Page 1

DCM 480

LVDT SIGNAL CONDITIONING

MODULE

www.cooperinstruments.com

PH: 540-349-4746 • FAX: 540-347-4755

DCM 480/2004 1

Page 2

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................................ 1

2. INSTALLATION INSTRUCTIONS .......................................................................... 1

2.1 EMC Requirements................................................................................................... 1

2.2 Supply/Output Connections...................................................................................... 1

2.3 Transducer Connections............................................................................................ 2

3. CONTROLS .................................................................................................................. 5

3.1 Coarse Zero Switch................................................................................................... 5

3.2 Fine Zero Potentiometer ........................................................................................... 5

3.3 Zero Input Switch ..................................................................................................... 5

3.4 Span Switch (Coarse gain)........................................................................................ 5

3.5 Fine Span Potentiometer........................................................................................... 6

3.6 Filter Switch.............................................................................................................. 6

4. SETTING UP PROCEDURE............................................................................. 7

4.1 Bipolar or Half-stroke Applications.......................................................................... 7

4.2 Offset Stroke Applications........................................................................................ 7

5. SPECIFICATION......................................................................................................... 8

6. WARRANTY AND SERVICE .................................................................................... 9

DCM 480/2004 ii

Page 3

1. INTRODUCTION

The DCM 480 is a two-wire, 4-20mA-output oscillator/demodulator for use with LVDT

transducers having suitable primary impedance. (Refer to sect 5).

Coarse and Fine controls for gain and zero (4mA) allow use with the full range of Cooper

transducers and a filter switch allows selection of optimum bandwidth/noise. The

differential signal amplifier circuit allows the use of long transducer cables.

The two-wire supply/output system allows use with long cables from the supply/monitor

with a wide range of supply voltage and high noise immunity.

In order to meet the primary impedance requirements of the DCM 480, some Cooper

transducers are modified to TM202. Section 2.4 refers.

Note: The DCM 480 is not suitable for use with differential or half-bridge transducers.

2. INSTALLATION INSTRUCTIONS

2.1 EMC Requirements

For EMC compliance, good quality shielded cable should be used for connection to this

instrument. The shields of both transducer and 4-20mA loop cables should be

connected as shown in Fig. 4.

• Note 1-Cable shields to be grounded at only one end - the instrument end.

• Note 2-When the instrument is a small part of a large electrical installation,

ensure the cables to and from the instrument are segregated from electrically

noisy cables.

• Note 3-Ensure cables to and from the instrument are routed away from any

obviously powerful sources of electrical noise, e.g. electric motors, relays,

solenoids.

• Note 4-ESD precautions should be used when working on the instrument circuit

board with the lid removed. The user should ensure he is "grounded" by use of a

wrist strap or at least touching ground before touching any component including

wires, terminals or switches.

• Note 5-The body of the transducer and the DCM 480 case should be grounded.

If the transducer fixing attachments do not provide a good ground, then a ground

strap should be used.

2.2 Supply/Output Connections

The two wires from the supply/output monitor are connected to terminals 6 and 7

Polarity of supply is irrelevant as a reverse polarity protection circuit automatically

energises the oscillator/demodulator with the correct polarity.

DCM 480/2004 1

.

