Page 1

DFI 2000

Process Monitor and

Control Instrument

User’s Guide

www.cooperinstruments.com

PH: 540-349-4746 • FAX: 540-347-4755

Page 2

CONTENTS

1.0 INTRODUCTION ...................................................................................................................4

1.1 System Overview ........................................................................................................................... 4

1.2 Process Monitoring Functions ..................................................................................................... 4

1.3 The Process Control Output Signals ........................................................................................... 6

1.4 Programmable Setpoints............................................................................................................... 6

1.5 The Analog Output......................................................................................................................... 7

1.6 Data Logging .................................................................................................................................. 7

1.7 Automatic Calibration.................................................................................................................... 7

1.8 Absolute and Relative Modes ....................................................................................................... 7

1.9 Scaling ............................................................................................................................................ 7

1.10 Units .............................................................................................................................................. 8

1.11 Menu Locking............................................................................................................................... 8

1.12 Automatic Power-Down............................................................................................................... 8

1.13 Manual Power-Down.................................................................................................................... 8

1.14 AC Outlet or Battery Operation................................................................................................... 8

1.15 Support for Third Party Transducers ......................................................................................... 8

2.0 BASIC OPERATION .............................................................................................................9

2.1 Initial Power-up .............................................................................................................................. 9

2.2 Key Definitions............................................................................................................................... 9

2.3 The Menu System......................................................................................................................... 10

2.4 Using the Track Function............................................................................................................ 12

2.5 Using the Peak Functions ........................................................................................................... 13

2.6 Using the Auto and Manual Record Functions ......................................................................... 13

3.0 APPLICATIONS ..................................................................................................................14

3.1 Monitoring Continuous Change ................................................................................................. 14

3.2 Recording Peak Readings........................................................................................................... 14

3.3 Uploading Logged Peak Readings to a Computer or Printer .................................................. 15

3.4 Digitizing a Force-Time Curve .................................................................................................... 16

3.5 Using the Output Signals ............................................................................................................ 17

3.6 Programming Third Party Sensors.............................................................................................19

4.0 APPENDIX ..........................................................................................................................21

4.1 Connecting the DFI 2000 ............................................................................................................. 21

5.0 BATTERY REPLACEMENT................................................................................................ 22

5.1 Specifications............................................................................................................................... 22

6.0 WARRANTY REPAIR POLICY ...........................................................................................23

CF 13 iii ver. 7.2 FEB. 99

Page 3

1.0 INTRODUCTION

1.1 System Overview

The DFI 2000 is a multi-function Process Monitor and Control instrument, designed to operate with Cooper auto-id

transducers. The DFI 2000 has been enhanced to support torque sensors with quadature encoders. This

functionality is supported via AutoID and third party sensor programming. Version 7.2 will have an encoder chip and

new software installed. For easy verification of version 7.2, if a torque sensor with encoder is attached at power up,

an >E= will be displayed at the end of the line of the sensor data.

Additional features of the DFI 2000 are additional options under the menu items:

• Settings

• Transducer

The DFI 2000 is a portable instrument, and comes with the following:

• carrying case,

• shoulder strap,

• 12 V 600 mA power supply, and

• this manual.

If any of these items are missing, call Cooper Instruments at (800) 344-3921.

Features

The DFI 2000 features:

• six process monitoring functions, including:

o a continuous tracking function,

o 3 peak logging functions,

o 2 waveform recording functions (with multiple record rates),

• 3 process control output signals (for High, Low and Target occurrences),

• programmable setpoints for Threshold, Target, High and Low Limits,

• analog output,

• storage capability for up to 8,000 peak readings,

• 4 [peak] data logging operations,

• automatic calibration with Cooper’s strain gage based auto-id sensors,

• collects absolute values or values relative to a user defined zero point,

• scaling adjustment for transducers,

• multiple unit capability and automatic units conversion,

• menu locking,

• automatic power-down,

• rechargeable Ni-Cad batteries, and

• support for third party transducers.

1.2 Process Monitoring Functions

The DFI 2000 provides six process monitoring functions:

• Track,

• - Peak,

• + Peak,

• +/- Peak,

• Auto Record, and

• Manual Record.

Track is always available by pressing the TRACK button. The FUNC button can be programmed for any one of the

other five functions.

Track

Track provides continuous monitoring of a process. The instrument takes readings at 5 kHz (without an encoder),

2kHz (with an encoder in >deg= mode), or 20Hz (with an encoder in >rpm= mode) averages them, and updates the

CF 13 4 ver. 7.2 FEB. 99

Page 4

display 4 times/second. In the Track function, re-taring zeros the encoder. (Track is designed for slowly changing

processes.)

Peak

The Peak functions (-, +, +/-) sample data at a rate of 5 kHz. However, if the encoder is enabled and in >deg=

mode, the sample rate is 2kHz. If the encoder is in >rpm= mode, the sample rate is 20 kHz.

In all Peak functions when readings drop below 80% of the user-defined Threshold Value, the PMAC engages a 100

msec timer. If readings rise above threshold within that time, the process cycle continues. If not, the process cycle

ends and readings are evaluated with respect to the limits. This timer is reset every time readings drop below

threshold.

Record

All functions except Manual record enable the encoder at the threshold for >deg= mode, or immediately for >rpm=

mode. Manual record enables the encoder at the manual trigger for >deg= mode. The Auto and Manual Record

functions have programmable record rates.

The >Record= functions will only allow 10kHz and 5kHz rates without an encoder. All other rates are allowed with an

encoder. The encoder is sampled at the record rate for Adeg@ or >rpm= mode.

The >Record= and Peak functions are limited to a total of 8,000 readings with or without an encoder.

