Page 1

DFI 2555

MEASURING AMPLIFIER

USER’S GUIDE

www.cooperinstruments.com

PH: 540-349-4746 • FAX: 540-347-4755

Page 2

CONTENTS

SAFETY INSTRUCTIONS............................................................................................................1

1.0 INTRODUCTION ....................................................................................................................2

1.1 Scope of supply ..............................................................................................................................2

1.2 General............................................................................................................................................. 2

1.3 Block diagram .................................................................................................................................3

2.0 MOUNTING ............................................................................................................................3

2.1 Pre-installation notes, factory settings......................................................................................... 3

2.2 Changing the factory settings .......................................................................................................3

2.2.1 Setting the analog output signal.............................................................................................4

2.2.2 Choosing the operating mode for synchronization .............................................................. 4

2.2.3 Replacing the fuses .................................................................................................................4

2.3 Installing the amplifier in a panel-frame .......................................................................................4

3.0 CONNECTIONS .....................................................................................................................4

3.1 Connecting the voltage supply...................................................................................................... 4

3.2 Connecting transducers................................................................................................................. 5

3.3 Analog output.................................................................................................................................. 6

3.4 Control inputs / outputs .................................................................................................................6

3.5 Synchronization .............................................................................................................................. 7

3.6 Setting the reading angle of the display.......................................................................................7

3.7 Connecting the serial interface......................................................................................................8

4.0 SETTING UP AND OPERATION ...........................................................................................8

4.1 Commissioning and factory settings............................................................................................8

4.2 Control concept and functional overview...................................................................................12

4.3 Button functions in measuring mode .........................................................................................13

4.3.1 Querying and setting limit values in measuring mode.......................................................13

4.4 Button functions in programming mode ....................................................................................14

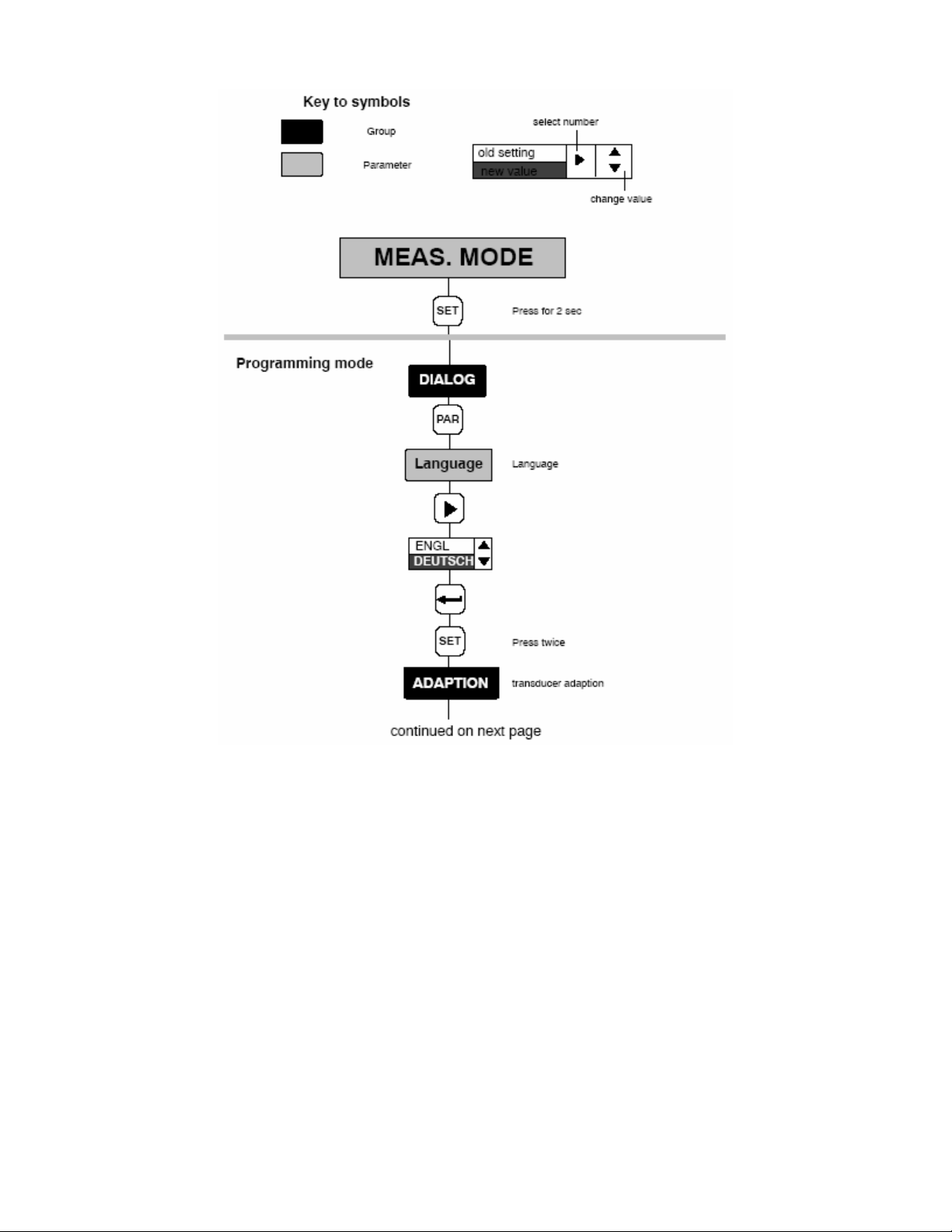

4.4.1 Changing from ”Measuring” Operating Mode to ”Programming” ....................................14

4.4.2 Programming..........................................................................................................................14

4.4.3 Switching from ”Programming” Mode to ”Measuring” ...................................................... 15

4.5 Overview of all groups and parameters......................................................................................15

4.5.1 Setting all parameters............................................................................................................ 16

4.5.2 Dialogue .................................................................................................................................. 19

4.5.3 Load/Save in parameter set (PARAM. SET) ......................................................................... 19

4.5.4 Adaptation...............................................................................................................................19

4.5.5 Calibration (CALIBR.).............................................................................................................21

4.5.6 Limit switches 1 ... 4 (LIMITVAL.1 ... 4).................................................................................22

4.5.7 Set peak value store (PV STORE) ......................................................................................... 23

4.5.8 Inputs and outputs (IN/OUT) .................................................................................................24

4.5.9 Additional functions (ADD. FUNCT) .....................................................................................25

5.0 EXAMPLE ............................................................................................................................27

6.0 ERROR MESSAGES ...........................................................................................................32

7.0 SPECIFICATIONS................................................................................................................32

8.0 WARRANTY REPAIR POLICY ............................................................................................36

CF 69 ii V-A0104-5.3 en

Page 3

SAFETY INSTRUCTIONS

To ensure safe operation, the device may only be operated in accordance with the information given in the Operating Manual. It is also essential to comply with the legal and safety requirements for the application concerned during use. The same applies to the use of accessories.

Before commissioning, find out whether the mains voltage and current type specified on the identification plate

match the mains voltage and current type at the place of use, and whether the circuit being used is adequately protected.

Built-in devices must only be operated while they are within the housing provided for them.

The device complies with the safety requirements of DIN EN 61010-Part 1 (VDE 0411-Part 1); Protection Class I.

As the device does not have a separate power switch, do not apply the power cable directly to the mains.

According to the VDE guideline, there must be a switching device to disconnect the device from the mains.

Use in accordance with the regulations

The DFI 2555 with connected transducers is only to be used for measurement tasks and directly associated control

functions. Use for any purpose other than the above shall be deemed to be not in accordance with the regulations.

General dangers due to non-observance of the safety instructions

The DFI 2555 is a state-of-the-art device and is fail-safe. The device may give rise to further dangers if it is inappropriately installed and operated by untrained personnel. Any person instructed to carry out installation, commissioning, maintenance or repair of the device must have read and understood the Operating Manual and in particular

the technical safety instructions.

Remaining dangers

The scope of supply and list of components provided with the DFI 2555 cover only part of the scope of measurement technique. In addition, equipment planners, installers and operators should plan, implement and respond to

the safety engineering considerations of measurement technique in such a way as to minimize remaining dangers.

Prevailing regulations must be complied with at all times. There must be reference to the remaining dangers connected with measurement technique.

In this manual, the remaining dangers are indicated by the following symbols:

Symbol:

Meaning: Maximum danger level

Warns of a decidedly dangerous situation in which failure to comply with safety requirements will lead to death or

serious physical injury.

Symbol:

Meaning: Dangerous situation

Warns of a potentially dangerous situation in which failure to comply with safety requirements can lead to death or

serious physical injury.

Symbol:

Meaning: Potentially dangerous situation

Warns of a possibly dangerous situation in which failure to comply with safety requirements could cause damage

to property or result in some kind of minor physical injury.

Symbols for using advices and helpful information:

Symbol:

Means that important information about the product or its handling is being given.

Symbol:

Meaning: CE mark

CF 69 1 V-A0104-5.3 en

DANGER

WARNING

CAUTION

NOTE

Page 4

The CE mark enables the manufacturer to guarantee that the product complies with the requirements of the relevant EC directives.

Working safely

Error messages must only be acknowledged when the cause of the error has been removed and no further danger

exists.

