MULTI

DUCTLESS INVERTER

HEAT PUMP

INSTALLATION

MANUAL

PANEL CONSOLE TYPE

INDOOR UNIT

Models:

GEN(12)AA-D3DNA1C/I

GEN(18)AA-D3DNA1C/I

Contents

The figures in this manual may be different with the material objects, please

refer to the material objects for reference.

This appliance is not intended for use by persons (including children) with

reduced physical , sensory or mental capabilities or lack of experience

and knowledge,unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Thank you for choosing a

C&H Multi Ductless Heat Pump!

You can feel confident in your selection because the same

pride incraftsmanship and engineering knowledge that goes

into millions of other C&H installed products worldwide has

gone into your unit.

Please read this owner’s manual carefully before

operationand retain it for future reference.

INSTALLATIONINSTRUCTIONS

1. Installation of indoor unit...........................................................................................1

2. Routine check after installation.................................................................................9

3. Configuration of connection pipe and additional volume of refrigerant......................10

INSTALLATION INSTRUCTIONS

The appliance shall not be installed in the laundry.

Installation of indoor unit

●

●

●

●

Such a place where cool air can be distributed

Such a place where condensation water is easily

Such a place that can handle the weight of indoor unit.

Such a place which has easy access for maintenance.

drained out.

throughout the room.

SELECTION OF INSTALLATION LOCATION.

Each type is similar to the other as follows;

●

●

THERE ARE 2 STYLES OF INSTALLATION.

CEILING TYPE

FLOOR TYPE

Schematic drawing of hooks:

Where there is too much of oil area.

Where it is acid base area.

Where there is irregular electrical supply.

●

●

●

TOOCCUR.

AIR CONDITIONER TROUBLEIS LIABLE

CAUTIONS FOR INSTALLATION WHERE

8in

(

200mm

)

Indoor unit

The indoor unit should be sited in a place where:

1) the restrictions on installation specified in the indoor

unit installation drawings are met.

2) both air intake and exhaust have clear paths met.

3) the unit is not in the path of direct sunlight.

4) the unit is away from the source of heat or steam.

5) there is no source of machine oil vapour (this may shorten indoor unit life).

6) cool(warm) air is circulated throughout the room.

7) the unit is away from electronic ignition type fluorwscent lamps

(inverter or rapid stert type) as they may shorten the remote

controller range.

8) the unit is at least 39in(1m) away from any television or

radio set(unit may cause interference with the picture or

sound).

Indoor Unit Installation Drawings

The indoor unit may be mounted in any of the three styles shown here.

Exposed

Floor lnstallation Wall Installation

Molding

Mounting plate

Half conceated

Concealed

Grid(field supply)

Location for securing the installation panel.

27in(

700

mm)

5in(

120

mm)

9in(

220

mm)

7in

(

170

mm)

1in(

30

mm)

25in(

644

mm)

120

mm

220

mm

6in

(

160

mm)

1in(

30

mm)

22in(

570

mm)

23in(

600

mm)

8in(

200

mm)

59in(150cm)

or more

59in(150cm)

6in(15cm) or

below from

the floor

59in(150cm)

or more

59in(150cm)

or more

or more

1

INSTALLATION

PAPER PLANK

3”

(75)

Refrigerant piping

1)Drill a hole ( 2 1/8”(55mm) in diameter ) in the spot indicated by the symbol in the illustration as

below .

2)The location of the hole is different depending on which side of the pipe is taken out .

3)For piping ,see Connecting the refrigerant pipe ,under Indoor Unit Installation(1).

4)Allow space around the pipe for a easier indoor unit pipe connection.

Min.allowable length

The suggested shortest pipe length is 98in(2.5m),in order to avoid noise from the outdoor unit and vibration.

(Mechanical noise and vibration may occur depending on how the unit is installed and the environment in which it is

used.)

See the installation manual for the outdoor unit for the maximum pipe length.

CAUTION

14in(350mm)

wall

Refrigerant pipe

1 3/4”

(45)

1 3/4”

(45)

1 3/4”

(45)

1 3/4”

(45)

1 3/4”

(45)

2 3/8”

(60)

3”

(75)

3”

(75)

3”

(75)

3”

(75)

1 3/4”

(45)

Left back piping

gnipipmottobthgiRgnipipmottobtfeL

Wall

Unit : in(mm)

Right back piping

Left/right piping

2

INSTALLATION INSTRUCTIONS

Installation of indoor unit

Floor

Drain piping

1)Use commercial regid polyvinyl chloride pipe general VP 20 pipe, outer diameter 1”(26mm), inner diameter

3/4”(20mm) for the drain pipe.

