Page 1

DFI 2555 SERIAL

COMMUNICATIONS GUIDE

www.cooperinstruments.com

PH: (540) 349-4746 • FAX: (540) 347-4755

Page 2

CONTENTS

SAFETY INSTRUCTIONS............................................................................................................1

1.0 INTRODUCTION TO OPERATION WITH COMPUTER OR TERMINAL...............................1

2.0 SERIAL INTERFACE: RS-232C OR RS-485.........................................................................1

2.1 Introduction to the Interface ..........................................................................................................1

2.2 Key data for the serial interface.....................................................................................................2

3.0 COMMUNICATION WITH THE DFI 2555 ..............................................................................2

3.1 Connect DFI 2555 and computer ...................................................................................................2

3.2 Activation of the RS232C or RS485 interface...............................................................................3

4.0 COMMAND SET OF THE INTERPRETER ............................................................................3

4.1 Important conventions ...................................................................................................................3

4.1.1 Command structure .................................................................................................................4

4.1.2 Data-output Structure ..............................................................................................................4

4.2 Description of Individual Commands............................................................................................5

4.2.1 Setting-up of functions in the additional functions group ................................................... 6

4.2.1.1 Setting of the RS232C interface parameters.......................................................................6

4.2.1.2 Setting of the RS485 interface parameters .........................................................................7

4.2.1.3 Querying for Device Identification/Firmware Status. ...........................................................8

4.2.1.4 Print functions .....................................................................................................................8

4.2.2 Setting-up of the Parameter-sets group................................................................................. 9

4.2.3 Define output format, measurement output ........................................................................11

4.2.3.1 Define output format.......................................................................................................... 11

4.2.3.2 Specify measurement output.............................................................................................12

4.2.4 Setting up the Adaptation group functions ......................................................................... 13

4.2.4.1 Setting up amplifier input................................................................................................... 13

4.2.4.2 Choose filter settings......................................................................................................... 14

4.2.4.3 Setting autocalibration....................................................................................................... 16

4.2.5 Setting up the Calibration group functions ......................................................................... 17

4.2.5.1 Selecting the unit of measure............................................................................................ 17

4.2.5.2 Selecting the indication upper limit....................................................................................18

4.2.5.3 Setting zero value..............................................................................................................19

4.2.5.4 Set measuring range.........................................................................................................19

4.2.5.5 Tare...................................................................................................................................20

4.2.6 Setting up the Limit Value 1...4 group functions.................................................................20

4.2.7 Setting up the functions of the Peak value store group.....................................................22

4.2.8 Setting up the functions of the Inputs/Outputs group........................................................ 23

4.2.8.1 Select amplifier input signal...............................................................................................23

4.2.8.2 Setting up the analog output .............................................................................................24

4.2.8.3 Setting up remote control ..................................................................................................25

4.2.8.4 Setting up assignment of the remotes............................................................................... 25

4.2.9 Setting up the Adaptation group functions ......................................................................... 26

4.2.9.1 Lock-control of the keys .................................................................................................... 26

5.0 ABBREVIATION/COMMAND INDEX ..................................................................................27

CF 127 iii V. -A0109-5.3 en

Page 3

SAFETY INSTRUCTIONS

The instrument complies with the safety requirements of DIN EN 61010, Part 1 (VDE 0411, Part 1); Protection

Class I. When connecting the instrument please adhere to the factory-set main voltage. This is shown on the rear

panel of the housing (230V/115V, 48...60Hz). Since the instrument is not fitted with its own mains switch, the power

cable must not be connected direct to the mains supply. According to VDE Guidelines it must be possible to

disconnect these instruments from the mains by means of a switching device (e.g. a mains switch).

1.0 INTRODUCTION TO OPERATION WITH COMPUTER OR TERMINAL

The DFI 2555 panel amplifier for panel-frame mounting (in accordance with DIN 43700) is suitable for recording

and processing measured data from passive transducers in the field of industrial test-facility engineering and

manufacturing-process monitoring.

Its main features are:

• Attachable transducers: SG full and half bridges, inductive full and half bridges, piezoresistive transducers,

LVDTs, potentiometers

• 10-character alphanumeric display

• Operation through touch-sensitive keypad; keys individually lockable

• 2 peak value stores for maximum and minimum values, also envelope and instantaneous value

• 4 limit monitors

• Parameter store for storing up to 8 data records

• Control I/Os (optocoupler-isolated)

This manual describes how to operate your DFI 2555 with a terminal or computer. It describes connection of a

computer via the RS232 for complete parameter input and scanning of measured data.

All steps required for setting up the instrument via the keypad, all information required for commissioning and all

menus are listed and described in a separate document, ”DFI 2555 User’s Guide”.

2.0 SERIAL INTERFACE: RS-232C OR RS-485

2.1 Introduction to the Interface

Through this serial interface data is transferred serially, one bit at a time. General properties are:

• Transmission speed relatively ”low”

• Requires in the simplest case a 3-core cable for bi-directional (duplex) transmission

• Only one device can be connected (point-to-point link)

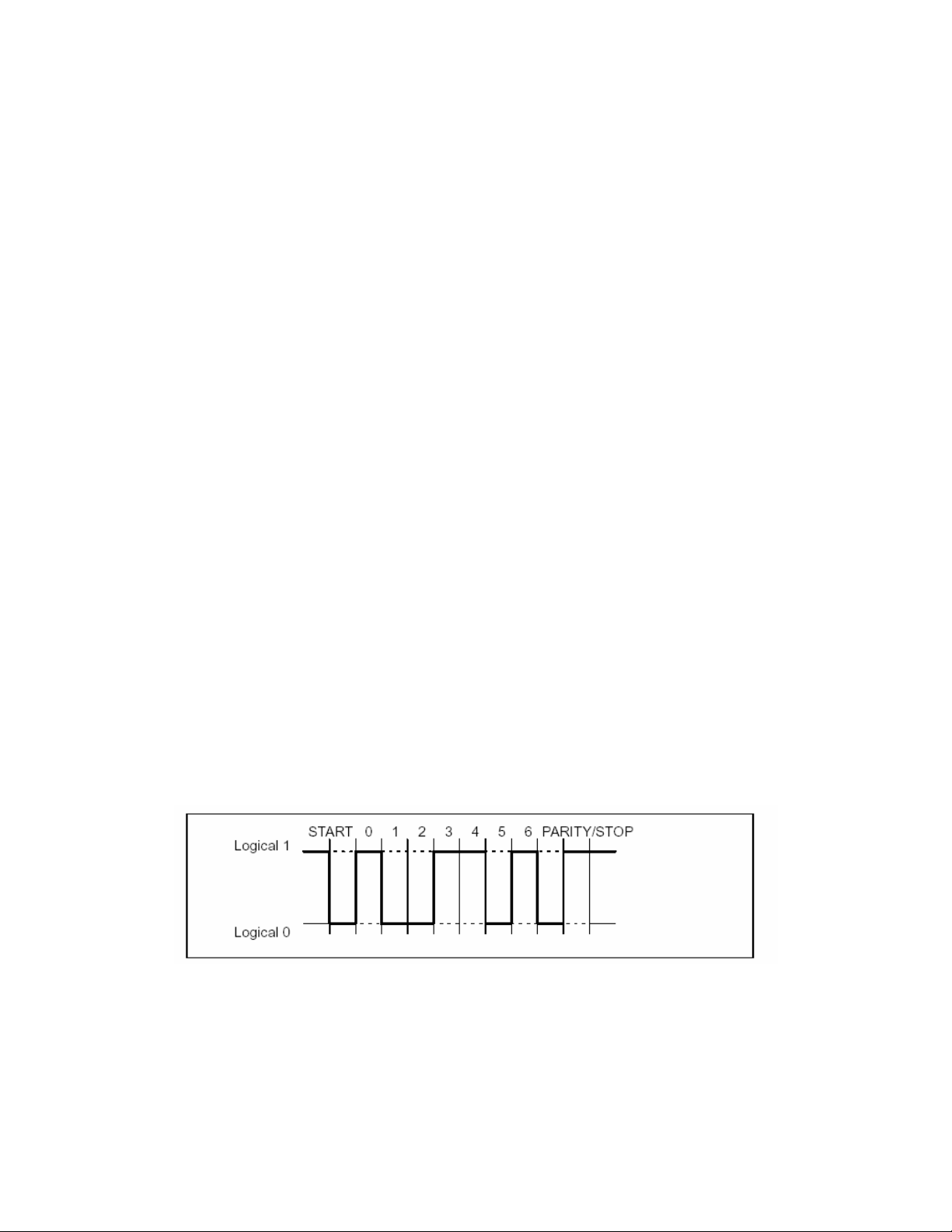

Figure 1:Line level of the character Y with negative logic

A start bit is placed in front of each character (data byte). Then follow the data bits and a stop bit. Since data is

transferred sequentially, the speed of the transmitter must match that of the receiver. The number of bits per

second is termed the baud rate. A receiver’s exact baud rate is synchronized by the start bit for each byte

transmitted. Then follow the data bits, all of equal length. Once the stop bit has been reached, the receiver enters

its waiting state until reactivated by the next start bit. Data transmission is controlled by means of the software

handshake X-ON (DC1) and X-OFF (DC3). When the instrument is ready to transmit data, it sends the control

character X–ON (DC1) down the data line. If it cannot accept data, e.g. if its memory is full, the control character X–

OFF (DC3) is sent.