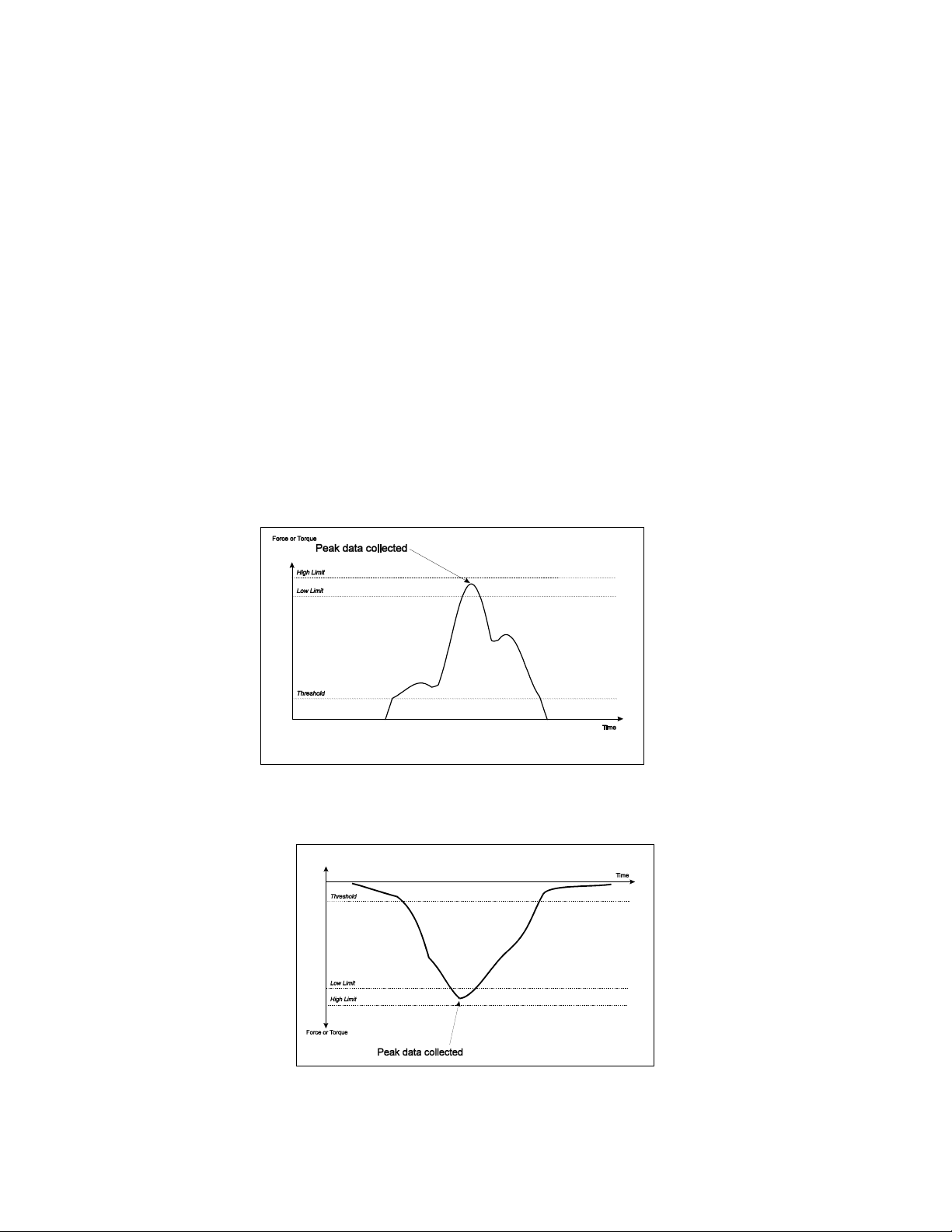

+ Peak

+Peak collects, displays and evaluates the highest [positive] peak value above the user-defined threshold.

+ Peak ignores negative values.

-Peak

-Peak collects, displays and evaluates the lowest [negative] peak value below the user-defined threshold.

- Peak ignores positive values.