2)The drain hose (outer diameter 3/4”(18mm) at connecting end, 9”(220mm) long)is supplied with the indoor unit.

Prepare the drain pipe picture below position.

3)The drain pipe should be inclined downward so that water will flow smoothly without any accumulation.(Should not

be trap.)

4)Insert the drain hose to this depth so it won’t be pulled out of the drain pipe.

5)Insulate the indoor drain pipe with 3/8”(10mm) or more of insulation material to prevent condensation.

6)Remove the air filters and pour some water into the drain pan to check the water flows smoothly.

4”(100mm)

Drain hose

4”(100mm)

6”(150mm)

Vinyl chloride

drain pipe

2”(50mm)

or more

Reducer

Must be no trap

Do not touch water

3

INSTALLATION INSTRUCTIONS

Installation of indoor unit

Boring a wall hole and installing wall embedded pipe

For walls containing metal frame or metal board ,be sure to use a wall embedded

pipe and wall cover in the feed-through hole to prevent water leakage.

Be sure to caulk the gaps around the pipes with caulking material to prevent

water leakage.

1)Bore a feed-through hole of 2 1/8”(55mm) in the wall so it has a down slope

toward the outside.

2)Insert a wall pipe into the hole.

3)Insert a wall cover into wall pipe .

4)After completing refrigerant piping, wiring, and drain piping, caulk pipe hole gap

with putty.

Inside Outside

Caulking

Wall embedded pipe

(field supply)

Wall hole cover

Wall embedded pipe

(field supply)

Φ

2 1/8”

(

55

mm)

Open the front panel, remove the 4 screws and dis-

mount the front grille while pulling it forward.

Follow the procedure below when removing the slit

portions.

Front panel

Open the front panel

Remove

front grille

Casing

Front

grille

Remove 4 screws

3 tabs

For Moldings

Remove the pillars. (Remove the slit portions on the

bottom frame using nippers.)

For Side Piping

Remove the pillars.

1)Remove the 7screws.

2)Remove the upper casing (2 tabs).

3)Remove the left and right casings (2 tabs on each

side ).

4)Remove the slit portions on the bottom frame and

casings using nippers .

5)Return by following the steps in reverse order(3>2>

1).

3)Side

casings

2)Upper casing

3)Side

casings

Remove the pillar

Remove 7 screws

Casing

Remove the pillar

Casing

Remove the pillar

Bottom frame

Secure using 6 screws for floor installations.(Do not forget to secure to the rear wall.)

For wall installations, secure the mounting plate using 5 screws and the indoor unit using 4 screws.

Follow the arrows to disengage the clasps on the

front case to remove it.

Installing indoor unit

1.Preparation

2.Installation

4

INSTALLATION INSTRUCTIONS

Installation of indoor unit

The mounting plate should be installed on a wall which can support the weight of the indoor unit.

1) Temporarily secure the mounting plate to the wall, make sure that the panel is completely level, and mark the boring

points on the wall.

2) Secure the mounting plate to the wall with screws.

6screws

Casing

Floor Installation

Wall Installation

6screws

Molding

3) Once refrigerant piping and drain piping connections are complete, fill in the gap of the through hole with putty. A gap

can lead to condensation on the refrigerant pipe, and drain pipe, and the entry of insects into the pipes.

4) Attach the front panel and front grille in their original positions once all connections are complete.

Flaring the pipe end

1)Cut the pipe end with a pipe cutter.

2)Remove burrs with the cut surface facing downward so that the chips do not enter the pipe.

3)Fit the flare nut on the pipe.

4)Flare the pipe.

5)Check that the flaring is properly made.

WARNING

1) DO not use mineral oil on flared part.

2) Prevent mineral oil from getting into the system as this would reduce the lifetime of the units.

3) Never use piping which had been used for previous installations. Only use parts which are delivered with the unit.

4) Do never install a drier to this R410A unit in order to guarantee its lifetime.

5) The drying material may dissolve and damage the system.

6) Incomplete flaring may cause refrigerant gas leakage.