Conversions and modifications

The DFI 2555 must not be modified from the design or safety engineering point of view except with our express

agreement. Any modification shall exclude all liability on our part for any resulting damage. In particular, any repair

or soldering work on motherboards is prohibited (this includes changing components other than EPROMs). When

exchanging complete modules, use only original parts from Cooper.

Qualified personnel

This instrument must only to be installed and used by qualified personnel, strictly in accordance with the technical

data and the safety requirements and regulations listed below. It is also essential to comply with the legal and

safety requirements for the application concerned during use. The same applies to the use of accessories. Qualified personnel means persons entrusted with the installation, assembly, commissioning and operation of the product that possess the appropriate qualifications for their function.

1.0 INTRODUCTION

1.1 Scope of supply

• Device with front frame

• 2 fastening straps

• One male cable connector DB-15P

• One 3-pin terminal strip connector (mains connection)

• One 3-pin terminal strip connector (interface)

• Two 9-pin terminal strip connectors (control inputs/outputs)

• Operating Manual and Serial Communications Guide for RS232/485.

1.2 General

The panel-frame measuring amplifier DFI 2555 for instrument panel mounting (in accordance with DIN43700) is

suitable for recording and processing measured values from passive transducers in the industrial test bench engineering sector and for monitoring production processes.

The essential features:

• Transducers that can be connected: S.G. full and half bridges, inductive full and half bridges, piezoresistive and

potentiometric transducers, LVDT

• 10-digit alphanumeric display

• Touch-sensitive keypad control; individual buttons can be locked

• Two peak value stores for maximum and minimum values, as well as envelope and instantaneous value

• Four limit switches

• RS232 or RS485 serial interface for connecting a computer or a printer

• Parameter memory for saving up to 8 data sets

• Control inputs and outputs (potential-separated through optical couplers)

• The DFI 2555-RS485 version can be operated together with other DFI 2555s (at a common RS485 bus)

All the commands needed for device setup over the serial interface and for querying the measured values are listed

and described in a separate manual, “DFI 2555 Serial Communications Guide”.

CF 69 2 V-A0104-5.3 en

Page 5

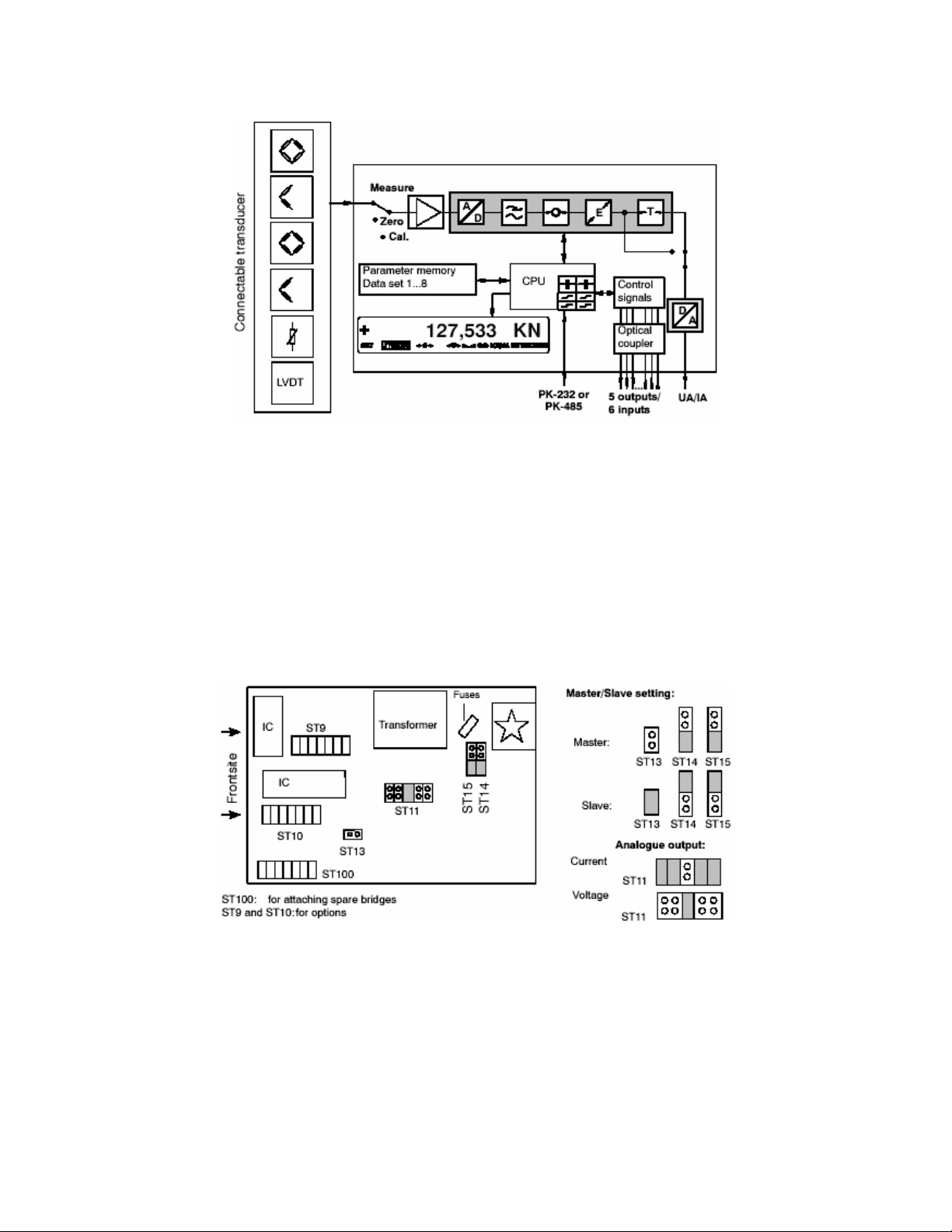

1.3 Block diagram

Fig. 1.1 DFI 2555 block diagram

2.0 MOUNTING

2.1 Pre-installation notes, factory settings

Before installing the device, check the parameters set at the factory, as the elements for selecting the analog output

signal (current/voltage output) and for setting synchronization, are located on the motherboard.

The factory settings are given below:

• Mains voltage: 230 V / 50 ... 60 Hz or 115 V / 50 ... 60 Hz, depending on order

• Analog output: output voltage ±10 V

• Synchronization: Master

Fig. 2.1: Location of jumpers on motherboard

2.2 Changing the factory settings

To change the factory settings, proceed as follows:

• Loosen the four screws at the back of the housing.

• Carefully extract the back panel of the housing backward, with the motherboard attached, until the jumper ar-

rangement is accessible. You can place a screwdriver between the connection board and the housing and lever

out the back panel.

• By following the diagram, change whichever setting is relevant to you with the aid of the jumpers.

CF 69 3 V-A0104-5.3 en

Page 6

2.2.1 Setting the analog output signal

To make the analog output signal setting (voltage or current), use jumpers ST11. Choose between ±20 mA or 4 ...

20 mA in the control dialogue.

2.2.2 Choosing the operating mode for synchronization

To synchronize several devices, set one device as the Master. All the other devices should then set to Slave. To

make the “Master” and “Slave” selections, use jumpers ST13, ST14 and ST15.

2.2.3 Replacing the fuses

To replace the fuse, remove the back panel of the housing as described. The fuse (230 V/100 mA; 115 V/200 mA)

will then be accessible on the motherboard (see Fig. 2.1).

