Page 1

DFI INFINITY CS

STRAIN METER/CONTROLLER

USER’S GUIDE

www.cooperinstruments.com

PH: 540-349-4746 • FAX: 540-347-4755

Page 2

CONTENTS

PREFACE ....................................................................................................................................1

1.0 INTRODUCTION....................................................................................................................2

1.1 Unpacking........................................................................................................................................2

1.2 Safety Considerations....................................................................................................................2

2.0 ABOUT THE METER .............................................................................................................3

2.1 Description ......................................................................................................................................3

2.2 Features...........................................................................................................................................3

2.3 Available Accessories....................................................................................................................3

2.4 Front of the Meter ...........................................................................................................................4

2.5 Back of the Meter............................................................................................................................5

2.6 Disassembly....................................................................................................................................6

3.0 GETTING STARTED..............................................................................................................7

3.1 Rating/Product Label......................................................................................................................7

3.2 Main Board Power Jumpers (Refer To Figure 3-1).......................................................................7

3.3 Panel Mounting ...............................................................................................................................9

3.4 Connecting Sensor Inputs .............................................................................................................9

3.5 Connecting Main Power ...............................................................................................................11

3.6 Connecting External Tare Switch................................................................................................12

3.7 Connecting Analog and Relay Outputs ......................................................................................12

4.0 CONFIGURING THE METER...............................................................................................14

4.1 Selecting the Input Type ...................................................................................................14

4.2 Selecting a Decimal Point Position ..................................................................................14

4.3 Using Reading Scale and Offset .....................................................................................14

4.3.1 Scaling with Known Loads (On-Line Calibration)...............................................................14

4.3.2 Scaling without Known Loads..............................................................................................16

4.4 Using Reading Configuration ...........................................................................................16

4.4.1 Selecting Ratiometric/Non-Ratiometric Operation..............................................................17

4.4.2 Setting Input Resolution........................................................................................................17

4.4.3 Displaying the Filtered/Unfiltered Input Signal ...................................................................17

4.4.4 Selecting Gross/Net or Peak Display ...................................................................................17

4.5 Selecting a Display Color .............................................................................................18

4.6 Using Setpoint 1 Configuration .......................................................................................18

4.6.1 Setting Setpoint 1’s Active Band..........................................................................................18

4.6.2 Selecting if Setpoint 1 is Latched of Unlatched..................................................................18

4.6.3 Assigning Setpoint 1 Values to Net or Gross Readings.....................................................18

4.7 Using Setpoint 2 Configuration .......................................................................................19

4.7.1 Setting Setpoints 2’s Active Band........................................................................................19

4.7.2 Selecting if Setpoint 2 is Latched or Unlatched..................................................................19

4.7.3 Assigning Setpoint 2 Values to Net or Gross Readings.....................................................19

4.8 Setting the Setpoint 1 Deadband .....................................................................................19

4.9 Setting the Setpoint 2 Deadband .....................................................................................20

4.10 Using Output Configuration ...........................................................................................21

4.10.1 Enabling or Disabling the Analog Output..........................................................................21

4.10.2 Selecting Analog Output as Current or Voltage................................................................21

4.10.3 Selecting Analog Output or Proportional Control.............................................................21

4.11 Using Output Scale and Offset .....................................................................................21

4.11.1 Examples for Output Scale and Offset...............................................................................22

DFI INFINITY CS (V- M3598/N/0906) ii CF 70

Page 3

4.12 Using Lock Out Configuration .......................................................................................23

4.12.1 Enabling or Disabling the RESET button in the Run Mode..............................................23

4.12.2 Enabling or Disabling the SETPOINT Changes.................................................................23

4.12.3 SETPOINT Display Function: Firmware version or Setpoint value ................................23

4.13 Using Display Brightness Configuration ............................................................................23

4.13.1 Changing Brightness Level.................................................................................................23

5.0 DISPLAY MESSAGES.........................................................................................................24

6.0 MENU CONFIGURATION DISPLAYS.................................................................................25

7.0 SETPOINT CONFIGURATION DISPLAYS..........................................................................28

8.0 SPECIFICATIONS................................................................................................................28

9.0 FACTORY PRESET VALUES..............................................................................................31

10.0 CE APPROVALS INFORMATION.....................................................................................31

WARRANTY REPAIR POLICY..................................................................................................32

DFI INFINITY CS (V- M3598/N/0906) iii CF 70

Page 4

PREFACE

Manual Objectives

This manual shows you how to set up and use the Programmable Digital Meter.

Standard Procedures:

• Checking voltage jumpers, or changing voltage power

• Mounting the panel

• Selecting the input type

• Selecting a decimal point position

• Scaling with known loads (on-line calibration)

• Scaling without known loads

• Selecting ratiometric/non-ratiometric operation

• Displaying the filtered/unfiltered input signal

• Selecting a display color

• Setting the setpoint’s active band

• Selecting a latched or unlatched operation

• Setting setpoint deadbands

• Enabling/disabling setpoint changes

• Enabling/disabling the RESET button in the Run Mode

Optional Procedures:

• Setting input resolution

• Enabling/ disabling analog output

• Selecting analog output as current or voltage

• Assigning the output to net/gross reading

• Scaling analog output

Features with

segment characters shown are for the “B” version.

are for the “B” version which has three-color programmable “Big” LED display – All

For first-time users: Refer to the QuickStart Manual for basic operation and set-up instructions.

Table A-1 Sections of the Manual

IF YOU WANT TO READ ABOUT: REFER TO SECTION

Unpacking; safety considerations 1 Introduction

Meter description and features 2 About the Meter

Main board power jumpers; panel mounting, sensor input, main power and

analog and relay output

Input type; decimal point position; reading scale & offset; reading

configuration; display color; setpoint configuration; setpoint deadbands;

output configuration (analog output); analog output scaling; lock out

configuration; display brightness

Display messages 5 Display Messages

Meter menu/sub-menu messages 6 Menu Configuration

Setpoint configuration messages 7 Setpoint Configuration Displays

Specifications 8 Specifications

Factory Preset Values 9 Factory Default Setup as Shipped

NOTES, WARNINGS and CAUTIONS

Information that is especially important to note is identified by three labels:

• NOTE

• WARNING

• CAUTION

• IMPORTANT

3 Getting started

4 Configuring the Meter

DFI INFINITY CS (V- M3598/N/0906) 1 CF 70

Page 5

NOTE: provides you with information that is important to successfully setup and use the Programmable

Digital Meter.

CAUTION or WARNING: tells you about the risk of electric shock.

CAUTION, WARNING or IMPORTANT: tells you of circumstances or practices that can affect the meter’s

functionality and must refer to accompanying documents.

TIP: provides you helpful hints.

1.0 INTRODUCTION

1.1 Unpacking

Remove the Packing List and verify that all equipment has been received. If there are any questions about the

shipment, please call Cooper Instruments at 1-800-344-3921.

Upon receipt of shipment, inspect the container and equipment for any signs of damage. Take particular n ote of

any evidence of rough handling in transit. Immediately report any damage to the shipping agent.

The carrier will not honor any claims unless all shipping material is saved for their examination. After

examining and removing contents, save packing material and carton in the event reshipment is necessary.

Verify that you receive the following items in the shipping box:

QTY DESCRIPTION

Programmable Digital Meter indicator/controller with all applicable connectors attached.

1

Owner’s Manual

1

Set Mounting brackets

1

If you ordered any of the available options, they will be shipped in a separate container to avoid any damage

to your indicator/controller.

1.2 Safety Considerations

This device is marked with the international caution symbol. It is important to read this manual before

installing or commissioning this device as it contains important information relating to Safety and EMC

(Electromagnetic Compatibility).

This instrument is a panel mount device protected in accordance with EN 61010-1:2001, electrical safety

requirements for electrical equipment for measurement, control and laboratory. Installation of this instrument should

be done by qualified personnel. In order to ensure safe operation, the following instructions should be followed.

This instrument has no power-on switch. An external switch or circuit breaker shall be included in the

building installation as a disconnecting device. It shall be marked to indicate this function, and it shall be in close

proximity to the equipment within easy reach of the operator. The switch or circuit-breaker shall not interrupt the

Protective Conductor (Earth wire), and it shall meet relevant requirements of IEC 947-1 and IEC 947-3

(International Electrotechnical Commission). The switch shall not be incorporated in the main supply cord.

Furthermore, to provide protection against excessive energy being drawn from the main supply in case of a

fault in the equipment, an overcurrent protection device shall be installed.

• Do not exceed voltage rating on the label located on the top of the instrument housing.

• Always disconnect power before changing signal and power connections.

• Do not use this instrument on a work bench without its case for safety reasons.

• Do not operate this instrument in flammable or explosive atmospheres.

• Do not expose this instrument to rain or moisture.

• Unit mounting should allow for adequate ventilation to ensure instrument does not exceed operating

temperature rating.

DFI INFINITY CS (V- M3598/N/0906) 2 CF 70

Page 6

• Use electrical wires with adequate size to handle mechanical strain and power requirements. Install

without exposing bare wire outside the connector to minimize electrical shock h azards.

EMC Considerations

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and power wires in the same conduit.

• Use signal wire connections with twisted-pair cables.

• Install Ferrite Bead (s) on signal wires close to the instrument if EMC problems persist.

Failure to follow all instructions and warnings may result in injury!

2.0 ABOUT THE METER

2.1 Description

The Digital Programmable Strain meter is a value packed indicator/controller. Four full digits and broad scaling

capability allow for a display in virtually all engineering units. A wide variety of DC current and voltage input ranges

cover typical strain applications. Standard features include sensor excitation and front panel or remote tare. Your

meter may be a basic indicator or it may include analog output or dual relay output. Analog or dual relay output

must be ordered at time of purchase. Analog output is fully scalable and may be configured as a proportional

controller, or to follow your display. Dual 5 amp, form C relays control critical processes. A mechanical lockout has

been included to guard against unauthorized changes.

