Page 1

XC/XPP/XST

Mechanical Force Gauges

User’s Guide

www.cooperinstruments.com

PH: 540-349-4746 • FAX: 540-347-4755

Page 2

MODELS

XC – with compression calibration

XST – with tension calibration

XPP - with compression/tension calibration

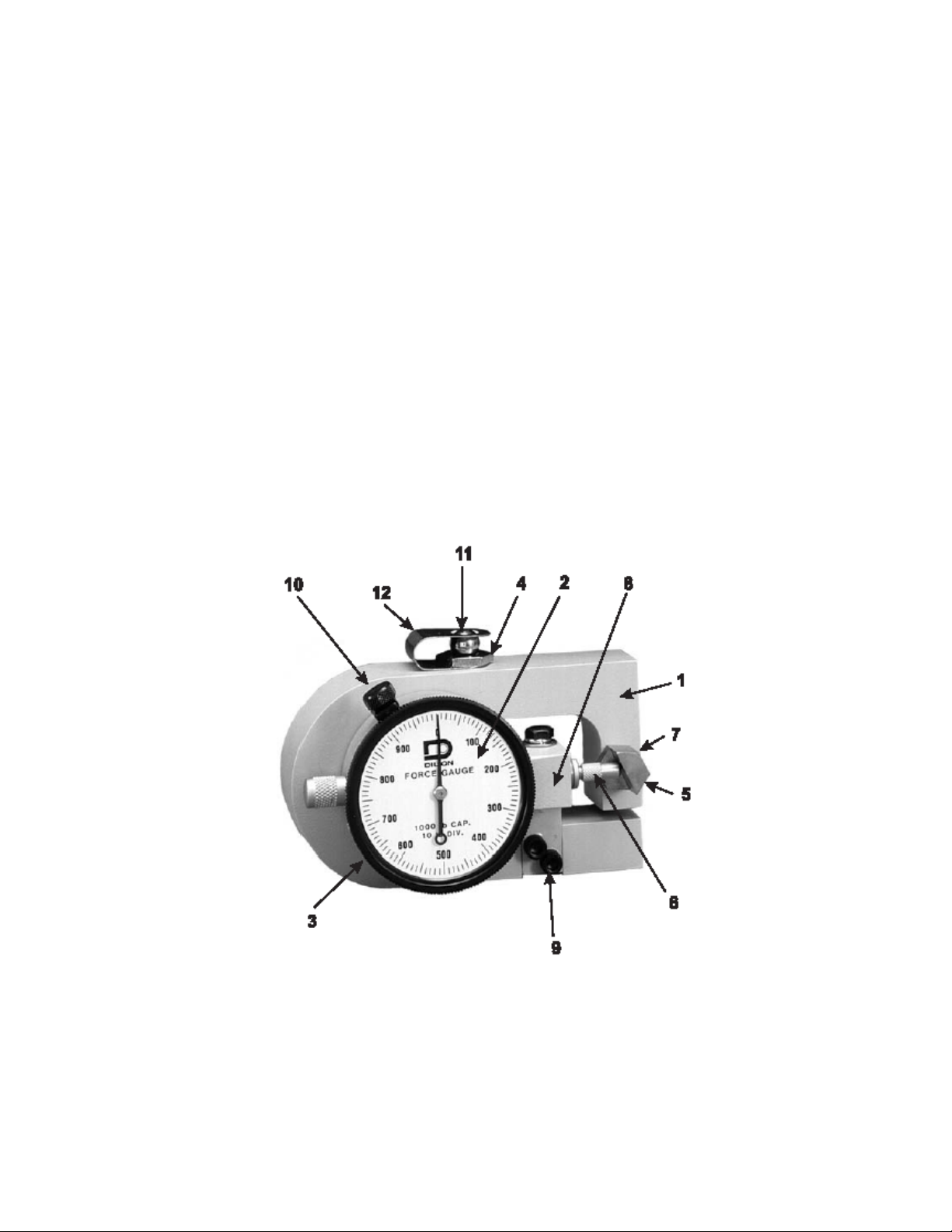

PRINCIPAL PARTS

For easy identification of Force Gauge parts*, the following illustration has been prepared. Correspondence with

our Service Department should refer to this illustration, and a rough pencil sketch of your particular setup will be

helpful.