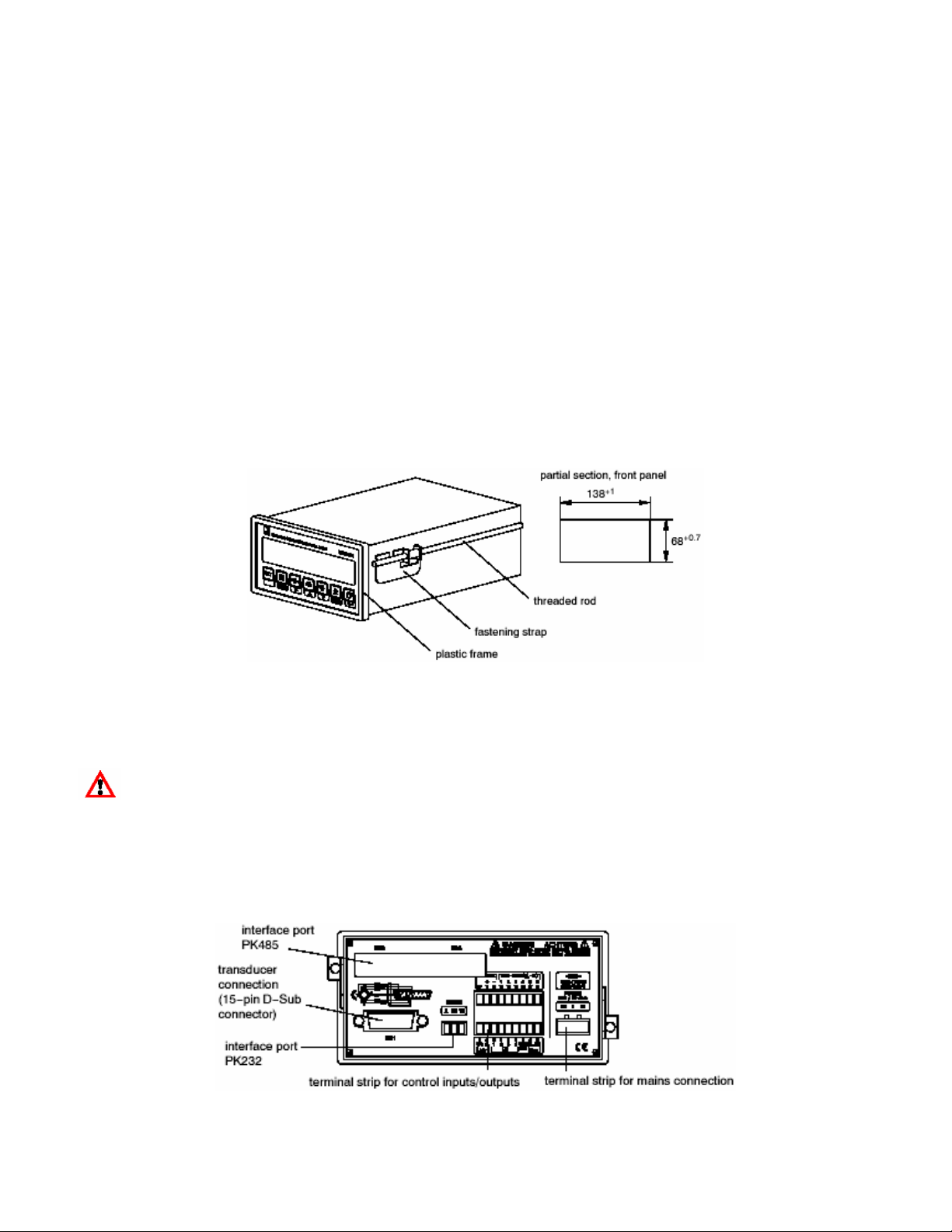

2.3 Installing the amplifier in a panel-frame

The DFI 2555 is designed to be installed in panel-frames, in accordance with DIN43700.

Installation steps:

• Remove the fastening strap.

• Insert the housing into the cutout in the panel-frame from the front.

• Hang up the fastening strap on both sides and fasten it to the cutout with the two threaded rods.

• Then connect the supply voltage and the transducer, as shown in chapter 3.

Fig. 2.2: Housing with fastening components

3.0 CONNECTIONS

CAUTION

Before commissioning the device, please observe the safety instructions.

3.1 Connecting the voltage supply

Check that the mains voltage of the device (details on the back of the device) matches the supply voltage. If this is

not the case, please contact Cooper Instruments.

Fig. 3.1 Back of the device

CF 69 4 V-A0104-5.3 en

Page 7

CAUTION

As the device does not have a separate power switch, do not connect the power cable directly to the

mains. According to the VDE guideline, there must be a switching device to disconnect the device from the

mains.

Connecting the mains cable:

• The cable must not be connected to the mains!

• Twist the wire ends of the mains cable and fit the end sleeves for strands

• Screw the wire ends to the terminal strip connector (3-pin)

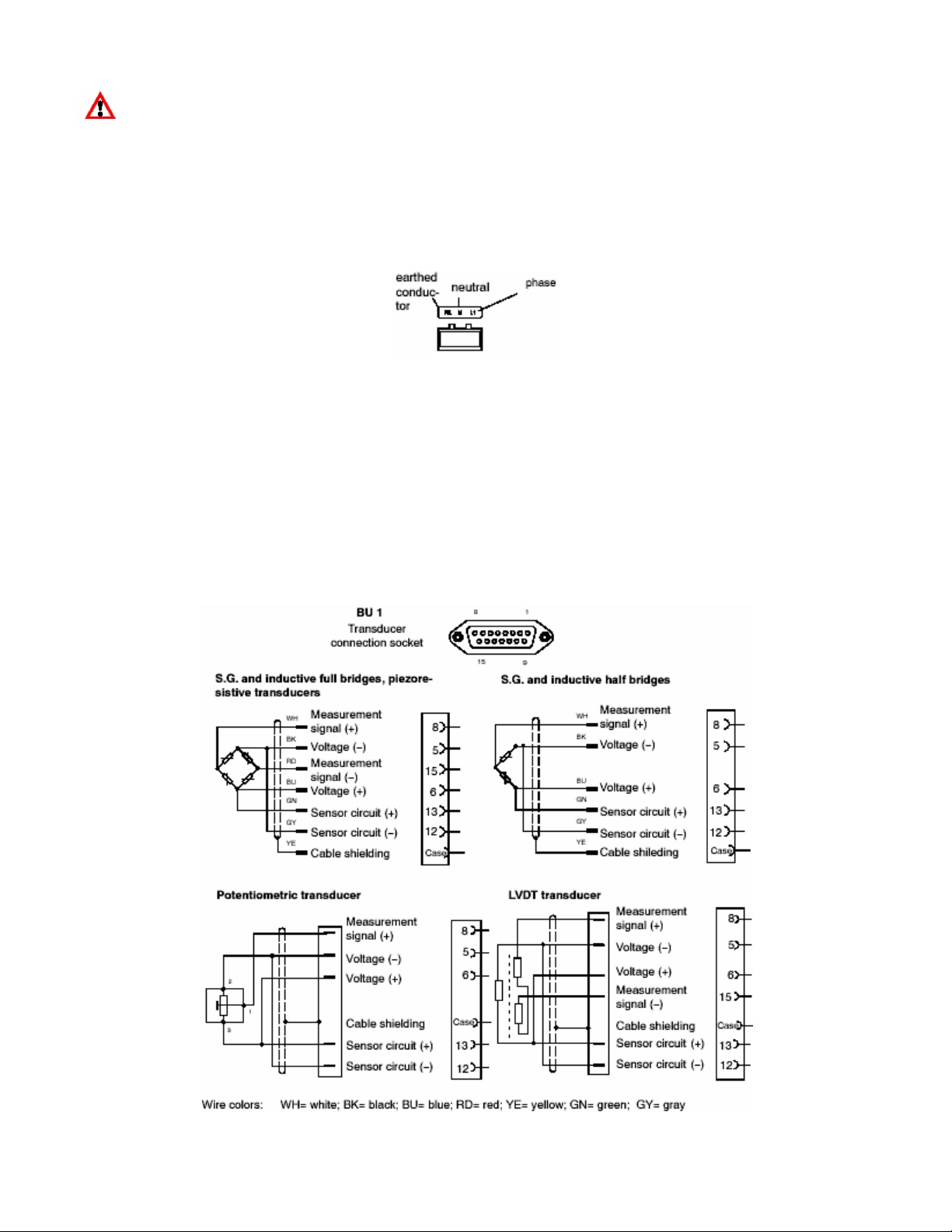

Fig. 3.2: Pin assignment of the terminal strip connector (3-pin)

• Plug the terminal strip connector (3-pin) into the mains connection socket

3.2 Connecting transducers

The following transducer types can be connected to the device:

• S.G. full and half bridge transducers

• Inductive full and half bridge transducers

• Potentiometric and piezoresistive transducers

• LVDT (Linear Variable Differential Transformer)

The connection is made using a 15-pin D-Sub connector on the back panel of the housing, labeled BU1 (cable end

connector: DB-15P).