2.2 Features

The following is a list of standard features:

• 4-digit, three color Programmable, Big LED display or

4-digit, Standard LED display

• NEMA 4 Front Bezel

• ±0.03 % accuracy

• 8 DC input ranges: 0-100 mV, ±50 mV, 0-5 V, 1-5 V, 0-10 V, ±5 V, 0-20 mA, and 4-20 mA

• 5,10,12, or 24 Vdc sensor excitation

• Peak detection

• Front panel and remote tare function

• Nonvolatile memory-no battery backup

• 115 or 230 Vac 50/60 Hz power supply or

10 – 32 Vdc or 26-56 Vdc

The following is a list of optional features:

• Dual 5 amp, form C relay output

• Scalable analog output

• Proportional control

• Easy setup for proportional control

2.3 Available Accessories

Table 2-1 Accessories and Add-Ons

Add-On Options

FS Special Calibration/Configuration

SPC4 NEMA-4 Splash proof Cover

SPC18 NEMA-4 Splash Proof Cover, NEW

Accessories

TP1A Trimplate panel adaptor - Adapts DIN1A/DIN2A cases to larger panel cutouts

RP18 19-in. Rack Panel for one (1) 1/8 DIN instrument

RP28 19-in. Rack Panel for two (2) 1/8 DIN instruments

DFI INFINITY CS (V- M3598/N/0906) 3 CF 70

Page 7

RP38 19-in. Rack Panel for three (3) 1/8 DIN instruments

2.4 Front of the Meter

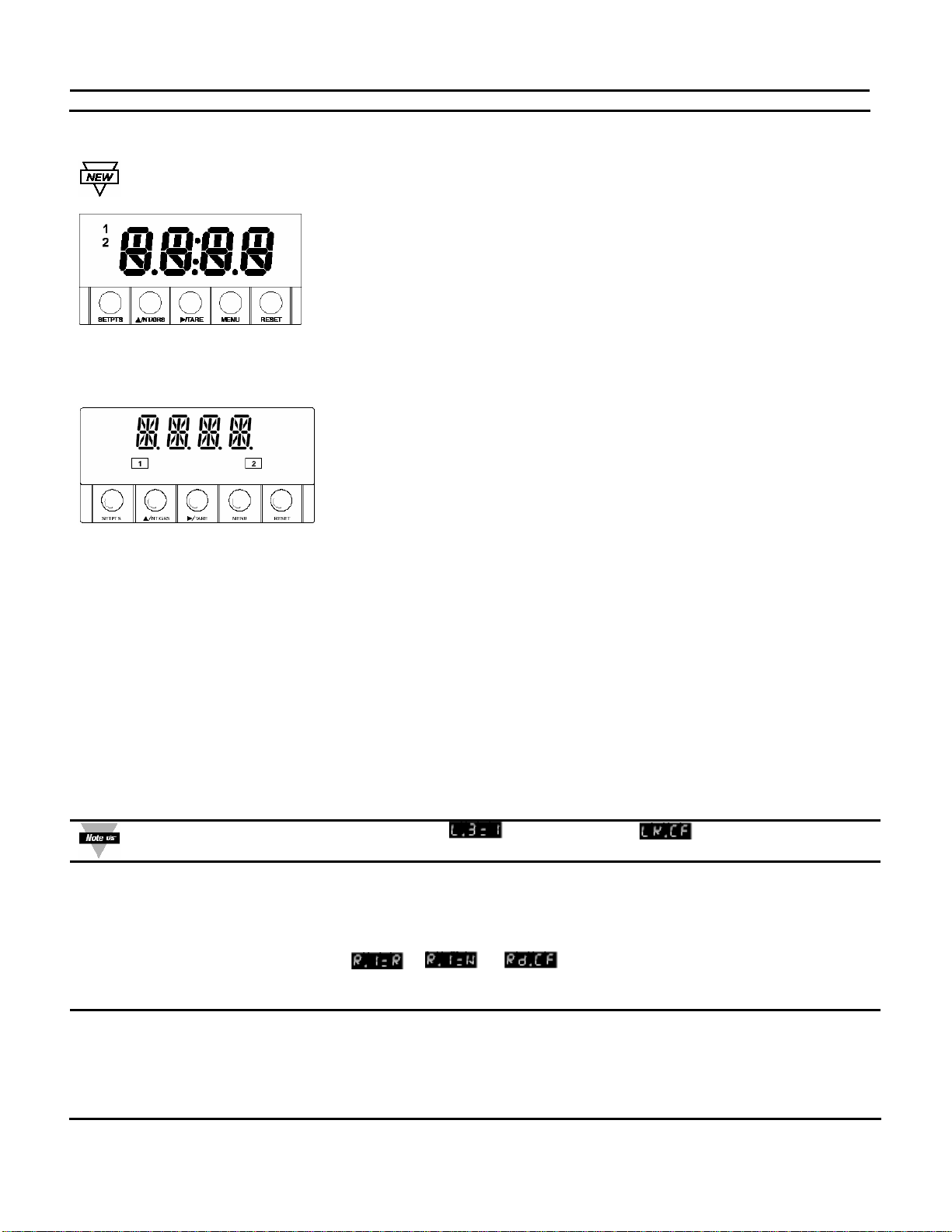

Figure 2-1 shows each part of the front of the three-color programmable “Big” LED display Meter (Version

B).

Digital LED Display:

-1.9.9.9 or 9.9.9.9 4-digit three color programmable, 21 mm (0.83”) high

LED display with programmable decimal point.

Figure 2-1 Front-Panel with Big Display

Figure 2-2 shows each part of the front of the standard LED display meter.

Digital LED Display:

-1.9.9.9 or 9.9.9.9 14 segment, 13.8 mm (0.54”)

high LED display with programmable decimal point.

Figure 2-2 Front-Panel with Standard Display

These meter display windows (both versions) light when appropriate:

1 Setpoint 1 status

2 Setpoint 2 status

5 Pushbuttons for programming the meter.

METER BUTTONS

SETPTS Button

In the Run Mode, this button will sequentially recall the previous setpoint settings. As necessary, use the

S/NT/GRS and X/TARE buttons to alter these settings, and then press the SETPTS button to store new values.

Unless you press the SETPTS, X/TARE, or SNT/GRS button within 20 seconds, the meter will scroll to setpoint 2

and then to the Run Mode.

If the dual relay option is not installed, or if

SETPTS button will display the meter’s firmware version.

S/NT/GRS Button

In the Run Mode, this button will toggle between net/gross readings or peak readings, depending upon setup.

In the Configuration Mode, press this button to change the value of the flashing digit shown on the display and/or

toggle between menu choices, such as

or on menu . When configuring your setpoint

values, press the S/NT/GRS button to advance the flashing digit’s value from 0 to 9 by 1.

X/TARE Button

In the Run Mode press the X/TARE button to tare your reading (zeroing).

In the Configuration Mode, press this button to scroll to the next digit.

is displayed on the menu, pressing the

DFI INFINITY CS (V- M3598/N/0906) 4 CF 70

Page 8

MENU Button

In the Run Mode, press the MENU button to terminate the current measuring strain and enter you into the

Configuration Mode.

Only if you have not installed the lock out jumpers on the main board.

In the Configuration Mode, press the MENU button to store changes in the nonvolatile memory and then advance

you to the next menu item.

RESET Button

If you hard reset (press the MENU button followed by the RESET button) or power off/on the meter, it shows

followed by

.

In the Run Mode, press the RESET button to reset the latched setpoints. The meter shows

and returns to

the Run Mode.

In the Configuration Mode, press the RESET button once to review the previous menu. Press the RESET button

twice to perform a hard reset and return to the Run Mode.

In the Peak Mode, press the RESET button to reset peak values. The meter shows and returns to the Run

Mode.

In the Setpoint Mode, press the RESET button to reset the latched setpoint. The meter shows

and enters

the Run Mode.

In the Tare Mode, press the RESET to reset. The meter shows

.

When in setpoint or Configuration Mode, if the meter shows 9999 or –1999 with all flashing digits, the

value has overflowed. Press the S/NT/GRS button to start a new value.

2.5 Back of the Meter

,

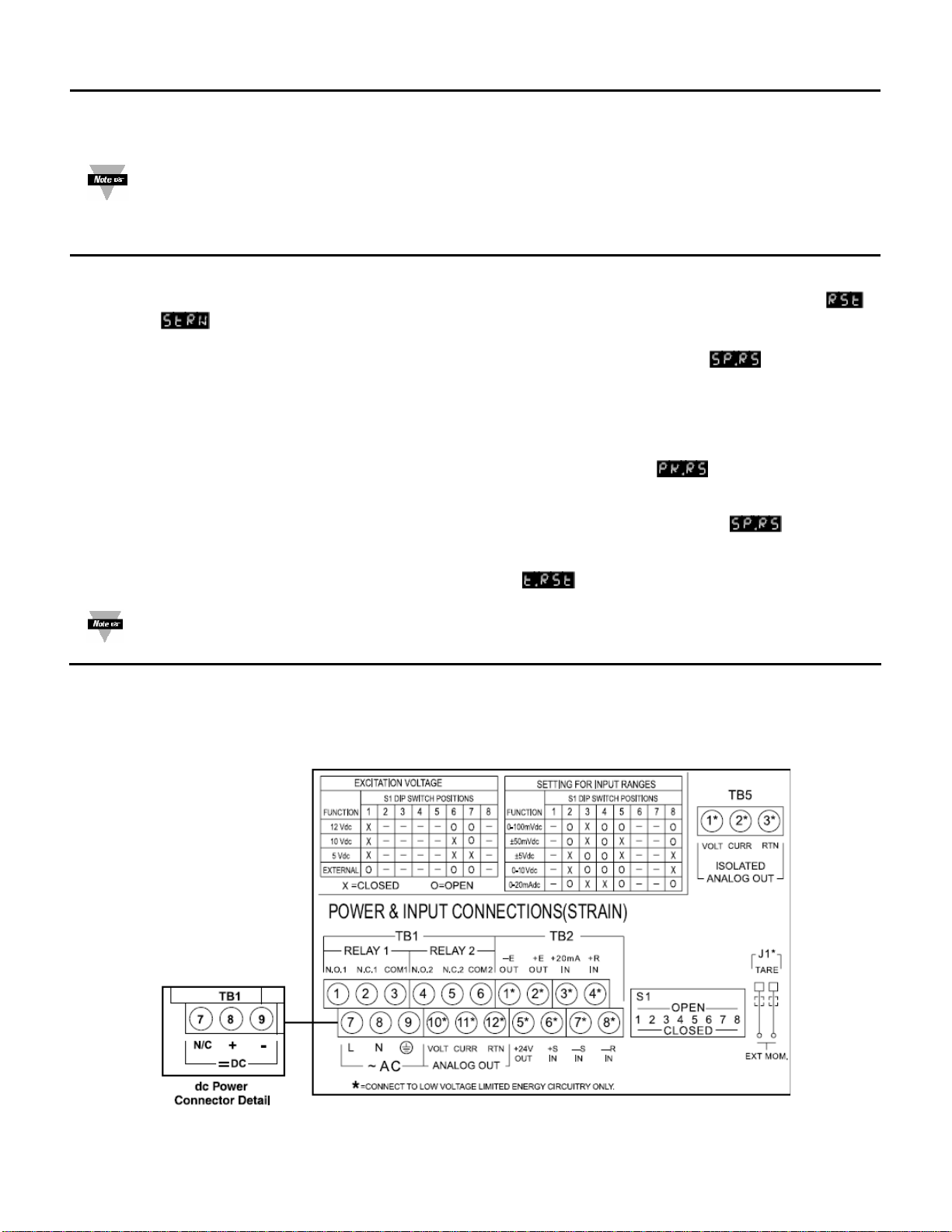

Figure 2-3 shows the label describing the connectors on the back of the meter. Table 2-2 on the following page

gives a brief description of each connector at the back of the meter.

