Page 1

APPLICATION

EMN Series Manual Line Starters and Enclosures are used to

provide motor starting protection and manual across-the-line

starting and stopping of single and poly-phase AC motors.

EMN Series Manual Line Starters and Enclosures are suitable for

use in Class I, Groups C, D; Class II, Groups E, F, G and

Class III hazardous (classified) locations, as defined by the

National Electric Code® as well as in damp, wet or corrosive

locations.

EMN Series Manual Line Starters and Enclosures should be

installed, inspected, maintained, and operated by qualified and

competent personnel.

INSTALLATION

1. Select a mounting location that will provide suitable strength

and rigidity for supporting all contained wiring and control

devices. Figure 1 shows the mounting dimensions of EMN

Series enclosures. Drill two 7/16 inch mounting holes.

2. Securely fasten enclosure to the mounting surface then

attach into conduit system.

3. Remove the six cover bolts then lift cover off and carefully set

it aside to prevent damage to the ground joint.

4. EMN Enclosure furnished with starter: Remove starter

from enclosure then pull wires into enclosure making sure

that they are long enough to make the required connections.

Note: EMN Manual Motor Starter Enclosures ordered

complete with starter are furnished with heaters. One heater

is furnished with two-pole AC or DC starters and three

heaters with three-pole starters.

EMN Enclosure furnished without starter: Select starter

from Table 1 on page 2 (ordered separately). Install heaters

on starter (ordered separately). Refer to heater selector

listings. Pull wires into enclosure.

5. Mount starter into enclosure and make electrical connections

utilizing the wiring scheme established for the starter.

CAUTION

Hazardous location information specifying class and group

listing of each device is marked on the nameplate of each

enclosure. Also note that:

•

No conduit openings are to be added in the field.

•

All unused conduit openings must be plugged and these

plugs must be a minimum of 1/8 in. thick and have a minimum

of five threads engaged.

•

All conduits entering and leaving the enclosure must be

sealed with explosion-proof seals within 18 in. of the

enclosure.

Motor Starter

EMN Series Manual Line Starters and Enclosures

Installation & Maintenance Information

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

IF677

WARNING

To provide protection against fire or shock hazard, the

electrical power must be OFF before and during installation and maintenance.

CAUTION

Hammers or prying tools must not be allowed to damage

the flat ground-joint surfaces. Do not handle the covers

roughly, or place them on surfaces that might damage or

scratch the flat ground-joint surfaces.