Fig. 3.3: Connecting different transducers

CF 69 5 V-A0104-5.3 en

Page 8

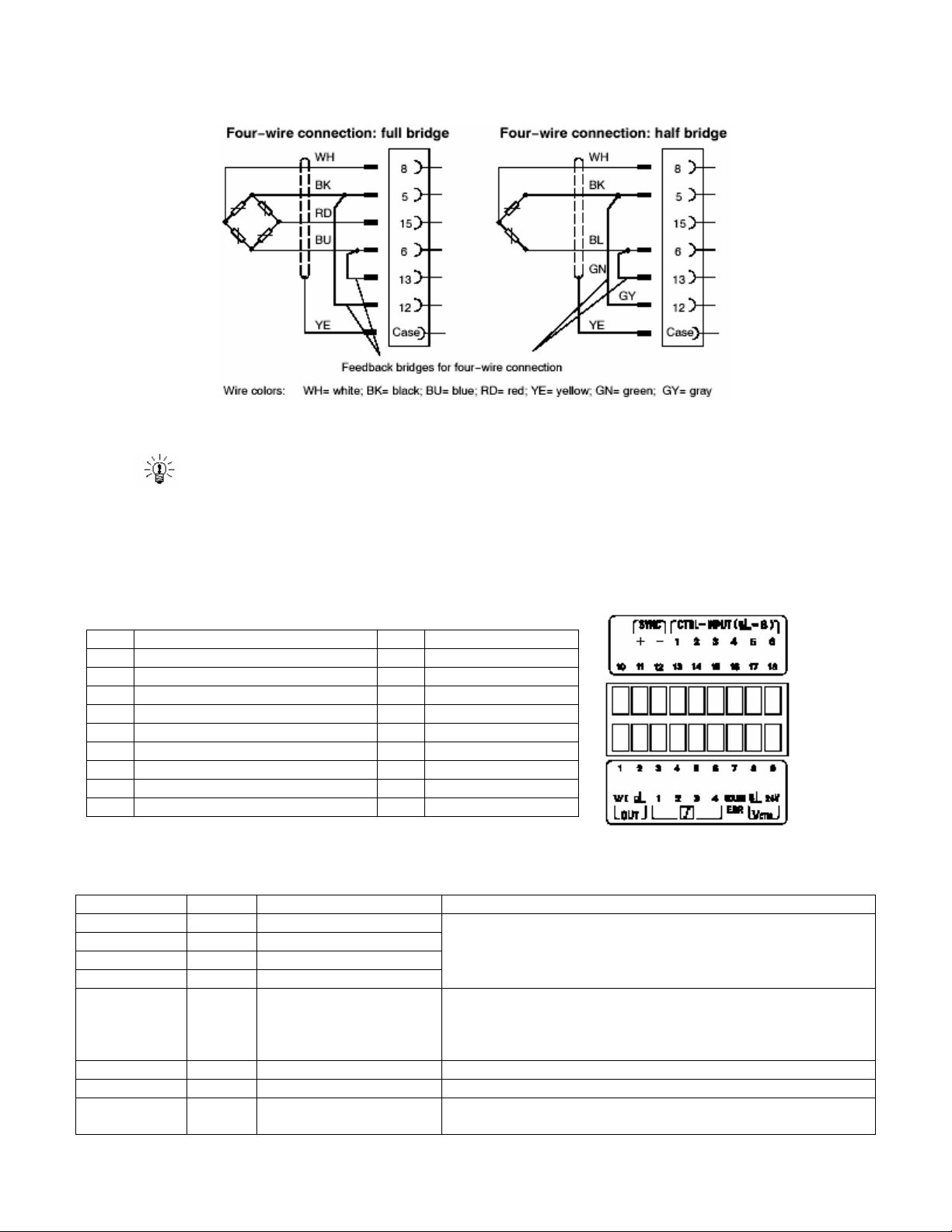

When connecting a transducer using four-wire technique, you must connect the sensor circuits with the relevant

bridge excitation circuit in the male cable connector (pin 5 with pin 12 and pin 6 with pin 13).

Fig. 3.4: Transducer connection in four-wire technique

NOTE:

To connect the transducers, use standard cable. If you use another shielded, low-capacitance

measurement cables, connect the shielding of the transducer cable to the connector housing, in accordance with HBM Greenline information (document G36.35.0). This guarantees EMC protection.

3.3 Analog output

The analog output signal is available as voltage (±10 V) or as current (±20 mA or 4 ... 20 mA) at terminals 1 and 2.

To choose current or voltage, use the jumpers on the amplifier motherboard, as described in Chapter 2.1.

Pin Function Pin Function

1 Output signal (V/I) 10 no function

2 Output signal (ground) 11 Synchronization (+)

3 LIMITVAL.1 12 Synchronization (-)

4 LIMITVAL.2 13 Remote1 (...)

5 LIMITVAL.3 14 Remote2 (...)

6 LIMITVAL.4 15 Remote3 (...)

7 Warning 16 Remote4 (...)

8 Ground 17 Remote5 (...)

9 External supply voltage 24 V= 18 Remote6 (...)

Fig. 3.5: Output pin assignment

3.4 Control inputs / outputs

Input/Output Terminal Function

←

←

←

←

←

→

→

→

3 Output LIMITVAL. 1

4 Output LIMITVAL. 2

5 Output LIMITVAL. 3

6 Output LIMITVAL. 4

7 Output warning (overflow) Warning active in the case of overflow,

8 Ground V

9 External supply voltage V

13-17 Input remote 1-6 (function

selectable)

With positive logic equivalent to V

24 V

Autocal and MOTION OUT

24 V =OK

0 V = Warning

0 V

ext.

24 V

ext.

see table on Page 46

ext.

CF 69 6 V-A0104-5.3 en

Page 9

DFI 2555

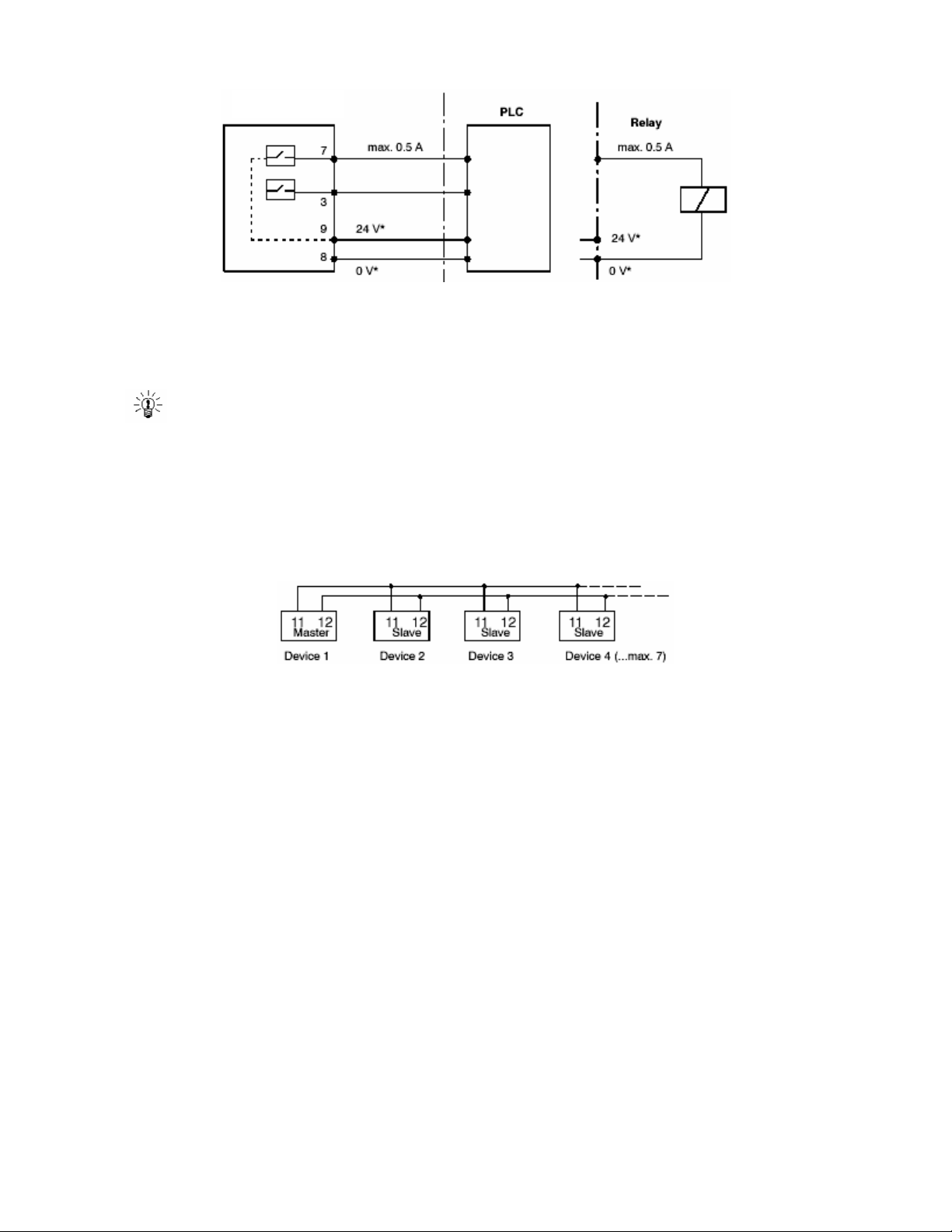

Fig. 3.6: Output assignments

The control inputs and outputs are available at the terminal strip socket (9-pin) and are potential-separated by optical couplers.

* The control outputs and inputs must be supplied with an external voltage (ground and 24 V).

NOTE

When the mains voltage is disconnected or fails and when the mains fuse blows, all the control outputs are

set to 0 V (V

ext.

).

3.5 Synchronization

If several devices are used right next to one another or if their cables run parallel, the devices should be synchronized. To achieve this, one device is set to Master and all the others (max. seven) to Slave. The setup with jumpers

on the amplifier motherboard is described in Chapter 2.1. As well as these settings, the devices must be linked together for synchronization.

Fig. 3.7: Terminal connections for synchronization

3.6 Setting the reading angle of the display

Depending on the mounting position, it may be possible to adjust the reading angle. A potentiometer is used for this

limited adjustment. The potentiometer is located behind the keyboard under the display. To set a new viewing angle, proceed as follows:

• Remove the plastic frame of the display from the housing.

• Carefully lever out the keyboard (e.g. with the aid of a screwdriver).

• Use a screwdriver to turn the potentiometer and set the optimum reading angle.

• Put back the keyboard. Make sure that the plug is correctly threaded at the bottom edge of the keyboard.

Quickly test the keyboard by pressing a key. If it functions correctly, you can continue.

• Insert and tighten the fastening screws.

• Push the plastic frame back on the housing.