CF 13 5 ver. 7.2 FEB. 99

Page 5

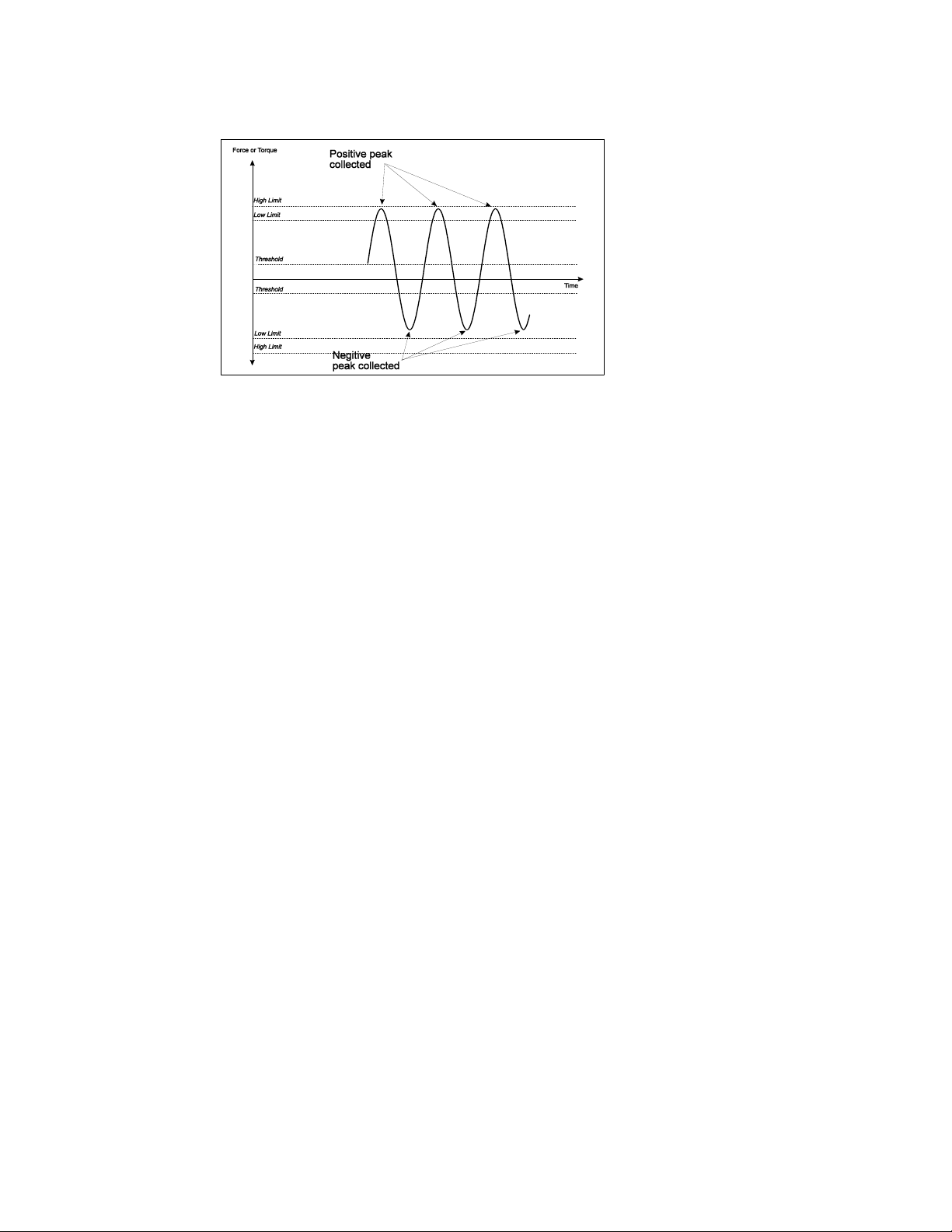

+/- Peak

+/- Peak collects, displays and evaluates the greatest positive or negative values.

All setpoints are symmetrical about the x-axis.

Note: The DFI 2000 collects only one reading per process cycle. If readings rise from negative to positive values

within a process cycle, (this happens if readings are between the positive and negative Threshold for less than 100

msec.) the instrument records the peak with the greatest absolute value.

Auto and Manual Waveform Recording

Auto and Manual waveform recording are data recording functions that digitize incoming signals. Up to 16,000 data

points can be stored. Neither function displays readings, or evaluates them with regard to the limits. The following

update rates are available: 10, 5, 2, and 1 kHz, and 500, 200, 100, 50, 20, 10, 5, 2, and 1 Hz. For the 10 kHz*

scanning rate, data is sampled and stored; the instrument does not average the data. For the 5 kHz* scanning rate,

data is sampled at 5 kHz and continuously averaged to store readings. For each of the other scanning rates, data is

sampled at a rate of 6 kHz and continuously averaged to store readings at the selected rate.

*10kHz and 5kHz rates are only available when the encoder is not used.

1.3 The Process Control Output Signals

The DFI 2000 has three open collector, process control output signals:

• High Condition Signal,

• Low Condition Signal, and

• Target Signal.

When a Peak function is selected, the Target Signal is a real-time signal transmitted when a reading equal to, or

greater than, the Target Value is detected. The High Condition and Low Condition Signals are post-process signals

transmitted after readings drop below threshold, and the peak value is evaluated. These readings are also evaluated

with respect to the encoder limits and target value.

When Track is selected, all signals are transmitted in real-time. When a waveform recording function is selected, all

signals are disabled.

All three signals are TTL compatible and are transmitted through the I/O connector on the back of the unit. (See the

chapter on Connecting the PMAC for more information.)

1.4 Programmable Setpoints

When each type of sensor (i.e., force, torque or displacement) is first connected to the DFI, the instrument sets all of

the setpoints to their default values.

Threshold Value = 5% of sensor's Full Scale

High Limit = sensor's Full Scale

Low Limit = 5% of sensor's Full Scale

CF 13 6 ver. 7.2 FEB. 99

Page 6

Target Value = sensor's Full Scale

Each of these values may be changed by the operator. (See the Basic Operation and Applications chapters.) The

DFI 2000 retains the most recent setpoint values for all three types of sensors; i.e., when you disconnect a torque

sensor and connect a force sensor, the setpoints are reset to the values used with the last force sensor connected

to the instrument.

1.5 The Analog Output

The analog output is the signal from the transducer, amplified and relayed through a low pass filter. The instrument

provides an excitation of 7 V. The amplifier has a gain factor of 76 for a nominal output of 1 V at 2 mV/V. This signal

is transmitted through the I/O connector. (See the Appendix for wiring diagrams.)

1.6 Data Logging

The peak functions log all peak values automatically. The DFI 2000 provides for:

• viewing [peak] readings on the DFI 2000 screen (one at a time),

• uploading the readings to a PC

• transmitting the readings directly to a serial printer, or

• erasing the readings.

The DFI 2000 can store up to 8,000 [maximum] peak readings.

Note: The data is stored in blocks, and each block contains a header. Each time you change transducer types or

units, the instrument must store an additional heading which reduces the memory available for storing peak values.

Leaving a waveform stored in memory will also reduce the memory available for storing peak values.

No data logging occurs when the Track or waveform recording functions are selected. Data collected by the

waveform recording functions must be uploaded to a PC or erased. It can not be viewed on the DFI 2000 screen.

Data Transmission

The DFI 2000 transmits data in ASCII format with the following parameters:

Baud Rate = 9600

Parity = None

Data Bits = 8

Stop Bits = 1

Flow Control = None or Xon/Xoff

1.7 Automatic Calibration

The DFI 2000 is designed to support Cooper’s auto-id sensors. Cooper’s auto-id sensors are equipped with an

EPROM that stores the sensor's Full Scale value, the mV/V output, and engineering units. The DFI 2000

automatically reads these values when:

• the sensor is initially connected,

• when the instrument is powered up, and

• when the operator exits the menu structure.