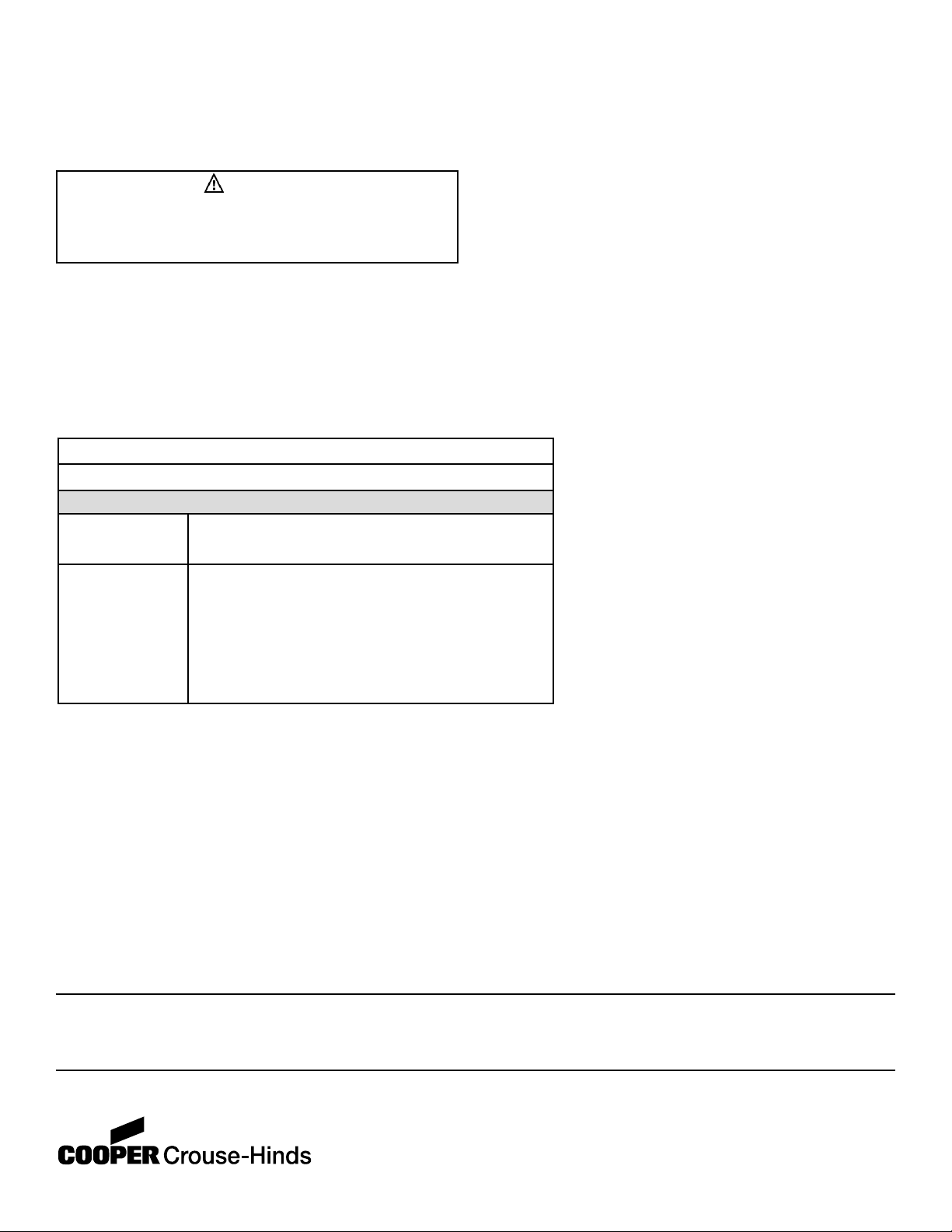

Figure 1 - Dimensions

IF 677 • 03/03 Copyright © 2003, Cooper Industries, Inc. Page 1

National Electrical Code ®is a registered Trademark of the National Fire Protection Association.

Page 2

All statements, technical information and recommendations contained herein are based on information and tests we believe to be

reliable. The accuracy or completeness thereof are not guaranteed. In accordance with Crouse-Hinds "Terms and Conditions of Sale",

and since conditions of use are outside our control, the purchaser should determine the suitability of the product for the intended use

and assumes all risk and liability whatsoever in connection therewith.

Cooper Industries Inc. IF 677

Crouse-Hinds Division Revision 2

PO Box 4999, Syracuse, New York 13221 • U.S.A. Revised 03/03

Copyright© 2003, Cooper Industries, Inc. Supercedes 04/02

6. Test for wiring correctness with continuity checks and also

for unwanted grounds with insulation resistance tester.

7. Place starter handle in OFF position making sure that the

internal mechanism of the cover will properly engage the

starter.

8. Install cover. Securely tighten all cover bolts making certain

that no cover bolts are omitted. Use only bolts supplied with

the enclosure.

9. Pour sealing compound into sealing fittings in accordance

with the instructions supplied with each of the approved

fittings and sealing compound package labels.

MAINTENANCE

1. Frequent inspection should be made. Aschedule for maintenance check should be determined by the environment and frequency of use. It is recommended that it

should be at least once a year.

2. If necessary to open enclosure for inspection or service,

always disconnect primary power source before opening

enclosure.

3. Perform visual, electrical, and mechanical checks on all

components on a regular basis.

•

Visually check for undue heating evidenced by

discoloration of wires or other components, damaged or

worn parts, or leakage evidenced by water or corrosion

in the interior.