CF 69 7 V-A0104-5.3 en

Page 10

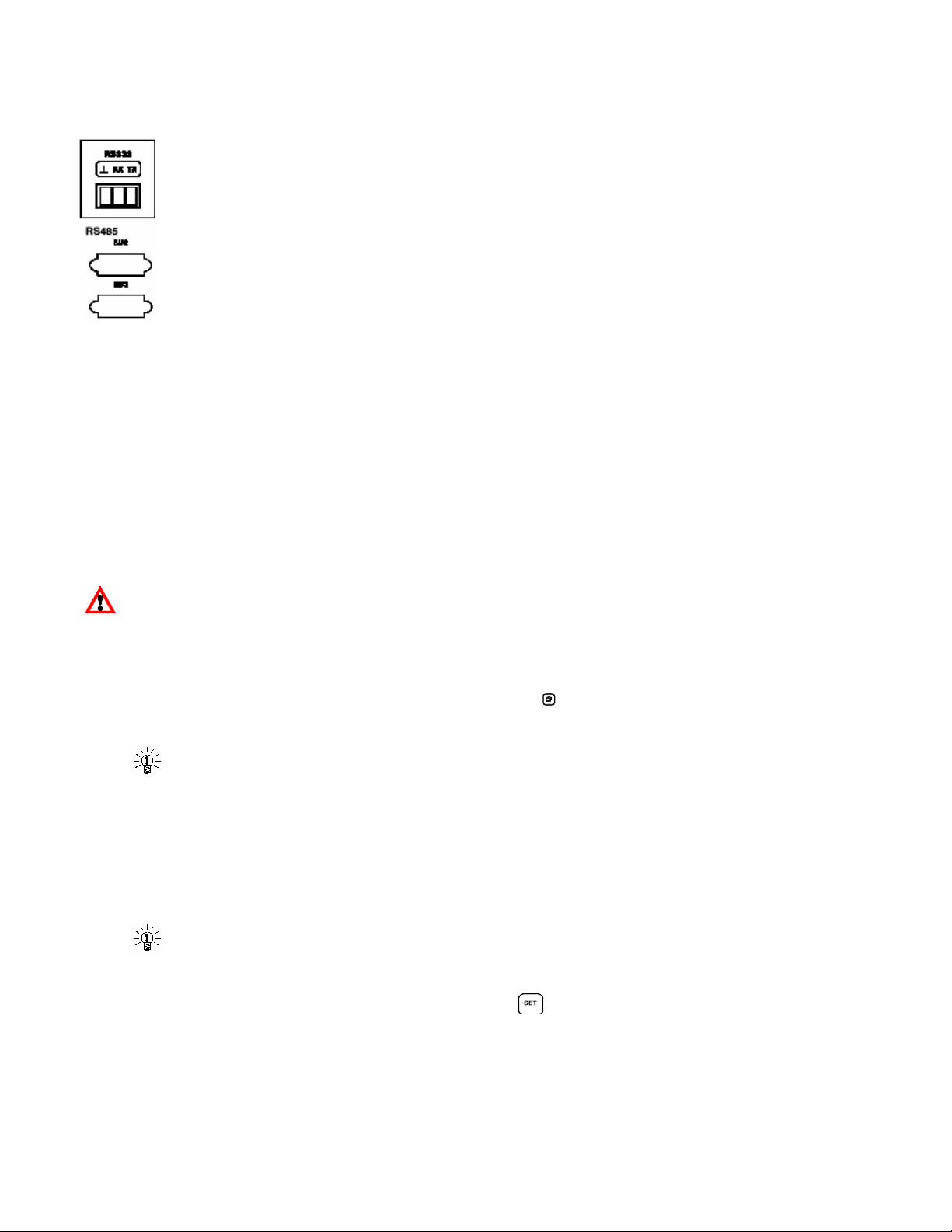

3.7 Connecting the serial interface

PK232-interface:

On the back of the device, there is an RS232 or RS485 serial interface for connecting a computer or

a terminal. The PK485-interface is brought out at sockets Bu2 and Bu3.

When connecting a printer, a simple line printer needing no more than 4 seconds to print a line is

sufficient. The printout has 12 columns. This corresponds to a line length of 132 characters. Select

the measured values to be printed as described in Chapter 4.4.11.

When connecting a computer, it is possible to enter into dialogue with the DFI 2555. You can use control commands to make all the device settings and query the measured values. An overview of the interface commands has

been compiled in another Operating Manual “DFI 2555 Serial Communications Guide”.

4.0 SETTING UP AND OPERATION

4.1 Commissioning and factory settings

Some of the steps you need to take to commission your measurement chain (panel-frame amplifier and transducer)

are listed below, so that you can carry out an initial function test of all components. The description basically covers

adapting the DFI 2555 to the transducer type to be used. We also warn about certain errors that can typically occur

during commissioning.

• Follow the steps given in the previous chapter to connect the mains cable and the transducer to the measuring

amplifier.

Please observe the safety instructions!

• Turn on the power switch.

• The device runs a function test and is then in measuring mode. Duration of the function test: 1.5 s (if auto-

calibration is enabled, approx. 2.5 s). During the function test, the warning output stays at 0 V. The factory

settings are active.

• Check the choice of output signal shown on the display. Use

display).

to select the gross signal (no labeling in the

NOTE

If the error message CALERR. appears here, this can have the following causes:

- No six-wire feedback connected

- Incorrect transducer/sensor connection

- No transducer/sensor connected

Remedy:

Switch off the device. Connect the transducer properly. Switch the device back on.

NOTE

If the error message “OVFL B, OVFL N,” appears, you must adjust the amplifier for your type of transducer. The

steps to take for each amplifier are described below.

• To get from measuring mode to device setup mode, press

play.

• Follow the examples given below to adjust the device to the connected transducer type.

CF 69 8 V-A0104-5.3 en

for about 2 s. ”DIALOG” will appear in the dis-

Page 11

Transducer types:

S.G. force transducer:

Adaptation:

Example

Transducer type: Full bridge/2 mV/V=20 kN

Excitation: 2.5 V

Input: 4 mV/V

Calibration Unit, nominal value/decimal point 20.000 kN

Measuring range 2 mV/V

Inductive displacement transducer:

Adaptation:

Example

Transducer type: Half bridge, 10 mV/V

(80 mV/V)

Excitation: 1.0 V

Input: 10 mV/V (100 mV/V)

Calibration: Unit, nominal value/decimal point: 20.000 mm

Measuring range: 10 mV/V (80 mV/V)

Piezoresistive transducer:

Adaptation:

Example

Transducer type: Half bridge

Excitation: 2.5 V

Input: 400 mV/V

Calibration: Unit, nominal value/decimal point: 30.000 bar

Measuring range: 200 mV/V

Potentiometric transducer:

Adaptation:

Example

Transducer type: Half bridge

Excitation: 1 V

Input: 1000 mV/V

Calibration: Unit, nominal value/decimal point: 10.000 mm

Measuring range: 1000 mV/V

CF 69 9 V-A0104-5.3 en

Page 12

CF 69 10 V-A0104-5.3 en

Page 13

Continued at right…

Continued below…

CF 69 11 V-A0104-5.3 en

Page 14

The settings are saved in parameter set 1 and the device switches to measuring mode. You can now run an initial

function test.

NOTE

The settings are only stored power fail safe, if they were saved as one of the parameter sets.

4.2 Control concept and functional overview

The control concept makes a distinction between two types of button functions:

-Buttons that are operative during measuring mode

-Buttons needed for programming.

CF 69 12 V-A0104-5.3 en

Page 15

4.3 Button functions in measuring mode

Key Meaning

Switch from me assuring operating mode to programming (and vice versa) by pressing for approx. 2 s.

Set the limit values LV1 ... 4 (see 4.3.1)

The additional parameters of the limit switches such as hysteresis, direction etc., are unchanged. Limit

value changing can be enabled in menu LIMITVAL 1 ... 4. (see 4.5.6)

Zeroing the measurement chain (also possible by remote). The signal at the input is applied as the zero

point.

Taring the measured value (also possible by remote). The current measured value is applied as the tare

value in the tare buffer.

Deletes the contents of the peak value store (also possible by remote). This function applies to all peak

value stores (Min, Max, Peak-to-Peak).

Output of measured values or parameters over the interface (also possible by remote).

For possible print parameters, see ”Additional function” starting on Section 4.5.9.

Only those parameters (PRINT xxx) selected in additional functions will be printed.

Switches the measured value display between:

Gross value No labeling in the display

Net value (=gross minus tare) ”NET” is displayed

Minimum value

Maximum value “MAX” is displayed

Peak-to-peak value ”MAXMIN” is displayed

”MIN” is displayed

4.3.1 Querying and setting limit values in measuring mode

You have several options available when choosing the limit values (in measuring mode):

a: Numerical value entry for limit values

b: Apply input signal as limit value

c: Fast search (keep arrow keys pressed for several seconds)

CF 69 13 V-A0104-5.3 en

Page 16

4.4 Button functions in programming mode

In this operating mode, you can make all the settings for using the amplifier in your application. The parameters are

collected into groups.

Significance of the buttons:

Change operating mode, select group (e.g. CALIBR.)

Parameter selection (e.g. NOM. VALUE)

Display last value set.

Select desired number.

Changes the number in ascending order

Changes the number in descending order

Apply measured value

Confirms input/modification

4.4.1 Changing from ”Measuring” Operating Mode to ”Programming”

Press for 2 s

If the password is 0000 (factory setting), the device changes the operating mode.

If a password has already been entered (and is not 0000), CODE appears, that is, the password has to be entered if you wish to continue ”Programming”.