Figure 2-3 Connectors (AC-Powered and DC-Powered Detail)

DFI INFINITY CS (V- M3598/N/0906) 5 CF 70

Page 9

Table 2-2 Connector Description

Connector Description

TB1-1

TB1-2

TB1-3

TB1-4

TB1-5

TB1-6

TB1-7

TB1-8

TB1-9

TB1-10

TB1-11

TB1-12

TB2-1

TB2-2

TB2-3

TB2-4

TB2-5

TB2-6

TB2-7

TB2-8

TB5-1

TB5-2

TB5-3

J1 (1-2) Remote tare connection with a momentary switch

The DIP switches are located at the S1 position (Refer to Figure 3-2). Use a small instrument such as a paper clip

to change the switches from open to closed. Table 2-3 lists DIP switch settings at the S1 position required to

complete the setup of your meter.

Function

C= Closed

O= Open

Internal 5/10/12 excitation

External 5/10/12 excitation

Internal 12 Vdc Excitation

Internal 10 Vdc Excitation

Internal 5 Vdc Excitation

0-100 mV dc

±50 mV dc

±5 Vdc

0-10 Vdc

0-20 mA dc

Setpoint 1: Normally open (N.O.1) connection

Setpoint 1: Normally closed (N.C.1) connection

Setpoint 1: Common (COM1) connection

Setpoint 2: Normally open (N.O.2) connection

Setpoint 2: Normally closed (N.C.2) connection

Setpoint 2: Common (COM2) connection

AC line connection (no connections on DC-powered units)

AC neutral connection (+ Input on DC-powered units)

AC earth ground (DC-power return on DC-powered units)

Analog voltage output

Analog current output

Analog return

-E: Negative excitation connection from meter (5,10,12 V)

+E: Positive excitation connection from meter (5,10,12 V)

+20 mA connection for analog input

+R (Not used)

+24 V output connection

+S: Positive signal input

-S: Negative signal input and return for +20 mA or +24 V

-R (Not used)

Isolated Analog Voltage Output

Isolated Analog Current Output

Isolated Analog Output Return

Table 2-3 DIP Switch Positions/Input Range & Excitation

S1 DIP Switch Positions

1 2 3 4 5 6 7 8

Settings for Excitation Voltage

C - - - - - - O - - - - O O C - - - - O O C - - - - C O C - - - - C C -

Settings for Input Ranges

-

-

-

-

-

O

O

C

C

O

C

C

O

O

C

O

O

O

O

C

O

C

C

O

O

-

-

-

-

-

-

-

-

-

-

O

O

C

C

O

The display must also be configured to the selected input type after setting the DIP switches (see Section

4.1, Selecting the Input Type)

2.6 Disassembly

You may need to open up the meter for one of the following reasons:

DFI INFINITY CS (V- M3598/N/0906) 6 CF 70

Page 10

• To check or change the 115 or 230 Vac power jumpers.

• To install or remove jumpers on the main board.

Disconnect the power supply before proceeding.

To remove and access the main board, follow these steps:

• Disconnect main power from the meter.

• Remove the back case cover.

• Lift the back of the main board upwards and let it slide out of the case.

3.0 GETTING STARTED

Caution: The meter has no power-on switch, so it will be in operation as soon as you apply power.

If you power off/on the meter, or perform a hard reset (press the RESET button twice), the meter shows

followed by

.

3.1 Rating/Product Label

This label is located on top of the meter housing (refer to Figure 3-4).

3.2 Main Board Power Jumpers (Refer To Figure 3-1)

Important: If you want to change the Factory preset jumpers, do the following steps, otherwise go to

Section 3.3.

Warning: Disconnect the power from the unit before proceeding. This device must only be reconfigured

by a specially trained electrician with corresponding qualifications. Failure to follow all instructions and

warnings may result in injury!

1. Remove the main board from the case. Refer to Section 2.6.

2. Locate the solder jumpers W1, W2, and W3 (located near the edge of the main board alongside the

transformer).

3. If your power requirement is 115 Vac, solder jumpers W1 and W3 should be wired, but jumper W2 should

not. If your power requirement is 230 V ac, solder jumper W2 should be wired, but jumpers W1 and W3

should not.

Note: W4 jumper is not used.

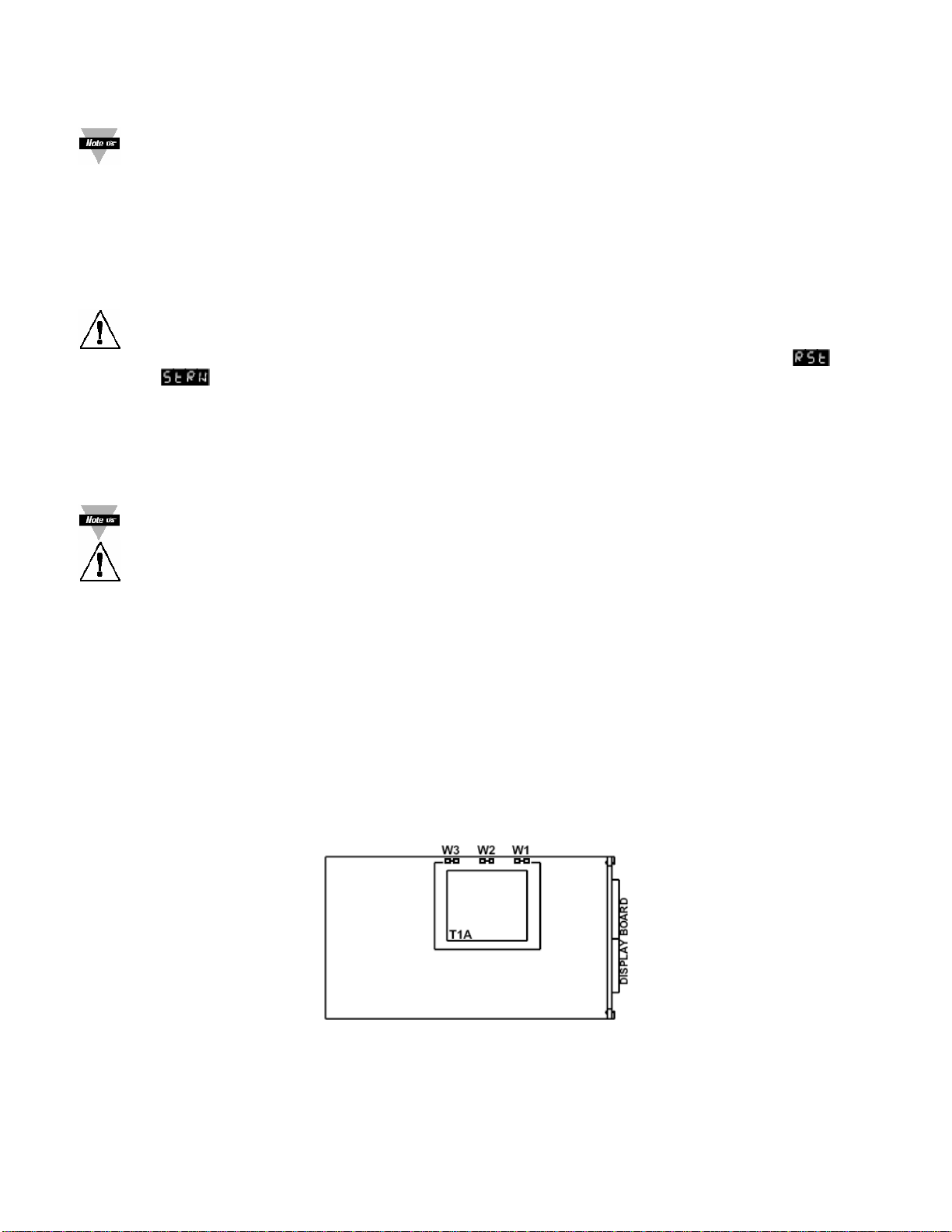

Figure 3-1 shows the location of solder jumpers W1 through W3.