•

Electrically check to make sure that all connections are

clean and tight, and that contacts in the components

make or break as required.

•

Mechanically check that all parts are properly

assembled, and operating mechanisms move freely.

CAUTION

Clean both ground-joint surfaces of body and cover before

installing. Dirt or foreign material must not accumulate on

flat ground-joint surfaces. Surfaces must seat fully against

each other to provide a proper explosionproof seal.

EMN Enclosure NEMA

Catalog No. Size Poles (Phase) Catalog Number

M-0

2 (1 Ph)

3 (3 Ph)

B100M0BX

B100M0CX

M-1

2 (1 Ph)

3 (3 Ph)

B100M1BX

B100M1CX

M-1P 2 (1 Ph) B100MDBX

1.

Two-pole starters require on heater, three-pole starters require

three heaters. These should be selected in accordance with t

he manufacturer's

recommendations. Most explosionproof motors are rated at 55oC, heaters should be selected accordingly.

Table 1

EMN24

Cutler-Hammer - B100 Series

Manaul Motor Line Starters

1

Page 3

APPLICATION

Les démarreurs et boîtiers de ligne manuelle, série EMN, sont

utilisés pour fournir une protection au démarrage d'un moteur,

ainsi que pour le démarrage et l'arrêt direct manuel des moteurs

à courant alternatif monophasé ou polyphasé.

Les démarreurs et boîtiers de ligne manuelle, série EMN, sont

conçus pour être utilisés dans des zones de risque (classifiées)

de classe I, groupes C et D, de classe II, groupes E, F et G et

de classe III, tel que défini par le Code national de l'électricité,

ainsi que dans les endroits humides, mouillés ou corrosifs.

Les démarreurs et boîtiers de ligne manuelle, série EMN, ne

doivent être installés, inspectés, entretenus et utilisés que par

un personnel qualifié et compétent.

INSTALLATION

1. Sélectionner un point de montage offrant une résistance et

une rigidité adéquates pour supporter tous les câbles et dispositifs de commande. La Figure 1 indique les dimensions

pour le montage des boîtiers de la série EMN. Percer deux

trous de 7/16 po pour le montage.

2. Fixer fermement le boîtier à la surface d'installation, puis le

raccorder au système de conduits.

3. Retirer les six boulons du couvercle puis soulever le couvercle pour le retirer, puis le mettre de côté pour prévenir l'endommagement du joint rodé.

4. Boîtier EMN avec démarreur : Retirer le démarreur du

boîtier puis y introduire les fils en s'assurant qu'ils sont assez

longs pour effectuer les connexions nécessaires.

Remarque : Les boîtiers de démarreur à moteur manuel

EMN commandés en entier avec le démarreur sont équipés

de dispositifs de protection contre la surcharge. Un dispositif

est fourni avec les démarreurs bipolaires CA ou CC, et trois

dispositifs avec les démarreurs tripolaires.

Boîtier EMN sans démarreur : Sélectionner le démarreur

dans le Tableau 1 de la page 2 (vendu séparément). Installer

des dispositifs de protection contre la surcharge (vendus

séparément) sur le démarreur. Se référer aux listes de sélection des dispositifs de protection contre la surcharge.

Introduire les câbles dans le boîtier.

5. Installer le démarreur dans le boîtier et effectuer les raccordements électriques en se référant au schéma de

câblage propre au démarreur.

ATTENTION

Des informations sur les zones de risque sont inscrites sur la

plaque signalétique de chaque boîtier, spécifiant le listage de

classe et de groupe. Noter également que :

•

Aucune ouverture de conduit ne doit être ajoutée dans le champ.

•

Toutes les ouvertures de conduit non utilisées doivent être recouvertes de bouchons, lesdits bouchons devant avoir une épaisseur

de 1/8 po minimum et un minimum de cinq filets introduits.

•

Tous les conduits qui entrent ou sortent du boîtier doivent être

isolés avec des joints préformés antidéflagrants, à moins de 18 po

du boîtier.