The DFI 2000 automatically recalibrates to the sensor when it detects a change in these values.

1.8 Absolute and Relative Modes

The DFI 2000 uses an internal reference bridge to define absolute zero. In Absolute mode, readings are taken with

respect to this value. In Relative mode readings are taken with respect to a tare value from the transducer.

Important: When using Absolute mode, it is important that the user-defined threshold be at least 25% greater than

sensor's offset from zero.

1.9 Scaling

The DFI 2000 multiplies all new readings by the scaling factor before storing or displaying the data. Changing the

CF 13 7 ver. 7.2 FEB. 99

Page 7

scale factor does not affect previously stored readings. With a scale factor of 1.0 the instrument stores and displays

readings exactly as taken.

The instrument retains the most recent scale factor for all three types of sensors. (Same as the setpoints for the limit

values.)

1.10 Units

The DFI 2000 provides automatic unit conversion. The Full Scale value for all Cooper’s auto-id sensors are

specified in engineering units. When the operator selects a different set of units, the DFI 2000 converts the Full

Scale value, the High and Low limits, the Threshold and Target values, and all readings [taken from that point on] to

the new units. The following units are available:

Force: oz, lbs, Tons, g, kg, N

Torque: inoz, inlbs, ftlbs, kgcm, kgm, NM

Displacement: mils, in, mm, cm

Absolute numbers: None

Note: The DFI 2000 will only allow the operator to select units that are consistent with the type of transducer

connected, i.e., torque units for a torque transducer.

1.11 Menu Locking

All of the above mentioned features are accessed through the DFI 2000's menu system. Each of the four menus

(see the Basic Operations chapter) can be locked to prevent accidental changes.

1.12 Automatic Power-Down

The DFI 2000 will automatically power-down 12 minutes after the transducer is disconnected (unless the instrument

is in the menu system).

1.13 Manual Power-Down

To power-down the instrument manually, hold the OFF key for five seconds and release.

1.14 AC Outlet or Battery Operation

The DFI 2000 can operate from an AC outlet or from the internal Ni-Cad batteries. When completely charged, the

batteries should last for approx. 8 hrs.

To completely charge the batteries, the instrument must be plugged into an outlet for 16 hrs. There is no danger of

over-charging the batteries if left plugged in for longer than 16 hrs.

Note: If the instrument is left charging for "several weeks", the batteries' charge life will be severely diminished. (This

is a property of all Ni-Cad rechargeable batteries.) Cooper recommends completely discharging the batteries on

occasion to maintain their charge life.

Note: When shipped from Cooper’s factory, the batteries will be completely discharged.

1.15 Support for Third Party Transducers

Third party transducers may be connected to the DFI 2000 using a standard 15 pin D-sub connector, or Cooper’s

auto-id connector (Model 90144). In either case, when the sensor is first connected to the DFI 2000, the instrument

will prompt you for the sensor's calibration data. (See the Applications chapter).

When using sensors with a standard 15 pin connector, the data is stored in RAM. So that it is not necessary to

reenter the calibration data if the sensor is disconnected and immediately reconnected. But it must be reentered if

another sensor is connected in the interim. These sensors are identified as "Raw".

When using sensors with Cooper's auto-id connector, the instrument writes the calibration data to the connector's

CF 13 8 ver. 7.2 FEB. 99

Page 8

EPROM; and retrieves it each time the sensor is connected. The DFI 2000 programs these connectors with the

transducer type, Full Scale value, the mV/V output, and the engineering units. This provides automatic calibration

every time the sensor is connected to the instrument. These sensors are identified as "Cus".

Note: Transducers that are programmed at Cooper Instruments factory include a "write protect" code. The DFI 2000

will never overwrite the values stored in these connectors.

2.0 BASIC OPERATION

2.1 Initial Power-up

Press any key to turn on the DFI 2000.

Initial Self Checks

On powering up, the instrument briefly displays "PMAC 2000 V7.2", indicating the software revision number.

If no transducer is connected, the DFI 2000 displays, "Check transducer".

Once a transducer is connected, the instrument displays:

"SDI 10 lb",

"Relative Mode or Absolute Mode

Counting . . ."

The first message is a description of the transducer.

ID NAME

FULL SCALE VALUE

SDI 10 NM

Note: When a third party transducer is connected, "Cus" or "Raw" will replace "SDI". The second message indicates

if the instrument is in Absolute or Relative Mode. The last message is displayed while the instrument determines

how much RAM is currently available for storing new readings.

Ready to collect data

When the instrument is ready to collect data it displays one of the following messages:

"R0000 Ready" - if a peak function was selected and there is no data stored,

"R0001 202.0lb" - if a peak function was selected and there is data stored,

"Ready to record" - for auto trigger recording, or

"Accept to record" - for manual trigger recording.

Note: If the screen goes blank, the instrument is set to Auto-record and readings may already be above the

threshold. Press ESC to cancel the data sampling.

2.2 Key Definitions

UNITS

The DFI 2000 has four keys. Each key has multiple functions, and is labeled with

its main function and its menu-navigation function.

CF 13 9 ver. 7.2 FEB. 99

Page 9

The main functions are as follows:

Enters the menu system.

Selects the Track function.

Programmable key-- can be set to select any one of the five following functions: +Peak, -Peak, +/-Peak, ARecord, or M-Record.

Hold for 5 sec. and release to turn off the DFI 2000. (The "OFF" feature is always available.)

Each key's additional functions are described in the following sections.

2.3 The Menu System

The DFI 2000 is configured through a menu system.