CF 127 1 V. -A0109-5.3 en

Page 4

2.2 Key data for the serial interface

Sampling rate 10 meas./s

Word length 8 bits

Stop bits 1*; 2

Parity odd, even* and none

Baud rate 300; 600; 1200; 2400; 4800; 9600*

* Factory setting

The interface configuration of the DFI 2555 (baud rate, parity and stop bit) must match that of the computer.

3.0 COMMUNICATION WITH THE DFI 2555

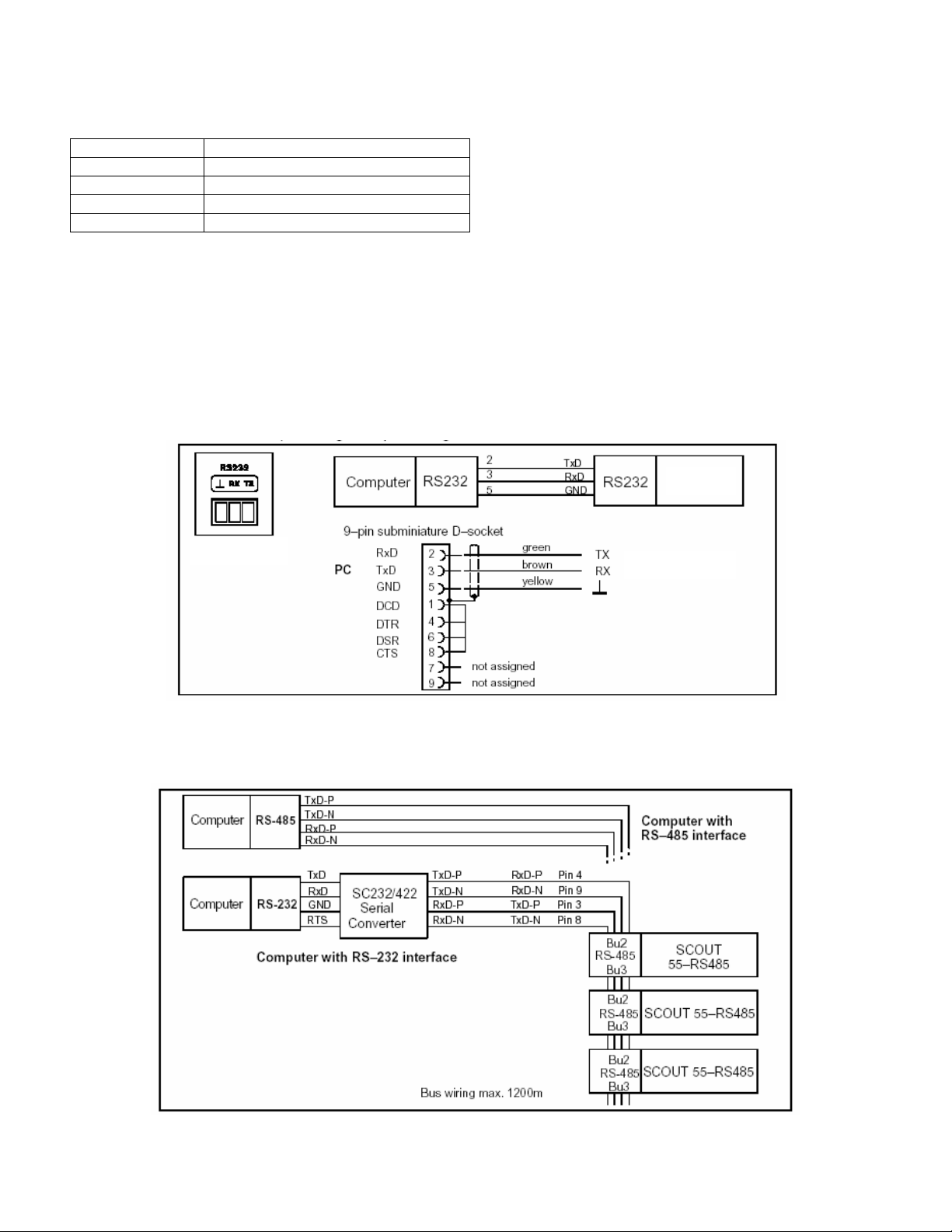

3.1 Connect DFI 2555 and computer

On the back of the instrument there is an RS232 serial interface for connecting a computer or terminal. For RS232

connection a connectorless cable (length 1.5m) and 9-pin subminiature socket* are supplied. Wiring and pin

assignment should be as illustrated below.

DFI 2555

Interface socket

on the DFI 2555

DFI 2555

*accessories

Figure 2: Computer / DFI 2555 connection

Figure 3: The RS485/422 bus with and without serial converter

CF 127 2 V. -A0109-5.3 en

Page 5

To connect the DFI 2555 to a computer proceed as follows:

• Connect both systems to the mains, leaving them switched off

• Connect the interface as shown in the diagram(s)

• The computer’s interface configuration (baud rate, data format) must match the DFI 2555’s basic setting. If it

does not, the interface configuration must be altered via the keypad (see DFI 2555 User’s Guide).

• Finally, switch both systems on.

When a printer is connected, a simple line printer operating at no more than 4 seconds per line is adequate. The

printout is in 12 columns. This corresponds to a line length of 132 characters.

3.2 Activation of the RS232C or RS485 interface

The Interpreter is activated by the following signal:

* CTRL R (DC2) computer operation without echo

Input of the control character puts the instrument into remote-operation mode; only the display’s output functions

can now be controlled. Computer operation without echo means that no command characters but only the data

generated are sent back to the DFI 2555. With the RS-232C interface each information-item generated is output as

soon as it is complete in the output buffer.

With the following command you can deactivate remote operation:

CTRL A (SOH); see also command DCL in Section 4.2.

4.0 COMMAND SET OF THE INTERPRETER

4.1 Important conventions

These conventions and general notes make working with the Interpreter’s commands easier for you.

Notation

• All commands can be input in lower or upper case.

Short commands

• Short commands consist of 3 to 5 characters and, depending on the command, a list of parameters separated

by commas.

e.g. BDR 6,2,1 (x)

Blanks

• Prefixed and following blanks in parameters are suppressed.

Command types

• Query commands – used for retrieving information – are identified by an added question mark (?)

e.g. BDR?

Responses

• The instrument’s responses given in the examples are shown in the User Manual in italics.

Command terminator

For input commands:

• (x) marks the command terminator. Permitted command terminators are: ”;”, LF, LFCR, CRLF

For output commands:

• (y) marks the command terminator. The command terminator is always CRLF.

I/O with numbers

• The numbers entered are changed to the relevant parameter’s numeric format

• Numbers are always output in fixed point format

CF 127 3 V. -A0109-5.3 en

Page 6

Serial interface

• With the RS232C interface, communication with a computer begins with the permitted control characters:

CTRL R or CTRL B and ends with CTRL A or the command DCL

• In the case of serial interfaces every command generates an output (response)

Acknowledgement

• Output commands – identified by a ? – always give rise to output data.

• Changing parameters

• If parameters affecting the measurement process itself are changed, calibration is performed after input; this

can take 1...3s.

Norms and standards

All commands used have a defined structure. There are essentially two types of command:

Set-up commands:

The DFI 2555 is set up through the computer.

Example: BDR6,2,1 (x)

0 (y)

The interface is set to 9600 baud, even parity and 1 stop bit.

Query commands:

Measured values or instrument settings are read from the

DFI 2555 and appear on the screen.

Example: BDR? (x)

6,2,1 (y)

The interface is set to 9600 baud, even parity and 1 stop bit.

4.1.1 Command structure

Short command Parameters End marker

TTT? p1,p2,...pn (x)

Example:

BDR? (x)

BDR Short commands as alphabetical characters (a...z)

? Only in query commands

p1,p2...pn Parameter values, consisting of sign (+/-) and numbers (0...9) or character strings (always in

quotation marks ” ”). A positive sign can be omitted.

, Separator

(x) Command terminator:

Line Feed (LF), Semi-colon (;) Carriage Return/Line Feed (CRLF) or Line Feed/Carriage

Return (LFCR)

CR ASCII characters: Carriage Return = decimal 13

LF ASCII characters: Line Feed = decimal 10

; ASCII characters: Semicolon = decimal 59

If an additional parameter - e.g. Parameter 2 - is omitted, at least the separator must be entered, e.g. ASA 1,,0(x)

If from a particular point all additional parameters are omitted, input can be concluded with the command

terminator.

4.1.2 Data-output Structure

q1,q2...qn (y)

Example 1:

IDN? (x)

HBM,MVD2555,0,P10 (y)

The responses sent by the DFI 2555 are printed in italics

q1,q2...qn Signed numerical values,

in this documentation (second line in the examples).