Démarreur de moteur

Démarreurs et boîtiers de ligne manuelle, série EMN

Information sur l'installation et l'entretien

CONSERVER CES INSTRUCTIONS POUR RÉFÉRENCE FUTURE

IF677

MISE EN GARDE

Afin d'assurer la protection contre les risques d'incendie

ou de choc électrique, l'alimentation électrique doit être

COUPÉE avant et pendant l'installation et l'entretien.

ATTENTION

Prendre garde d'endommager les surfaces planes des

joints rodés avec des marteaux ou leviers. Ne pas manipuler brutalement les couvercles ou les placer sur des surfaces qui risquent d'endommager ou d'égratigner les surfaces planes des joints rodés.

Figure 1 - Dimensions

IF 677 • 03/03 Copyright © 2003, Cooper Industries, Inc. Page 3

Le Code National de l'électricité® est une marque déposée de la National Fire Protection Association.

Page 4

Tous les énoncés, et toutes les informations techniques et recommandations contenus dans cette fiche sont basés sur des informations

et des essais que nous croyons fiables. La précision ou l'exhaustivité de ces informations n'est pas garantie. Conformément aux

Modalités de vente de Crouse-Hinds, et du fait que les conditions d'utilisation sont en dehors de notre contrôle, l'acheteur doit déterminer la pertinence du produit en regard de l'utilisation prévue et il assume tous les risques et responsabilités, de quelque nature que

ce soit, qui s'y rapportent.

Cooper Industries Inc. IF 677

Crouse-Hinds Division Révision 2

PO Box 4999, Syracuse, New York 13221 • U.S.A. Révisé le 03/03

Copyright© 2003, Cooper Industries, Inc. Remplace celle de 04/02

6. Vérifier le bon fonctionnement du câblage en effectuant un

contrôle de continuité, et vérifier la présence de mises à la

terre indésirables avec un appareil de mesure de résistance

d'isolement.

7. Placer le démarreur en position d'arrêt (OFF) en vous assurant que le mécanisme interne du couvercle engage

adéquatement le démarreur.

8. Installer le couvercle. Serrer fermement tous les boulons du

couvercle, en s'assurant de n'en omettre aucun. Utiliser

uniquement les boulons fournis avec le boîtier.

9. Appliquer le produit de jointoiement sur les raccords étanches en respectant les instructions fournies avec chacun des

raccords approuvés et celles qui sont inscrites sur les étiquettes de l'emballage du produit de jointoiement.

ENTRETIEN

1. Des inspections doivent être effectuées de manière

fréquente. Un programme de vérifications d'entretien doit

être établi suivant l'environnement et la fréquence d'utilisation. L'inspection au moins une fois par année est recommandée.

2. Lorsqu'il est nécessaire d'ouvrir le boîtier pour l'inspection ou

la réparation, toujours couper la source d'alimentation primaire avant de l'ouvrir.

3. Effectuer sur une base régulière des vérifications visuelles,

électriques et mécaniques sur tous les composants.

•

Vérifier visuellement tout signe de chaleur excessive

indiqué par la décoloration des câbles ou autres composants, la présence de pièces endommagées ou usées, ou

toute fuite manifestée par la présence d'eau ou de corrosion

à l'intérieur.

•

Faire les vérifications électriques pour s'assurer que

toutes les connexions sont propres et bien serrées, et que

les contacts des composants s'établissent ou se coupent tel

que requis.

•

Faire les vérifications mécaniques pour s'assurer que

toutes les pièces sont adéquatement assemblées, et que les

mécanismes de commande se déplacent librement.

ATTENTION

Nettoyer la surface des joints rodés du bâti et du couvercle avant de procéder à l'installation. Il ne faut pas que de

la saleté ou des corps étrangers s'accumulent sur les surfaces planes des joints rodés. Les surfaces doivent bien

être en contact les unes avec les autres pour créer un joint

antidéflagrant.