Enter password:

press twice

Enter password (four-figure number)

If you enter an incorrect password, the device goes back to measuring mode. If the password matches, the

DIALOG group appears in the display.

4.4.2 Programming

Typical programming mode operations

Select the value/parameter from a given ta-

ble (example DIALOGUE LANGUAGE)

Enter a numerical value as a parameter (example CALIBR./RANGE)

Apply a signal produced by the transducer when a defined loading occurs.

*Only possible when setting the zero value, the measuring range and the limit values

CF 69 14 V-A0104-5.3 en

Page 17

4.4.3 Switching from ”Programming” Mode to ”Measuring”

When the parameters are changed, you are asked whether the modified parameters are to be saved power fail

safe.

NOTE

The settings are only stored power fail safe, if they were saved as one of the parameter sets.

4.5 Overview of all groups and parameters

PARAM BUTT.TARE FILTER ZERO VALUE HYSTERESIS SET CONTACT 2 STOPBITS

↓ BUTT.PVS MOTION CNT RANGE LOGIC CONTACT 3 COMM.ADDR

DIALOG

LANGUAGE RECALL TRANSDUCER UNIT ENABLE ENABLE SOURCE UA P34

PASSWORD SAVE? EXCITATION NOM. VALUE SOURCE PVS1 MODE UA SERIAL NO.

BUTT.LVS SET INPUT DEC.POINT SWITCH DIR. PVS2 INPUT SIGN. BAUDRATE

↓

BUTT.ZERO AUTOCAL STEP LEVEL ENVELOPE CONTACT 1 PARITY

BUTT.PRINT MOTION DIG TARE VALUE LV BUTT CONTACT 4 PRINT GROSS

BUTT.SIGN MOTION OUT SET SET CONTACT 5 PRINT NET

SET1) SET CONTACT 6 PRINT MAX

Parameter

1)

Use to next group

PARAM.

SET

ADAPTATION CALIBR.

→

Groups

LIMITVAL.

1 … 4

PV STORE IN/OUT ADD. FUNCT.

REMOTE PRINT MIN

SET PRINT PP

PRINT LVS

PRINT OVERL

PRINT PAR.

ZERO/TARE

SET

CF 69 15 V-A0104-5.3 en

Page 18

4.5.1 Setting all parameters

CF 69 16 V-A0104-5.3 en

Page 19

CF 69 17 V-A0104-5.3 en

Page 20

CF 69 18 V-A0104-5.3 en

Page 21

4.5.2 Dialogue

Select language (LANGUAGE)

Factory setting: DEUTSCH

You can choose the following languages:

German (DEUTSCH), English (ENGLISH), French (FRANCAIS), Italian (ITALIANO), Spanish (ESPANOL)

Choose password (PASSWORD)

When switching from Measuring to Programming, you are asked for a password (see 4.4.1). The password pre-

vents unauthorized operation of the DFI 2555. Parameters can only be changed if the valid password is entered.

The password can only be changed if the old password is known.

CODE Function

0000 no password; factory setting

0001 ... 9999 password set

Enable/lock buttons

BUTT. LVS :

BUTT. ZERO:

BUTT. TARE:

BUTT. PVS:

BUTT. PRINT:

BUTT. SIGN :

Factory setting: ENABLED

Factory setting: ENABLED

Factory setting: ENABLED

Factory setting: ENABLED

Factory setting: ENABLED

Factory setting: ENABLED

4.5.3 Load/Save in parameter set (PARAM. SET)

The current device amplifier settings can be saved power fail safe in eight parameter sets and later queried. When

switching from the programming operating mode to measuring mode, you will be asked whether or not the change

is to be saved. This is described in Chapter 4.4.3.

You can also use remotes (PARACODE1 ... 2, see Chapter 4.5.8) to Activate/Load parameter sets.

RECALL: Parameter set 1 (parameter set 1 ... 8) and the factory setting (FACT. SETUP) are loaded

SAVE: Save as parameter set 1 ... 8

4.5.4 Adaptation

TRANSDUCER:

Depending on the type of transducer, you can choose between the following bridge types:

Selectable bridge types

EXCITATION:

The excitation voltage for the transducer is selected.

Selectable excitation voltages

INPUT:

Depending on which excitation voltage is chosen, the input range (approximate measuring range) can be selected

for the transducer type.

Input range

I

II

III

1) No distinction is made here between transducers with strain gauges and inductive transducers.

Full bridge

UB = 2.5 V UB = 1 V

±4 mV/V ±10 mV/V

±40 mV/V ±100 mV/V

±400 mV/V ±1000 mV/V

1) Half bridge 1) LVDT

1 V 2.5 V

CF 69 19 V-A0104-5.3 en

Page 22

AUTOCAL:

Depending on the application and on the stability requirement, you can start an autocalibration cycle. This lets you

correct zero point and full scale value drift and the long-term constancy of the measuring amplifier.

Possible settings:

ON

OFF

ONCE

Autocalibration is run once, as soon as you confirm it with . Autocalibration stays on/off, depending

Autocalibration switched on

Autocalibration switched off

on the state previously selected.

CAUTION

If you need the analog output signal for continuous monitoring, you must switch autocalibration off. Reason: during the autocalibration cycle, no measured values are recorded. This produces a “monitoring gap”

(interval approx. 5 min., duration approx. 1 s), which is undesirable if not dangerous during production

processes.

FILTER:

Different filter cutoff frequencies and the filter characteristics can be selected:

Bessel (BE)

(Hz)

Sampling rate

(measured values per sec)

2)

Butterworth (BU)

(Hz)

Sampling rate2)

(measured values per sec)

0.05 18.75 5.0 1200

0.1 37.5 10 1200

0.2 75 20 1200

0.5 300 40 1200

1.25 600 80 1200

2.5 1200 200 1200

5.0 1200

10 1200

20 1200

40 1200

100 1200

200 1200

2) See Motion count (MOTION CNT)

MOTION CNT (Motion count)

To activate the motion count, you must set the number of measurements. During these measurements, the measured value must fall within the given tolerance for ”standstill” to be reported. (for sampling rate, see table).

Settings

+255 MEAS Maximum possible number of measurements

MOTION DIG

Input of tolerance field in digits in display units.

000110 kN

MOTION OUT

Output of motion count status (control output terminal 7; warning).

Possible settings:

+000 MEAS Motion count switched off

OFF The motion count status is not output over WARNING

ON WARNING active, if no standstill or device error

CF 69 20 V-A0104-5.3 en

Page 23

Fig. 4.1: Effect of the motion count

4.5.5 Calibration (CALIBR.)

UNIT

You can select the following units:

Selectable unit

N S cm

OZ PPM mm

LB % µm

TON % PSI

KT M/SS KPAS

T M/S HPAS

KG µm/m PAS

G INLB PA

V FTLB mBAR

mV/V KNm BAR

MP INCH KN

---- m A

mA

NOM. VALUE

You can adjust the nominal value. Specify the nominal value including the desired decimal places.

Examples:

a. You want to measure in a pressure range between 0 and 1000.00 bar:

Enter nominal value: 100000

b. With a 50 kg load cell, you want to display the measured value with 3 decimal places.

Enter nominal value: 50000

DEC. POINT

Changes the position of the decimal point.

Selectable positions

For above example a: .00

For above example B: .000

STEP

You can choose the step or the digit step.

Selectable steps

ZERO VALUE

The maximum zero balance range matches the particular maximum measuring range in the following table.

.0000 0.000 00.00 000.0 0000

1 2 5 10 20 50 100 200 500 1000

CF 69 21 V-A0104-5.3 en

Page 24

RANGE:

Sets a full scale value (unit mV/V). If this value lies outside the input range, the minimum or maximum possible

value is accepted.

Input range Measuring range at UB = 2.5 V Measuring range at UB = 1 V

I ± 0.2 ... 4 mV/V ± 0.5 ... 10 mV/V

II ± 2 ... 40 mV/V ± 5 ... 100 mV/V

III ± 20 ... 400 mV/V ± 50 ... 1000 mV/V

When the measuring range is set, an analog output signal is allocated to the input signal range.

TARE VALUE:

You can specify a tare value (in display units) (net value = gross value minus tare value).

4.5.6 Limit switches 1 ... 4 (LIMITVAL.1 ... 4)

The parameters for setting the limit switches are collected in a group for each limit value. The status of the limit

switches is shown on the display and carried out over the control outputs. The function of the limit switches and

their parameters are shown in the following diagram:

Fig. 4.2: Limit switch functions and parameters

ENABLE

OFF

ON

SOURCE

Limit switch evaluated:

GROSS.VALUE

NET VALUE

PVS1 MAX

PVS2 MIN

PVS3 PP

SWITCH DIR.

Specify here the switch direction or the working direction (see Fig. 4.2.).

HIGHER

LOWER

LEVEL

The level is set in display units (e.g. 2,000 kN).

HYSTERESIS

The hysteresis value prevents “fluttering” of the limit switches upon reaching the switching threshold. Hysteresis results from the difference between the activation and deactivation threshold.

The value is set in display units (e.g. 2 kN).