1. “U” SHAPED DEFLECTION BEAM

2. DIAL INDICATOR

3. BEZEL (FOR ZERO ADJUSTMENT PURPOSES)

4. PRESSURE BUTTON

5. ANVIL

6. DIAL INDICATOR GAUGE MOVEMENT PLUNGER

7. ANVIL SET SCREW

8. DIAL INDICATOR MOUNTING BRACKET

9. MOUNTING BRACKET SCREWS

10. BEZEL LOCKING SCREW

11. LOADING BALL

12. SPRING RETAINER CLIP

* An optional MAXIMUM POINTER is available but not shown.

CF 109 1 11/02

Page 3

OPERATIONAL DATA

IMPORTANT!

When adjusting bezel-locking screw, #10, only tighten as much as is necessary to hold bezel in proper position.

DO NOT OVERTIGHTEN, as this will distort the thin housing of the dial indicator gauge; affect the smooth

action of the movement and produce false readings!

Your Force Gauge is ready to go to work for you without any special assembly. Upon removing it from the

storage case, it is only necessary to check the zero setting. This is done by placing the unit on a flat table with

the pressure button, # 4, at the top. Note that the dial bezel, # 3, is locked lightly by a knurled thumbscrew, # 10.

Simply loosen this knurled screw and then revolve the bezel in either direction, depending upon which way zero

may be off. Revolving the bezel causes the dial to follow. With zero positioned directly under the pointer tip,

again tighten the locking screw, and the instrument is ready to use.

Because of the sensitivity of the Cooper Gauge, zero should always be set with the unit resting on the lower or

thicker portion of the deflection beam as illustrated. This is the same position it occupies during calibration.

Ordinarily, zero will be retained indefinitely. However, under repeated stress or through accidental banging

around, it may go off slightly. Thus, it is a good plan to check zero occasionally.

Caution: The small anvil, #6, against which the dial indicator plunger rides, should never be altered except by

factory technicians. This anvil has nothing to do with zero setting. By careful adjustment, it has been positioned

in such a way that, for full load application within the range of the instrument, the pointer will revolve 360°.

TAMPERING WITH THE SETTING OF THIS ANVIL AUTOMATICALLY VOIDS THE ACCURACY

GUARANTEE. If the anvil should be accidentally thrown out of position by dropping or striking against another

object, the entire gauge should be returned to the factory for resetting and calibration check.

HELPFUL POINTERS

It is a good plan to test the tightness of the hardened dial indicator plunger, #6, occasionally. This part is

screwed into a finely threaded seat and may sometimes work loose. This would cause the gauge to read high

and might be mistaken for an off zero condition. Be sure not to force the plunger tip too tightly when screwing it

down since, as explained, the threads are fairly delicate and might break off.

Note that threaded mounting holes have been provided in opposite faces of the “U” shaped deflection beam, #1.

In the upper mounting hole, a spherically recessed pressure button, #4, is screwed. This button is hardened

and plated. It receives the loading ball, #11. Force should be applied directly against this ball. In operation, the

deflection beam bends inward slightly, and the ball revolves, tending to keep the line of force vertical. A drop of

light oil on the ball assists this action.

Never fasten the “U” shaped deflection beam in such a way that the free movement of the upper portion will be

retarded. The lower or thicker “leg”, however, may be tightened as securely as desired, using a stud or bolt

through the threaded mounting hole.

Since the deflection beam is hardened, it is not possible nor would it be recommended, to drill and tap it once it

is in the field. If special mounting holes are desired, these can be provided during early stages of manufacture,

but must be specified at that time.

If a particular test calls for load application through a pulley, roller or chuck, etc., due care should be taken to

see that the load is applied in a true vertical line through the center of the top-mounting hole #4. Off-center

loading would introduce leverage, thereby increasing or decreasing readings from their true value. Universal

joints or hinged fittings should be carefully machined to obviate side slop or play. If in doubt about the best

method of applying load for specific arrangement, don’t hesitate to consult our Engineering Department.