CF 127 4 V. -A0109-5.3 en

Page 7

Character strings (always in quotation marks) or ’?’ as an error message

; Separator

(y) End of sequence (CRLF)

4.2 Description of Individual Commands

On the following pages each command is listed, its structure analyzed and explained with an example.

Command

The character string that must be input to operate the instrument, e.g.:

BDR

Syntax

Mandatory notation for a command, e.g.:

BDR p1,p2,p3 (x)

BDR p1,,p3 (x)

Parameters

The meaning of any parameters is explained:

e.g. if for command ASA parameter p1=1, this means:

1V bridge excitation voltage

Effect

e.g. explanation of how the instrument is set up.

Response

The instrument responds to your input. In operation via terminal this response appears on the screen

(always in the case of output commands).

Example

The example shows you the command entered and the instrument’s response. The response is always

shown in italics.

Command

DCL Device Clear

Terminate communication

Syntax: DCL (x) or with RS232C/RS485 control character

CTRL A (ASCII code 01 decimal).

Parameters: none

Effect: Remote control operation is terminated.

Example: DCL(x)

Interpreter is no longer active.

Note:

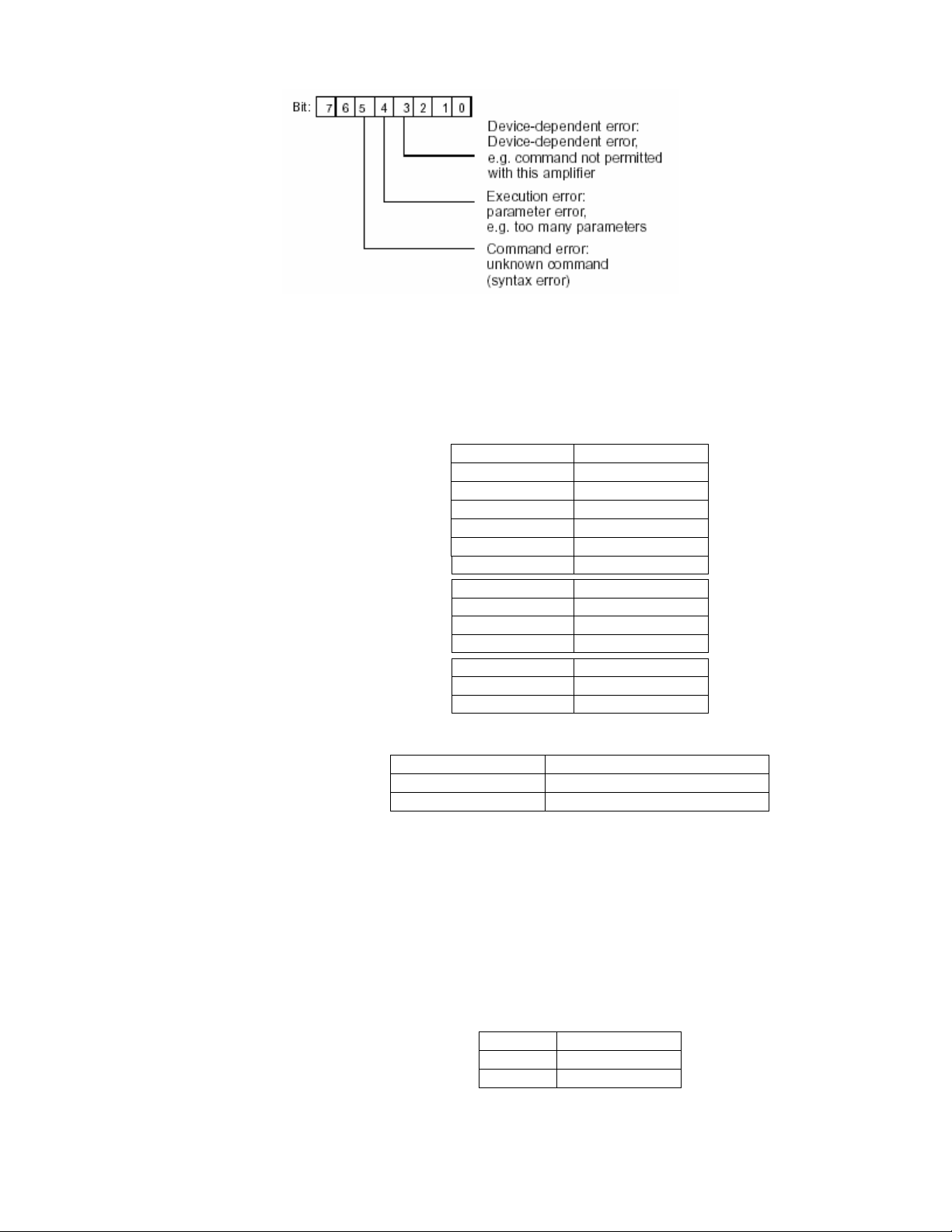

ESR?

Output of the event-status register

Syntax: ESR? (x)

Parameters: none

Effect: Output of the contents of the standard event-status register (ESR) in decimal

q1 8, 16 or 32

Response: none

After this command you can input a new command only after approx. 3s.

Standard Event Status Register

equivalent.

The standard event-status register (ESR) is set if errors occur in communication.

Different causes of error set different bits, so that errors can be specified precisely.

Response: q1( y)

CF 127 5 V. -A0109-5.3 en

Page 8

All other bits are undefined.

4.2.1 Setting-up of functions in the additional functions group

4.2.1.1 Setting of the RS232C interface parameters

Command

BDR Baud rate

Syntax: BDR p1,p2,p3 (x)

Parameters:

Transmission is always carried out with a character length of 8 bits.

Effect: The serial interfaces’ baud rate, parity bit and number of stop-bits are reset.

Response:

Example: The DFI 2555 is being operated via the RS232C interface:

Command

BDR?

Output serial-interface parameters

Syntax: BDR?(x)

Parameters: none

Effect: The serial interface’s set baud rate, parity bit and number of stop bits are output.

Response: q1,q2,q3 (y)

Example: BDR? (x)

Setting of the RS232C parameters

p1 Baud rate

1 300

2 600

3 1200

4 2400

5 4800

6 9600

p2 Parity

0 None

1 Odd

2 Even

p3 Stop Bits

1 1 stop bit

2 2 stop bits

Acknowledgement Meaning

0 Command has been executed

? Error

BDR6,2,1 (x)

0 (y)

The RS232C interface has been set to 9600 baud, even parity and 1 stop bit.

Baud Rate Query

q1 Baud rate

q2 Parity

q3 Stop bits

6,2,1 (y)

CF 127 6 V. -A0109-5.3 en

Page 9

The interface has been set to 9600 baud, even parity and 1 stop bit.

4.2.1.2 Setting of the RS485 interface parameters

ADR Address

Assign RS485 address to the instrument

Syntax: ADR p1(x)

Parameters:

Effect: The command specifies the instrument’s RS485 address (see also command Sxx

on next page).

Response:

Acknowledgement Meaning

ADR? Address Query

Output the device address

Syntax: ADR?(x)

Parameters: none

Effect: Output the device address.

The RS485 address can be set using the command ADR or via the keypad in the

additional functions under COMM.ADR.

Response:

q1(y)

Command

Sxx

Select

Selects the DFI with the address xx

Syntax: S00(x) to S99(x)

Parameters: none

Effect: With the Select command

you can actuate individually up to 32 MGC devices

connected to one RS422/485 bus. There are 32 usable addresses 0...31. With the

Select command these addresses are mapped again on to addresses 32...63 and

64...95, i.e. the commands S00, S32, S64 actuate the devices with the address 00, but

their effect on them is not the same. Addresses 96...99 are provided for special

functions.

