Page 1

4

DFI Infinity-Using This Quick Start Manual

Use this Quick Start Manual to get your High Performance

Strain Gage Indicator up and running right out of the box.

These instructions use the factory default settings of 100mV

unipolar input and 10 Vdc sensor excitation. If you have

voltage or current input, refer to the main manual. To start your

unit:

¥ Connect ac power

¥ Wire the sensor

¥ Configure the meter, using the front panel buttons and the

configuration menus

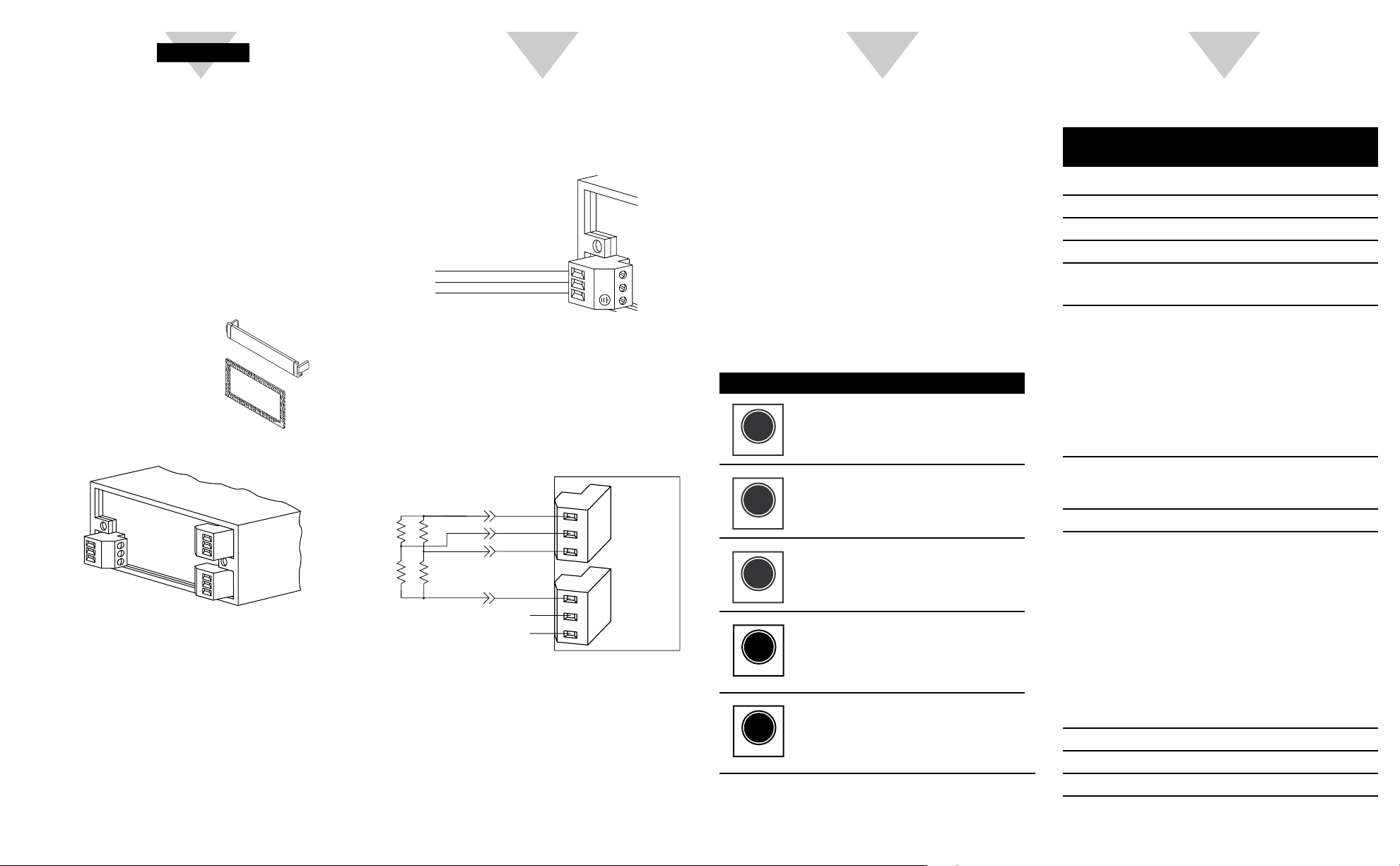

Before You Begin

Your unit should have the following parts:

¥ Meter

¥ Front panel button cover

¥ Panel mounting gaskets

¥ ac Power Connector (orange -P1), Input Connectors (2)

(P3 and P9), and rear protective cover (mounted).