Remember, a rough pencil sketch or snapshot will aid tremendously in understanding your problem. Never oil

the dial indicator at any point. It is unnecessary. If oil or other fluids should get on the unit, wipe off gently, but

well. Foreign matter lodging on the plunger, #6 will retard its free action, resulting in inaccurate readings.

If accidental overload is anticipated, a solid steel rod about 3/4 inch in diameter can be inserted at the center

point of the Gauge between the “U” shaped bar. Length of this rod should be figured so that the upper, flexible

half of beam will bottom against it, once the full capacity of the instrument has been reached. Further load will

CF 109 2 11/02

Page 4

then pass through this solid path without harm to the Force Gauge. Note the method of mounting the dial

indicator to the supporting bracket on the reverse side of the case. Allen screws are used. Be sure to check

these screws at intervals, making sure that they are always tight. Vibration may in time loosen them slightly,

and it is best to take this precaution.

TENSILE MODEL

Generally speaking, the same requirements and suggestions applying to the compression model Force Gauge

also apply to the tensile unit. The main exception, of course, is that on the tensile model, load is applied through

the use of special end rod bearings.

Model XPP

These bearings are available for all tensile models as standard equipment. They are a perfect fit and without

any side play. Bearing pins can be machined from drill rod to suit your particular test plan. Remember that if

you require a special adapter of some kind in place of these bearings; be sure that such adapters are selfaligning so that applied force is always able to assume a vertical line.

Caution: Because there is the possibility that in service the ball-socket connectors can become unscrewed from

the beam, the operator should check these parts at intervals to make sure that some of the threaded shank is

ALWAYS showing on the inside of the “U” shaped beam. If it is not showing, no further loads should be applied

until the connector is screwed down to its normal position.

Do not attempt to weld, cotter pin, or otherwise make tensile connectors a solid part of the bar since every

requirement is different as to the length of the shank that has to be utilized. In summation, we must emphasize

that Cooper will not be liable for any incident that might result from accidental or intentional screw-out or break

away of the ball-socket connectors. For your own protection, keep these parts properly seated at all times.

Tare settings cannot be made on the Force Gauge without a slightly resultant loss in accuracy. This is due to

the fact that the dial layout is not 100% linear. Each unit is individually machined and thus must be individually

calibrated. While this makes for split-hair accuracy, division marks are not equidistant and hence do not lend

themselves to tare adjustment. Instead, any tare weight encountered in a typical test should simply be deducted.

CF 109 3 11/02

Page 5

WARRANTY REPAIR POLICY

Limited Warranty On Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material or in

workmanship within one year of the date of shipment by Cooper will be repaired or replaced free of charge

provided that a return material authorization is obtained from Cooper and the defective product is sent,

transportation charges prepaid, with notice of the defect, and it is established that the product has been properly

installed, maintained, and operated within the limits of rated and normal usage. Replacement or repaired

product will be shipped F.O.B. from our plant. The terms of this warranty do not extend to any product or part

thereof which, under normal usage, has an inherently shorter useful life than one year. The replacement

warranty detailed here is the buyer’s exclusive remedy, and will satisfy all obligations of Cooper whether based

on contract, negligence, or otherwise. Cooper is not responsible for any incidental or consequential loss or

damage which might result from a failure of any and all other warranties, express or implied, including implied

warranty of merchantability or fitness for particular purpose. Any unauthorized disassembly or attempt to repair

voids this warranty.

Obtaining Service Under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item, contact

the Repair Department c/o Cooper Instruments at (540) 349-4746 for a Return Material Authorization number.

Shipment to Cooper shall be at buyer’s expense and repaired or replacement items will be shipped F.O.B. from

our plant in Warrenton, Virginia. Non-verified problems or defects may be subject to a $100 evaluation charge.

Please return the original calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty

applies only to those items that were found defective and repaired; it does not apply to products in which no

defect was found and returned as is or merely recalibrated. It may be possible for out-of-warranty products to

be returned to the exact original specifications or dimensions.

* Technical description of the defect: In order to properly repair a product, it is absolutely necessary for Cooper

to receive information specifying the reason the product is being returned. Specific test data, written

observations on the failure and the specific corrective action you require are needed.

CF 109 4 11/02

Loading...

Loading...