Boîtier EMN NEMA

No du catalogue. Taille Pôles (phases) Numéro de catalogue

M-0

2 (1 Ph)

3 (3 Ph)

B100M0BX

B100M0CX

M-1

2 (1 Ph)

3 (3 Ph)

B100M1BX

B100M1CX

M-1P 2 (1 Ph) B100MDBX

1.

Les démarreurs bipolaires nécessitent un réchauffeur, alors que trois sont

nécessaires pour les démarreurs tripolaires. Ces

derniers doivent être choisis conformément aux

recommandations du fabricant. La température nominal

e de la plupart des moteurs antidéflagrants est

de 55ºC, les réchauffeurs appropriés devront donc être choisis selon ce

critère.

Tableau 1

EMN24

Cutler-Hammer - Série B100

Démarreurs de ligne manuelle de moteur

1

Page 5

APLICACIÓN

Los arrancadores de línea manuales y envolventes serie EMN

se utilizan para proporcionar protección al arranque del motor y

arranque y paro manual a través de la línea de motores

monofásicos y polifásicos de corriente alterna.

Los arrancadores de línea manuales y envolventes serie EMN

son adecuados para utilizarse en áreas peligrosas (clasificadas)

Clase I, Grupos C, D; Clase II, Grupos E, F, G y Clase III, como

se definen por el National Electrical Code® así como en lugares

mojados, húmedos o corrosivos.

Los arrancadores de línea manuales y envolventes serie EMN,

deben instalarse inspeccionarse, mantenerse y operarse por

personal calificado y competente.

INSTALACIÓN

1. Seleccione un lugar de montaje que proporcione el esfuerzo

y rigidez adecuados para soportar todo el alambrado y dispositivos de control contenidos. La Figura 1 muestra las

dimensiones del montaje de las envolventes Serie EMN.

Perfore dos orificios de montaje de 11 mm (7/16 pulgada).

2. Sujete firmemente la envolvente a la superficie de montaje

entonces fíjela en el sistema de la canalización de tubería.

3. Quite los seis pernos de la cubierta entonces levante la

cubierta y cuidadosamente colóquela de lado para prevenir

que se dañe la unión de tierra.

4. Envolvente EMN provista con arrancador: Quite el arran-

cador de la envolvente entonces jale los alambres en la

envolvente asegurándose de que son lo suficientemente largos para hacer las conexiones requeridas.

Nota: el pedido completo de la Envolvente del Arrancador

Manual De motor EMN con arrancador se proporciona con

calentadores. Un calentador se proporciona con arrancadores de dos polos de corriente alterna o directa y tres

calentadores con arrancadores de tres polos.

Envolvente EMN proporcionada sin arrancador:

Seleccione el arrancador de la Tabla 1 en la página 2 (pedida por separado). Instale los calentadores en el arrancador

(pedido por separado). Refiérase al listado del selector del

calentador. Jale los alambres en la envolvente.

5. Monte el arrancador en la envolvente y haga las conexiones

eléctricas utilizando el diagrama de alambrado establecido

para el arrancador.

PRECAUCIÓN

La información del área peligrosa que especifica el listado de la

clase y grupo de cada dispositivo está marcada en la placa de

datos de cada envolvente. También note que:

•

Ninguna apertura de la canalización de tubería debe agregarse

en el campo.

•

Todas las aperturas de la canalización sin usar deben taparse y

estos tapones deben tener un espesor mínimo de 3,2 mm (1/8") y

tener un mínimo de cinco cuerdas enroscadas.

•

Todas las canalizaciones de tubería que entran y salen de la

envolvente deben sellarse con sellos a prueba de explosión dentro

de 457 mm (18 in) de la envolvente.

Arrancador de motor

Arrancadores de Línea Manuales y Envolventes Serie EMN

Información de Instalación y Mantenimiento

CONSERVE ESTAS INSTRUCCIONES PARA FUTURAS CONSULTAS

IF677

AVISO

Para proporcionar protección contra fuego o riesgo de

choque, debe DESCONECTARSE la energía eléctrica

antes y durante la instalación y mantenimiento.

