Page 1

LCL4 MULTI-LINE LASER

USER GUIDE

Page 2

CONTENTS

Page 2

Contents:

3. Warranty

4. Features

6. Laser Safety & Battery Placement

7. Operation

9. Using the Universal Mount

10. Applications

11. Laser Offsets

12. Calibration

14. Specifications

15. Care & Maintenance

16. Standard Accessories

Page 3

WARRANTY

Page 3

Statement of Limited Warranty:

This laser is warranted to be free from defects in performance and workmanship for a

period of twelve months from date of purchase. The warranty covers all cost of repair or

replacement of parts. The seller is not responsible for the cost of transportation for returning

the instrument for repair.

Limits and Exclusions:

The warranty will not apply to any damage resulting from negligence, accident damage,

misuse, repair or storage, or in case of abnormal use.

The warranty is considered void if any attempt whatsoever is made to repair, modify or recalibrate the unit. In these circumstances we reserve the right to charge for costs incurred

in repair or replacement of the unit.

We Are Not Liable For:

1. Loss of income or inconvenience relating to defect in performance of the unit.

2. Leasing charges of alternative equipment during repair of a defective unit.

We require that the customer make reasonable attempts to inform us of problems with the

product prior to returning the unit for repair.

Page 4

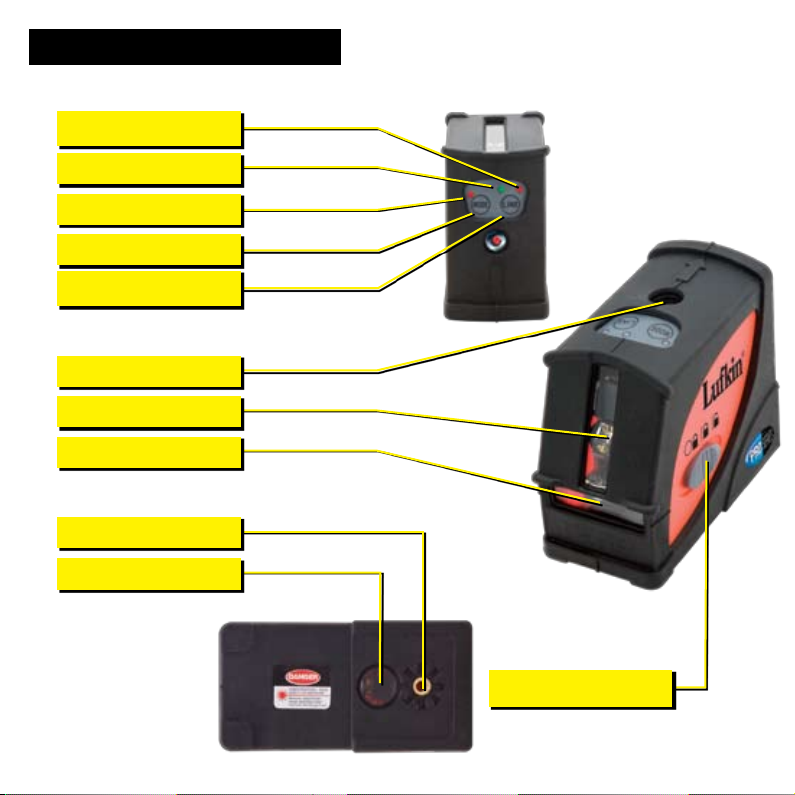

FEATURES

Low battery, Out of Level,

External Power LED

Working Mode LED

Pulse Mode LED

Pulse Mode Button

Horizontal, Vertical &

Cross Line Select Button

Plumb Up Beam Window

Vertical Beam Window

Horizontal Beam Window

1/4” Tripod Mount

Plumb Down Beam Window

Page 4

Top View

Bottom View

Pendulum Lock & Control

Switch

Page 5

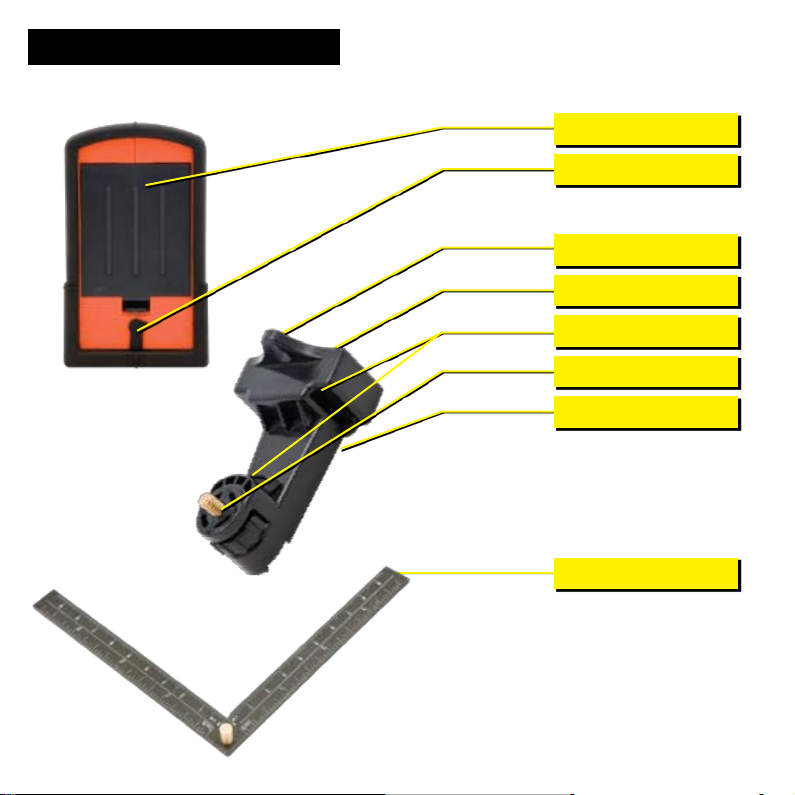

FEATURES

Page 5

Battery compartment