Page 4

2.3 Transducer Connections

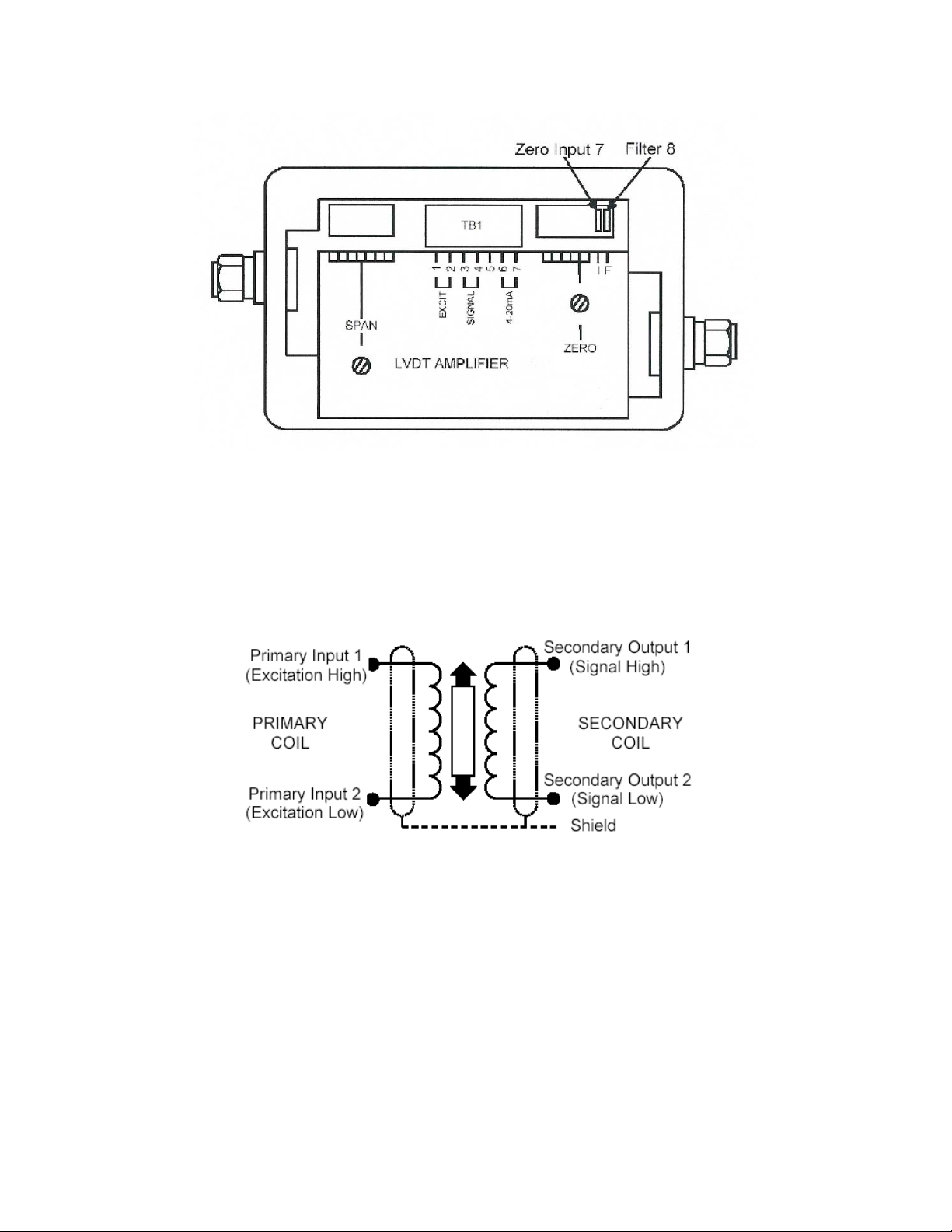

Fig. 1 General view of DCM 480

Fig. 2 Connection for LVDT Transducers

Function TB1 PIN

Excitation Hi Excit 1

Excitation Lo Excit 2

Signal Hi Signal 3

Signal Lo Signal 4

Shield Gland shell

(see Fig. 4)

Some Cooper LVDTs have a BLACK wire. This

must be insulated.

If when connected, the phase of the amplifier

output is not as required (for example, an

inward moving armature causes a rising

amplifier output when a falling output is

required) then reversing the signal high and

signal low wires will correct this.

DCM 480/2004 2

Page 5

DCM 480 Case

Fig. 3 Connection Schematic

DCM 480/2004 3

Page 6

DCM 480/2004 4

Page 7

3. CONTROLS

Please refer also to Fig. 1 for locations. The locations of all controls are also shown on

the legend plate mounted on the PCB.

3.1 Coarse Zero Switch

The toggles or levers 1 to 6 of an 8-way DIL switch are used to inject varying amounts of

offset into the output signal circuit. This, together with the Fine Zero Potentiometer,

allows aligning the 4mA output point to coincide with any desired armature position. For

example, an ACT1000 can be made to give a 4-20mA output with a stroke of -0.5in. to

+1in., etc.