There are four menus:

1. Log operations,

2. Settings,

3. Transducer setup, and

4. Menu locking

You enter the menu system by pressing MENU

Note: The DFI 2000 does not collect data while in the menus.

The menu system is as follows:

Log Operations Settings Transducer setup* Menu locking

View log Func: <current> Type: <current> L-Menu: <current>

Upload log R-rate: <current> Unit: <current> S-Menu: <current>

Print log Unit: <current> FS: <current> T-Menu: <current>

Erase log ZMode: <current> mV/V: <current>

Thrshld: <current> EPPR: <current>

LLimit: <current> Write to AutoID

Target: <current>

HLimit: <current>

Scale: <current>

Emode: <current>

ELLimit: <current>

ETarget: <current>

EHLimit : <current>

Echo: <current>

*Note: The "Transducer setup" menu is only available when "Cus" or "Raw" sensors are connected to the

instrument. (i.e. no auto-id - See page 7.)

In the menu system, the keys perform the following functions:

Selects displayed menu items for change.

Scrolls through menu or submenu choices.

Accepts changes and exits submenu./ Performs displayed operation.

CF 13 10 ver. 7.2 FEB. 99

Page 10

Discards changes, exits submenu and returns to higher menu.

Log Operations Menu

To execute any log operations, press Accept. While uploading or printing, the DFI 2000 displays the data on screen as it is

sent; while erasing data, the DFI 2000 will display "Erasing". When Viewing Data the keys perform the following functions:

-No Function

Scrolls to the next reading.

Scrolls to the previous reading

Exits the subroutine and returns to the "Log Operations" submenu.

The “Erase log” command requires confirmation. To confirm the “Erase log” command, press Next and Accept.

Settings Menu

The "Settings" menu contains four multiple choice items:

Function, R-rate, Unit, and ZMode.

and nine numeric items:

Threshold, High Limit, Target, Low Limit, Scale, Encoder Low Limit, Encoder Target, Encoder High Limit, and

Echo.

When changing a multiple choice item:

Selects the currently displayed item for changing and enters the submenu containing the available choices.

Scrolls to the next available choice in a submenu.

Accepts the currently displayed item, and returns to the "Settings" menu.

Exits the submenu and returns to the "Settings" menu.

When changing numeric items:

Selects the currently displayed item for changing and accesses the numeric entry subroutine. Changes the

value of the current digit position.

Scrolls to the next digit.

Accepts the currently displayed value, and returns to the "Settings" menu.

Discards the new value./ Press twice to exit the subroutine and return to the Settings" menu.

See the Applications Chapter for examples of setting up the DFI 2000 for various tasks.

Transducer Settings Menu

The "Transducer settings" menu is for entering calibration data into the Model 90144 connector, and for changing the data

for raw sensors. This menu is only available when a Model 90144 or a standard 15 pin connector is connected to the DFI,

and is never available when a Cooper sensor is connected to the instrument.

This menu contains three multiple choice items:

transducer type (force, torque or displacement),

units,

encoder (y/n),

three numeric items:

full scale value,

mV/V output, and

encoder pulses per rev (EPPR).

CF 13 11 ver. 7.2 FEB. 99

Page 11

and the command "Write to AutoID".

The keys work the same in this menu as they do in the "Settings" menu. And the "Write to AutoID" requires

confirmation (the same as the "Erase Log" command.)

Note: The "Transducer settings" comes up automatically when a connector [that has never been programmed] is

first connected to the instrument. At that time it is not necessary to press the Next key to go from one menu item to

the next. But when accessing this menu from the menu system you must press the Next key to go from one menu

item to the next.

Menu Locking

The Locking Menu is used to protect menu selections from accidental change. Each of the three submenus can be

individually locked.

The DFI 2000 requires a password to access the "Menu Locking" menu. The password is "290". (See the section on

entering numeric values above for further instructions.)

When a menu is locked, you will be able to enter it and view the currently selected item or values, but you will not be

able to change them.

When the menus are locked:

• The "Settings" and "Transducer setup" submenus, Next will scroll through the values, but Change and

Accept will not function. Esc will exit the submenu.

• In the "Log operations" submenu, the View Data, Upload Data, and Print Data will function normally, but you

will not be able to Erase Data. Esc will exit the submenu.

If you attempt to change a locked item, the DFI 2000 will respond by flashing the message "*** LOCKED ***" for

one second.

2.4 Using the Track Function

When the Track function is selected, the instrument displays:

The keys perform the following functions:

Enters the menu system.

Tares the sensor.

Selects the programmed function.

Tares the sensor.

Note: The DFI 2000 does not log readings when the Track function is selected. With the encoder function, no limits

are displayed with the angle function.

CF 13 12 ver. 7.2 FEB. 99

Page 12

2.5 Using the Peak Functions

When any of the three peak functions are selected, the instrument displays the reading number, the most recent

peak reading, and the units as shown:

Readings are logged, and the display is updated after each loading cycle; i.e., after readings rise above and then

drop below the Threshold Value.

The keys perform the following functions:

Enters the menu system.

Selects the Track function

Will decrement the reading number, allowing the last reading to be re-taken.

Toggles between Absolute and Relative Modes.

2.6 Using the Auto and Manual Record Functions

The Auto and Manual Record functions are identical except for the initial trigger. The Auto Record function uses the

Threshold Value as its signal to begin recording data. The Manual Record function requires pressing the Accept key

to begin recording data.

The DFI 2000 stops recording when either of the following occur:

• the memory is full, or

• the ESC key is pressed.

Before recording data, the instrument displays "Ready to record". While the instrument is recording, the screen

will be blank and the green indicator light will flash at the recording rate. (Refer to the section on the menu system

for information on selecting the scanning rate.)

When the instrument is done recording, it displays "Accept to upload". Pressing the Accept key uploads the

data to a computer via the RS-232 port.