LOGIC

You can change the output logic of the remotes as required. The following allocation was made:

Disable individual limit switches

Enable individual limit switches

Gross

Net

Store for maximum values

Store for minimum values

Store for peak-to-peak value

The switch-on level is higher than the switch-off level for a rising measured value

The switch-off level is higher than the switch-on level for a falling measured value

CF 69 22 V-A0104-5.3 en

Page 25

ACTIVE.HIGH

Switched on = High

Switched off = Low

ACTIVE.LOW

Switched off = High

Switched on = Low

LV BUTT:

ENABLED

LOCKED

Setting the limit value with possible

Setting the limit value with locked

4.5.7 Set peak value store (PV STORE)

Two peak value stores are available to you for monitoring processes. The following allocation has been made:

PVS1

PVS2

Store for maximum values

Store for minimum values

Use

key to display the Min/Max values in Measure mode.

An additional value is determined arithmetically.

PVS3

Store for peak-to-peak value

Linking with PVS1 regarding control functions and envelope.

Both can be operated as peak value stores or as instantaneous value stores. The choice of operating mode is

made with the remotes.

PVS1 INST

PVS1/Hold

PVS2 INST

PVS2/Hold

Instantaneous or peak value for PV1/PV3

Run / Hold mode for PV1/PV3

Instantaneous or peak value for PV2

Run / Hold mode for PV2

The following diagram shows the function of the remotes:

Fig. 4.3: Function of the remotes shown in the example of PVS1, peak value and instantaneous value stor-

age (also applies to PVS2 and PVS3).

If the stores are operated as peak value stores, it is possible to display an envelope by setting a discharge rate.

This discharge rate affects all peak value stores.

CF 69 23 V-A0104-5.3 en

Page 26

Fig. 4.4: Envelope function

You can set the following parameters:

ENABLE:

You can enable or lock the peak value stores.

PVS ON

PVS OFF

PVS1 INPUT:

Choice of input signal for peak value store PV1.

GROSS.VALUE NET VALUE

PVS2 INPUT:

Choice of input signal for peak value store PV2.

GROSS.VALUE NET VALUE

ENVELOPE:

You can choose the discharge rate (time constant of the discharge function) of the envelope function for both the

peak value stores. The specification corresponds to a time in s.

000.00

000.100 to 60.000 s

4.5.8 Inputs and outputs (IN/OUT)

In this menu, you can make the required settings for the DFI 2555 input signal, the analog output and the remotes.

SOURCE UA:

The following signals can be specified as the source of the analog signal:

GROSS.VALUE

NET VALUE

PVS1 MAX

PVS2 MIN

PVS3 PP

MODE UA:

Depending on the analog signal you select, the following options are possible:

Display Meaning

UA OFF 0 TO 20mA output ± 20 mA

4 TO 20MA output +4 ... 20 mA

UA OFF -

10 VOLT output ±10 V

Enable peak value store

Peak value store locked

envelope function off

envelope function on

Gross

Net

Store for maximum values

Store for minimum values

Store for peak-to-peak value

NOTE

The current output or voltage output selection is made using jumpers on the amplifier motherboard.

CF 69 24 V-A0104-5.3 en

Page 27

INPUT SIGN.:

For test purposes, a calibration signal and a zero signal can be displayed instead of the measurement signal. You

can choose the following input signals:

MEAS.SIGNAL

CAL SIGNAL3)

ZEROSIGNAL3)

3)

To display the measurement signal, you must return to measuring mode.

The display corresponds to 50 % of the current full scale value

Measuring mode

Internal zero point

CONTACT 1 ... 6:

Remotes are available on the connector strip for controlling DFI 2555 functions. The pin assignment or allocation of

the remotes is freely configurable.

Functions Level 0 V Level 24 V

NO FUNCT. No function (factory setting)

AUTOCAL Autocalibration ON Autocalibration OFF

TARE For the transition 0 V – 24 V, the tare value is adopted

PVS1 INST Peak value operating mode for PV1 Instantaneous value operating mode for PV1

PVS1/HOLD Store contents PV1 and PV3 are updated Store contents PV1 and PV3 are frozen

PVS2 INST Peak value operating mode for PV2 Instantaneous value operating mode for PV2

PVS2/HOLD Store contents PV2 are updated Store contents PV2 are frozen

ZEROING For the transition 0 V – 24 V, the current instantaneous input signal is adopted as the zero value

PRINT A printout is triggered over the interface

GROSS/NET Gross at analog output Net at analog output

PARACODE 1

PARACODE 2

External selection of parameter sets and binary coded inputs

(see following table)

PARACODE 3

BUTT.LOCK Enabled Locked

PARAM. SET

PARACODE

3 2 1

1 0 0 0

2 0 0 1

3 0 1 0

4 0 1 1

5 1 0 0

6 1 0 1

7 1 1 0

8 1 1 1

REMOTE

Device control through remotes can be locked or enabled.

ON

OFF

display

No display Operating using keyboard and remotes

LOCAL Keyboard operation only

4.5.9 Additional functions (ADD. FUNCT)

P_ _:

In order to provide better support should you experience technical problems, the firmware status is indicated by this

parameter. If you have any questions for our service department, giving the existing firmware version will enable us

to provide effective support.

Example: P34 Software version P34

SERIAL NO.:

Display the serial number of the device.

Baud rate:

Choose the baud rate to match the baud rate of the connected device (PC, PLC).

Selectable baud rates

300 600 1200 2400 4800 9600

CF 69 25 V-A0104-5.3 en

Page 28

PARITY:

The following settings are possible:

Selectable parity

EVEN PAR. ODD PAR. NO PAR.

Stop bit:

The following settings are possible:

1 STOPBIT

2 STOPBIT

COMM. ADDR:

Input the device address

Selectable device addresses

4)

Address selectable only for RS485 version; for RS232, set address to 1

4)

00 to 31

PRINT GROSS:

Output the gross value over the serial interface:

OFF/ON

Print NET:

Output the net value over the serial interface:

OFF/ON

Print MAX:

Output the maximum value over the serial interface:

OFF/ON

Print MIN:

Output the minimum value over the serial interface:

OFF/ON

PRINT PP:

Output the MIN/MAX value over the serial interface:

OFF/ON

PRINT LVS:

Output limit switch states over serial interface:

OFF/ON

PRINT OVERL

Adjust repetition rate. Heading comprising the source of the measured value and the unit.

0 = no heading (measured value only)

1 = Heading always

10 = Heading every 10 times etc.

Print PAR:

Output all the parameters:

START

NOTE

The chosen print functions (apart from PRINT PAR) are run in measuring mode (by pressing

or by re-

mote contact).

ZERO/TARE:

A change to the tare value or zero value by using the buttons

or is automatically stored in the current pa-

rameter set (EEPROM) power fail safe.

CF 69 26 V-A0104-5.3 en

Page 29

This backup can be switched on or off:

SAVE OFF

SAVE ON

NOTE: The EEPROM is restricted to approx. 10000 write cycles.

5.0 EXAMPLE

The following example uses a measurement task to show you the functionality of the device and the required settings.

Problem definition:

The forming process in a press is to be monitored in order to obtain uniform product quality. The maximum force

exerted by the press is to be recorded in each cycle. To guarantee the production process, this maximum force

must fall between the lower (F1) and upper (F2) force limit.

Solution:

The force characteristic measured with an S.G. force transducer (e.g. C9B/10 kN; 1 mV/V) is amplified and evaluated by the DFI 2555. The peak value store (maximum) is used to record the maximum force and it is evaluated

with two limit switches with regard to the lower and upper limits. An additional limit switch is provided for overload

protection (emergency shut down) of the machine.

A PLC takes over the control of the process. As well as the control commands for the press, it gives the DFI 2555 a

start signal to begin the pressing cycle and once the process has finished, logically links the limit switch outputs to

the ”Good/Bad evaluation”.

The start signal from the PLC clears the contents of the peak value store through the DFI 2555 control input. To

prevent unintentional modifications, during measurement, only the ”Display signal selection” button is enabled for

the machine operator on site.

The parameter setups are protected against unauthorized modification by a password.

Device control through the remotes (remote control) must be activated.

Wiring diagram:

DFI 2555

CF 69 27 V-A0104-5.3 en

Page 30

Time chart:

Evaluation of limit value message by the PLC:

Good Reject

LV1 1 0 1

LV2 1 1 0

Choose the following settings:

LV1 Checks whether the lower force limit has been reached. The input signal is the output of the peak value

store (maximum value). If limit LV1 is exceeded, a High signal is generated. A positive switch direction

must be set with positive output logic.

Limit2 Checks whether the upper force limit has been reached. The input signal is the output of the peak value

store (maximum value). If limit LV2 is exceeded, a Low signal is generated. A positive switch direction

must be set with positive output logic.

LV3 Checks whether the maximum load limit of the machine is exceeded (emergency shutdown function).

The input signal is the gross measured value. If limit LV3 is exceeded, a High signal is generated. A

positive switch direction must be set with positive output logic.

PVS1 Records the maximum peak value of the force characteristic. Must be enabled, the envelope function

must be deactivated. The input signal is the gross measured value. PVS1 is cleared with remote 1 by

switching to instantaneous value.

Remote 1 Clears the contents of the peak value store. The function PVS1 INST must be selected. Remote con-

trol must be activated.