Figure 3-1 Main Board Power Jumpers

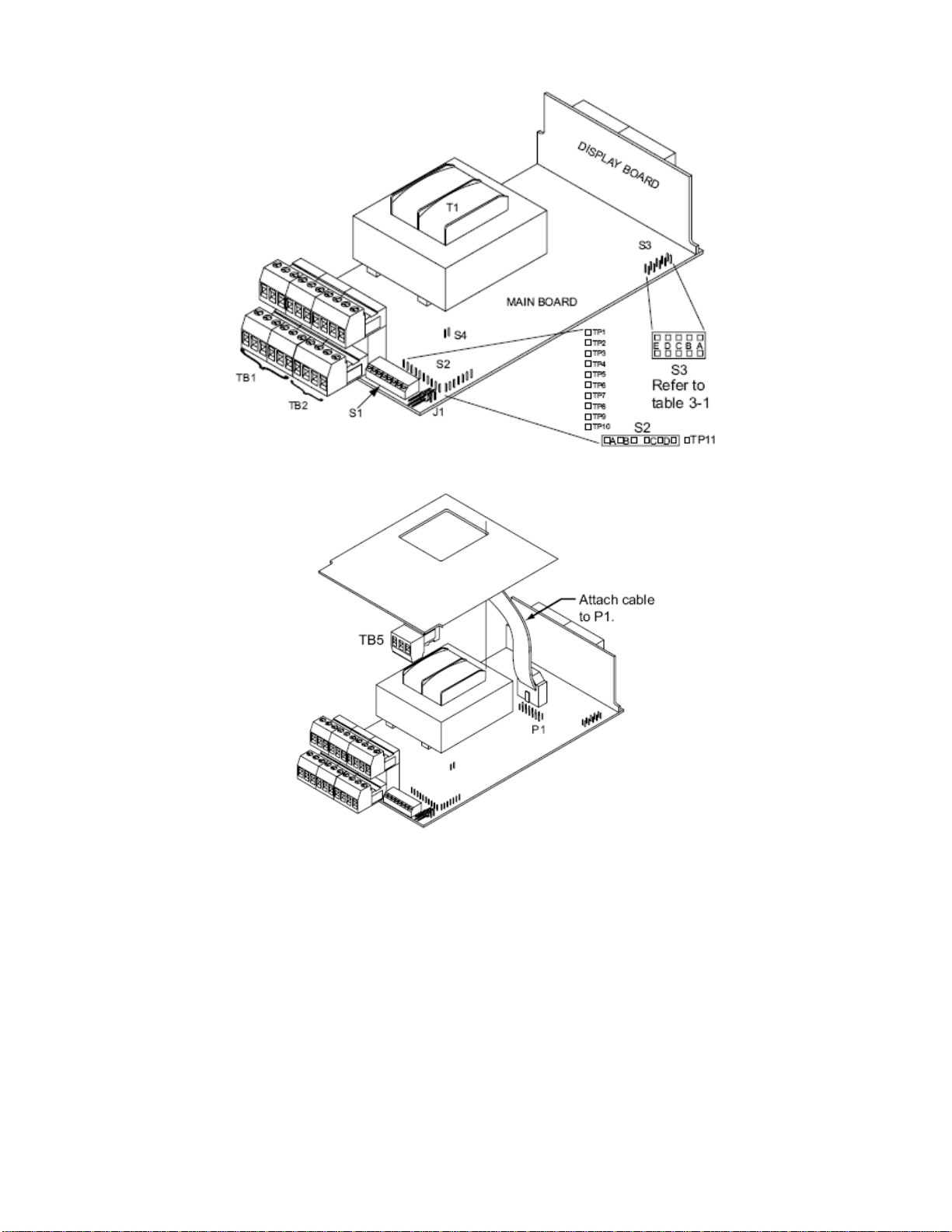

Figure 3-2 shows the location jumper positions on the main board.

DFI INFINITY CS (V- M3598/N/0906) 7 CF 70

Page 11

Figure 3-2 Main Board Jumper Positions

Figure 3-3 Upper Isolated Analog Output Option Board Installation

S2 jumpers are used for testing purposes. Do not use as reading errors may result.

S3 jumpers are used for the following (refer to Figure 3-2):

• To enable or disable the front panel push-buttons

• To allow for an extremely low resistance load button for analog output

• To disable the MENU button

• To perform factory calibration procedure

Test pins TP1 – TP11 are for testing purposes. Do not use as reading errors may result.

S4-A factory default jumper is removed.

DFI INFINITY CS (V- M3598/N/0906) 8 CF 70

Page 12

Jumper Description

S3-A

S3-B Removed. For factory calibration only.

S3-C Removed. Not Used

S3-D Installed for ex ternal ratiometric.

S3-E If installed without S3-B, the MENU button locks out. If you

3.3 Panel Mounting

Table 3-1 S3 Jumper Functions

Install to enable front panel push buttons.

Remove to disable all front panel push-buttons

press the MENU button, the meter shows

.

Figure 3-4 Meter – Exploded View

1. Cut a hole in your panel, as shown in Figure 3-4. For

specific dimensions refer to Figure 3-5.

2. Insert the meter into the hole. Be sure the front bezel

gasket is flush to the panel.

3. Slide on mounting bracket to secure.

4. Proceed to Section 3.4 to connect your sensor input

and main power.

NOTE: Dimensions in Millimeters (Inches)

Figure 3-5 Panel Cut Out

3.4 Connecting Sensor Inputs

Figure 3-6 shows excitation supplied from the meter’s internal supply (50mA maximum). Select 5,10, or 12 volt

excitation at DIP switch.

DFI INFINITY CS (V- M3598/N/0906) 9 CF 70

Page 13

Connections with ”typical wire colors”

+E = Positive Excitation (red)

-E = Negative Excitation (black)

+S = Positive Signal Input (green)

-S = Negative Signal Input (white)

Figure 3-6 Meter-powered Bridge Input

Figure 3-7 shows the connections required for an externally-powered bridge input: the external supply is brought to

the meter’s buffer circuits to permit ratiometric readings. Set S1 DIP switch for external excitation for Figure 3-7

and 3-8.

Connections with ”typical wire colors”

+E = Positive Excitation (red)

-E = Negative Excitation (black)

+S = Positive Signal Input (green)

-S = Negative Signal Input (white)

Figure 3-7 Externally-powered Bridge Input

Figure 3-8 4-Wire DC Input Connections with External Excitation

DFI INFINITY CS (V- M3598/N/0906) 10 CF 70

Page 14

Figure 3-9 Current Input Connections with Internal Excitation

Figure 3-10 Current Input Connections with External Excitation

3.5 Connecting Main Power

Connect the AC main power connections as shown in Figure 3-11.

WARNING: Do not connect AC power to your device until you have completed all input and output

connections. This device must only be installed by a specially trained electrician with correspondin g

qualifications. Failure to follow all instructions and warnings may result in injury!

Figure 3-11 Main Power Connections - AC

Table 3-2 shows the wire color and respective terminal connections for both USA and Europe.

DFI INFINITY CS (V- M3598/N/0906) 11 CF 70

Page 15

Table 3-2 AC-Power Connections

WIRE COLORS

TB1 AC POWER EUROPE USA

7

8

9

Connect the DC main power connections as shown in Figure 3-12.

When using DC power, refer to Table 8-1 Color Chart in the Specifications Section for Display Color,

Intensity, Excitation Voltage and Current, and Analog Output Isolated Option. Failure to use proper ratings

may result in damaging the unit.

AC Line

AC Neutral

AC Earth

Figure 3-12 Main Power Connections DC

Brown Black

Blue White

Green/Yellow Green

3.6 Connecting External Tare Switch

Connect external tare connections as shown in Figure 3-13.

Figure 3-13 External Tare Connections

3.7 Connecting Analog and Relay Outputs

If your have purchased a meter with analog or dual relay or isolated analog output, refer to the following drawings

for output connections.

DFI INFINITY CS (V- M3598/N/0906) 12 CF 70

Page 16

Figure 3-14 Analog Output Connections

Figure 3-15 Relay Output Connections

Figure 3-16 Isolated Analog Output Connections

DFI INFINITY CS (V- M3598/N/0906) 13 CF 70

Page 17

4.0 CONFIGURING THE METER

Refer to Table 6-1 for a summary list of menu configuration.

For first-time users: Refer to the QuickStart Manual for basic operation and set-up instruction s .

4.1 Selecting the Input Type

To select your appropriate input type signal, follow these steps:

Before proceeding, set the input DIP switch settings at the back of your meter. (Refer to

Table 2-3).

1. Press the MENU button. The meter shows

2. Press the X/TARE button. The meter flashes one of the following:

•

•

•

•

•

3. Press the S/NT/GRS button to scroll through available choices.

4. Press the MENU button to store your selection. The meter momentarily shows

(Decimal Point).

(for 0-100 mV dc) (Default)

(for ±50 mV dc)

(for 0-10 V dc)

(for ±5 V dc)

(for 0-20 mA dc).

4.2 Selecting a Decimal Point Position

.

, followed by

Refer to Table 6-1 for a summary list of menu configuration.

To select a decimal point display position, follow these steps:

1. Press the MENU button until the meter shows

2. Press the X/TARE button. The meter shows one of the following:

•

•

•

•

3. Press the S/NT/GRS button to scroll between available choices.

4. Press the MENU button to store your choice. The meter momentarily shows

(Reading Scale and Offset). Or you can press the RESET button to abort and go back to the

(Default)

, followed by

menu.

4.3 Using Reading Scale and Offset

Refer to Table 6-1 for a summary list of menu configuration.

To scale the meter to show readings in engineering units. There are two methods. One method is to scale with

known inputs. Another method is to scale without known inputs: you calculate input values based on the

transducer specifications and manually enter them through the keyboard.

4.3.1 Scaling with Known Loads (On-Line Calibration)

For maximum resolution, find the maximum signal that will be applied to the meter input.

• For regular voltage input, refer to the main body of Table 4-1.

• For millivolt or milliamp input, refer to the main body of Table 4-2.

Set the DIP switch positions as indicated at the top of either Table 4-1 or 4-2. The numbers 1 through 8 in the top

row of either table represent dip switches 1 through 8 and the O, C or X directly below the number indicates the

correct position of each switch.

• ‘O’ switch should be open or up.

DFI INFINITY CS (V- M3598/N/0906) 14 CF 70

Page 18

• ‘C’ switch should be closed or down.

• ‘X’ switch is used to control excitation (refer to Table 2-3 to determine correct position of these switches).

Once DIP switches have been positioned correctly, apply power. Proceed to the

(Reading Configuration)

and set R2 equal to the value in the right hand column of the chart.