Only one digitized curve can be stored in memory at a time. The instrument retains all data when you enter the

menu system or turn off the DFI 2000. Recorded data must be manually erased.

To Erase data:

1. Press ESC to initiate the "Erase data" command.

2. Press Next to scroll to "Yes".

3. Press Accept to confirm the "Erase data" command.

The keys perform the following functions:

Enters the menu system.

Selects the Track function. /Scrolls from "No" to "Yes" when confirming the "Erase data" command.

CF 13 13 ver. 7.2 FEB. 99

Page 13

Begins recording in Manual. /Uploads data. /Confirms the Erase command.

Stops data recording. /Initiates "Erase Data" command.

3.0 APPLICATIONS

3.1 Monitoring Continuous Change

Use the Track function to monitor continuous changes. Select the Track function by pressing the TRACK key.

(Outside of the menus.) The instrument will monitor the sensor and update the display four times per second (4 Hz).

Readings may be taken in either Relative or Absolute mode. In Relative mode the instrument tares the sensor and

readings are relative to the sensor's offset. In Absolute mode, readings are taken with respect to absolute zero;

defined by the instrument's internal reference bridge.

3.2 Recording Peak Readings

The DFI 2000 can collect and store peak readings from any force, torque or displacement. The instrument can also

automatically convert readings from one unit to another as the readings are collected. (The instrument will not

convert the units of readings already stored.)

Example

Suppose you have a 50 kg load cell (with a 0.05 kg offset) and you want to record peak readings in pounds.

To set up the DFI 2000, do the following:

Step Action Instrument Displays:

DFI 2000 V7.2

Transducer check

1 Connect the sensor and power-up the instrument.

Enter the menu system.

SDI 50 kg

Absolute mode

A0000 Ready

2

Assign a Peak function to the FUNC key.

3

4

5

6

7

Select the units.

8

9

CF 13 14 ver. 7.2 FEB. 99

to enter the menu system.

to scroll to the "Settings" menu.

to enter the "Settings" menu.

to enter the "Function" submenu.

(twice) to scroll through the function

choices.

to select the currently displayed function.

(twice) to scroll to the "Units" submenu.

to enter the "Units" submenu.

Log operations

Settings

Func: +peak

Indicates the current function.

New Fn: +peak

New Fn: -peak

New Fn: +/-peak

Func: +/-peak

Unit: kg

New Unit: kg

Page 14

Step Action Instrument Displays:

10

11

12

[Optional] Erase any previously recorded data.

13

14

15

16

17

18

Exit the menu system.

19

The instrument is now set up to collect peak reading.

(4 times) to scroll to lbs.

to select the displayed units.

to exit the "Settings" menu.

(twice if using an SDI sensor, three times

if using a third party sensor) to scroll to

the "Log operations" menu.

to enter the "log operations" menu.

(3 times) to scroll to "Erase log".

to erase the log.

and

to confirm the erase log command.

To exit the "Log operations" menu.

to exit the menu system.

New Unit: lb

Unit: lb

Settings

Log operations

View log

Erase log

Erase log: No

The instrument asks for confirmation.

Erase log: Yes

Erasing

Erase log

Note: if the log only contains a few

entries, "Erasing" may be displayed to

quickly to be seen.

Log operations

Transducer check

A0000 Ready

3.3 Uploading Logged Peak Readings to a Computer or Printer

To calculate any statistics from collected peak data, it is necessary to upload the collected data to a computer. The

readings may also be sent directly to a printer.

There are three steps to uploading the data:

Step 1: Connect the DFI to either the computer or the printer. Use the RS-232 port on the back of the DFI 2000,

and the serial port on the computer or printer.

To connect to a printer, use a standard IBM serial printer cable.

To connect to a PC, use a standard IBM null modem cable.

Step 2: Prepare the PC to receive the data.

i. Launch a terminal emulation application such as Windows Terminal or Hyperterminal.

ii. Set the communications settings to:

Baud Rate = 9600

Parity = None

Data Bits = 8

Stop Bits = 1

Flow Control = None

Note: Since data is in raw ASCII format, it is not necessary to set the terminal emulation.

iii. Select "Receive Text File" from the data transfer options.

CF 13 15 ver. 7.2 FEB. 99

Page 15

You will be prompted for a file name. (Depending on the program, this may occur before or after the

data transfer.) All the data transmitted to the computer will be stored in this file.

iv. Enter a file name.

Step 3: Upload the data.

To upload peak readings to PC do the following:

Step Action Instrument Displays:

Enter the menu system.

1

2

3

4

[Optional] Erase Readings.

Note: Peak readings are not automatically erased, and can be downloaded to a computer or printer as many times

as desired.

5

6

7

8

Exit menu system.

9

To enter the menu system.

to enter the "Log

operations" menu.

(once) to scroll to "Upload

Log."

Or

(twice) to scroll to "Print

Log".

to upload or print the data.

to scroll to "Erase Log".

to erase the peak readings.

and

to confirm "Erase log"

command.

to exit "Log operations"

menu.

to exit the menu system

Log operations

View log

Upload log

or

Print log

The instrument will scroll through the readings as it uploads or prints

them.

Note: Uploading is faster than printing.

Erase log

Erase log: No

The instrument asks for confirmation.

Erase log: Yes

Erasing

Erase Log

Note: if the log only contains a few entries, "Erasing" may be

displayed to quickly to be seen.

Log operations

Transducer Check

R0000 Ready

3.4 Digitizing a Force-Time Curve

The DFI 2000 provides two functions for digitizing waveforms, the A-record function and the M-record function. To

capture a force-time curve with the M-record function, follow this procedure:

To set up the DFI 2000:

Step Action Instrument Displays:

DFI 2000 V7.2

Transducer Check

1 Connect the sensor and power-up the instrument.

Enter the menu system.