Make sure that the

flare nut is fitted

The pipe end must

be evenly flared in

a perfect circle

Flare’s inner

surface must

be scratch-free

Cut exactly

at right

angles

Renove

burrs

Flaring

Set exactly at the position shown below

A

Die

A

0-0.5mm

1.0-1.5mm

1.5-2.0mm

Flare tool for R410A

Clutch-type

Clutch-type

(Rigid-type)

Wing-nut type

(lmperial-type)

Conventional flare tool

8in (

200

mm

)

5

INSTALLATION INSTRUCTIONS

Installation of indoor unit

Connecting the refrigerant pipe

Wrench

Indoor unit tubing

Open-end wrench (fixed)

Connection pipe

Flare nut

1)Use torque wrenches when tightening the flare nuts to prevent damage to the flare nuts and gas leaks.

Coat here with refrigeration oil

2)Align the centres of both flares and tighten the flares and tighten the flare nuts 3 or 4 turns by hand.

Then tighten them fully with the torque wrenches.

3)To prevent gas leakage, apply refrigeration oil on both inner and outer surfaces in the flare. (Use refrigeration oil for

R410A.)

Liquid side

09K/12K

09K/12K

18K

09K 18K

09K/12K/18K18K

3/8 inch 1/2 inch 1/4 inch

31-35

N.m

50-55

N.m 15-20

N.m

Flare nut tightening torque

Gas side

Caution on piping handling

1)Protect the open end of the pipe against dust and moisture.

2)All pipe bends should be as gentle as possible. Use a pipe bender for

bending.

(Bending radius should be 1 1/6in to 1 3/5in (30 to 40mm) or larger.)

Gas pipe

Gas pipe

insulstion

Finising tape

Inter-unit wiring

Liquid pipe

Liquid pipe

insulation

Selection of copper and heat insulation materials

When using commercial copper pipes and fittings, observe the

following:

1)Insulation material: Polyethylene foam

Heat transfer rate:0.041 to 0.052W/mK(0.035 to 0.045kca/(mh

°C)

Refrigerant gas pipe’s surface temperature reaches 230

°F

(110

°C)

max.

Choose heat insulation materials that will withstand this temperature.

2)Be sure to insulate both the gas and liquid piping and to provide insulation dimensions as below.

Liquid side

Liquid pipe

thermal insulation

O.D.

3/8”

O.D. 1

/2”

O.D.

1/4”

I.D. 1

/2”-3/5”

I.D.

9/16”-5/8”

I.D.

5/16”-3/8”

noitalusnilamrehtepipsaGedissaG

0.38in (10mm) Min.

ssenkcihT

0,03in (0.8mm)

ssenkcihT

3)Use separate thermal insulation pipes for gas and liquid refrigerant pipes.

Be sure to

place a cap.

If no flare cap is

available,cover

the flare mouth

with tape to keep

dirt or water out.

INSTALLATION INSTRUCTIONS

Installation of indoor unit

6

7

Checking for gas leakage

1)Check for leakage of gas after air purging

2)See the sections on air purges and gas leak checks in

the installation manual for the outdoor unit.

Attaching the connection pipe

Check for leakage here

Apply soapy water and check carefully for leaking gas.

wipe soapy water off after

the check is complete.

Attach the pipe after checking for gas leakage, described above.

1)Cut the insulated portion of the on-site piping, matching it up with the connecting portion.

2)Secure the slit on the refrigerant piping side with the butt joint on the auxiliary piping using the tape, making sure there

are no gaps.

3)Wrap the slit and butt joint with the included insulation sheet, making sure there are no gaps.

Refrigerant

pipe

Refrigerant

pipe

Refrigerant

pipe

Slit

Slit

Tape

Auxiliary pipe

Insulation sheet

CAUTION

1)Insulate the joint of the pipes securely.

Incomplete insulation may lead to water leakage.

2)Push the pipe inside so it does not place undue force on the front grille.

Connecting the drain hose

Insert the supplied C drain hose into the socket

of the drain pan.

Fully insert the drain hose until it adheres to a

seat of the socket.

Drain pan

Seal

Drain pan

Seal

Drain hose

INSTALLATION INSTRUCTIONS

Installation of indoor unit

Live the sensor securing plate, remove the front metal plate cover, and connect the branch wiring to the terminal block.

1)Strip wire ends 3/5”(15mm)

2)Mach wire colours with terminal numbers on indoor and outdoor unit’s terminal blocks and firmly screw wires to

the corresponding terminals.

3)Connect the earth wires to the corresponding terminals.