Universal Mount

External Power

Attachment Hole

Magnetic Back

Strap Raceway

1/4” Tripod Screw

5/8” Tripod Mount

Square Attachment

4.5V DC

Page 6

LASER SAFETY

AVOID EXPOSURE: Laser radiation is emitted from this product. Use of controls,

adjustments or procedures other than those specified herein may result in laser radiation

exposure. Never stare directly at the beam or view directly with optical instruments.

Page 6

This label is attached to the unit at the laser aperture.

AVOID EXPOSURE

LASER LIGHT IS EMITTED

FROM THIS APERTURE

IMPORTANT: “DANGER” labels are attached to every LCL4. They are not to be removed or

defaced.

Do not disassemble or attempt to perform any internal servicing. Doing so will void the

warranty. Repairs or service to this device are to be performed by authorized service

centres only. Do not aim the laser beam at people or

animals.

The LCL4 contains semiconductor laser diodes with

wavelengths of 635-650 nanometers. The total continuous

output of the beams never exceeds 4.99 milliwatts. The

LCL4 complies with US CDRH performance standards, 21

CFR, Sub chapter J and the regulations stipulated in EN60825-1/1994.

BATTERY PLACEMENT

1. Open the battery cover

2. Place all three AA batteries into the battery compartment according

to the battery installation indicators displayed in the battery

compartment.

Note: Alkaline batteries offer the longest battery life when used in this

device. This device can not use rechargeable batteries.

Page 7

OPERATION

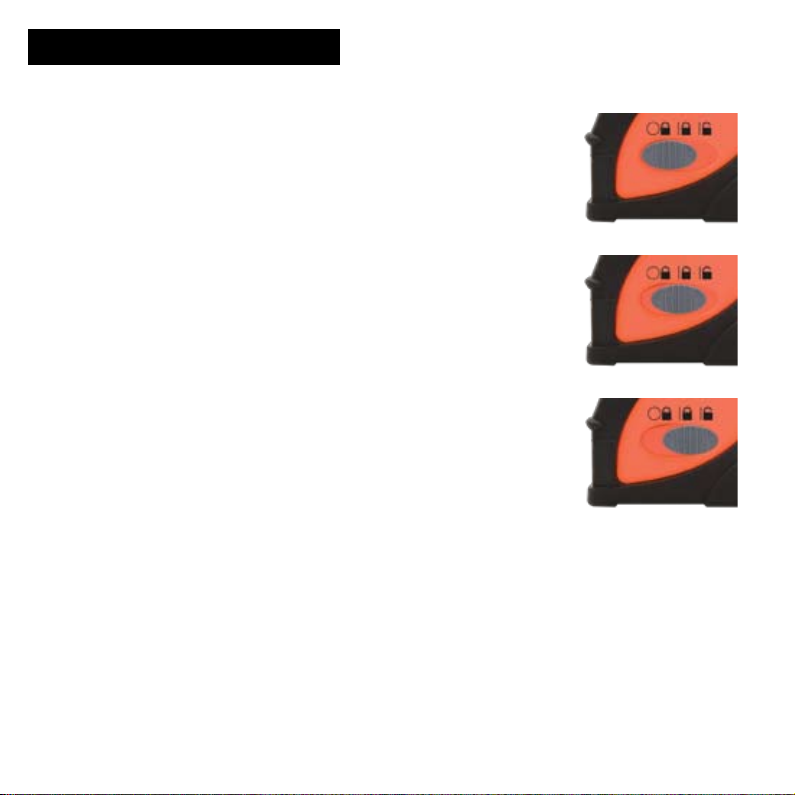

Pendulum Lock

The LCL4 is a precision instrument and should be treated with

care. When not in use, the pendulum should always be in the off

position (figure1). Locking the pendulum allows the LCL4 to better

withstand vibrations and shock incurred during transportation or

if the unit is dropped.