Contact the Customer Service Department using

the number listed on the front of this manual if any of these

parts are missing, or if you have questions.

In addition to the unit and related parts, you will need the

following items to set up your unit:

¥ ac power as listed on meterÕs product/ID label

¥ External sensor (e.g.; load cell)

¥ 1/8Ó Phillips head screwdriver

¥ 1/8Ó flat blade screwdriver

Key Sequences and Menus

MENU key Sub Menu 1

MENU key Submenu 1 Action/Description

(䊳/MIN)

L1CNF

Skip past

L2CNF

Skip past

L3CNF

Skip past

L4CNF

Skip past

INPUT bridge

Select meter input

Sub Menu 1 choice (BRIDGE)

RDG.CNF RDG.1=0

Scaling y = mx+b

RDG.2=0

Active decimal point

RDG.3=0

Normal display brightness

RDG.4=1

Leading zeroes suppressed

RDG.5=0

Not used, skip past

RDG.6=1

Activates RDG SC/OF

RDG.7=0

External hard reset vs peak reset

RDG SC

See previous formula in

"Determine Meter Scaling Factor"

section.

RDG OF 000000

INCNF INP.1=0

60 Hz ac power

INP.2=0

Slow reading

(S1A jumper omitted)

INP.3=0

Unipolor input

(S1B jumper omitted)

INP.4=0

Std, for BRIDGE inputs

INP.5=0

Not used, skip past

INP.6=0

Disables IN.SC.OF

(Input Scale and Offset)

INP.7=1

Ratiometric input

IN.SC.OF

Skip past

DEC PT FFFF.FF

Select decimal point

CNT BY

Press RESET twice

Now you are in RUN mode. If the meter does not read zero,

refer to ÒConfigure Reading OffsetÓ section.

Determine Meter Scaling Factor

Calculate the scaling factor so the meter displays the desired

engineering units. Assuming no known load, use the formula:

RDG SC = display span/[(sensorÕs mV/V output) (10,000)]

where: display span = desired display at full scale

sensorÕs output span = mV/V

Configure the Meter

Use the front panel buttons to access the configuration menus,

to either verify or set the unit values. The first table that follows

describes functions of each button on the front of the meter.

The second table summarizes the key sequences you must

press and the menus you will see to get your meter running.

For a step-by-step procedure of specific tasks, refer to the

configuration sections following the tables.

Meter Button Descriptions

Press This Button To:

Access the configuration program

menus and move from one menu

to the next.

Enter and scroll through a

submenu.

Change the value of a submenu.

Move backward one menu (press

once), or exit the configurations

menus (press twice).

Change the Setpoints.

䊱/MAX

䊳/MIN

MENU

Connect ac Power

1. Remove the rear protective cover and set it aside. The

cover is secured with a Phillips-head screw.

2. Locate connector P1 on the bottom-left-rear of the unit. The

connector has three screw-down terminals (see below).

3. Insert the correct wire in each terminal and tighten the

lockdown screw. Tug gently on each wire to verify the

connection.

Wiring a Millivolt Output Sensor

The following example shows wiring a bridge input to the meter.

1. Locate connectors P3 and P9 on the right-side rear of the

unit.

2. Attach the wires and tighten the retaining screws. Tug

gently on the wires to verify the connection.

Wiring Example (Factory set at 10Vdc Excitation

3. Apply ac power. The front panel of the unit flashes

RESET2

. If it does not:

a. Remove ac power.

b. Verify the P1 power and sensor connections.

c. Check your power source.

d. Apply ac power again.

4. Replace the rear cover. Thread the sensor wires through

the slots on the side of the cover. Replace the rear cover

retaining screw.