4)Pull wires to make sure that they are securely latches up, then retain wires with wire retainer.

CAUTION

1)Do not use tapped wires, stranded wires, extensioncords, or starburst connections, as they may cause overheating,

electrical shock, or fire.

2)Do not use locally purchased electrical parts inside the product. (Do not branch the power for the drain pump, etc, from

the terminal block.) Doing so may cause electric shock or fire.)

8

INSTALLATION INSTRUCTIONS

Installation of indoor unit

Outdoor unit

Indoor unit

Firmly fix the wires with the

terminal screws

Firmly fix the wires with the

terminal screws

When wire length exceeds 10m,

use 2.0mmdiameter wires

2 3

Terminal block

Electrical

component

box

Wire retainer

Use the specified wire type.

Shape wires so

that the front metal

plate cover will fit

securely.

Firmly secure wire

retainer so that

wires sustain no

external stress.

Front metal

plate cover

Sensor securing plate

N(1

)

Routine check after installation

INSTALLATION INSTRUCTIONS

9

Check after installation

Items to be checked Possible malfunction Situation

Has it been fixed firmly?

Have you done the refrigerant leakage test?

Is heat insulation sufficient?

Does the unit drain well?

Is the voltage in accordance with the rated

voltage marked on the nameplate?

Is the electrical wiring and piping connection

installed correctly and securely?

Has the unit been connected to a secure earth

connection?

Is the power cord specified?

Has the inlet and outlet been covered?

Has the length of connection pipes and the

refrigerant charge been record?

The unit may drop,shake or emit noise.

It may cause insufficient refrigerating capacity.

It may cause condensation and dripping.

It may cause condensation and dripping.

It may cause electric malfunction or damage the

part.

It may cause electric malfunction or damage the

part.

It may cause electrical leakage.

It may cause electric malfunction or damage the

part.

It may cause insufficient refrigerating capacity.

The refrigerating capacity is not accurate

INSTALLATION INSTRUCTIONS

10

Configuration of connection pipe and additional volume of refrigerant

1. Standard length of connection pipe

16ft(5m)、24ft(7.5m)、26ft(8m)

2. Min length of connection pipe

For the unit with standard connection pipe of 16ft(5m), there is no

limitation

for the min length of connection pipe. For the unit with standard

connection

pipe of 24ft(7.5m) and 26ft(8m), the min length of connection

pipe is 9ft(3m).

3. Max length of connection pipe

4. The calculation method of additional refrigerant oil and refrigerant charging

amount after prolonging connection pipe

After the length of connection pipe is prolonged for 32ft(10m) at the basis

of standard length, you should add 5ml of refrigerant oil for each

additional 16ft(5m) of connection pipe.

The calculation method of additional refrigerant charging amount (on the

(1) Additional refrigerant charging amount= prolonged length of liquid pipe × additional

refrigerant charging amount per meter

(2) When the length of connection pipe is above

16ft(5m)

, add refrigerant

according

to the prolonged length of liquid pipe. The additional refrigerant

charging

amount per meter is different according to the diameter of liquid pipe. See

Sheet 2.

basis of liquid pipe):