Locked Line Angle

In the locked line angle position (Figure 2), the pendulum is

locked and will not automatically level or plumb the lines. When

in the locked line angle position, both the horizontal and vertical

beams will be on to allow angled lines. The green LED will blink

once per second.

Note: The unit will not change between Level Line Mode and

Plumb Line Mode while in the locked angle position.

Automatic Levelling

When the switch is in the pendulum unlock position (Figure 3) then the pendulum will

automatically level and plumb the horizontal and vertical lines, so long as the base is within

5º of true level. When the base is more than 5º out of level then the lines will flash once per

second accompanied by a warning beeping from the unit.

Figure 1

Figure 2

Figure 3

Page 7

If the device is left out of level for more than 3 minutes then it will switch off. To reactivate

the unit, switch it off and then back on again.

Page 8

OPERATION

Horizontal, Vertical, Plumb & Cross Line Options

The LCL4 has three line options, accessible by using the line options button located on

the top of the instrument. If the unit has been turned on, the plumb up and down beams

will always be on. Use the line option button to cycle through the level (horizontal), plumb

(vertical) or cross line modes, as shown below.

Page 8

Default line

Horizontal & Plumb up and down line

Press 2x

Cross & Plumb up and down line Cross & Plumb up and down line locked

Press 1x

Vertical & Plumb up and down line

Auto-Off Feature

A battery saving Auto-Off feature has been incorporated into the LCL4. It will shut the device

off automatically after 60 minutes unless overridden. To disable the Auto-Off feature press

and hold the line options button when turning the unit on. The green LED will flash twice per

second to indicate the Auto-Off feature has been disabled.

Low Battery Indicator

When the battery charge becomes low, the red LED will flash twice per second. Note: the

LCL4 can be used for up to one hour during low battery indication before it will turn off

completely.

Pulse Mode

Pressing the pulse mode button, will place the unit into pulse mode so that it can work

with optional laser detector. Pressing the button again, returns to non-pulse mode. In pulse

mode, the Pulse Mode LED will be on.

Page 9

USING THE UNIVERSAL MOUNT

The LCL4 comes with a multi-purpose universal mount that allows the unit to be attached to

multiple surfaces including wood, metal, pipes, construction tripods, camera tripods and flat

surfaces.

1/4” Tripod Mount

Use the threaded hole, located on the bottom of the universal mount, to mount the universal

mount and the attached LCL4 to a camera tripod.

5/8” Tripod Mount

Use this threaded hole, located on the bottom of the universal mount, to mount the

universal mount and the attached LCL4 to a surveyor’s tripod.

Screw / Nail Attachment Hole

Use the attachment hole to fasten the universal mount and the attached LCL4 to walls with

drywall screw of at least 2” (5cm) long.

Strap Raceways

Use the horizontal and vertical strap raceways to fasten the universal mount and the

attached LCL4 to objects such as pipes and wooden studs with a width of approximately

150mm (6”) or less

Magnets

Use the magnets, located on the back of the universal mount, to fasten the universal mount

and the attached LCL4 to objects such as steel studs. Use the magnets. Located on the

bottom of the mount, to mount the square, the universal mount and the attached LCL4 on

the floor.

Page 9

Square

Square can be used as a right-angled ruler. If the LCL4 is to be used on the floor, install the

square in the universal mount to improve the stability of unit.

Page 10

APPLICATIONS

Page 10

Cabinet installation Wall panelling and wallpapering Bathroom tiling

Drilling & sawing alignmentWall tilingFloor tiling

• Carpentry: Level and set cabinets and counter tops and Install trim

• Stair Layout: Level and plumb decks, plumb framing and partition walls, plumb windows

and door frames

• Concrete: Set forms and footings

• Electrical: Level electrical outlets, transfer lighting layout from floor to ceiling using plumb beam

• Plumbing: Layout piping, sewer lines, drainage and supply lines, transfer sprinkler system

layout from floor to ceiling using plumb beam

• Interior Decorating: Picture hanging, wall or floor tiling, wallpapering

Page 11

APPLICATIONS

28mm

32mm

Hanging pictures Aligning shelves Hanging pendant lamps

Window framing

LASER OFFSETS

Laser Offsets

Use the laser offset information provided in

the adjacent illustration to speed plumbing

and levelling operations.

