data being viewed is from a

File on the memory card. All View, Compress and Zoom functions work on the prerecorded file. Use the Left (◄) or

Right (►) buttons to move through the file. Data will be presented as oldest samples first.

To return to the current real time trend, press the MENU button. View File will automatically abort if the data card is

removed.

3.5.6 Card Status!

To display the status of the memory card, press the MENU button, use the Up Arrow (▲) or Down Arrow (▼) button

to highlight CARD STATUS! and then press the MENU button again. A pop-up window will be displayed showing

information about the memory card including the size of the card, the amount of space left as a percentage and the

equivalent record time at the current settings.

To remove the Card Status pop-up window, select CARD STATUS! again.

3.5.7 Sample Rate

To adjust the sample rate (the rate at which data is recorded and displayed), press the MENU button, use the Up

Arrow (▲) or Down Arrow (▼) button to highlight SAMPLE RATE and then press the MENU button again.

⇒ The SAMPLE RATE menu option may be password protected.

When entering the SAMPLE RATE menu, the rate highlighted is the current sampling rate. To exit at this stage

without changing the current setting, press either the Left (◄) or Right (►) button. In this manner the user can

check the current sampling rate at any time without affecting the recording.

To change the sampling rate, use the Up Arrow (▲) or Down Arrow (▼) button to highlight the desired sample rate

and then press the MENU button. The sample rates vary from a high of 100 S/sec (Samples per second) to the

slowest 10 min/S (minutes per sample, sec/S is seconds per sample).

To return to the graphic screen, press either the Left (◄) or Right (►) button.

3.5.8 Password (Protection)

To set, reset or change a password, press the MENU button, use the Up Arrow (▲) or Down Arrow (▼) button to

highlight PASSWORD and then press the MENU button.

⇒ This menu option may be password protected.

Follow the prompts. Enter a 4-digit password using a combination of ◄►▼▲ buttons. The key presses are echoed

in a pop-up window and roll around, first in first out. Once you have entered your password, press the MENU

button.

If you are entering a new password, you will be asked to repeat your password and then press the MENU button. At

this point the password is entered and the unit is protected.

To clear the password, enter the current password and then simply press the MENU button when prompted to enter

the new password. A null password is no password at all.

3.5.9 Adv. Setup (Advanced Setup)

See Section 4.

3.5.10 Display Adj (Adjust)

To adjust the backlight brightness and viewing angle, press the MENU button, use the Up Arrow (▲) or Down

Arrow (▼) button to highlight DISPLAY ADJ and then press the MENU button again.

CF 151 16 AJW 10306 REV 1.0 05/07

Page 20

Adjust the Viewing Angle using the ◄ and ► keys and the Backlight Intensity using the ▲ and ▼ keys. Press the

MENU button to accept the changes and exit.

3.6 Event Triggering

The recorder has the ability to be triggered by certain events that are generated internally or, optionally, externally,

which will enable it to automatically change sampling speed or begin or end a recording session. The trigger can be

any alarm or the external input. The user can thus set the unit to record at a slow sample speed until some alarm

condition is triggered and then change to a higher sample rate to record the transient. Another example is the use

of the external event trigger to start and stop recording allowing the selective recording of specific events.

The event triggering is setup in the Advanced Setup Menu option. The control of recording, stopping and starting is

set in the REC. TRIG. (Record Trigger) menu option (Section 4.9), while the changing of sample speed is controlled

via the SAMPLE TRIGger menu option where a second set of sample speeds will be presented for the triggered

speed change (Section 4.8). This rate may be slower or faster than the regular rate depending on application.

The external event may be used in the same manner as the internal alarms for triggering a change of speed or

record status. The external event trigger characteristics are set in the ADV. SETUP - EXT. INPUT menu option.

If the recorder is triggered but not recording, the red LED will blink at a 1 second interval.

3.7 Status Line Indicators

The bottom line of the graphics LCD display is used to indicate the status of the display and of the recorder itself.

These status icons consist of reverse video characters or letters that appear according to operations performed and

are intended to prevent data on the display from being misinterpreted and to indicate the status of the alarms.

From left to right these icons are as follows:

- These icon symbols indicate that the alarms are enabled (1 is Alarm 1 etc.). Any number of them may be

present depending on how the alarms have been set up. If an alarm is enabled a solid block will be present. If the

alarm has exceeded the setpoint (i.e. is in an alarm condition) its symbol will be blinking.

- This symbol indicates that the external input is enabled. If the external input is triggered this symbol will blink.