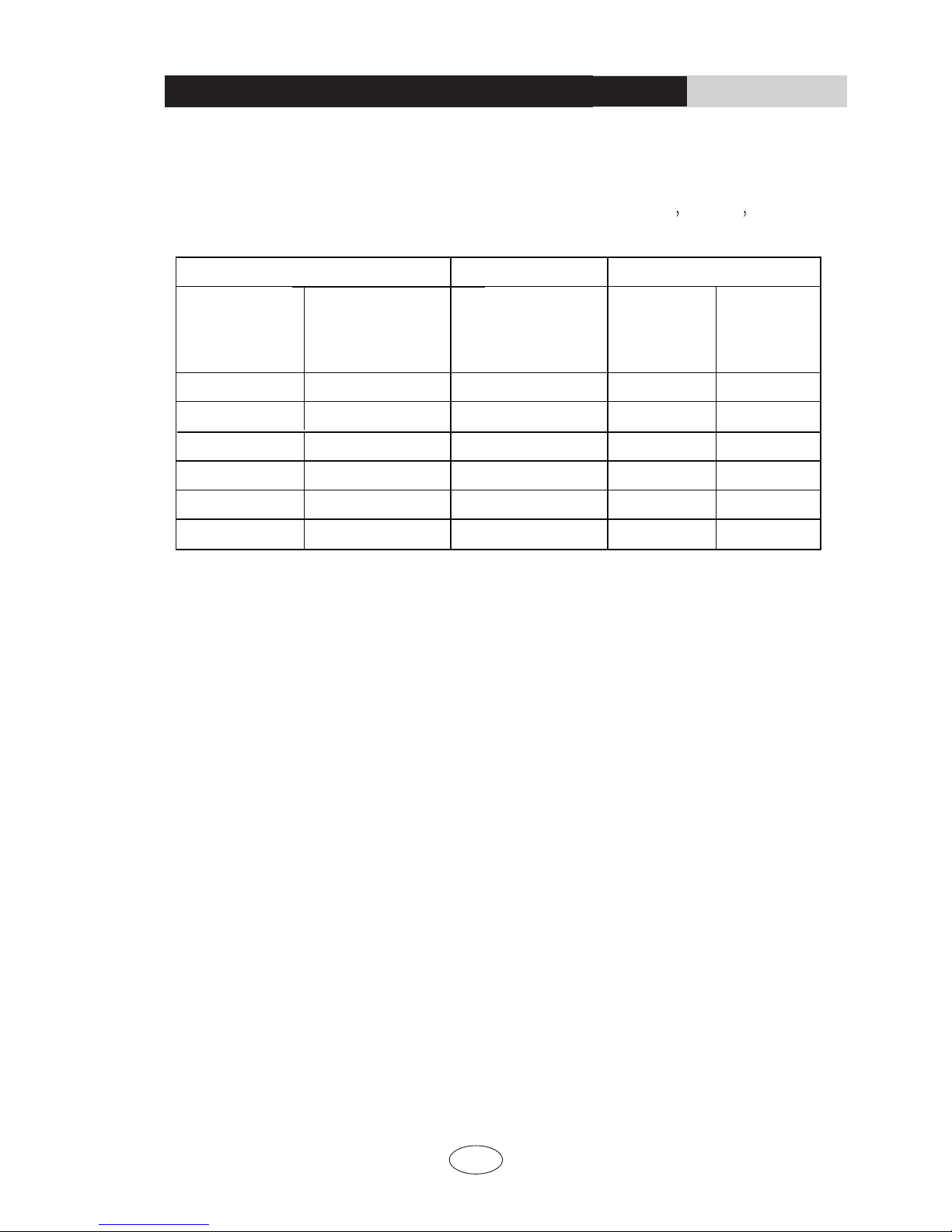

Sheet 1 Max length of connection pipe Unit: ft(m)

Capacity

Max length of

connection pipe

Capacity

Max length of

connection pipe

5000 Btu/h

(1465 W)

49(15)

24000 Btu/h

(7032 W)

7000 Btu/h

(2051 W)

49(15)

28000 Btu/h

(8204 W)

9000 Btu/h

(2637 W)

36000 Btu/h

(10548 W)

12000 Btu/h

(3516 W)

42000 Btu/h

(12306 W)

18000 Btu/h

(5274 W)

48000 Btu/h

(14064 W)

49(15)

65(20)

82(25)

82(25)

98(30)

98(30)

98(30)

98(30)

INSTALLATION INSTRUCTIONS

11

Configuration of connection pipe and additional volume of refrigerant

Sheet 2. Additional refrigerant charging amount

for R22 R407C R410A

and R134a

Note: The additional refrigerant charging amount in Sheet 2 is recommended

value, not compulsory.

Diameter of connection pipe in(mm) Indoor unit throttle Outdoor unit throttle

Liquid pipe Gas pipe Cooling only,

cooling and heating

(g / m)

Cooling only

(g / m)

Cooling and

heating

(g / m)

Ф3/8”(9.5) or Ф1/2”(12)

20 15 20

Ф1/4”(6) or Ф3/8”(9)

50 15 50

Ф1/2”(12) Ф3/4”(19)

30 120

Ф5/8”(16)

60 120

Ф3/4”(19)

-

250 250 250

Ф3/4”(22.2)

350 350 350

Ф5/8”(16) or Ф3/4”(19)

100

Ф1/4”(6)

Ф1”(25.4) or

Ф1 1/6”(31.8)

170

-

66162665

Add: West Jinji Rd, Qianshan, Zhuhai, Guangdong, China, 519070

MANUFACTURER: GREE ELECTRIC APPLIANCES, INC. OF ZHUHAI

www.cooperandhunter.us

Loading...

Loading...