The amount of offset for each lever setting is shown below:

Lever On mA Output Shift (approx.)

1 -7

2 -5

3 -3

4 -2

5 +2

6 +3

3.2 Fine Zero Potentiometer

This control is used together with the coarse zero switch to set the 4mA output level.

Refer also to Section 3.1. Avoid applying excessive tightening force to the locking nut.

3.3 Zero Input Switch

Toggle/lever 7 of the Zero Switch, when set to ON, zeroes the amplifier input signal

irrespective of the transducer position. This simulates the transducer mid-stroke (zero

output) signal and may be used to set the mid-range output level (e.g. 12mA) or

transducer mid-stroke position without disconnecting the transducer secondary.

3.4 Span Switch (Coarse gain)

This is an 8-toggle/lever DIL switch which, when used with the Fine Span control, allows

a 4-20mA output to be obtained with a wide range of transducer signals. Typically,

transducer manufacturers' data sheets or calibration certificates will give a figure

allowing the full-scale output to be calculated. Possible formats for this are as follows;

the examples assume a transducer range of ±50mm.

DCM 480/2004 5

Page 8

Sensitivity format Explanation To convert to F.S. output

mV/V/mm

e.g. 46mV/V/mm

V/V at full-scale,

e.g. 2.3 V//V

mV/mm at a specified

excitation voltage.

E.g. 230mV/mm at 5V

exc.

Millivolts of output, per volt of

excitation, per mm of travel

Volt of output, per volt of

excitation, at full-scale

Millivolts of output, per mm

of travel, given a specified

excitation voltage.

Sensitivity x 0.5 x range in mm

e.g. 0.046 x 0.5 x 50 = 1.15V

Sensitivity x 1

e.g. 2.3 x 0.5 = 1.15V

(Sensitivity / specified

excitation voltage) x 0.5 x

range in mm

e.g. (0.230/5) x 0.5 x 50=1.15V

The standard excitation of the DCM 480 is 0.5V for mod 6 onward, as used in the calculations

above.

The following table shows the band of transducer full-scale output voltages appropriate

to each of the 8 Gain Range Settings. For example, a transducer with a full-scale output

of 1.15V would be correctly set as gain range 2.

The table below shows the V r.m.s. signals required for full

output with the Fine Span either at minimum or maximum:

Lever On

2 to 4 1

1-2 2

0.7-1 3

0.4-0.7 None

0.25-0.44 4

0.15-0.25 5

0.1-0.15 6

0.05-1 7

0.03-0.05 8

3.5 Fine Span Potentiometer

This control interpolates between the ranges of the Span switch. (Section 3.4).

Avoid applying excessive tightening force to the locking nut.

3.6 Filter Switch

Toggle/lever 8 of the "zero" DIL switch is used to select the bandwidth/noise

performance as shown in the specification:

DCM 480/2004 6

Page 9

4. SETTING UP PROCEDURE.

4.1 Bipolar or Half-stroke Applications

1. Connect the transducer and supply as shown in Section 2.

2. Select the relevant gain range by setting the Coarse Span switch as shown in

Section 3.4. Refer also to the transducer data to determine the input signal.

3. Set Zero Input lever to ON, all other Zero levers to OFF.

4. Adjust Fine Zero potentiometer for 12mA output.

5. Reset Zero Input lever to OFF and adjust the transducer armature for 12mA

output. This determines the transducer center stroke position.

6. Move the armature to the required full-scale position and adjust Fine Span for

20mA output. (Note: primary or secondary connections may be reversed to

reverse the output polarity.)

7. Move the armature to the required zero position (an equal but opposite

displacement to that in step 6) and check the output is 4mA. Trim Fine Span and

zero if necessary for optimum linearity over the 4-20mA range.