- This symbol indicates the display is in the COMPRESSED mode. The amount of compression can be

determined from the time date stamps on the display. To exit from the Compressed Mode simply press the MENU

button.

- This symbol indicates the display is in the HOLD mode. The displayed data is no longer real time and will not

be updated. The Hold mode is entered by pressing either the LEFT or RIGHT arrow button, entering the

compressed mode, or viewing any internally buffered data.

- This symbol indicates the data on the display is from a FILE on the MEMORY CARD and not current data. To

view data from a file, use the MENU selection option "VIEW FILE". Note that if currently recording, viewing a file

does not disrupt the recording procedure provided that the file you are viewing is on the same memory card as the

one you are recording on OR you do not exceed the buffer storage time on the recorder if you are using another

memory card.

3.8 Entering Data

When adjusting or entering values you have to use the ▼▲►◄ button keys.

Alphanumeric Values – The ► key moves the cursor to the right to select the character to be edited. It will wrap

around from right to left. The ▼▲ change the character as shown in Appendix A. The MENU button accepts the

data and exits and the ◄ key escapes.

CF 151 17 AJW 10306 REV 1.0 05/07

Page 21

Numeric Values – work a little differently; the value increments and decrements according to the up ▲ or ▼ down

keys. Single presses increment or decrement the value by 1. If the button is pressed and held down the value will

increment or decrement in steps of 10. If the MENU button is held down and the ▲ or ▼ button is pressed and held

down, the value increments or decrements by 100. The MENU button accepts the data and exits and the ◄ key

escapes.

This space intentionally left blank.

CF 151 18 AJW 10306 REV 1.0 05/07

Page 22

3.9 Top Level Menu Overview

CF 151 19 AJW 10306 REV 1.0 05/07

Page 23

4.0 ADVANCED SETUP

The ADVANCED SETUP menu may be password protected. This menu is used to

program the various operating parameters of the recorder. This includes analog

inputs, alarms, display settings, the clock and various trigger modes.

All items on this menu have one or more sub-menus. To locate the Advanced Setup

menu, press the MENU button from any normal view mode. The Advanced Setup

menu will not be visible when the menu first appears. Use the Up Arrow (▲) and

Down Arrow (▼) buttons to scroll and highlight ADV. SETUP and press the MENU

button. This will bring up the Advanced Setup menu shown on the left. Current

settings in sub menus are indicated by a √ (check mark) along side the item or by the

item being highlighted. See above for details on entering data.

CHAN A SETUP..

CHAN B SETUP..

ALARMS..

RELAYS..

DISPLAY..

DATA CARD..

CLOCK..

BEEPER..

SAMPLE TRIG..

REC. TRIG..

EXT. INPUT..

UNIT TAG..

COMMS..

4.1 Channel Setup

This menu option enables the user to program the inputs of the recorder. Each channel can be set up as an analog

input – volts, currents, thermocouple or RTDs, or as digital inputs from RPM or frequency measurements. There is

no need to swap out modules since the inputs are universal. Filtering may be applied to each channel for stability of

readings or to catch peak values if the display rate is slower than the sample rate. (The unit always samples at 100

samples per second per channel. For increased accuracy each range may be calibrated independently. Use the Up

Arrow (▲) and Down Arrow (▼) buttons to scroll and highlight CHAN n SETUP (n = A or B) and press the MENU

button. The menu options are shown expanded below.

CF 151 20 AJW 10306 REV 1.0 05/07

Page 24

4.2 Alarms

This option is used to program the alarms. There are four alarms and each is programmed independently. Each

alarm may be turned on or off and may be assigned to either channel.

Use the Up Arrow (▲) or Down Arrow (▼) buttons to scroll and highlight ALARMS.. and press the MENU button.

The menu options are shown expanded below.

CF 151 21 AJW 10306 REV 1.0 05/07

Page 25

4.3 Relays

This option is used to program the physical relay outputs. There are two relays and each is programmed

independently. The relays can be assigned to one or more ALARM events or the EXTernal INPUT. Use the Up

Arrow (▲) or Down Arrow (▼) buttons to scroll and highlight RELAYS.. and press the MENU button. The menu

options are shown below.

4.4 Display

This option is used to set up the display. The Window Configuration allows the user to choose how to display data either as a trend or as digital values or as a combination of both. The time stamp that appears on the trend can be

customized, the menu can be set to disappear and have the display revert back to normal, and the backlight can be

set to go off after a period of inactivity. (The backlight will restore on any event.) Use the Up Arrow (▲) or Down

Arrow (▼) buttons to scroll and highlight DISPLAY.. and press the MENU button. The menu options are shown

below.