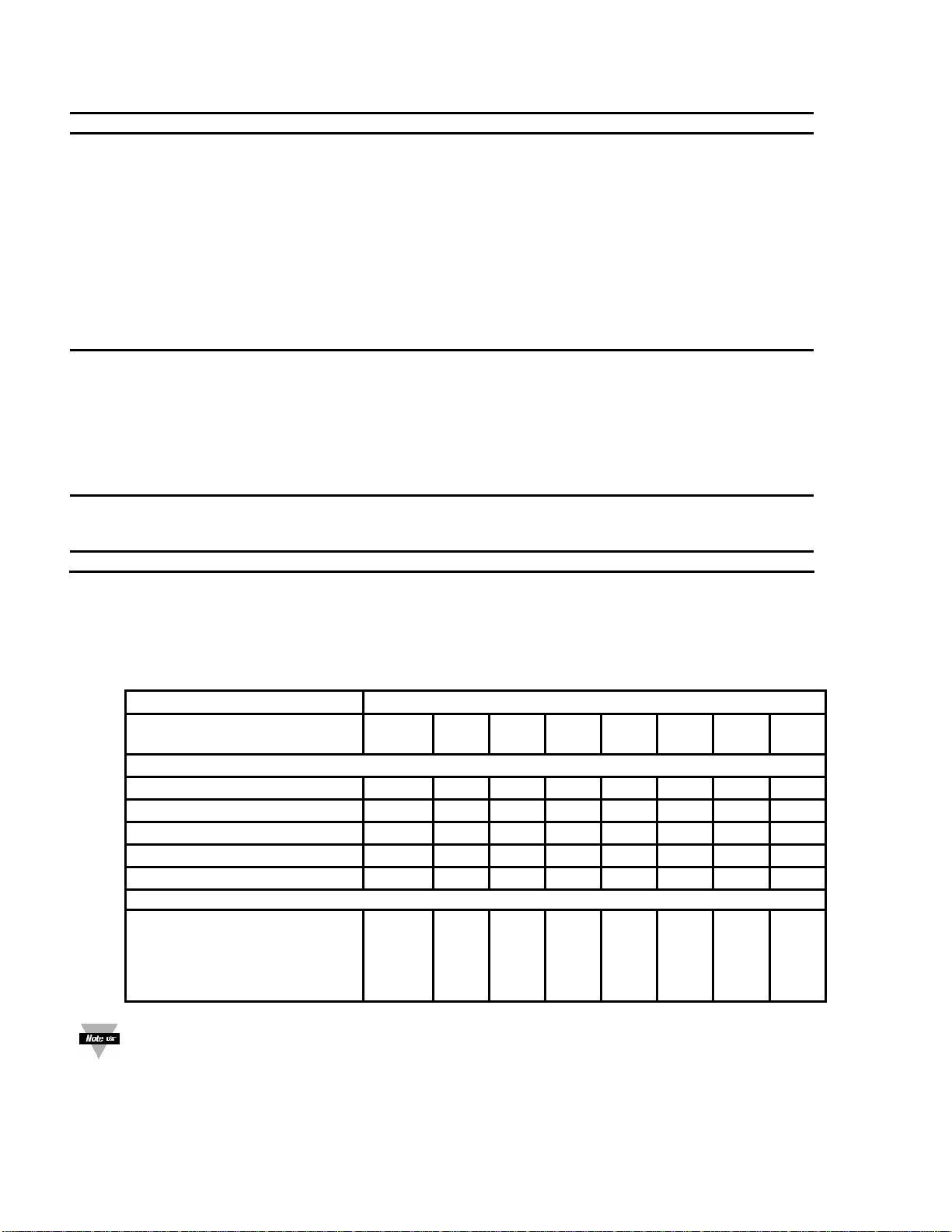

Table 4-1 Range Selection DIP Switch Positions for Regular Voltage Input

12345678

XCOOOXXC

12345678

XCOOCXXC

RD.CF*

R2=

0 – 10 V ±5 V 4

0 – 5 V ±5 V 3

0 – 3 V ±3 V 2

0 – 2 V ±2 V 1

0 – 1 V ±1 V 0

Table 4-2 Range Selection DIP Switch Positions for Millivolt/Milliamp Input

12345678

XOCOOXX0

12345678

XOCOCXX0

12345678

XOCCOXX0

RD.CF*

R2=

0 – 100 mV ±50 mV 0 – 20 mA 4

0 – 50 mV ±50 mV 0 – 10 mA 3

0 – 30 mV ±30 mV 0 – 6 mA 2

0 – 20 mV ±20 mV 0 - 4 mA 1

0 – 10 mV ±10 mV 0 – 2 mA 0

* Reading Configuration

To scale with known inputs: apply known loads to a transducer connected to a meter, or simulate the transducer

output with a voltage or current simulator. To scale with known inputs, follow these steps:

1. Apply a known load equal to approximately 0% of the transducer range.

2. Press the MENU button until the meter shows

.

3. Press the X/TARE button. The meter shows (Input 1).

(Input 1) is the unscaled display reading at minimum input.

4. Press the X/TARE button again. The meter shows the last stored value for Input 1.

5. Press the X/TARE button once more. The meter shows the actual signal being received.

6. Press the MENU button to store this value as

(Input 1). The meter shows (Read 1).

(Read 1) is the desired display reading at Input 1.

7. Press the X/TARE button. The meter shows the last stored value for Read 1.

8. Press the S/NT/GRS button to change the value of your digits.

9. Press the X/TARE button to scroll horizontally to the next digit.

10. Press the MENU button to store this value as

(Input 2) is the unscaled display reading at maximum input.

. The meter shows (Input 2).

11. Apply a known load equal to approximately 100% of the transducer range.

12. Press the X/TARE button again. The meter shows the last stored value Input 2.

13. Press the X/TARE button once more. The meter shows the actual signal being received.

14. Press the MENU button to store Input 2 value. The meter shows

(Read 2).

(Read 2) is the desired display reading at Input 2.

15. Press the X/TARE button. The meter shows the last stored value for Read 2.

16. Press the S/NT/GRS button to change the value of your digits.

17. Press the X/TARE button to scroll horizontally to the next digit.

18. Press the MENU button to store this value as

by

. Meter scaling is now complete.

(Read 2). The meter momentarily shows , followed

DFI INFINITY CS (V- M3598/N/0906) 15 CF 70

Page 19

4.3.2 Scaling without Known Loads

To scale without known inputs, calculate input values based on transducer specifications and manually enter them

via the front-panel push buttons. The following example assumes load cells with these specifications:

Maximum Load: 100.0 lbs

Output: 3.1 mV/V

Sensor Excitation: 10 Vdc

Output: 31 mV = (3.1 mV/V) x (10 V)

1. Determine the correct values for

are equal to the minimum and maximum of the transducer output span. The example assumes &

are equal to the range of the load = 0 and = 100.0). Calculate and using the

load cell output span and the following equation:

= (Sensor Output) x (Natural Gain) x (Multiplier).

Input range Span units Natural gain

0 to 100 mV Millivolts 100 cts/mV

±50 mV Millivolts 40 cts/mV

0 to 10 V Volts 1000 cts/V

±5 V Volts 400 cts/V

0 to 20 mA Milliamps 500 cts/mA

2. Determine the multiplier by the Input Resolution setting (

Typically

3. Determine

4. Press MENU button until the meter shows

5. Press the X/TARE button. The meter shows

6. Press the X/TARE button again. The meter shows the last Input 1 value, with the fourth digit flashing.

7. Press the S/NT/GRS button to change the value of your digits.

8. Press the X/TARE button to scroll horizontally to the next digit.

9. Press the MENU button to store this value. The meter shows

10. Press the X/TARE button. The meter shows the last value for Read 1.

Repeat steps 7, 8 and 9 until

stored.

INPUT RANGE R.2 = 4 R.2 = 3 R.2 =2 R.2 = 1 R.2 =0

0 to 100 mV 1.000 2.000 3.333 5.000 10.00

0 to 10 V 1.000 2.000 3.333 5.000 10.00

0 to 20 mA 1.000 2.000 3.333 5.000 10.00

±50 mV 1.000 1.000 1.667 2.500 5.000

±5 V 1.000 1.000 1.667 2.500 5.000

resolution (

Example:

is suitable for most applications.

and input range and resolution. The example selects the 0 to 100 mV range and 10 uV

).

= (0 mV) x (100 cts/mV) x (1.000) =0

= (31 mV) x (100 cts/mV) x (1.000) = 3100

= 0000

= 100.0

, and have been displayed, verified, changed (if necessary) and

and , based on the load cell specifications. In most cases, &

Table 4-3 Natural Gain

in the menu) and the input range selected.

Table 4-4 Input Resolution Multiplier

.

.

.

4.4 Using Reading Configuration

Refer to Table 6-1 for a summary list of menu configuration.

DFI INFINITY CS (V- M3598/N/0906) 16 CF 70

Page 20

You may use Reading Configuration to configure your meter for the following:

• To select ratiometric or non-ratiometric operation

• To set the input resolution of your meter

• To display the filtered/unfiltered signal input value

• To select gross/net vs. peak reading

4.4.1 Selecting Ratiometric/Non-Ratiometric Operation

1. Press the MENU button until displays.

2. Press the X/TARE button. The meter flashes one of the following:

•

•

3. Press the S/NT/GRS button to view the last stored selection and to toggle between selections.

4. Press the X/TARE button to select input resolution or press the MENU button to store your selection and

shows

(Ratiometric reading) (Default – for strain meters)

(Non-ratiometric reading – typically for voltage & current transducers)

menu.

4.4.2 Setting Input Resolution

To set the input resolution of your meter, follow these steps:

1. Press the MENU button until

or

Press the X/TARE button from

One of the following displays (default is

= 10µV Unipolar inputs. 25 µV for bipolar inputs.

= 1µv for Unipolar inputs. 5 µV for bipolar inputs.

= 2µV for Unipolar inputs. 10 µV for bipolar inputs.

= 3µV for Unipolar inputs. 15 µV for bipolar inputs.

= 5µV for Unipolar inputs. 25µV for bipolar inputs.

Example: 3 µV resolution means that if you input 0-30 mV, at 30 mV the meter shows

2. Press the S/NT/GRS button to scroll through available selections.

3. Press the X/TARE button to display the filtered/unfiltered signal input or press the MENU button to store your

selection and shows

menu.

displays, then press the X/TARE button twice.

.

):

.

4.4.3 Displaying the Filtered/Unfiltered Input Signal

To display the filtered/unfiltered signal input, follow these steps:

1. Press the MENU button until

or

Press the X/TARE button from

One of the following displays:

•

•

2. Press the S/NT/GRS button to toggle between available choices.

3. Press the MENU button to store your selections.

= (Filtered value) (Default)

= Unfiltered value

displays, then press the X/TARE button three times.