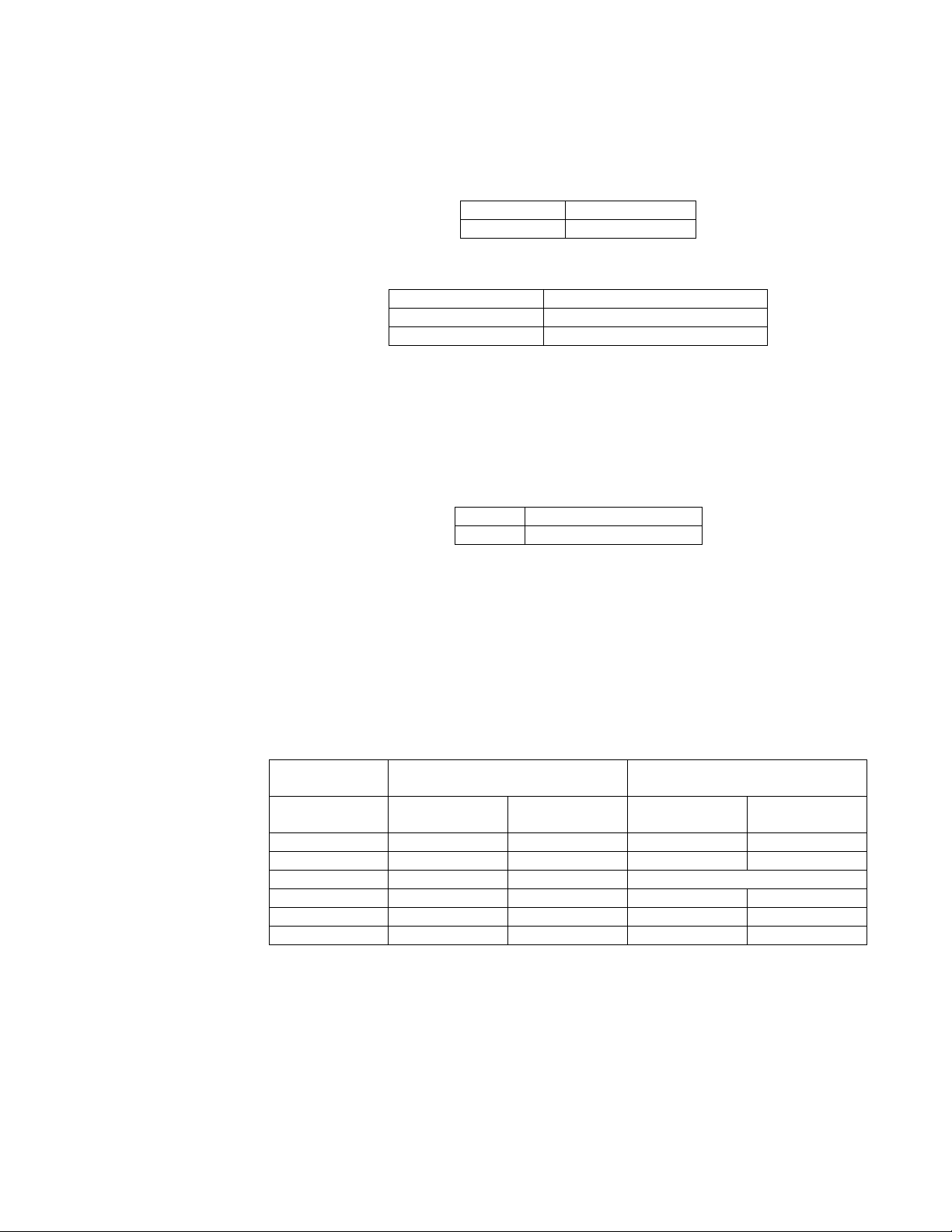

Address Sxx Device with the

specified address Sxx

Execute

Command

00…31 Yes Yes2) No No

32…63 Yes Yes2) Yes No1)

64…95 Yes No1) as for last address selected

96 No No No No

97,98 Yes No1) Yes No1)

993) Yes Yes2) Yes Yes2)

1) The response to the previous command is stored internally.

2) The stored response to the previous command is output subsequently.

3) Factory setting

Explanation:

S00...S31(x)

Only the instrument with the specified address receives commands, executes them and responds.

S32...S63(x)

All instruments receive all commands and execute them. Only the instrument with the specified address (S32 =

device 0) responds on behalf of all instruments.

p1 Device address

0…31

0 Command has been executed

? Error

q1 Device address

0…31

All other devices

Responses Execute

Responses

Command

CF 127 7 V. -A0109-5.3 en

Page 10

S64...S95(x)

The instrument with the specified address is accepted as a supplementary station that receives and executes all

commands but sends no responses.

S96(x)

All instruments wait for Select and send no responses.

S97 (x) or S98(x)

All instruments receive all commands and execute them, but send no responses.

S99(x)

All instruments on the bus are active, receive all commands and send responses (where there are multiple stations

this leads to collisions on the bus). Presetting of the devices after switching on (default).

Response: none

Example: S03(x)

Instrument with the address 03 executes all commands and responds.

S35(x)

All instruments on the bus receive and also execute all commands. Instrument with the address 03 (35-32)

responds on behalf of all instruments.

4.2.1.3 Querying for Device Identification/Firmware Status.

Command

AID?

Output of device identification

Syntax: AID?(x)

Parameters: none

Effect: Output of amplifier identification (firmware status)

Example: AID? (x)

Instruction

SNR? Serial Number

Output serial number of device

Syntax: SNR?

Parameter: None

Effect: Output of the serial number of the device

Response: Character string (10 characters)

Example: SNR? (x)

Response: Character string (20 characters)

Amplifier Identification Query

HBM,MVD2555,0,P15 (y)

Company, device designation, serial number, software version number

4021837410

4.2.1.4 Print functions

Command

PFS

Define print-format

Syntax: PFS p1 (x)

Parameters:

Effect: Signal to be printed is specified.

Print Format Select

p1 Signal to be printed

0 Value shown on the display

1 Gross value

2 Net value

4 Peak value1 (maximum)

8 Peak value2 (minimum)

16 Peak value3 (peak-to-peak)

63 All signals and status of limit values

You can set all signal-combinations by totaling the code numbers.

CF 127 8 V. -A0109-5.3 en

Page 11

The setting affects print-output through the initiation of printing (key, remote)

Response:

Acknowledgment Meaning

0 Command has been executed

? Error

Example: Gross value, Net value are to be printed

p1 = 1+2

PFS 3 (x)

0 (y)

Command

PFS?

Print Format Select Query

Query print-format

Syntax: PFS?(x)

Parameters: none

Effect: Signal being printed is output.

Response: q1 (y)

Signal, or signal-combination which was set with the PFS command (Coding: see

PFS command).

Example: PFS? (x)

1 (y)

The gross signal is printed (initiation via key or remote).

4.2.2 Setting-up of the Parameter-sets group

Command

MDD

Input of amplifier set-up data

Syntax: MDD p1 (x)

Parameters: p1

Effect: The command is used to save and recall complete set-ups.

Response:

Memory Device Data

Amplifier set-up data obtained from the amplifier with the MDD? command (as a

hexadecimal string ” ___ ”, approx. 100 bytes = 200 characters).

To change individual parameters, please use the relevant command (e.g. IMR).

Acknowledgment Meaning

0 Command has been executed

? Error

Example: MDD ”____(hexadecimal string)____” (x)

0 (y)

The amplifier is now set up.

Command

MDD?

Memory Device Data Query

Output of amplifier set-up data

Syntax: MDD? (x)

Parameters: none

Effect: The amplifier’s set-up parameters are output.

Response: ”___( hexadecimal string)___” (y) ”approx. 100 bytes = 200 characters

Example: MDD? (x)

”0a00ff.......” (y)

All set-up parameters are output.

Command

TDD

Transmit Device Data

Save amplifier settings

Syntax: TDD p1,p2 (x)

CF 127 9 V. -A0109-5.3 en

Page 12

Parameters:

p1 Amplifier settings

0 Factory settings (set-up)

1 RECALL from parameter set 1…8

2 SAVE from parameter set 1…8

3 Automatic saving of zero/tare values

if p1=0 (factory setting); p2 no effect

if p1=1 or p1=2 ; p2=parameter-set no.

p2 Number of the parameter set

(if p1=1 or p1=2)

1..8 Parameter set 1 to 8

if p1=3: p2=1, status of automat. saving of zero/tare values

p2 Status of automatic zero/tare value saving

(if p1=3)

0 Off

1 On

Effect: The amplifier settings are saved or stored. Automatic saving of zero/tare values to

the EEPROM can be switched on or off.

Response:

Acknowledgment Meaning

0 Command has been executed

? Error

Example 1: TDD2,8 (x)

0 (y)

The current amplifier settings are stored in parameter set 8.

Note: This command triggers a calibration process that permits communication to

continue only after 1...3s.

Example 2: TDD3,1 (x)

0 (y)

Automatic saving of zero/tare values is switched on. At each zeroing the zeroing

value is stored in the current parameter set. At each taring the tare value is stored

in the current parameter set.

Command

TDD?

Transmit Device Data Query

Query source of the amplifier settings.

Syntax: TDD?p1 (x)

Parameters:

p1

0 Source of the amplifier setting

3 Status of automat. saving of zero/tare values

Effect: The source of the currently active amplifier setting is output or the status of

zero/tare value saving is indicated.

Response: if p1 = 0; q1 shows the source of the amplifier settings

q1 Source of the amplifier settings

1…8 Parameter set 1…8

? Error

if p1 = 3; q1 corresponds to the status of tare/zero value saving

q1 Status of automat. saving of zero/tare

0 Off

1 On

CF 127 10 V. -A0109-5.3 en

Page 13

Example1: TDD?0 (x)

2 (y)

The source of the currently active amplifier setting is parameter set 2.

Example 2: TDD?3 (x)

1 (y)

Automatic saving of zero/tare values is switched on.

4.2.3 Define output format, measurement output

4.2.3.1 Define output format

Command

COF

Change format of measurement output

Syntax: COF p1 (x)

Parameters:

Change Output Format

p1 Measurement output format

0 Measured value, status (ASCII format)

1 Measured value (ASCII format)

2 Binary measurement output 4 bytes (MSB XXXX LSB)

3 Binary measurement output 4 bytes (LSB XXXX MSB)

4 Binary measurement output 2 bytes (MSB LSB)

5 Binary measurement output 2 bytes (LSB MSB)

6 BCD measurement output

Binary 4-byte output:

Binary 2 byte output: 1=MSB, 2=LSB

BCD output:

Measured values are scaled to the indication upper limit. Where output is in ASCII

format, account is taken of the decimal point. In binary/BCD format the decimal

point must be included by the user in processing of measured values.