CF 13 16 ver. 7.2 FEB. 99

SDI 50 kg

Absolute mode

A0000 Ready

Page 16

Step Action Instrument Displays:

2

Assign a record function to the FUNC key.

3

4

5

6

7

Select the Recording Rate

8

9

10

11

to enter the menu system.

to scroll to the "Settings" menu.

to enter the "Settings" menu.

to enter the "Function" submenu.

to scroll to the desired function.

(In this case M-record)

to assign the displayed function to the FUNC key.

to scroll to "R-rate".

to enter the "R-rate" submenu.

to scroll to the desired recording rate. (In this case, 500Hz.)

to select the displayed recording rate

Log operations

Settings

Func: +/-peak

New Fn: +/-peak

New Fn: M-record

Func: M-record

R-rate: 10kHz

New rate: 10kHz

New rate: 500Hz

R-rate: 500Hz

12

Exit the menu system.

13

To record the force-time curve:

1. Press Accept to begin recording data.

2. Apply loads to the sensor.

3. When you are done applying loads, Press ESC to stop recording.

4. Press Accept to upload the data to a computer, or press ESC to erase the data. The instrument will ask for

confirmation. Press Next and Accept to confirm the erase command.

to exit the "Settings" menu

to exit the menu system.

Settings

Transducer check

Accept to record

3.5 Using the Output Signals

Example

Suppose you are fastening bolts with a nutrunner. The application requires that torque be between 90-100 in-lbs.

You want the PMAC to turn off the nutrunner when it detects a torque of 92 in-lbs; and you want to trigger an audible

alarm if the actual peak torque is not with in the specified range.

To set up the DFI 2000, do the following:

Step 1: Purchase a standard 9 pin D-sub male connector.

Step 2: Wire the connector to each of the alarms according to the following diagram.

CF 13 17 ver. 7.2 FEB. 99

Page 17

Note: In some cases you can connect the load directly to the instrument, but most cases do require a buffer as

shown.

Pins 1 and 5 are for the Target Signal; 6 and 7 are for the High Condition Signal; and 8 and 9 are for the Low

Condition Signal.

Step 3: Program the DFI to trigger the signals according to the following procedure:

Step Action Instrument Displays:

DFI 2000 V7.2

Connect the sensor and power-up the

1

instrument.

Transducer Check

SDI 50 kg

Absolute mode

A0000 Ready

Enter the menu system.

2

to enter the menu system.

Log operations

Assign a Peak function to the FUNC key.

3

4

to scroll to the "Settings" menu.

to enter the "Settings" menu.

Settings

Func: +peak

indicates the current function

5

6

7

to enter the "Function" submenu.

(twice) to scroll to the +/- peak

function.

To select the currently displayed

function.

New Fn: +peak

New Fn: -peak

New Fn: +/-peak

Func: +/-peak

Set the High and Low Limits for acceptable Peak Values; and the Target Value

8

9

10

11

12

13

CF 13 18 ver. 7.2 FEB. 99

(four times) to scroll to the Low

Limit

to change the Low Limit.

(11 times) to change the first digit

to "9".

to move to the second digit.

(twice) to change the second digit

to "0"

to scroll to the third digit.

LLimit:: 10.00

New LL: The underline indicates the

currently selected digit.

New LL: 9

New LL: 9_

New LL: 90

New LL: 90_

Page 18

Step Action Instrument Displays:

14

15

to change the third digit to ".".

to scroll to the fourth digit.

16 Repeat step 12.

17

18

19

20

21

22

Repeat Steps 10-18, entering 92.0 for the

Target Value.

Repeat Steps 9-17, entering 100.0 for the

High Limit.

to accept the displayed value.

to scroll to the Target Value.

to scroll to the High Limit.

to exit the "Settings" menu.

New LL: 90.

New LL: 90._

New LL: 90.0

LLimit: 90.0

Target: 200.0

Target: 92.0

HLimit: 200.0

HLimit: 100.0

Settings

Exit the menu system.

23

to exit the menu system.

A0000 Ready

To operate the instrument, apply torque to the sensor. When the instrument detects a torque equal to the Target

Value, it will send the Target Signal.

After each loading cycle is completed, the instrument will display the peak value and evaluate it relative to the High

and Low Limits. If the peak value falls above the High Limit, the instrument will send the High Condition Signal. If the

peak value falls below the Low Limit, the instrument will send the Low Condition Signal.

3.6 Programming Third Party Sensors

The DFI 2000 is designed for automatic calibration, and works best with a sensor that has our auto-id connector.

Fortunately, this connector may be attached to any manufacturer’s sensors. To configure another manufacturer’s

sensor to work with the DFI 2000, follow this procedure:

Step 1: Purchase a 15 pin D-sub connector or Cooper’s auto-id connector (Model 90144). To order the Model

90144, call 1 (800) 344-3921.

Step 2: Wire the connector to the sensor according to the following diagram:

Pins 9-15

Used for auto-id

Shield

- Excitati

- Sign

+ Sign

+ Excitati

This configuration may apply to both types of connectors.

CF 13 19 ver. 7.2 FEB. 99

5

4

3

2

1

Pins 6-8

Reserved for

furture use

Page 19

Step 3: Enter the sensor's calibration data into the auto-id connector with the DFI 2000.

Programming Example

Suppose you purchased a 200 in-lb rotary torque sensor with a 3.0 mV/V output from another manufacture, and

wanted to use it with the DFI 2000. After purchasing the connector and wiring it to the sensor, the calibration data

would be programmed into the auto-id connector in the following manner.

Step Action Instrument Displays:

1 Connect the sensor.

Custom AutoId

2 Power-up the instrument.

The instrument is informing you that there is not

calibration data stored in the sensor's connector.

3

4

5

6

7

8

9

to enter the transducer type menu. Type: force

to scroll through the sensor type submenu. Type: torque

to select the type of sensor displayed on the

screen, and enter the torque units submenu.

to scroll to the desired units. UNIT: inlb

to select the units and go to the Full Scale

Value.