CF 151 22 AJW 10306 REV 1.0 05/07

Page 26

4.5 Data Card

This option contains duplicate menu items to those found in the RECORD MODE menu. In addition it enables the

user to test the card and format it for use (recommended). Use the Up Arrow (▲) or Down Arrow (▼) buttons to

scroll and highlight DATA CARD.. and press the MENU button. The menu options are shown below.

CF 151 23 AJW 10306 REV 1.0 05/07

Page 27

4.6 Clock

This option allows the user to set the time and date and determine what is displayed for time on the bottom right of

the display. Use the Up Arrow (▲) or Down Arrow (▼) buttons to scroll and highlight CLOCK.. and press the

MENU button. The menu options are shown below.

4.7 Beeper

This option allows the user to have various events sound the beeper, Alarms, message boxes and key presses.

The tone of the beeper may also be programmed. Use the Up Arrow (▲) or Down Arrow (▼) buttons to scroll and

highlight BEEPER.. and press the MENU button. The menu options are shown below.

CF 151 24 AJW 10306 REV 1.0 05/07

Page 28

4.8 Sample Trigger

This option allows the user to program what will trigger a change of sample rate in the displayed or recorded data.

Use the Up Arrow (▲) or Down Arrow (▼) buttons to scroll and highlight SAMPLE TRIG.. and press the MENU

button. The menu options are shown below.

⇒ Note that if an event is selected to change the sample rate, when exiting the menu the sample rate menu

will be displayed. Use the Up Arrow (▲) or Down Arrow (▼) buttons to scroll and highlight the new sample

speed and press the MENU button to select and the Left Arrow (◄) button to exit.

4.9 Record Trigger

This option allows the user to choose an event to start the recording. Use the Up Arrow (▲) or Down Arrow (▼)

buttons to scroll and highlight REC. TRIG.. and press the MENU button. Select either OFF, ALARM 1 through 4 or

EXTERNAL INPUT as the record trigger.

⇒ Note that if an alarm reset delay is set (see Section 4.2), the unit will continue to record for this time period

AFTER the alarm has gone away.

4.10 External Input

This option allows the user to program the external digital input. This needs to be programmed before it can be

used for event triggering if programmed above. Use the Up Arrow (▲) or Down Arrow (▼) buttons to scroll and

highlight EXT. INPUT.. and press the MENU button. The menu options are shown below.

4.11 Unit Tag

The unit tag is used to identify the recorder. It is saved to the data file when recording and can be read back by the

analyzing software. It is also displayed on the top of the main menu when the MENU button is pressed for the first

time. It can be a maximum of 15 characters. Select this option then use the ▼▲► keys to adjust and the ◄ key to

escape or the MENU key to Save and Exit. See Entering Data above for details.

4.12 Comms

This option allows the user to set the IP Address and Subnet Gateway for the Ethernet Option. Use the .key to

select the digit to change (Indicated by [123]) and ▼▲ to change it. Use the MENU to accept or ◄ to escape.

CF 151 25 AJW 10306 REV 1.0 05/07

Page 29

5.0 MISCELLANEOUS

5.1 Battery Backup Option

If the recorder contains the Battery Backup Option, there is a toggle switch on the back panel below the terminal

block. The switch is marked ON and OFF.

In the OFF position, the battery is disconnected from the load and the recorder is off. The battery charges with the

switch OFF when the recorder is plugged into AC power.

In the ON position, with external power applied, the unit runs normally and automatically switches to battery backup

in the event of a power failure. The recorder continues to run from the battery until power is restored. If the battery

voltage reaches a preset low voltage threshold, the battery is automatically disconnected and the recorder shuts

off. When external power is restored, the unit starts up normally and the batteries begin to recharge. Likewise, the

unit can run off internal battery without external power by simply turning the unit ON. The recorder switch should be

turned OFF when not in use.

Additionally there is a procedure to turn the backlight off when the unit is running on battery. See Section 4.4. This

action extends the battery life and the unit continues to operate normally. The green power LED on the front panel

will blink when the recorder is being powered from the battery. Run times vary from 8 to more than 12 hours

depending on load conditions. It takes 10 to 14 hours for the battery to fully charge.

5.2 Ethernet Option

The Ethernet option is field installable and can be added to the recorder at any time PROVIDED there is no USB