Effect: With the following MSV commands measured values are output in the preferred

form.

CF 127 11 V. -A0109-5.3 en

Page 14

Response:

Acknowledgment Meaning

0 Command has been executed

? Error

Example: COF0 (x)

0 (y)

Measured values and status are output in ASCII format.

Command

COF?

Change Output Format Query

Query format of measurement output

Syntax: COF?(x)

Parameters: none

Effect: Code number for the output format is output.

Response: q1 (y)

Example: COF?(x)

0 (y)

ASCII format is set as the output format for measured value and status.

4.2.3.2 Specify measurement output

Command

MSV?

Output of the measured value

Syntax: MSV p1,p2 (x)

Parameters:

Measuring Signal Value Query

p1 Signal

1 GR Gross (with display filtering)

2 NET Net (with display filtering)

3 STORE1 Peak value 1 (maximum)

4 STORE2 Peak value 2 (minimum)

5 STORE3 Peak value 3 (peak-to-peak)

6 LVS1 Level

7 LVS1 Hysteresis

8 LVS2 Level

9 LVS2 Hysteresis

10 LVS3 Level

11 LVS3 Hysteresis

12 LVS4 Level

13 LVS4 Hysteresis

14 GR Gross (dyn., without filtering)

15 NET Net (dyn., without filtering)

p2 Number of measured values

0 Send continuously

1…65535 Default = 1

Effect: The measured value from the required signal p1 is output. Format dependent on the

last COF command.

Response: Measured value (output format: see COF command).

CF 127 12 V. -A0109-5.3 en

Example 1: Output in full ASCII format

COF0(x)

0 (y)

Fetch a gross measured value.

MSV?1 (x)

9,998.0 (y)

Status byte*

Measured value = 9.998

Fetch three net measured values.

Page 15

* See 4.2.3.1

MSV?2,3 (x)

9,998.0 CRLF

9,998.0 CRLF

9,998.0 CRLF (y)

Status byte*

Measured value = 9.998

Example 2: Output in 4 byte binary format

Binary 4 byte format

COF2 (x)

0 (y)

Fetch a gross measured value.

MSV?1 (x)

#0ffeedd00CRLF(y)

Status byte*

3 byte measured value

Identification key for binary output

Example 3: Continuous output

Gross measured values are output continuously.

MSV?1,0 (x)

#0ffeedd00CRLF

#0ffeedd00CRLF

#0ffeedd00CRLF

STP(x) Terminate output

Command

STP

Stop

End of measurement output

Syntax: STP (x)

Parameters: none

Effect: The measurement output initiated with MSV?1,0 is stopped.

Response: none

Example: STP (x)

4.2.4 Setting up the Adaptation group functions

4.2.4.1 Setting up amplifier input

Command

ASA

Input bridge excitation voltage, transducer type and input range

Syntax: ASA p1,p2,p3 (x)

Parameters:

Amplifier Sensor Adaptation

P1 Bridge excitation voltage

1 1 V

2 2.5 V

P2 Transducer type

1 Full bridge

2 Half bridge

3 LVDT

P3 Input signal range (at Eop)

1 4mV/V (Eop=2.5 V) / 10mV/V (Eop=1V)

2 40mV/V / 100mV/V

3 400mV/V / 1000mV/V

Effect:

Response:

Bridge excitation voltage, transducer type and input-signal range are set.

Acknowledgement Meaning

0 Command has been executed

CF 127 13 V. -A0109-5.3 en

? Error

Page 16

Example: The DFI 2555 is being set up:

ASA1,2,2 (x)

0 (y)

The DFI 2555 is set to bridge excitation voltage 1 V, half bridge and input-signal

range 100mV/V.

Command

ASA?

Amplifier Sensor Adaptation Query

Output bridge excitation voltage, transducer type and input range

Syntax: ASA?p1(x)

Parameters:

p1

0 Output bridge excitation voltage, transducer type and input-

signal range settings

1 Output table of possible settings for bridge excitation voltage,

transducer type and input-signal range

Effect: The amplifier outputs the bridge excitation voltage, transducer type and input-

signal ranges.

Response: ASA?0 (x)

q1,q2,q3 (y)

q1 Bridge excitation voltage

q2 Transducer type

Example: ASA?0 (x)

q3 Input signal ranges

1,2,2 (y)

The DFI 2555 is currently set to bridge excitation voltage 1V, half bridge and inputsignal range

100mV/V.

Response:

ASA?1 (x)

q1,q2,q3 (y)

Table of available settings

q1 Bridge excitation voltage

q2 Transducer type

Example: ASA?1 (x)

q3 Input signal ranges

Amplifier’s response:

”01.002.50”, ”123”, ”123”(y)

4.2.4.2 Choose filter settings

Command

ASF Amplifier Signal Filtering

Syntax: ASF p1,p2(x)

Parameters:

Effect: The low-pass filter is set to a frequency value and set of filter characteristics.

Response:

Example: Input of cutoff frequency and filter characteristics:

Input of cutoff frequency and filter characteristics

p1 Filter frequency

1..n Code number for frequency value (corresponds to the index from the

frequency table, which can be output with the command ASF?0) see below.

p2 Filter characteristics

1 Bessel

2 Butterworth

Acknowledgement Meaning

0 Command has been executed

? Error

ASF 10,1(x)

0 (y)

CF 127 14 V. -A0109-5.3 en

Page 17

The Filter is set to a cutoff frequency of 40Hz and Bessel characteristics (see

Command ASF?)

Command

ASF? Amplifier Signal Filtering Query

Syntax: ASF?p1(x)

Parameters:

Output of cutoff frequency and filter characteristics.

p1 Filter code number

0 Current filter settings

1 Frequency table (Bessel and Butterworth)

Effect: Output of the low-pass filter parameters, i.e. set cutoff frequency and filter

characteristics

Response: If p1 =0

q1,q2 (y)

q1 Code number for the filter frequency

q2 Filter characteristics (1=Bessel, 2=Butterworth)

Table of available filter frequencies (Bessel/Butterworth)

Example: Table of available filter frequencies

ASF?1 (x)

”0.050 0.100 0.200 0.500 1.250 2.500 5.00 10.00 20.00 40.00 100.0 200.0 400.0”,

”5.000 10.00 20.00 40.00 80.00 200.0” (y)

The following table shows a summary of the available cutoff frequencies and the

index of the frequency to be set (each element is 5 characters long).

p1 Bessel frequencies (Hz) Butterworth frequencies (Hz)

1 0.050 5.000

2 0.100 10.00

3 0.200 20.00

4 0.500 50.00

5 1.250 80.00

6 2.500 200.0

7 5.000 500.0

8 10.00

9 20.00

10 40.00

11 100.0

12 200.0

13 400.0

Command

MTC Motion Control

Syntax:

Parameters:

Specify motion-count indication (measured values/tolerance band/output)

MTC p1,p2,p3 (x)

p1 Number of measured values

0 Motion count indication off

1..255 Number of measurements; in conjunction with the chosen filter frequency

p2 Tolerance band

In digits

p3 Motion-count indication output status

0 No output of status via “WARNING”

1 Output of status via “WARNING”

Effect: The motion-count indication function is set up.

Example: MTC 200,10,1 (x)

0 (y)

this yields the corresponding time-span

CF 127 15 V. -A0109-5.3 en

Page 18

Assumption:

Filter setting: f<2.5Hz = sampling rate of 1200 values/sec

Indication upper limit: 100.00N, resulting in a time span of 166ms

Motion count indication is set:

If 200 measured values lie within a tolerance band of

0.1N (10 digits), motion-count indication is activated.

The status is also output via ”WARNING”.

Command

MTC? Motion Control Query

Syntax: MTC?p1(x)

Parameters:

Output of motion-count indication

p1

0 Motion-count indication settings

Effect: Output of motion–count indication settings

Response: If p1=0; output of motion–count indication

1 Motion-count indication status

settings

q1,q2,q3 (y)

q1 Number of measured values

q2 Tolerance zone in displayed units

q3 “WARNING” output status

If p1=1; q1 shows the status of motion-count indication

Example: MTC?0 (x)

0,0,0 (y)

Motion-count indication has not been activated. The status of motion-count indication

is not output via ”WARNING”.

4.2.4.3 Setting autocalibration

Command

ACL Autocal

Syntax: ACL p1 (x)

Parameters:

Effect: Switchover of autocalibration setting

Response:

Example: ACL1 (x)

Hint: A calibration is triggered and cyclic autocalibration is switched on. This interrupts the

Command

ACL? Autocal Query

Syntax: ACL ? (x)

Parameters: none

Switching on/off of autocalibration

Acknowledgment Meaning

0 (y)

measurement process approximately every 5 minutes and calibrates the amplifier. If

such interruption during a measurement process would be a problem, automatic

calibration must remain switched off.