Page 11

Page 12

CALIBRATION

x x

A1 B1

4-5m

15cm

Surface 1 Surface 2

Figure 1

It is recommended that you check your LCL4 periodically to assure its accuracy.

To check level:

Choose two walls approximately 4 - 5 metres apart (figure 1).

Turn on the LCL4 to the “auto level” setting. With the laser 15cm away

from and facing Surface 1, carefully mark the center of the line where

the lines cross. Label this mark “A1” (figure 1).

Swivel the laser 180 degrees and mark the center of the line where the lines cross on

Surface 2. Label this mark “B1” (figure 1).

Now move the laser 15cm away from and facing Surface 2 (figure 2). Carefully mark the

center of the line where the line cross. Label this mark “B2” (figure 2).

Swivel the laser 180 degrees and mark

the center of the line where the lines

cross on Surface 1 (figure 2). Label this

mark “A2”.

Next. Measure the distance between

“A1” and “A2” and between “B1” and

“B2”. If the distances are the same,

the unit is calibrated. If the differences

between the two sets of marks is greater

than 3mm the laser is out of calibration.

Page 12

Page 13

x x

A2 B2

4-5m

15cm

Surface 1 Surface 2

Figure 2

CALIBRATION

A B

C

D

Figure 3

To check plumb:

Choose a door jamb

with a minimum of 2.5

metres clearance on

each side of the door.

Turn on the LCL4 to “auto level” setting.

With your laser at point “A” (figure 3),

make two marks on the floor.

Make the first mark at 2.5 metres from

point “A” centred on the door header

above. Mark this point “B”.

Make a second mark 5 metres from point “A”. Make this point “C”.

Without moving the laser, make a third mark on the door header. Make this point “D”.

Now move the laser to point “C”. EXACTLY align the beam with point “B”. Notice where the

beam falls at point “D”. If it is within 4mm of point “D”.

The laser is in calibration.

Page 13

Page 14

SPECIFICATIONS

Accuracy

Self-levelling Range

Operating Range

Fan Angle

Out-of-level Indication

Unit Tripod Mount

Pendulum Lock/Off

Unit Dimensions

Unit Weight

Universal Mount Dimensions

Universal Mount Weight

Storage Temperature

Operating Temperature

Laser Diode

Power Supply

Operating time

Page 14

± 3mm @ 10m

Plumb beams: ± 1.5mm @ 5m

± 5°

30m indoors

Outdoor Mode - Up to 50m outdoors,

working with laser detector

140° vertical and 130° horizontal

Blinking laser lines and audible alarm

¼” x 20 camera tripod

Protects pendulum during transportation

and storage for added durability

110mm x 57mm x 97mm

470g

89mm x 57mm x 46mm

200g

-20°C to +70°C

-10°C to +50°C

Class IIIA 635nm diodes

3 “AA” batteries

12 hours continuous using 2 lines

Specifications subject to change without notice.

Page 15

CARE & MAINTENANCE

This device is a product of precision design and manufacture and should be treated with

care. The suggestions below will help the user fulfill any warranty obligations and also allow

the user to enjoy this product for many years.

When using the device:

Keep it and all its parts and accessories out of small children’s reach.

This laser is built to be operated under wet conditions (IEC 529;IP 54), however the unit

should always be dried off before storage.

Do not store in hot areas. High temperatures can shorten the life of electronic devices, damage batteries, and warp or melt certain plastics.

Do not store in cold areas. When the device warms up to its normal operating temperature,

moisture can condense inside where it may damage circuit boards.

Although the LCL4 is dust and dirt resistant, do not store in dusty, dirty areas as long-term

exposure to these elements may damage internal moving parts.

Do not attempt to open the LCL4. Non-expert handling of the device may cause damage and

will void the warranty.

Do not drop, knock, or shake the LCL4. Rough handling can break the unit or compromise

its functionality.

Page 15

Do not use harsh chemicals, cleaning solvents, or strong detergents to clean the LCL4. Wipe

it with a soft cloth, slightly dampened in a mild soap and water.

Keep the laser aperture windows clean by periodically wiping them with a cotton swab

dipped in isopropyl alcohol.

Page 16

STANDARD ACCESSORIES

• Laser (LCL4)

• Universal mount

• Square

• Strap

• User guide

• 3 “AA” batteries

• Pouch

Page 16

Page 17

519 Nurigong Street

PO Box 366, Albury NSW 2640

Phone: (02) 6058 0300

Fax: (02) 6021 7403

E-mail: coopertoolsaus@coopertools.com

Web Site: www.cooperhandtools.com.au

Issue: 0708829A

Loading...

Loading...