ADA

CF 69 28 V-A0104-5.3 en

Page 31

Continued at right

CF 69 29 V-A0104-5.3 en

Page 32

PTATION

Continued at right

CF 69 30 V-A0104-5.3 en

Continued on next page

Page 33

Continued at right

CF 69 31 V-A0104-5.3 en

Page 34

6.0 ERROR MESSAGES

Error message Cause Remedy

FIX The given value cannot be altered. Example: For unit

V and mV/V, the nominal value setting is fixed at 10,000

OVFL B Gross value overflow

OVFL N Net value overflow

CAL.ERR Incorrect transducer/sensor connection:

No transducer/sensor connected

No six-wire feedback connected

Connect the transducer properly.

Switch device off and then back on

again.

Measuring bridge connected incorrectly (e.g. full bridge

set, but half bridge connected)

HIGHER The value chosen for measuring range, zero point

value, nominal value or tare value cannot be set, as it

exceeds the permissible limits.

The device sets the maximum or

minimum value automatically, as

soon as the error message has been

acknowledged by “ENTER”

DATA ERROR. A transmission error occurred when

saving the parameters

7.0 SPECIFICATIONS

Type DFI 2555

Accuracy class 0.1

Mains connection/supply voltage

Power Consumption, max.

Safety fuse (slow blowing)

Amplifier

Carrier frequency

Excitation voltage U

(±5%)

B

Connectable transducers

S.G. half and full bridge

Inductive half and full bridge,

LVDT’s

Permissible cable length between transducer and

amplifier

Measurement frequency range,

adjustable 9-1 dB)

Input level

Measuring range UB=2.5 V

U

=1 V

B

Bridge balance range

=2.5 V

U

B

U

=1 V

B

Noise voltage1) 0…200 Hz

0…1.25 Hz

Effect of 10K change1) in ambient temperature

(Autocalibration on / off)

Sensitivity

Zero Point

1) For UB =2.5 V, relative to the input

V

Hz

VA

mA

Hz

Vrms

Ω

mH

m

Hz

mV/V

mV/V

mV/V

mV/V

µV/V

µV/V

%

µV/V

PP

PP

115/230, +6%; -10%;

48…60

8

200 (115 V) / 100 (230 V)

4800 ± 0.32

1 or 2.5

UB =1 V

40…5000

6…19

max. 500

rms

UB =2.5 V

rms

80…5000

2.5…20

max. 500

0.05…200

low medium high

0.2…4

0.5…10

±4

±10

0.5

0.015

0.04/0.1

0.2/2

2…40

5…100

±40

±100

1

0.1

0.04/0.1

2/20

20…400

50…1000

±400

±1000

10

1

0.04/0.1

20/200

CF 69 32 V-A0104-5.3 en

Page 35

Measurement frequency range

Butterworth low-pass

Bessel low-pass

Nom.

val fc

(Hz)

Nom.

val fc

(Hz)

1.25

0.05

500

200

80

40

20

10

400

200

100

40

20

10

2.5

0.5

0.2

0.1

5

5

-1 dB

(Hz)

485

245

78

38

19

9.1

4.6

-1 dB

(Hz)

400

215

111

39

21

11

5.3

2.7

1.4

0.7

0.17

0.09

0.044

-3 dB

(Hz)

580

290

98

50

26

12.5

6.3

-3 dB

(Hz)

750

395

190

68

37

19

9.7

4.9

2.4

1.2

0.3

0.16

0.075

Run

Time

(ms)

1.1

1.7

4.3

7.1

12

22

41

Run

Time

(ms)

0.8

1.3

2.5

8.1

14

25

48

90

180

700

1400

2900

5

Rise

Time

(ms)

0.7

1.3

3.8

7.3

14

28

56

Rise

Time

(ms)

0.6

1.0

2.1

5.5

10

19

38

75

150

300

1200

2300

4700

Overshoot.

about

10%

12

11

10

8

7

6

5

Overshoot

about

10%

2

2

2.5

1.1

1

0.7

0.3

0

0

0

0

0

0

CF 69 33 V-A0104-5.3 en

Page 36

Max. permissible common-mode voltage

Common-mode rejection

Max. differential voltage DC

Linearity variation

Long-term drift over 48 hours,

Meas. range 2 mV/V

30 minutes after switching on

(warm-up time)

Analogue output

Applied voltage

Permissible load resistance, min.

internal resistance, max.

Impressed current

Permissible load resistance, max.

internal resistance, min.

The analogue output can show gross, net, positive

and negative peaks and peak/peak values

V

DB

V

%

µV/V

V

kΩ

Ω

mA

Ω

kΩ

± 5 V

typically 110

± 10 V

typically 0.05

Autocalibration on/off

<0.2/ <0.4

± 10 V (asymmetric)

5

1.5

± 20; 4…20

500

100

Interference voltage at the output, typ.

Residual carrier voltage 38.4 kHz

Residual carrier voltage 4800 Hz

Long-term drift (over 48 h)

(30 minutes after switching on)

Effect of 10K change in ambient temperature (ad-

ditional effect to digital value)

Zero point

Sensitivity

Limit switches

Number

Reference level

Reference excit. (independently adjustable)

Factory settings, hysteresis

Adjustment accuracy

Response time

Peak value stores

Number

Function

Update rate

Clearing the peak value store.

Recording the current value/peak value

Time constant for envelopes

mV

PP

mV

PP

mVPP

mV

mV

%

V

V

V

mV

ms

ms

ms

ms

ms

4

3

2

< 3

< 3

< 0.05

4

Gross, net, peak values

-10…+10

0.1

0.33

0.83

(All Butterworth filter frequencies and Bes-

sel filters >1.25 Hz. The values double

each time for the next lower measurement

frequency)

2

Positive; negative; peak-to-peak

0.03

(with Butterworth filter and

Bessel filter >100 Hz)

3.3 (Remote contacts)

3.3 (Remote contacts)

100…60 000 (±6%)

CF 69 34 V-A0104-5.3 en

Page 37

Control outputs (limit switch 1…4,

Warning V

CTRL

)

Nominal voltage, external power supply

Permissible supply voltage range

Output current, max.

Short-circuit current, typ.

Short-circuit period

Isolation voltage, typ.

Remote contacts

Input voltage range, LOW

Input voltage range, HIGH

Input current, typ., HIGH level = 24 V

Interface

Measuring rate, ASCII output

Binary output

Number of data bits

Baud rate

Parity

Stop bit

Parameter Memory (EEPROM)

Display

Number of points

Character height

Type

Keyboard

Dialogue languages

Effect of operating voltage in the case of changes

in the specified range, relative to the full scale

On zero point

On sensitivity

Nominal temperature range

Operating temperature range

Storage temperature range

Degree of protection,

under DIN IEC 60 529

Protection class

Dimensions, over everything (WxHxD)

Front panel frame dimensions

Front panel display section

(according to DIN 43 700)

1)

default settings

Weight, approx.

V

V

A

A

Vrms

V

V

mA

Meas.

/s

Bit

Baud

300,600,1200,2400,4800,9600

odd, even and no

24

11…30

0.5

0.8

unlimited

350

0…5

10…24

12

Approx. 25

Approx. 50

8

1)

1

; 2

1)

8 (parameter sets)

mm

(16-segment, plus var. special characters)

±10

12.5

LCD

(inverse with LED background lighting)

Touch-sensitive keypad with 7 deposited button elements on the printed circuit board Ger-

man/English/French/Italian/Spanish

%

%

°C

°C

°C

mm

mm

mm

kg

IP40 (device) IP51

(front, touch-sensitive keypad)

153x72x212 (220)

0.01

0.01

-20…+45

-20…+45

-20…+70

I

144x72

138x68

1

CF 69 35 V-A0104-5.3 en

Page 38

8.0 WARRANTY REPAIR POLICY

Limited Warranty On Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in workmanship within one year of the date of shipment by Cooper will be repaired or replaced free of charge provided that

a return material authorization is obtained from Cooper and the defective product is sent, transportation charges

prepaid, with notice of the defect, and it is established that the product has been properly installed, maintained, and

operated within the limits of rated and normal usage. Replacement or repaired product will be shipped F.O.B. from

our plant. The terms of this warranty do not extend to any product or part thereof which, under normal usage, has

an inherently shorter useful life than one year. The replacement warranty detailed here is the buyer’s exclusive

remedy, and will satisfy all obligations of Cooper whether based on contract, negligence, or otherwise. Cooper is

not responsible for any incidental or consequential loss or damage which might result from a failure of any and all

other warranties, express or implied, including implied warranty of merchantability or fitness for particular purpose.

Any unauthorized disassembly or attempt to repair voids this warranty.

Obtaining Service Under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact the

Repair Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number. Shipment to Cooper shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from our

plant in Warrenton, Virginia. Non-verified problems or defects may be subject to a $100 evaluation charge. Please

return the original calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty applies

only to those items that were found defective and repaired; it does not apply to products in which no defect was

found and returned as is or merely recalibrated. It may be possible for out-of-warranty products to be returned to

the exact original specifications or dimensions.

* Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper to

receive information specifying the reason the product is being returned. Specific test data, written observations on

the failure and the specific corrective action you require are needed.

CF 69 36 V-A0104-5.3 en

Loading...

Loading...