START HERE

2

3

GASKET

P1

L

1

N

2

©

3

1

2

P9

3

1

2

P3

3

~AC LINE

~AC NEUTRAL

~AC EARTH GROUND

P1

L

1

N

2

3

+

EXC

+

SIG

–

SIG

–

EXC

NC

NC

+

E

1

+

S

–

S

–

E

P9

2

3

1

2

3

METER

P3

RESET

SETPTS

Page 2

56

7 8

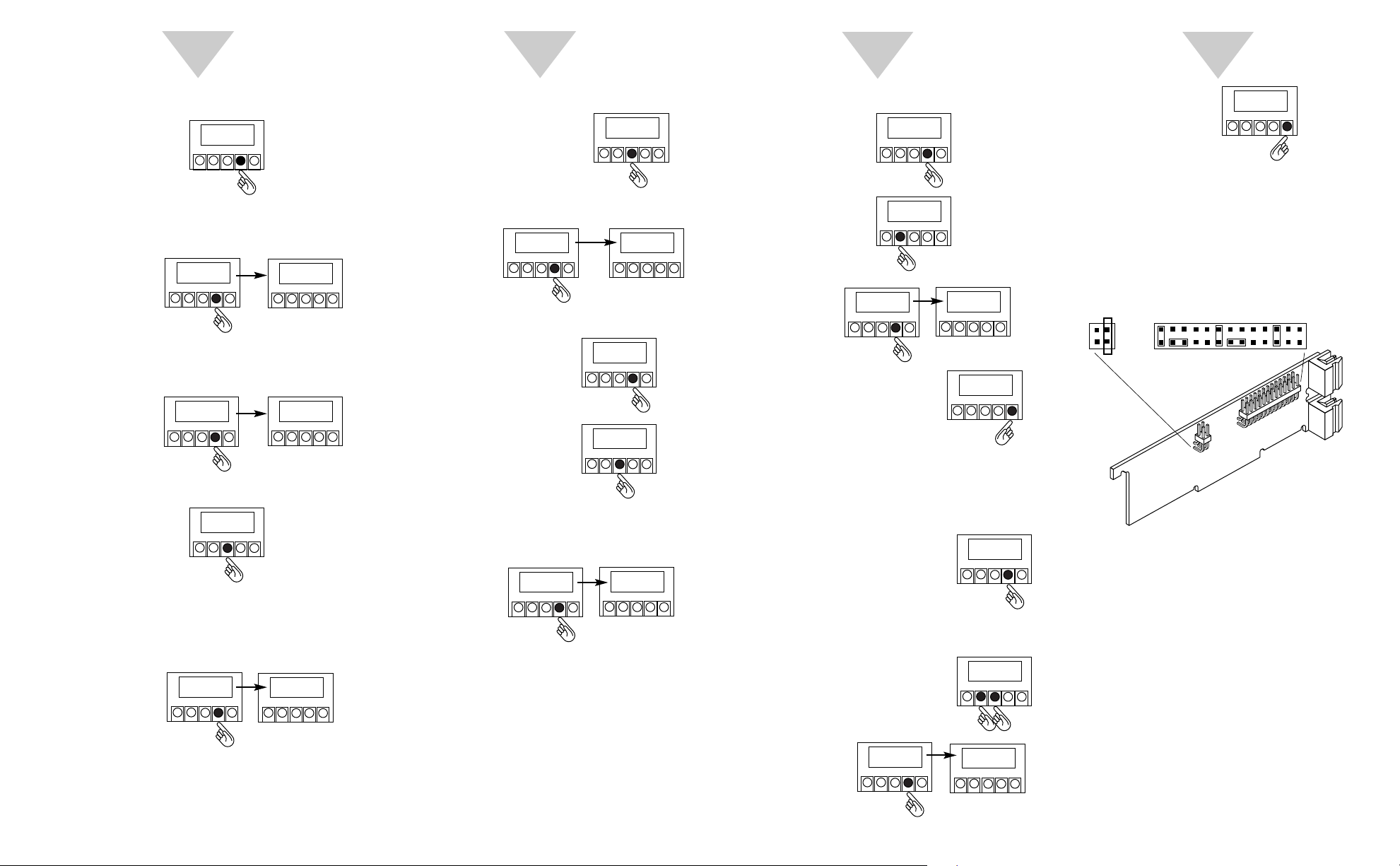

To Configure Scaling Factor:

1. Press 䊳/MIN to display and to select

the digit (or decimal point) you want

to change.

2. Press 䊱/MAX to increase the value

of the selected digit.

3. Repeat steps 1 and 2 until each digit is the desired value

(your calculated scaling factor).

4. Press MENU.

The meter displays:

To Configure Meter Inputs:

1. Press MENU until

the meter displays:

2. Press 䊳/MIN to display:

3. Press 䊱/MAX, if necessary to change the configuration

value.