Switching on/off of autocalibration

q1 Motion-count indication status

q2 No standstill; conditions not satisfied

q3 Standstill; conditions satisfied

p1 Automatic calibration

0 Switch off

1 Switch on

0 Command has been executed

? Error

CF 127 16 V. -A0109-5.3 en

Page 19

Response:

Command

CAL

Response:

Effect: Status of autocalibration is output.

q1 Status

0 Autocalibration is off

Example: ACL? (x)

1 (y)

Autocalibration has been switched on.

Calibrate

Calibration

Syntax: CAL (x)

Parameters: none

Effect: A single calibration is triggered.

Acknowledgment Meaning

Example: CAL (x)

0 (y)

Calibration is performed.

Note: This command initiates a single calibration, permitting further communication

only after 1 to 3s.

1 Autocalibration is on

0 Command has been executed

? Error

4.2.5 Setting up the Calibration group functions

4.2.5.1 Selecting the unit of measure

Command

ENU

Response:

Command

ENU? Engineering Unit Query

Engineering Unit

Input of the unit of measure

Syntax: ENU p1(x)

Parameters:

Effect: The unit of measure is set.

Example: ENU11(x)

0 (y)

kN is set as the unit of measure.

Output of the unit of measure

Syntax: ENU?p1(x)

Parameters:

p1 Input of the unit of measure

1…n Code number for the desired unit of measure (see table)

Acknowledgment Meaning

0 Command has been executed

? Error

p1 Output of the unit of measure

0 Output of currently set unit of measure

1 Output of all available settings

CF 127 17 V. -A0109-5.3 en

Effect: The currently selected unit of measure is output

Response: q1 (y)

Example 1: ENU?0 (x)

Example 2: ENU?1 (x)

11 (y)

kN has been selected as the unit of measure

”mV/V, V, g, kg, T, kT, TON, LB, oz, N, kN, bar, mbar, Pa, PAS, HPas, KPas

PSI, µm, mm, cm, m, Inch, Nm, kNm, FTLB, INLB, µm/m, m/s, m/ss, %, ‰, PPM s,

MP, MN ” (y)

Page 20

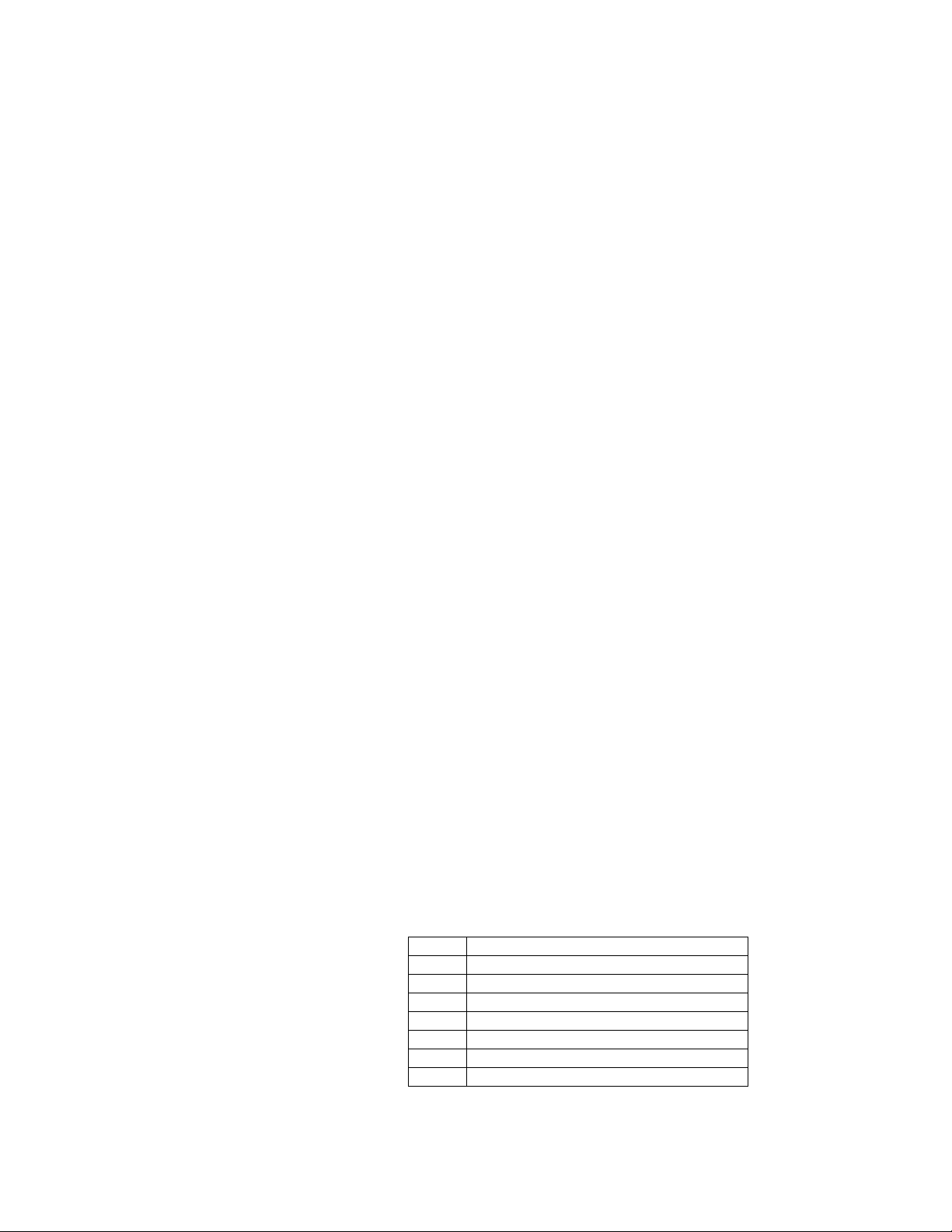

Summary of all available units and code numbers

Index Index Index Index

1 mV/V 13 mbar 25 kNm 37 MN

2 V 14 Pa 26 FTLB 38 A

3 g 15 PAS 27 INLB 39 mA

4 kg 16 HPas 28 µm/m

5 T 17 kPas 29 m/s

6 kT 18 PSI 30 m/ss

7 TON 19 µm 31 %

8 LB 20 mm 32 %0

9 oz 21 cm 33 PPM

10 N 22 m 34 s

11 kN 23 inch 35 “blank”

12 bar 24 Nm 36 MP

4.2.5.2 Selecting the indication upper limit

Command

IAD Indication Adaptation

Syntax: IAD p1,p2,p3 (x)

Parameters:

Effect: This command is used to input the indication adaptation values.

Note: For ”V” and ”mV/V” scaling is fixed.

Response:

Example: IAD 10000,3,4 (x)

Command

IAD? Indication Adaptation Query

Syntax: IAD?(x)

Parameters: none

Effect: Output of the current settings for indication upper limit, decimal point, step width

Response: q1,q2,q3 (y)

Parameters: see IAD command

Example: IAD? (x)

Input, indication upper limit, decimal point, step width

p1 Indication upper limit without decimal point (max. 200000)

p2 Decimal point (number of decimal places 0…5)

p3 Step width (see table)

p3 Step width

1 1

2 2

3 5

4 10

5 20

6 50

7 100

8 200

9 500

10 1000

Acknowledgment Meaning

0 Command has been executed

? Error

0 (y)

Indication adaptation is set to:

indication upper limit 10,000 with step width 10

Output input, indication upper limit, decimal point, step width

10000,3,4 (y)

Indication adaptation is set to:

CF 127 18 V. -A0109-5.3 en

Page 21

indication upper limit 10,000 with step width 10

4.2.5.3 Setting zero value

Command

CDW Calibration Dead Weight

Response:

Command

CDW? Calibration Dead Weight Query

Syntax: CDW (x) or CDW p1(x)

Parameters: p1 (optional)

Effect: The value entered is stored in the amplifier’s zero store.

Example 1: Start zeroing

CDW (x)

Example 2: Input zero value 2.0000 mV/V (selected input range 4 mV/V)

CDW 2.0000(x)

Syntax: CDW?p1(x)

Parameters:

Start zeroing /Input zero value (balance)

p1 Zero value in mV/V

0 (y)

The current measured value is adopted as zero value.

0 (y)

If for p1 the value read with CDW?1 is sent, the adjacent measurement signal is

set to zero.

Output of zero value

Value is input in mV/V; within the input-signal range

Acknowledgment Meaning

0 Command has been executed

? Error

p1 Zero value

0 Currently set zero value (mV/V)

1 Current measured value (mV/V)

Response: q1 (y)

Effect: This command causes the currently set zero value or currently adjacent measured

value to be output.

Example 1: CDW?0 (x)

3.256 (y)

Currently set zero value is 3.256 mV/V.

Example 2: CDW?1 (x)

2.001 (y)

Measured value currently applied is output. CDW2.001sets this signal to zero.