(4 times) to change the first digit to "2". FS: 2

to move the cursor to the next digit, and FS: 2_

(twice) to change the digit to a "0". FS: 20

UNIT: inoz

FS: _

10 Repeat step 9 for the third digit. FS: 200

Repeat step 9, entering a decimal point for the fourth

11

digit.

FS: 200.

12 Repeat step 9, entering another "0". FS: 200.0

13

Repeat steps 8, 9 and 13 as necessary to enter the

14

mV/V value (in this case 3.0).

to enter the displayed value, and go to the

mV/V.

mV/V: _

Write to AutoID: No

18

and

to write the entered values to the auto-id

connector.

Write to AutoID: Yes

Transducer check

A0000 Ready

Note: When entering these values, note that they are stored in the DFI 2000's RAM until the operator selects "Write

to AutoID". Then they are written to the connector's EPROM. For proper calibration, it is important to enter all four

values at the same time.

CF 13 20 ver. 7.2 FEB. 99

Page 20

4.0 APPENDIX

4.1 Connecting the DFI 2000

There are four connectors on the back of the DFI 2000.

RS-232

The RS-232 connector is used to upload and print data.

DGND

TRANSM IT

RECEIVE

5

3

2

I/O

The I/O connector is used for:

• Analog Output,

• High Condition Signal,

• Low Condition Signal, and

• Target Signal.

LOW COND

LOW COND

HI COND

HI COND

TARGET

AOUT -

GND

AOUT +

TARGET

5

9

4

8

3

7

2

6

1

The analog output is a differential output across AOUT+ and AOUTB. It has a common mode voltage of 2.5 V with

respect to chassis ground. AOUTB is the reference and AOUT+ is driven positive or negative with respect to it. The

Output impedance of each is 620 Σ and the output voltage is +1.0 V nominal for 2 mV/V full scale sensor.

Wire the connections for the output signals according to the following diagram.

Pins: 1 and 5 Target Signal

2 and 6 High Condition Signal

CF 13 21 ver. 7.2 FEB. 99

Page 21

8 and 9 Low Condition Signal

AC Adapter/Charger (12 V dc)

The AC adapter is used to power the instrument, and charge the battery.

Transducer Wiring

12 V dc

GND

The standard 15-pin D sub Connector and the Model 90144

Connector are wired according to the diagram:

Ground

CW Trail

CW Lead

Shield

- Exc

- Sig

+ Sig

+ Exc

Pins 9-15 used

for auto-id

Pins 6-9

reserved for

future use

5.0 BATTERY REPLACEMENT

The DFI 2000 uses two types of batteries:

• a 9.6 V rechargeable Ni-Cad battery pack, and

• one 3 V lithium coin battery.

The rechargeable Ni-Cad batteries power the instrument when it is not plugged into a wall socket. If the "charge life"

of these batteries decreases significantly, or if the instrument refuses to work unless plugged into a wall socket, the

Ni-Cad batteries need to be replaced. This must be done at Cooper Instruments. Contact our service department at

1 (800) 344-3921 for shipping instructions.

The coin battery supplies power to the RAM when the instrument is turned off. This protects the collected data from

being erased when the instrument powers down. When this battery needs replacement, the instrument will display

the message: "Low Coin Battery". Replace this battery with a Duracell DL2025 or equivalent 3 V lithium coin battery.

5.1 Specifications

Sampling Rates

Peak and Track functions5 kHz

With encoder 2 kHz

Record functions

selectable up to 10 kHz

With encoder selectable up to 2 kHz

Frequency Response

Accuracy

(-3 dB) at 1000 Hz

max error = 0.05% of Full Scale

Sensor Interface

Max Input at Full Scale " 4.5 mV/V

Polarity Bipolar

Bridge excitation 7 V supplied

Min Bridge Impedance

120 Σ

Data Output

RS-232 port

ASCII

9600 baud

8-N-1

Power

AC Adapter 115 V ac/12 V dc

Batteries 9.6 V internal/rechargeable

CF 13 22 ver. 7.2 FEB. 99

Page 22

Physical Dimensions

Height 1.75 in

Width 6 in

Depth 8 in

Weight 2.4 lbs

6.0 WARRANTY REPAIR POLICY

Limited Warranty on Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in

workmanship within one year of the date of shipment by Cooper will be repaired or replaced free of charge provided

that a return material authorization is obtained from Cooper and the defective product is sent, transportation charges

prepaid, with notice of the defect, and it is established that the product has been properly installed, maintained, and

operated within the limits of rated and normal usage. Replacement or repaired product will be shipped F.O.B. from

our plant. The terms of this warranty do not extend to any product or part thereof which, under normal usage, has

an inherently shorter useful life than one year. The replacement warranty detailed here is the buyer’s exclusive

remedy, and will satisfy all obligations of Cooper whether based on contract, negligence, or otherwise. Cooper is

not responsible for any incidental or consequential loss or damage which might result from a failure of any and all

other warranties, express or implied, including implied warranty of merchantability or fitness for particular purpose.

Any unauthorized disassembly or attempt to repair voids this warranty.

Obtaining Service under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact the

Repair Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number.

Shipment to Cooper shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from our

plant in Warrenton, Virginia. Non-verified problems or defects may be subject to a $100 evaluation charge. Please

return the original calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty applies

only to those items that were found defective and repaired; it does not apply to products in which no defect was

found and returned as is or merely recalibrated. It may be possible for out-of-warranty products to be returned to the

exact original specifications or dimensions.

* Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper to

receive information specifying the reason the product is being returned. Specific test data, written observations on

the failure and the specific corrective action you require are needed.

CF 13 23 ver. 7.2 FEB. 99

Loading...

Loading...