.

momentarily displays, followed by Menu.

4.4.4 Selecting Gross/Net or Peak Display

To select gross/net or peak display.

1. Press the MENU button until

or

Press the X/TARE button from

One of the following displays:

•

•

2. Press the S/NT/GRS button to toggle between available choices.

3. Press the MENU button to store your selections.

= Gross/Net Display (Default)

= Peak Display

displays, then press the X/TARE button three times.

.

momentarily displays, followed by Menu.

DFI INFINITY CS (V- M3598/N/0906) 17 CF 70

Page 21

4.5 Selecting a Display Color

Refer to Table 6-1 for a summary list of menu configuration.

Selecting Display Color is not active unless your meter is a Version “B”.

To select a display color, follow these steps:

1. Press the MENU button until the meter shows

2. Press the X/TARE button. The meter shows one of the following:

•

•

•

3. Press the S/NT/GRS button to scroll between available choices.

Press the MENU button to store your choice. The meter momentarily shows

(Setpoint 1 Configuration). Or you can press the RESET button to abort and go back to the menu.

4.6 Using Setpoint 1 Configuration

Refer to Table 6-1 for a summary list of menu configuration.

Setpoint 1 Configuration

display whether the

• To set the setpoint’s active band above or below your chosen value

• To select whether the setpoint operation is latched or unlatched

• Assigning setpoint values to the net or gross reading

4.6.1 Setting Setpoint 1’s Active Band

1. Press the MENU button until the meter shows .

2. Press the X/TARE button. The meter shows one of the following:

•

•

3. Press the S/NT/GRS button to toggle between available choices.

4. Press the X/TARE button to select if Setpoint 1 is latched/unlatched or press the MENU button to store your

selection. The unit shows

= (Active above the setpoint) (Default)

= Active below the setpoint

4.6.2 Selecting if Setpoint 1 is Latched of Unlatched

1. Press the MENU button until displays, then press the X/TARE button twice.

or

Press the X/TARE button from

The meter shows one of the following:

•

•

2. Press the S/NT/GRS button to toggle between available choices.

3. Press the X/TARE button to assign Setpoint 1 values to net or gross reading or press the MENU button to

enter

= Setpoint 1 to be unlatched (Default)

= Setpoint 1 to be latched

(Setpoint 2 Configuration).

4.6.3 Assigning Setpoint 1 Values to Net or Gross Readings

1. Press the MENU button until displays, then press the X/TARE button twice.

or

Press the X/TARE button from

The meter shows one of the following:

is not active unless your meter has dual relay output capabilities. The LED’s will

is active or not. You may use Setpoint 1 Configuration for the following:

.

.

.

.

, followed by the next menu

DFI INFINITY CS (V- M3598/N/0906) 18 CF 70

Page 22

• = Setpoint 1 assigned to net reading (Default)

•

2. Press the S/NT/GRS button to toggle between available choices.

3. Press the MENU button to store your selection(s). The meter momentarily shows

(Setpoint 2 Configuration).

= Setpoint 1 assigned to gross reading

, followed by

4.7 Using Setpoint 2 Configuration

Refer to Table 6-1 for a summary list of menu configuration.

Setpoint 2 Configuration

display whether the

• To set setpoint’s active band above or below your chosen value

• To select whether the setpoint operation is latched or unlatched

• To assign setpoint values to the net or gross reading

is not active unless your meter has dual relay output capabilities. The LED’s will

is active or not. You may use Setpoint 2 Configuration for the following:

4.7.1 Setting Setpoints 2’s Active Band

1. Press the MENU button until the meter shows .

or

2. Press the X/TARE button. The meter shows one of the following:

•

•

3. Press the S/NT/GRS button to toggle between available choices.

4. Press the X/TARE button to select if Setpoint 2 is latched/unlatched or press the MENU button to store your

selection. The meter shows

= (Active above the setpoint) (Default)

= (Active below the setpoint)

.

4.7.2 Selecting if Setpoint 2 is Latched or Unlatched

1. Press the MENU button until displays, then press the X/TARE button twice.

or

Press the X/TARE button from

The meter shows one of the following:

•

•

2. Press the S/NT/GRS button to toggle between available choices.

3. Press the MENU button to store your selection(s). The meter momentarily shows

(Setpoint 1 Deadband).

= Setpoint 2 to be unlatched (Default)

= Setpoint 2 to be latched

.

, followed by

4.7.3 Assigning Setpoint 2 Values to Net or Gross Readings

1. Press the MENU button until displays, then press the X/TARE button twice.

or

Press the X/TARE button from

The meter will show one of the following:

•

•

2. Press the S/NT/GRS button to toggle between available choices.

3. Press the MENU button to store your selection(s). The meter momentarily shows

(Setpoint 1 Deadband).

= Setpoint 2 assigned to net reading (Default)

= Setpoint 2 assigned to gross reading

.

, followed by

4.8 Setting the Setpoint 1 Deadband

Refer to Table 6-1 for a summary list of menu configuration.

Setpoint 1 Deadband

display whether the

(hysteresis) of Setpoint 1, follow these steps:

DFI INFINITY CS (V- M3598/N/0906) 19 CF 70

is not active unless your meter has dual relay output capabilities. The LED’s will

is active or not. The Setpoint 1 Default deadband is 0003. To change the deadband

Page 23

1. Press the MENU button until the meter shows .

2. Press the X/TARE button. The meter shows the last previously stored 4-digit number (0000 through 9999)

with flashing 4

th

digit.

3. Press the S/NT/GRS button to change the value of the flashing digit. If you continue to press the S/NT/GRS

button, the flashing digit’s value continues to change.

4. Press the X/TARE button to scroll to the next digit.

5. Press the MENU button to store the selection. The meter momentarily shows

, followed by

(Setpoint 2 Deadband).

4.9 Setting the Setpoint 2 Deadband

Refer to Table 6-1 for a summary list of menu configuration.

Setpoint 2 Deadband

display whether the

(hysteresis) of Setpoint 2, follow these steps:

1. Press the MENU button until the meter shows

2. Press the X/TARE button. The meter shows the last previously stored 4-digit number (0000 through 9999)

with flashing 4

th

digit.

3. Press the S/NT/GRS button to change the value of the flashing digit. If you continue to press the S/NT/GRS

button, the flashing digit’s value continues to change.

4. Press the X/TARE button to scroll to the next digit.

5. Press the MENU button to store your selection. The meter momentarily shows

(Output Configuration) if you have analog output capabilities.

is not active unless your meter has dual relay output capabilities. The LED’s will

is active or not. The Setpoint 2 default deadband is 0003. To change the deadband

.

, followed by

Figure 4-1 Alarm Example

DFI INFINITY CS (V- M3598/N/0906) 20 CF 70

Page 24

To reset latched alarms you must:

1. Input a signal OUT of the alarm zone

2. Then press SETPTS and then, RESET button

4.10 Using Output Configuration

Refer to Table 6-1 for a summary list of menu configuration.

Output Configuration

whether analog output is present or not. Analog output must be ordered at time of purchase.

Use Output Configuration

• To enable or disable the analog output

• To select if the analog output is current or voltage

• To assign the output to the net or gross reading

is not active unless your meter has analog output capabilities. The menu will display

to select the following:

4.10.1 Enabling or Disabling the Analog Output

To enable or disable the analog output, follow these steps:

1. Press the MENU button until the meter shows

2. Press the X/TARE button. The meter shows one of the following:

•

•

3. Press the S/NT/GRS button to toggle between available choices.

4. Press the X/TARE button to select analog output as current or voltage or press the MENU button to store your

selection and enter

= (Analog output enabled) (Default))

= (Analog output disabled)

(Output Scale and Offset).

.

4.10.2 Selecting Analog Output as Current or Voltage

1. Press the MENU button until it shows , and then press the X/TARE button twice.

or

Press the X/TARE button from

The meter will show one of the following:

•

•

2. Press the S/NT/GRS button to toggle between available choices.

3. Press the X/TARE button to select analog output or proportional control or press the MENU button to store

your selection and enter

= (Analog output=current) (Default)

= (Analog output=voltage)

.

(Output scale and Offset).

4.10.3 Selecting Analog Output or Proportional Control

1. Press the MENU button until it shows , and then press the X/TARE button twice.

or

Press the X/TARE button from

The meter shows one of the following:

•

•

2. Press the S/NT/GRS button to toggle between available choices.

3. Press the MENU button to store your selection. The meter momentarily shows:

(Output Scale and Offset).

= (Net Reading) (Default)

= (Gross Reading)

.

, followed by

4.11 Using Output Scale and Offset

Refer to Table 6-1 for a summary list of menu configuration.

Output Scale and Offset

display whether analog output is present or not. Output Scale and Offset

DFI INFINITY CS (V- M3598/N/0906) 21 CF 70

is not active unless your meter has analog output capabilities. The menu will

scales your analog output to be

Page 25

equal to the meter’s display and/or any engineering units you require. You may scale the output for direct (4-20

mA, 0-10 V, etc) or reverse acting (20-4 mA, 10-0 V, etc).

1. Press the MENU button until

2. Press the X/TARE button.

displays.

(Read 1) displays.

This is your first point of display reading.

3. Press the X/TARE button again. The meter shows the last previously stored 4-digit number (-1999 through

9999) with flashing 4

th

digit.

4. Press the S/NT/GRS button to change the digits.

5. Press the X/TARE button to scroll to the next digit.

6. Press the MENU button to store your selection.

(Output 1) displays.

This starting analog signal corresponds to your Read 1 display.

7. Press the X/TARE button. Selected output displays.

If you select

signal output. If you select

for voltage, the maximum signal you may select is 10.00 for a 0-10 Vdc

for current, the maximum signal you may select is 20.00.

8. Press the S/NT/GRS button to enter the Output 1 signal selection. If you continue to press the S/NT/GRS

button, the flashing digit’s value continues to change.

9. Press the X/TARE button to scroll horizontally to the next digit.

10. Press the MENU button to store your selection.

(Read 2) displays.

This is your second point of display reading.

11. Press the X/TARE button. The meter shows the last previously stored 4-digit number (-1999 from 9999) with

flashing 4

th

digit.