PRECAUCIÓN

No se permiten martillos o herramientas de palanca

porque pueden dañar las superficies planas de la unión de

tierra. No maneje las cubiertas bruscamente, o las

coloque en superficies que podrían dañar o raspar las

superficies planas de la unión de tierra.

Figura 1 - Dimensiones

IF 677 • 03/03 Copyright © 2003, Cooper Industries, Inc. Page 5

®National Electrical Code es una Marca Registrada de la National Fire Protection Association.

Page 6

Todas las declaraciones, información técnica y recomendaciones contenidas aquí, se basan en la información y pruebas que creemos

que son confiables. La exactitud o integridad de estas no se garantiza. De acuerdo con los "Términos y Condiciones de Venta" de

Crouse-Hinds, y puesto que las condiciones de uso están fuera de nuestro control, el comprador debe determinar la conveniencia del

producto para su uso destinado y asumir todos los riesgos y responsabilidad en absoluto en conexión con esto.

Cooper Industries Inc. IF 677

Crouse-Hinds Division Revisión 2

PO Box 4999, Syracuse, New York 13221 • U.S.A. Revisado 03/03

Copyright© 2003, Cooper Industries, Inc. Reemplaza 04/02

6. Pruebe que el alambrado está correcto con medidores de

continuidad y también para las tierras no deseadas con un

probador de resistencia de aislamiento.

7. Coloque la manija del arrancador en la posición de APAGADO, asegurándose que el mecanismo interior de la tapa se

acoplará al arrancador adecuadamente.

8. Instale la cubierta. Firmemente apriete todos los pernos de

la cubierta asegurándose que no se omite ningún perno de

la cubierta. Utilice únicamente los pernos proporcionados

con la envolvente.

9. Vierta el compuesto sellador en los accesorios para sellar de

acuerdo con las instrucciones proporcionadas con cada uno

de los accesorios aprobados y las etiquetas del empaque del

compuesto sellador.

MANTENIMIENTO

1. Debe hacerse la inspección frecuente. Debe determinarse

un programa para las verificaciones de mantenimiento por el

ambiente y frecuencia de uso. Se recomienda que deba ser

por lo menos una vez al año.

2. Si es necesario abrir la envolvente para inspección o servicio, siempre desconecte la fuente de energía primaria antes

de abrir la envolvente.

3. Realice verificaciones visuales, eléctricas y mecánicas en

todos los componentes en una base regular.

•

Verifique visualmente para calentamiento indebido evidenciado por descoloramiento de alambres u otros componentes, partes dañadas o gastadas, o goteo evidenciado por

agua o corrosión en el interior.

•

Verifique eléctricamente para asegurarse que todas las

conexiones están limpias y firmes, y que los contactos en los

componentes se cierran o abren como se requiere.

•

Verifique mecánicamente que todas las partes están

ensambladas apropiadamente, y que los mecanismos de

operación se mueven libremente.

PRECAUCIÓN

Limpie ambas superficies de la unión de tierra del cuerpo

y la cubierta antes de instalar. No debe acumularse polvo

o material extraño en las superficies planas de la unión de

tierra. Las superficies deben asentarse totalmente una

contra otra para proporcionar un sello a prueba de

explosión apropiado.

Envolvente EMN Tamaño

Catálogo No. NEMA Polos (Fase) Número de Catálogo

M-0

2 (1 Fase)

3 (3 Fases)

B100M0BX

B100M0CX

M-1

2 (1 Fase)

3 (3 Fases)

B100M1BX

B100M1CX

M-1P 2 (1 Fase) B100MDBX

1.- Los arrancadores de 2-Polos requieren de una ca

lentador, los arrancadores de 3- Polos requieren

tres calentadores. Estos deden seleccionarse de acuer

do con las recomendaciones del fabricante. La

mayoría de los motores a prueba de explosión están clasificados para 55° C, las resistencias deben

seleccionarse basado en lo anterior.

Tabla 1

EMN24

Cutler-Hammer - Serie B100

Línea de Arrancadores Manuales para Motores

1

Loading...

Loading...