4.2 Offset Stroke Applications

1. Carry out steps 1 to 5 in Section 4.1, then: -

2. Move the armature to the desired half-stroke position and use the Coarse Zero

switch to suppress the output to near 12mA (refer to Section 3.1). Trim for

exactly 12mA via Fine Zero.

3. Move the armature to the desired full-scale position and adjust Fine Span for

20mA output.

4. Repeat steps 2 and 3 for consistent results.

5. Move the armature to the desired 4mA position and check for 4mA output.

DCM 480/2004 7

Page 10

5. SPECIFICATION

(Note: all figures are typical values)

Supply Voltage

Output regulation

Loop Resistance (Max)

(Min)

Output regulation

Excitation 0.5V rms. 5kHz sinusoidal at 4mA max.

Signal Range 30mV to 4V

Zero Range ±8mA

Linearity 0.05%

Bandwidth

Filter ON

Noise

Filter ON

Zero Temperature Coefficient

Gain Temperature Coefficient

Maximum Output Overload 45mA

EMC Performance When subjected to radiated electromagnetic energy

Operating Temperature -20 to 85°C (to 100°C possible)

Dimensions 125 x 80 x 57mm (4.7 x 3.2 x 2.1 inches)

Weight 550g (1.2lb)

Seal To IP65

Gland Cable Diameter 3 to 6.5mm (0.12 to 0.26 inches)

Note 1 The maximum allowable total external circuit

Note 2 Where the supply voltage is higher than 24 volts and

12 to 36V dc universal polarity

1µA/V

50 (12V) to 1200 (36V). See Note 1 below

See Note 2 below

2µA/100

250Hz flat

25Hz

50µA peak-peak

15µA peak-peak

0.005% FS/°C

0.015% FS/°C

(as IEC 801-3) an additional error can occur at

certain spot frequencies:

Field Strength

30V/m 0.5mA

3V/m 0.25mA

resistance is calculated from:

R max = 50(Vs – 11)

the ambient temperature higher than 25°C, then a

minimum value of loop resistance is required:

R min = (Vs – 28)(t – 25)

Where Vs = supply voltage (volts) and t = ambient

temperature (°C)

E.g. at 36 volts supply and 85°C ambient, the value

of RL must be between 480 ohms and 1200 ohms.

Typical Max. Error

DCM 480/2004 8

Page 11

6. WARRANTY AND SERVICE

WARRANTY

Cooper Instruments & Systems products are warranted against defects in materials or

workmanship. This warranty applies for one year from the date of delivery. We will

repair or replace products that prove to be defective during the warranty period provided

they are returned to Cooper Instruments & Systems.

This warranty is in lieu of all other warranties, expressed or implied, including the implied

warranty of fitness for a particular purpose to the original purchaser or to any other

person. Cooper Instruments & Systems shall not be liable for consequential damages of

any kind.

If the instrument is to be returned to Cooper Instruments & Systems for repair under

warranty, it is essential that the type and serial number be quoted, together with full

details of any fault.

SERVICE

We maintain comprehensive after-sales facilities and the instrument can, if necessary,

be returned to our factory for servicing.

Equipment returned to us for servicing, other than under warranty, must be accompanied

by an official order as all repairs and investigations are subject to at least the minimum

charge prevailing at the date of return.

The type and serial number of the instrument should always be quoted, together with full

details of any fault and services required.

IMPORTANT NOTES

1. No service work should be undertaken by the customer while the unit is under

2. If the instrument is to be returned to Cooper Instruments & Systems for repair,

3. It is regretted that the above warranty only covers repairs carried out at our

warranty except with the authorization of Cooper Instruments & Systems.

(including repair under warranty) it is essential that it is suitably packed and that

carriage is insured and prepaid. Cooper Instruments & Systems can accept no

liability whatsoever for damage sustained during transit.

factory. Should the instrument have been incorporated into other equipment that

requires our engineers to perform the repair on site, a charge will be made for the

engineer's time to and from the site, plus any expenses incurred. The

aforementioned provisions do not extend the original warranty period of any

product that has been either repaired or replaced by Cooper Instruments &

Systems.

DCM 480/2004 9

Loading...

Loading...