12. Press the S/NT/GRS button to change the value of the flashing digit. If you continue to press the S/NT/GRS

button, the flashing digit’s value continues to change.

13. Press the X/TARE button to scroll horizontally to the next digit.

14. Press the MENU button to store your selection. The meter shows

(Output 2).

This analog signal should correspond to your Read 2 display.

15. Press the X/TARE button. The meter shows the selected output.

If you select

If you select

for voltage, the maximum signal you may select is 10.00 for a 0-10 V signal output.

for current, the maximum signal you may select is 20.00 for a 0-20 or 4-20 mA DC

signal output.

16. Press the S/NT/GRS button to change the value of the flashing digit. If you continue to press the S/NT/GRS

button, the flashing digit’s value continues to change.

17. Press the X/TARE button to scroll horizontally to the next digit.

18. Press the MENU button to store your selection. The meter momentarily shows , followed by

(Lock Out configuration).

WARNING: If the meter shows flashing values on any time, the value has overflowed. Press the

S/NT/GRS button to start new values.

4.11.1 Examples for Output Scale and Offset

Example: You want to spend 4-20 mA output for 0 to 100.0. The meter has 0.1 degrees resolution. Complete the

following steps:

1. Press the MENU button until the meter shows

2. Press the X/TARE button. The meter shows

3. Press the X/TARE button to show the existing value.

4. Change the value of Read 1 to 000.0 by pressing the S/NT/GRS and X/TARE buttons.

5. Press the MENU button to store your selection. The meter shows

6. Press the X/TARE button to show the existing value.

7. Change the value of Output 1 to 04.00 by pressing the S/NT/GRS and X/TARE buttons.

8. Press the MENU button to store your selection. The meter shows

.

(Read 1).

(Output 1).

(Read 2).

DFI INFINITY CS (V- M3598/N/0906) 22 CF 70

Page 26

9. Press the X/TARE button to show the existing value.

10. Change the value of Read 2 to 100.0 by pressing the S/NT/GRS and X/TARE buttons.

11. Press the MENU button to store your selection. The meter shows

12. Press the X/TARE button to show the existing value.

13. Change the value of Output 2 to 20.0 by pressing the S/NT/GRS and X/TARE buttons.

14. Press the MENU button to store your selection. The meter shows

(Output 2).

(Lock Out Configuration).

4.12 Using Lock Out Configuration

Refer to Table 6-1 for a summary list of menu configuration.

Use Lock Out Configuration

• To enable or disable setpoint changes

• To enable or disable the RESET button in the Run Mode

• To enable or disable displaying meter firmware version

for the following:

4.12.1 Enabling or Disabling the RESET button in the Run Mode

1. Press the MENU button until the meter shows (after .)

2. Press the X/TARE button. The meter shows one of the following:

•

•

3. Press the S/NT/GRS button to toggle between available choices.

4. Press the MENU button to store the changes. The meter shows

the meter shows

= To enable the RESET button in the Run mode (Default)

= To disable the RESET button in the Run mode

if the new value is different otherwise

and returns to the Run mode.

4.12.2 Enabling or Disabling the SETPOINT Changes

1. Press the MENU button until the meter shows (after )

2. Press the X/TARE button twice. The meter shows one of the following:

•

•

3. Press the S/NT/GRS button to toggle between available choices.

4. Press the MENU button to store the changes. The meter shows

the meter shows

= To enable the setpoint changes (Default)

= To disable the setpoint changes

if the new value is different otherwise

and returns to the Run Mode.

4.12.3 SETPOINT Display Function: Firmware version or Setpoint value

1. Press the MENU button until the meter shows (after )

2. Press the X/TARE button three times. The meter shows one of the following:

•

•

3. Press the S/NT/GRS button to toggle between the choices above.

4. Press the MENU button to store the changes. The meter shows

the meter shows

= SETPTS button will display setpoint values.

= SETPTS button will display the meter’s firmware version.

if the new value is different otherwise

and returns to the Run Mode.

If your meter does not have the relay option, setpoint menu items above will not be available and SETPTS

button will always display the meter’s firmware version. These units will have

memory indicated by Alarm 1 & 2 LED displays. LEDs can be reset by pressing MENU then RESET

button or by Power OFF then ON.

4.13 Using Display Brightness Configuration

(overload) or

4.13.1 Changing Brightness Level

Changing Display Brightness is not active unless your meter is a Version “B”.

1. Press the MENU button the meter shows

2. Press the X/TARE button from

DFI INFINITY CS (V- M3598/N/0906) 23 CF 70

. The meter shows one of the following:

(after ).

Page 27

• = Medium Brightness

•

•

3. Press the S/NT/GRS button to toggle between available choices.

4. Press the MENU button to store your selection. The meter momentarily shows

= Low Brightness

= High Brightness(Default)

, , and then measured value.

5.0 DISPLAY MESSAGES

Table 5-1 Display Messages

MESSAGE DESCRIPTION

Strain Meter

Hard (Power On) Reset

Input Type

Decimal Point Position

Reading Scale and Offset

Reading Configuration

Display Color

Setpoint 1 Configuration

Setpoint 2 Configuration

Setpoint 1 Deadband

Setpoint 2 Deadband

Output configuration

Output Scale and Offset

Lock Out configuration

Display Brightness

+Overload Signal

- Overload Signal

Resolution Overflow

Value Overflow in Setpoint/Menu Routines

Value Overflow in Setpoint/Menu Routines

Net Value Overflow

Gross Value Overflow

2 Coordinate Format Programming Error

Peak Value

Peak Reset

Tare Reset

Setpoint Reset

Net Value

Gross Value

Setpoint 1 Value

Setpoint 2 Value

Resolution Over Scale

Firmware Version (where 8 is 0 ~ 9)

Operating Mode

followed by ,

DFI INFINITY CS (V- M3598/N/0906) 24 CF 70

Page 28

6.0 MENU CONFIGURATION DISPLAYS

Not all items display on standard meters.

Table 6-1 Menu Configuration Displays

(Defaults in Bold and Italics)

MENU X/TARE S/NT/GRS

Show input choices:

Show current decimal point position

(Reading Scale &

Offset)

Enter new value

2

and show

Enter new value

4

and show

Enter new value

6

and show

Show

1

Shows prior value entered and flashing

digit. Scrolls to the next digit

• If X/TARE is pressed, actual input is

shown and cannot be changed with

S/NT/GRS.

• If S/NT/GRS is pressed, unit can

scroll through digits with X/TARE.

Shows prior value entered and flashing

3

digit. Scrolls to the next digit.

Shows prior value entered and flashing

5

digit. Scrolls to the next digit.

• If X/TARE is pressed, actual input is

shown and cannot be changed with

S/NT/GRS.

• If S/NT/GRS is pressed, unit can

scroll through digits with X/TARE.

Shows prior value entered and flashing

7

digit. Scrolls to the next digit.

(Default)

(Default)

Changes the value of the flashing

digit.

Changes the value of the flashing

digit.

Changes the value of the flashing

digit.

Changes the value of the flashing

digit.

DFI INFINITY CS (V- M3598/N/0906) 25 CF 70

Page 29

MENU X/TARE S/NT/GRS

Reading Configuration

Display Color Selection

Setpoint 1 Configuration

R.1=

R.2=

R.3=

R.4=

Show input choices:

S.1=

(Ratiometric Reading)

(Non-ratiometric reading)

(1µV resolution for unipolar & 5µV

resolution for bipolar)

(2µ V resolution for unipolar & 10µV

resolution for bipolar)

(3µ V resolution for unipolar & 15µV

resolution for bipolar)

(5µ V resolution for unipolar & 25µV

resolution for bipolar)

(10µ V resolution for unipolar & 25µV

resolution for bipolar)

Note: 3 µV resolution means if your input is 0-30mV,

at 30mV the display shows 9999.

(Filtered value)

(Unfiltered value)

(Gross/Net Display)

(Peak Display)

Green

Red

Amber

(Active above)

(Active below)

Setpoint 2 Configuration

Setpoint 1 Deadband

Setpoint 2 Deadband

S.2=

S.3=

S.1=

S.2=

S.3=

Press to scroll to the next

digit to the right.

Press to scroll to the next

digit to the right

(Unlatched)

(Latched)

(Net Reading)

(Gross Reading)

(Active above)

(Active below)

(Unlatched)

(Latched)

(Net Reading)

(Gross Reading)

Press to change the value of the flashing digit.

Press to change the value of the flashing digit

DFI INFINITY CS (V- M3598/N/0906) 26 CF 70

Page 30

MENU X/TARE S/NT/GRS

Output Configuration

0.1 =

0.2 =

(Analog output is enabled)

(Analog output is disabled)

(Analog output is current)

(Analog output is voltage)

Output Scale & Offset

(Shown if

Configuration Menu

Enter new value and

2

show

Enter new value and

4

show

Enter new value and

6

show

Lock Out Configuration

in Output

.

.

.

0.3 =

Show

1

)

Shows prior value

entered and flashing digit.

Scrolls to the next digit

Shows prior value

3

entered and flashing digit.

Scrolls to the next digit.

Shows prior value

5

entered and flashing digit.

Scrolls to the next digit.

Shows prior value

7

entered and flashing digit.

Scrolls to the next digit.

RS =

Changes the value of the flashing digit.

Changes the value of the flashing digit.

Changes the value of the flashing digit.

Changes the value of the flashing digit.

(Net Reading)

(Gross Reading)

(Enable RESET button in the Run Mode)

(Disable RESET button in the Run Mode)

Brightness Configuration

DFI INFINITY CS (V- M3598/N/0906) 27 CF 70

Shows input choices:

SP =

L3 =

(Enable setpoint changes)

(Disable setpoint changes)

(SETPTS button display setpoint values)

(SETPTS button display firmware version

(Medium Brightness)

(Low Brightness)

(High Brightness)

where 8 is 0 ~ 9)

Page 31

Table 6-2 Run Mode Displays

Display X/TARE S/NT/GRS RESET Description

/

Displays NET or GROSS

Press to

activate

reading. Once reading shows,

respective value shows.

Will reset your

tare when

viewing this

function

Peak Reading

Toggle between Net and Gross

values.