4.2.5.4 Set measuring range

Command

IMR Input Measuring Range

Response:

Syntax: IMR p1(x)

Parameters:

Effect: The measuring range is set.

Example: IMR 2.0 (x)

Input of the upper limit of the measuring range

p1 Upper limit of the measuring range in mV/V

0 (y)

Value is input in mV/V; within the input signal range

Acknowledgment Meaning

0 Command has been executed

? Error

CF 127 19 V. -A0109-5.3 en

Page 22

The measuring range is set to 2.0 mV/V.

Command

IMR? Input Measuring Range Query

Syntax: IMR?p1(x)

Parameters:

Output of the upper limit of the measuring range

p1 Upper limit of the measuring range

0 Current measuring range in mV/V

1 Current measuring signal in mV/V

2 Maximum and minimum adjustable upper limits of the

measuring range in mV/V

Effect: Output of the set measuring range.

Response: q1,q2 (y)

Example 1: IMR?0 (x)

1.987 (y)

Currently set upper limit of the measuring range is 1.987 mV/V.

Example 2: IMR?2 (x)

4.0,0.2 (y)

With a selected input-signal range of 4 mV/V, 4.0 mV/V is output as the maximum

and 0.2 mV/V as the minimum value.

4.2.5.5 Tare

Command

TAR Tare Instruction

Response:

Command

TAR? Tare Value Query

Syntax: TAR (x) or TAR p1(x)

Parameter: p1 (optional) or tare value in displayed units

Effect: This command tares the signal/sets a tare value.

Example 1: Start taring

The current measured value is adopted as tare value.

Note: Taring is done computationally, not by balancing of the input signal.

Example 2: TAR200.0 (x)

Syntax: TAR?(x)

Parameters: none

Effect: The tare value is output in displayed units.

Response: q1 (y)

Tare value in displayed units

Example: TAR? (x)

Start taring/Input tare value

Acknowledgment Meaning

0 Command has been executed

TAR (x)

0 (y)

0 (y)

Input value is written to the tare store.

Output tare value

200.0 (y)

Suppose, for example, that an indication upper limit of 2000.0kN has been set. The

tare value is 200.0kN.

? Error

4.2.6 Setting up the Limit Value 1...4 group functions

Command

LIV Limit Value

CF 127 20 V. -A0109-5.3 en

Page 23

Syntax: LIV p1,p2,p3,p4,p5,p6,p7,p8 (x)

Parameters:

Input of limit monitor settings

p1 Limit monitors

1 1

2 2

3 3

4 4

p2 Limit value monitoring

0 OFF

1 ON

p3 Source of limit values

1 Gross value

2 Net value

3 Peak value store 1 (maximum)

4 Peak value store 2 (minimum)

5 Peak value store 3 (peak-to-peak)

p4 Operating directions

1 Operates when overrange occurs

2 Operates when underrange occurs

p5 Limit value level in displayed units

Value is specified in displayed units (e.g. kN)

p6 Hysteresis value in displayed units.

Value is specified in displayed units (e.g. 100kN); always positive

p7 Output logic of the limit monitors

1 Active corresponds to On

2 Active corresponds to Off

p8 Level-setting by limit value key in measuring mode

0 Locked

1 Enabled

Effect: With this command limit monitor p1 is activated, set to input signal p3, switching

direction p4, switching-level p5, and also to hysteresis p6 and output logic p7.

Level-setting by the limit value key is set to p8.

Response:

Acknowledgment Meaning

Example: LIV1,1,3,1,100,10,1,1 (x)

0 (y)

Limit monitor 1 has been activated and the input signal assigned to Store/Max

(maximum). The limit monitor on exceeding of the On-level of 100kN and hysteresis

of 10kN (Off-level 90kN). The control output is active. Level-setting by limit value

key for LV1 is possible.

Important:

All limit monitors required for the measurement process must be set in sequence

according to the above scheme.

Command

LIV? Limit Value Query

Syntax: LIV? p1,p2 (x)

Output of the limit-monitor settings

0 Command has been executed

? Error

CF 127 21 V. -A0109-5.3 en

Page 24

Parameters:

p1 Limit monitors

0 Query the signal value of p2 (output in displayed units)

1 Current LV1 settings

2 Current LV2 setting

3 Current LV3 setting

4 Current LV4 setting

P2 Signal code-number, if p1=0

1 Current gross signal in displayed units

2 Current net signal in displayed units

3 Current maximum value in displayed units

4 Current minimum value in displayed units

Effect: This command causes the setting of limit monitor p1 to be output.

5 Current peak-to-peak value in displayed units

Response: q1,q2,q3,q4,q5,q6,q7,q8 (y)

q1 Number of the limit monitor

q2 Limit value monitoring On/Off

q3 Input signal of the limit monitor

q4 Operating direction positive/negative

q5 Switching level of the limit monitor

q6 Hysteresis value

q7 Logic of the control output

Example 1: LIV?2 (x)

q8 Level-setting in measuring mode

2,1,3,1,100,10,1,1 (y)

Limit monitor 2 has been activated and the input signal assigned to Store/Max

(maximum). The limit monitor operates if the level of 100kN is exceeded

(corresponds to On-level). Hysteresis is 10kN (Off-level 90kN). The control output

is active. Level-setting by limit value key for LV2 is enabled.

Example 2: LIV?0,3 (x)

200 (y)

The value stored in Store1/Max is 200kN.

4.2.7 Setting up the functions of the Peak value store group

Command

PVS Peak Value Select

Syntax: PVS p1,p2,p3,p4 (x)

Parameters:

Effect:

Response:

Input of the peak value store settings

p1 Peak value store

1 Maximum

2 Minimum

3 Peak-to-peak

p2 Peak value determination (applies to all stores)

0 Off

1 On

p3 Source of stores

1 Gross value

2 Net value

p4 Envelopes (applies to all stores)

0 Envelope function is off

00100…60000 Timing constant in ms

This command is used to set the function of the peak value store p1.

Acknowledgment Meaning

0 Command has been executed

CF 127 22 V. -A0109-5.3 en

Page 25

Command

PVS? Peak Value Select Query

Response: q1,q2,q3,q4 (y)

Example: PVS1,1,1,0 (x)

0 (y)

The gross signal is assigned to peak value store 1 (maximum). All peak value

stores are enabled; the envelope function is switched off.

Output of peak value store settings

Syntax: PVS?p1(x)

Parameters: p1

Code number for the peak value store (see command PVS)

Effect: This command causes the setting of peak value store p1 to be output.

q1 Code number for the peak value store

q2 Peak value determination On/Off

q3 Source of store

q4 Timing constant for envelope function in ms

? Error

Command

CPV Clear Peak Value

Response:

Example: PVS?1 (x)

1,1,1,0 (y)

The gross signal has been assigned to peak value store 1 (maximum). All peak

value stores are enabled; the envelope function is switched off.

Clear peak value store

Syntax: CPV (x)

Parameters: none

Effect: This command clears the peak-–value stores

Acknowledgment Meaning

0 Command has been executed

Example: CPV (x)

0 (y)

Peak value store 1 (max), peak value store 2 (min) and peak value store 3 (min-

max) are cleared.

Note: After clearing of the peak value store the output signal of stores 1 and 2 is the

adjacent measured value. Store 3 (min-max) has the value zero.

? Error

4.2.8 Setting up the functions of the Inputs/Outputs group

4.2.8.1 Select amplifier input signal

Command

ASS Amplifier Signal Select

Response:

Syntax: ASS p1(x)

Parameters:

Effect: Selection of the amplifier input signal.

Example: The DFI 2555 is being set up:

Select amplifier input signal

p1 Input source

0 Internal zero signal

1 Internal calibration signal

Acknowledgment Meaning

2 Measuring signal

0 Command has been executed

? Error

CF 127 23 V. -A0109-5.3 en

Page 26

ASS 0(x)

0 (y)

The amplifier input is switched to internal zero signal.

Note: This command triggers a calibration process which permits communication to

continue only after 1...3s.

To resume measurement, enter p1=2

Command

ASS? Amplifier Signal Select

Syntax: ASS?(x)

Parameters: none

Effect: The amplifier input signal’s type is output

Response: q1 (y)

Output amplifier input signal

q1 Amplifier’s input signal source

0 Internal zero signal

1 Internal calibration signal

Example: ASS? (x)

2 Measuring signal

2 (y)

Amplifier input is switched to the measuring signal.

4.2.8.2 Setting up the analog output

Command

OPS Output Path Select

Syntax: OPS p1,p2 (x)

Parameters:

Effect: A signal is assigned to the analog output and the operating mode is set.

Note*): The analog output (voltage or current) is selected by rearranging jumpers on the

Response:

Assign signal to the analog output and select operating mode

P1 Signal

1 Gross signal at analog output

2 Net signal at analog output

3 Store 1 (maximum) at analog output

4 Store 2 (minimum) at analog output

5 Store 3 (peak-to-peak) at analog output

P2 Mode of analog output (U/I)*

0 Analog output OFF

1 +/- 10V (U) / +/- 20mA (I)

2 No funct. (U) / 4…20mA (I)

PCB. The setting-up procedure is described in the DFI 2555 User’s Guide.