4. Repeat steps 2 and 3 for

INP.2

through

INP.7

5. Press MENU.

The meter displays:

To Configure Type of Input:

1. Press MENU until the

meter displays:

2. Press

䊳/MIN to display a flashing input type.

3. Press MENU.

The meter displays:

4. Press MENU and

bridge

stops flashing.

5. Press MENU.

The meter displays:

To Configure Meter Display Readings:

1. Press 䊳/MIN to display:

2. Press 䊱 /MAX, if necessary to change the configuration

value to 0or 1.

3. Repeat steps 1 and 2 for

RDG.2

through

RDG.7

4. Press MENU.

The meter displays:

To Set Decimal Point Position:

1. Press MENU until

the meter displays:

2. Press 䊳/MIN to display:

Press 䊱/MAX to move

the decimal point to the

desired location.

3. Press MENU.

The meter displays:

4. Press RESET twice. The meter flashes

and displays an output reading.

The meter is now in RUN mode.

Configure Reading Offset

Now that you are in the run mode with a transducer connected

to the meter, do the following:

1. Simulate a load on the transducer (leave the pressure

port open).

2. Note the display reading. LetÕs assume

the display shows 43.5.

3. To make the display show zeroes, press

MENU until the meter displays:

4. Press 䊳/MIN to display the previous reading offset value.

5. Using 䊳/MIN to scroll through the digits

and 䊱/MAX to change the value, enter

the value -0043.5.

6. Press MENU.

The meter displays:

7. Press RESET twice.

The meter flashes and

then displays a value.

Your meter is now in RUN mode and operational.

If You Have Bipolar Input ±50mV

The typical setting for your meter is unipolar. If, however, you

have bipolar input ±50mV, you must install jumper S1B.

Remove the outer panel mounting sleeve to expose the

jumper.

S1 Jumper Location on Signal Input Board

In addition, you must set configuration menu value INP.3=1

(under IN CNF menu). Refer to the Configuration sections of

this Quick Start manual.

MQS1291/N/0401

12458ML-01 Rev. D

input1

䊱䊳

/MAX

SETPTS /MIN MENU RESET

stored

䊱䊳

SETPTS /MIN MENU RESET

/MAX

bridge

䊱䊳

/MAX

SETPTS /MIN MENU RESET

stored

䊱䊳

/MAX

SETPTS /MIN MENU RESET

rdg.cnf

䊱䊳

/MAX

SETPTS /MIN MENU RESET

rdg.1=0

䊱䊳

/MAX

SETPTS /MIN MENU RESET

SETPTS /MIN MENU RESET

stored

䊱䊳

/MAX

rdg SC

䊱䊳

/MAX

SETPTS /MIN MENU RESET

0.00000

䊱䊳

/MAX

SETPTS /MIN MENU RESET

stored

䊱䊳

/MAX

SETPTS /MIN MENU RESET

rdg of

䊱䊳

/MAX

SETPTS /MIN MENU RESET

in cnf

䊱䊳

/MAX

SETPTS /MIN MENU RESET

inp.1=0

䊱䊳

/MAX

SETPTS /MIN MENU RESET

SETPTS /MIN MENU RESET

stored

䊱䊳

/MAX

in.sc.of

䊱䊳

/MAX

SETPTS /MIN MENU RESET

DeC pt

䊱䊳

/MAX

SETPTS /MIN MENU RESET

FFFF.FF

䊱䊳

/MAX

SETPTS /MIN MENU RESET

stored

䊱䊳

/MAX

SETPTS /MIN MENU RESET

cntby

䊱䊳

/MAX

SETPTS /MIN MENU RESET

reset2

䊱䊳

/MAX

SETPTS /MIN MENU RESET

rdg of

䊱䊳

/MAX

SETPTS /MIN MENU RESET

-0043.5

䊱䊳

/MAX

SETPTS /MIN MENU RESET

reset2

䊱䊳

/MAX

SETPTS /MIN MENU RESET

R

M

S1

A

C

A

B

B

K

E

H

G

D

F

P

L

Q

N

J

STU

V

S2

J9

J3

stored

䊱䊳

/MAX

SETPTS /MIN MENU RESET

in cnf

䊱䊳

/MAX

SETPTS /MIN MENU RESET

Loading...

Loading...