Tare Reset

Reset Latched Alarms

Pressing the RESET button

resets your latched alarm

7.0 SETPOINT CONFIGURATION DISPLAYS

Table 7-1 Setpoint Configuration Displays

MENU X/TARE S/NT/GRS Description

Press to scroll to the

next digit to the right

Press to scroll to the

next digit to the right

Press to change the

value of the flashing

digit

Press to change the

value of the flashing

digit

SETPOINT 1

Select from –1999 through 9999

SETPOINT 2

Select from –1999 through 9999

8.0 SPECIFICATIONS

SIGNAL INPUT

Input Ranges: 0-100mV, ± 50 mV, 0-10 V, ± 5 V, 0-20 mA, 4-20 mA

Isolation: Dielectric strength to 2500V transient per 3mm spacing based on EN 61010 for

260Vrms of DC working Voltage

Noise Rejection: Normal Mode Rejection (NMR) = 60dB

Common Mode Rejection (CMR) = 120dB

Resistance: 100 Meg ohms for 100 mV or ±50 mV input range

1 Meg ohm for 10 or +5 V input range

5 ohms for 20 mA current input range

Big Display

Symbol:

Standard Display: 4-digit, 14-segment LED, 13.8 mm (0.54”)

Symbol:

: 4-digit, three color programmable 9-segment, LED 21 mm (0.83”)

(-1.9.9.9 ~ 9.9.9.9)

(-1.9.9.9 ~ 9.9.9.9.)

ANALOG TO DIGITAL

Technique: Dual slope

Internal resolution: 15 bits

Read Rate: 3/sec Polarity Automatic

DFI INFINITY CS (V- M3598/N/0906) 28 CF 70

Page 32

ACCURACY AT 25oC

Max Error Strain: ±0.03% of reading, ± 1 count

Span Tempco: 50 ppm/°C

Step Response: 1 sec

Warm Up to Rated Accuracy: 30 min

Excitation Voltage: AC power units

24 V @ 25 mA, Refer to Table 8-1

12 V @ 50 mA, Color chart for DC Output

10 V @ 120 mA, Excitation

5 V @ 60 mA

Load Regulation: 1.1%

Line Regulation: 0.02% per Vac

DC power units

ALARM OUTPUTS (if applicable)

2 Form “C” on/off relays. Configurable for latched and unlatched by software.

Max current: 5 AMPS, resistive load

Max voltage: 250 Vac or 30 Vdc

ANALOG OUTPUT (if applicable)

Signal Type: Current or voltage

Signal Level: Current: 10 V max compliance at 20 mA output

Voltage: 20 mA max for 0-10 V output

Function: May be assigned to a display range or proportional control output with setpoint #1

when used as a control output.

Linearity: 0.2%

Step Response Time: 2 – 3 seconds to 99% of the final value

ISOLATED ANALOG OUTPUT (TB5, if applicable)

Same as non-isolated analog output except isolated.

Signal Type: Current or voltage

Signal Level: Current: 10 V max compliance at 20 mA output

Voltage: 20 mA max for 0-10 V output

Function: May be assigned to a display range or proportional control output with Setpoint #1

when used as a control output.

Linearity: 0.2%

Step Response Time: 2 – 3 seconds to 99% of the final value

Isolation: 130 Vrms working voltage, 1000 V/60sec Dielectric test

Only one analog output is available on each unit and it must be factory installed.

INPUT POWER INFORMATION

AC units 115/230 V~(AC) ±10%, 50/60 Hz

9.5 W max, power consumption (Non-Isolated Analog Out)

11.0 W max, power consumption (Isolated Analog Out)

DC Units 10-32 Vdc or 26-56 Vdc, 8 W

Do not use a combination of dc power and internal excitation or Isolated Analog

Out, unless using dc power of 20-32 Vdc.

Refer to Table 8-1 below

External Fuse Required:

DFI INFINITY CS (V- M3598/N/0906) 29 CF 70

IEC 127-2/111

Power Fuse

115V 125 mA @ 250 (T)

230V 63 mA @ 260 (T)

UL 248-14 (Listed Fuse)

Power Fuse

115V 175 mA @ 250 V Slow-Blo w

230V 80 mA @ 250 Slow-Blo w

Page 33

ENVIRONMENT

Operating Temperature: 0° to 50°C (32° to 122°F)

Storage Temperature: -40° to 85°C (-40° to 185° F)

Relative humidity: 90% at 40°C (non-condensing)

MECHANICAL

Panel cutout: 1/8” DIN 3.62 x 1.78” (45 x 92mm)

Weight: 1.27 lb (575 g)

Case material: Polycarbonate, 94 V-O UL rated

Protection: NEMA-4/Type 4 Front Bezel

Table 8-1 Color Chart for DC Power

COLOR HIGH BRIGHTNESS MEDIUM & LOW BRIGHTNESS

Sensor Excitation:

24 V @ 25 mA,

RED

GREEN

AMBER

12 V, 10 V, 5 V @ 35 mA Max

Analog Output:

Non-Isolated option only

Warning:

• Do not use Internal Excitation.

Use External Excitation.

• Do not use Isolated Analog Output.

Use Non-Isolated Analog Output.

Any combination of Sensor

Excitation and Analog Output

24 V @ 25 mA,

12 V @ 35 mA Max

10 V @ 35 mA Max

5 V @ 35 mA Max

Analog Output:

Non-Isolated options or

Isolated Analog option

HIGH/LOW Brightness and AMBER are only available on Version “B” meters. Standard display meters are

MEDIUM Brightness.

Figure 8-1 Meter Dimensions/Panel Cutout

DFI INFINITY CS (V- M3598/N/0906) 30 CF 70

Page 34

9.0 FACTORY PRESET VALUES

Table 9-1 Factory Preset Values

MENU ITEM FACTORY PRESET VALUES

Sensor Excitation: 10Vdc

Input Type: 0-100 (0-100 mV input)

Decimal Point Position:

Reading Scale and Offset:

0-100 mV = 0-1000

Reading Configuration:

(Ratiometric)

(10µV resolution for unipolar & 25 µV resolution for

bipolar)

(Filtered value)

(Gross/net reading)

Normal Color Display:

or (Note: depending how unit was ordered)

Setpoint 1 Configuration:

(Setpoint is active above)

(Setpoint is unlatched)

(Net Reading)

Setpoint 2 Configuration:

(Setpoint is active above)

(Setpoint is unlatched)

(Net Reading)

Setpoint 1 Deadband:

Setpoint 2 Deadband:

Output Configuration:

(Analog output is enabled)

(Analog output is current)

(Analog output follows the Net value)

Output Scale and Offset:

0-1000 = 4-20 mA DC

Lock Out Configuration

(Enable the RESET button in the Run Mode)

(Enable setpoint changes)

(Display setpoint values)

(Brightness Level)

Setpoint 1 Value:

Setpoint 2 Value:

10.0 CE APPROVALS INFORMATION

This product conforms to the EMC directive 89/336/EEC amended by 93/68/EEC, and with the European Low

Voltage Directive 72/23/EEC.

Electrical Safety EN61010-1:2001

Safety requirements for electrical equipment for measurement, control and laboratory.

Double Insulation

Pollution Degree 2

Dielectric withstand Test per 1 min

DFI INFINITY CS (V- M3598/N/0906) 31 CF 70

Page 35

• Power to Input/Output: 2300 Vac (3250 Vdc)

• Power to Input/Output: 500 Vac (720 Vdc)

(Low Voltage dc Power Option*)

• Power to Relays Output: 2300 Vac (3250 Vdc)

• Relay 1 to Relay 2: 2300 Vac (3250 Vdc)

• Isolated Analog to Inputs: 1000 Vac (1420 Vdc)

• Analog to Inputs: No Isolation

Measurement Category I

Category I are measurements performed on circuits not directly connected to the Mains Supply (power). Maximum

Line-to-Neutral working voltage is 50 Vac/dc. This unit should not be used in Measurement Categories II, III, IV.

Transients Overvoltage Surge (1.2 / 50uS pulse)

• Input Power: 2500 V

• Input Power: 500 V

(Low Voltage dc Power Option*)

• Isolated Analog: 500 V

• Input/Output Signals: 500 V

Note: *Units configured for external low power dc voltage, 10-32 Vdc (Basic Insulation)

EMC EN61326:1997 + and A1:1998 + A2:2001

Immunity and Emissions requirements for electrical equipment for measurement, control and laboratory.

• EMC Emissions Table 4, Class B of EN61326

• EMC Immunity** Table 1 of EN61326

Note: **I/O signal and control lines require shielded cables and these cables must be located on conductive cable

trays or in conduits. Furthermore, the length of these cables should not exceed 3 0 meters

Refer to the EMC and Safety installation considerations (Guidelines) of this manual for additional

information.

WARRANTY REPAIR POLICY

Limited Warranty On Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in

workmanship within one year of the date of shipment by Cooper will be repaired or replaced free of charge provided

that a return material authorization is obtained from Cooper and the defective product is sent, transportation

charges prepaid, with notice of the defect, and it is established that the product has been properly installed,

maintained, and operated within the limits of rated and normal usage. Replacement or repaired product will be

shipped F.O.B. from our plant. The terms of this warranty do not extend to any product or part thereof which, under

normal usage, has an inherently shorter useful life than one year. The replacement warranty detailed here is the

buyer’s exclusive remedy, and will satisfy all obligations of Cooper whether based on contract, negligence, or

otherwise. Cooper is not responsible for any incidental or consequential loss or damage which might result from a

failure of any and all other warranties, express or implied, including implied warranty of merchantability or fitness for

particular purpose. Any unauthorized disassembly or attempt to repair voids this warranty.

Obtaining Service Under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact the

Repair Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number.

Shipment to Cooper shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from our

plant in Warrenton, Virginia. Non-verified problems or defects may be subject to a $150 evaluation charge. Please

return the original calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty applies

only to those items that were found defective and repaired; it does not apply to products in which no defect was

found and returned as is or merely recalibrated. It may be possible for out-of-warranty products to be returned to

the exact original specifications or dimensions.

DFI INFINITY CS (V- M3598/N/0906) 32 CF 70

Page 36

* Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper to

receive information specifying the reason the product is being returned. Specific test data, written observations on

the failure and the specific corrective action you require are needed.

DFI INFINITY CS (V- M3598/N/0906) 33 CF 70

Loading...

Loading...