Acknowledgment Meaning

0 Command has been executed

? Error

Example: OPS1,1 (x)

0 (y)

The gross signal is assigned to the analog output. +/– 10V is set as the operating

mode.

(Assumption: voltage has been specified as the analog output signal)

Command

OPS? Output Path Select Query

CF 127 24 V. -A0109-5.3 en

Syntax: OPS?p1(x)

Output input-signal of the analog output and operating mode

Page 27

Parameters:

p1 Analog output: signal and operating mode

0 Currently assigned input signal

1 “Voltage” or “current” operating-mode set

Response: q1,q2 (y)

Effect: The analog output’s currently assigned input signal is output or the selected

operating-mode is output.

q2 corresponds to parameter p2 (see command OPS)

q1 Operating mode (set)

1 Voltage

Example: OPS?0 (x)

2 (y)

The net signal is now assigned to the analog output.

Example: OPS?1 (x)

2,2 (y)

Current output set; mode 4...20mA selected

2 Current

4.2.8.3 Setting up remote control

Command

LOR Local/Remote

Response:

Command

LOR? Local / Remote Query

Syntax: LOR p1 (x)

Parameters:

Effect: Switching to remote control of certain amplifier functions via remote control inputs.

Example: LOR1 (x)

Syntax: LOR? (x)

Parameters: none

Effect: Local/Remote control status is output

Response: q1 (y) corresponds to p1 (see command LOR)

Example: LOR? (x)

Switching between Local/Remote

p1 Status

0 Remote, remote control through remote outputs

0 (y)

Local control is enabled, i.e. all set-up functions for amplifier parameters via the

remote control inputs are blocked.

Query Local / Remote status

0 (y)

Remote control is enabled, i.e. all set-up functions for amplifier parameters via the

remote control inputs are enabled.

1 Local, no remote control

Acknowledgment Meaning

0 Command has been executed

? Error

4.2.8.4 Setting up assignment of the remotes

Command

RFP Remote Function Programming

Syntax: RFPp1,p2 (x)

Parameters: p1 corresponds to the number of the remote (1..6)

Assignment of remote functions

p2 corresponds to the code number of the function(see table)

CF 127 25 V. -A0109-5.3 en

Page 28

p2 Function

0 NOP No function

1 ACAL Autocalibration

2 TARE Taring

3 CPV1 Store 1/Curr

4 HLD1 Store 1/Hold

5 CPV2 Store 2/Curr

6 HLD2 Store 2/Hold

7 ZERO Zeroing

8 PRNT Print

9 PAR1 Bit for querying param. set 1…8

10 PAR2 Bit for querying param. set 1…8

11 PAR3 Bit for querying param. set 1…8

The default assignment after a ”Set-up” of the instrument is ”No function” for all

remotes. The functions PAR1, PAR2 and PAR3 can be used to retrieve the eight

parameter sets in binary form (000 to 111) (see DFI 2555 User’s Guide).

Effect: The remote’s effect on the selected amplifier functions is specified.

Response:

Acknowledgment Meaning

0 Command has been executed

Example: RFP 2,1 (x)

? Error

0 (y)

The Autocal function (Acal) is now assigned to remote 2.

Note: Switching between Remote and Local remains possible even when the instrument

is in local status.

Command

RFP? Remote Function Programming Query

Syntax: RFP?p1(x)

Parameters:

Query re: assignment of the remote functions

p1

0 Output table of available functions

1…6 Output assignment of remote functions

Effect: Output assignment of remote functions at the cable-connector

Example 1: RFP?0 (x)

”NOPACALTARACPV1HLD1CPV2HLD2NULLPRNTPAR1PAR2PAR3” (y)

Response: q1 (y)

Example 2: RFP?2 (x)

1 (y)

The Autocal function (Acal) is now assigned to remote 2.

4.2.9 Setting up the Adaptation group functions

4.2.9.1 Lock-control of the keys

Command

KLC Key Lock Control

Syntax:

Parameters:

CF 127 26 V. -A0109-5.3 en

Key lock control

KLC p1,p2 (x)

p1 Key lock control

1 Set LVS key

2 ZERO key

3 TARE key

4 Clear STORE key

5 Initiate PRINTING key

6 Select SIGN key

p2 Key authorization

Page 29

0 Lock

Response:

Command

KLC? Key Lock Control Query

Response:

Effect: Direct keys can be individually locked.

Acknowledgment Meaning

Example: KLC 2,0 (x)

0 (y)

The ZERO key has been locked.

Querying key-lock control

Syntax: KLC?p1 (x)

Parameters: p1 corresponds to the key selected (see command KLC)

Effect: Enablement status of the selected key is output.

1 Free

0 Command has been executed

? Error

q1 Key status

0 Locked

1 Enabled

Example: KLC?2 (x)

0 (y)

The ZERO key has been locked.

5.0 ABBREVIATION/COMMAND INDEX

ABBREVIATION COMMAND SECTION

A

ACL

ACL?

ADR

ADR?

AID?

ASA

ASA?

ASF

ASF?

ASS

ASS?

Autocal

Enable/disable autocalibration

Autocal Query

Enable/disableAutocalibrationAutocalibration

Address

Assign an address to the device

Address Query

Output address of devices

Amplifier Identification Query

Output device identification

Amplifier Sensor Adaption

Enter excitation voltage, transducer type and input range

Amplifier Sensor Adaption Query

Output excitation voltage, transducer type and input range

Amplifier Signal Filtering

Input cutoff frequency and filter characteristics

Amplifier Signal Filtering Query

Output cutoff frequency and filter characteristics

Amplifier Signal Select

Select amplifier input signal

Amplifier Signal Select

Output amplifier input signal

4.2.4.3

4.2.4.3

4.2.1.2

4.2.1.2

4.2.1.3

4.2.4.1

4.2.4.1

4.2.4.2

4.2.4.2

4.2.8.1

4.2.8.1

B

BDR

BDR?

Baud Rate

Set serial interface parameters

Baud Rate Query

Output serial interface parameters

4.2.1.1

4.2.1.1

CF 127 27 V. -A0109-5.3 en

Page 30

C

CAL

CDW

CDW?

COF

COF?

CPV

Calibrate

Calibration

Calibration Dead Weight

Start zeroing / enter zero value (balance)

Calibration Dead Weight Query

Output zero value

Change Output Format

Change measurement output format

Change Output Format Query

Request measurement output format

Clear Peak Value

Clear min/max storage

4.2.4.3

4.2.5.3

4.2.5.3

4.2.3.1

4.2.3.1

4.2.7

D

DCL

Device clear

Terminate communication

4.2

E

ENU

ENU?

ESR?

Engineering Unit

Input unit

Engineering Unit Query

Output unit

Standard Event Status Register

Output error status register

4.2.5.1

4.2.5.1

4.2

I

IAD

IAD?

IMR

IMR?

Indication Adaptation

Input, end value, decimal point, step

Indication Adaptation Query

Output input, end value, decimal point, step

Input Measuring Range

Input final scale value

Input Measuring Range Query

Output final scale value

4.2.5.2

4.2.5.2

4.2.5.4

4.2.5.4

K

KLC

KLC?

Key Lock Control

Key lock control

Key Lock Control Query

Query key lock control

4.2.9.1

4.2.9.1

L

LIV

LIV?

LOR

LOR?

Limit Value

Input limit value settings

Limit Value Query

Output limit value settings

Local / Remote

Local / Remote switch

Local / Remote Query

Request Local/Remote status

4.2.6

4.2.6

4.2.8.3

4.2.8.3

M

MDD

MDD?

MSV?

MTC Motion Control 4.2.4.2.

Memory Device Data

Input amplifier set–up data

Memory Device Data Query

Output amplifier set–up data

Measuring Signal Value Query

Output measured value

4.2.2

4.2.2

4.2.3.2

CF 127 28 V. -A0109-5.3 en

Page 31

MTC?

O

OPS

OPS?

P

PFS

PFS?

PVS

PVS?

R

RFP

RFP?

S

STP

T

TAR

TAR?

TDD

TDD?

Define motion control

Motion Control Query

Output motion control

Output Path Select

Assign signal to analog output and choose operating mode

Output Path Select Query

Output source of analog output and operating mode

Print Format Select

Define print format

Print Format Select Query

Request print format

Peak Value Select

Input peak–value store settings

Peak Value Select Query

Output peak–value store settings

Remote Function Programming

Assignment of remote functions

Remote Function Programming Query

Request assignment of remote functions

Stop

Stop measurement output

Tare Instruction

Start taring / input tare value

Tare Value Query

Output tare value

Transmit Device Data

Back up amplifier set–ups

Transmit Device Data Query

Query source of amplifier set–ups

4.2.4.2

4.2.8.2

4.2.8.2

4.2.1.4

4.2.1.4

4.2.7

4.2.7

4.2.8.4

4.2.8.4

4.2.3.2

4.2.5.5

4.2.5.5

4.2.2

4.2.2

CF 127 29 V. -A0109-5.3 en

Loading...

Loading...