Page 1

Description

• Time Delay surface mount fuse capable of replacing

glass tube fuses in certain applications

• Environmentally rugged, complies with EIA-IS-722

Standard

• Solder Immersion Compatible

• Targeted for Consumer Electronics

Agency Information

• UL Recognition Guide & File numbers: JDYX2 & E19180.

• CSA Component Acceptance: 053787 C 000 & Class

No: 1422 30.

Environmental Data

•Life Test: MIL-STD-202, Method 108A, Test Condition D

• Load Humidity: MIL-STD-202, Method 103B

• Moisture Resistance: MIL-STD-202, Method 106E

• Thermal Shock: MIL-STD-202, Method 107D, air-to-air

• Case Resistance: EIA/IS-722

• Resistance to Dissolution of Metallization:

ANSI J-STD-002, Test D

• Mechanical Shock: MIL-STD-202, Method 213B, Test

Condition A

• High Frequency Vibration: MIL-STD-202, Method 204D,

Test Condition D

• Resistance to Solvents: MIL-STD-202, Method 215A

Ordering

• Specify product code and packaging code

Soldering Method

• Wave Immersion:260°C, 3 sec max.

• Infrared:260°C, 30 sec max.

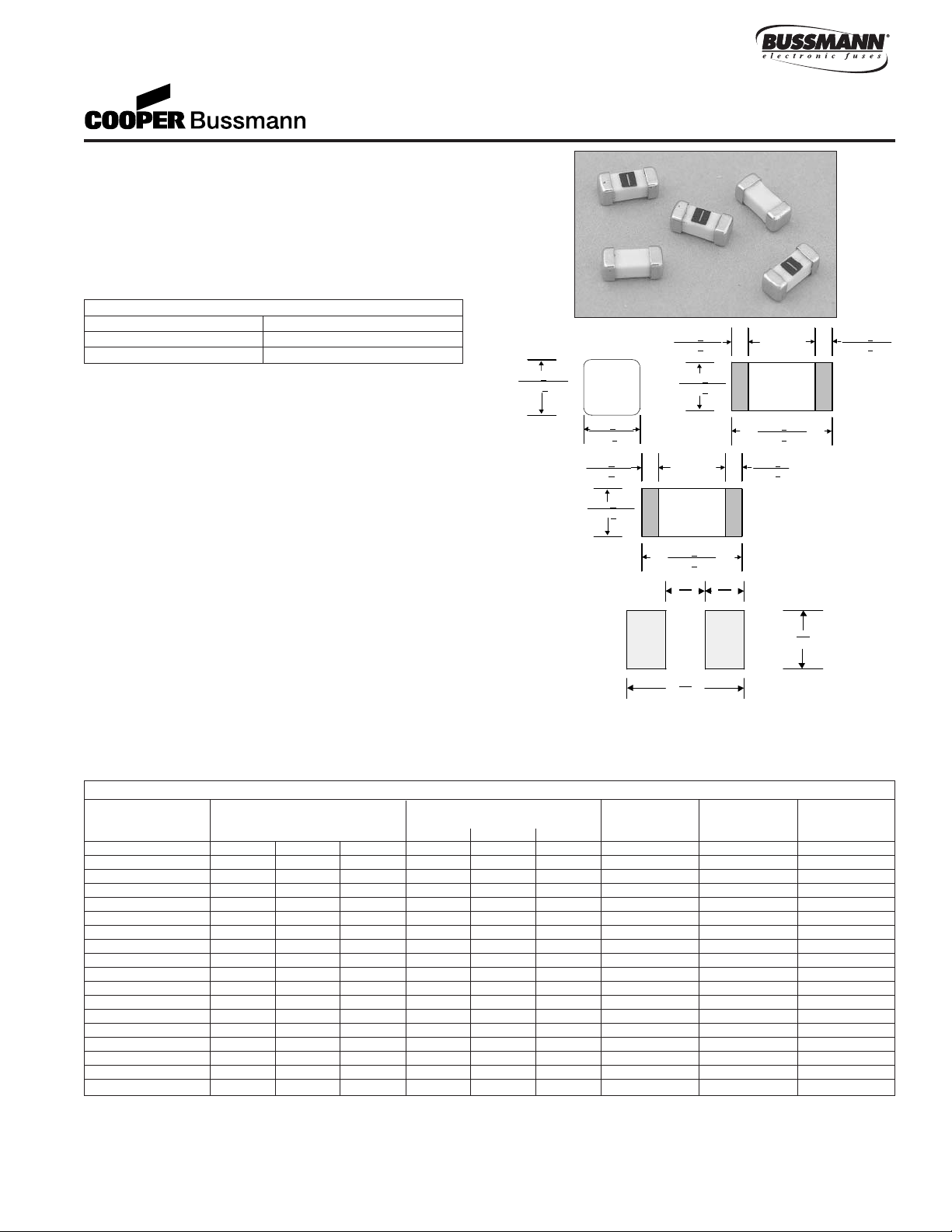

2.6 3.0

(0.102) (0.118)

4.0

(0.157)

8.6

(0.338)

Land Pattern

Dimensions mm⁄(inches)

Brick™Fuses

6125TD Series,Time Delay

ELECTRICAL CHARACTERISTICS

% of Amp Rating Opening Time

100% 4 Hours Minimum

200% 1 Second Minimum

200% 2-4 Seconds Typical

200% 60 Seconds Maximum

SPECIFICATIONS

Product Voltage Interrupting DC Cold Typical Typical

Code Rating Rating* Resistance** (ohms) Melting Voltage

AC DC 125VAC 60VDC min. typ. max. I2t† Drop‡

6125TD500mA 125V 60V 50A 50A .3350 .4025 .4700 0.716 245 mV

6125TD750mA 125V 60V 50A 50A .2000 .2350 .2700 1.07 250 mV

6125TD1A 125V 60V 50A 50A .1350 .1680 .2000 2.88 256 mV

6125TD1.5A 125V 60V 50A 50A .0550 .0630 .0700 2.35 125 mV

6125TD2A 125V 60V 50A 50A .0380 .0480 .0580 9.45 133 mV

6125TD2.5A 125V 60V 50A 50A .0280 .0350 .0420 16.2 130 mV

6125TD3A 125V 60V 50A 50A .0225 .0263 .0300 15.3 97 mV

6125TD3.5A 125V 60V 50A 50A .0170 .0195 .0220 14.5 95 mV

6125TD4A 125V 60V 50A 50A .0160 .0185 .0210 38.8 106 mV

6125TD5A 125V 60V 50A 50A .0115 .0133 .0150 34.4 100 mV

6125TD7A 125V 60V 50A 50A .0073 .0087 .0100 90.2 99 mV

*AC Interrupting Rating (Measured at designated voltage, 100% power factor);DC Interrupting Rating (Measured at designated voltage, time constant of less than

50 microseconds, battery source)

** DC Cold Resistance (Measured at 10% of rated current)

†Typical Melting I

2

t (Measured with a battery bank at rated DC voltage, 10x-rated current (not to exceed IR), time constant of calibrated circuit less than 50 microseconds)

‡Typical Voltage Drop (Measured at rated current after temperature stabilizes)

Device designed to carry rated current for four hours minimum.An operating current of 80% or less of rated current is recommended, with further derating required at

elevated ambient temperatures.

Page 2

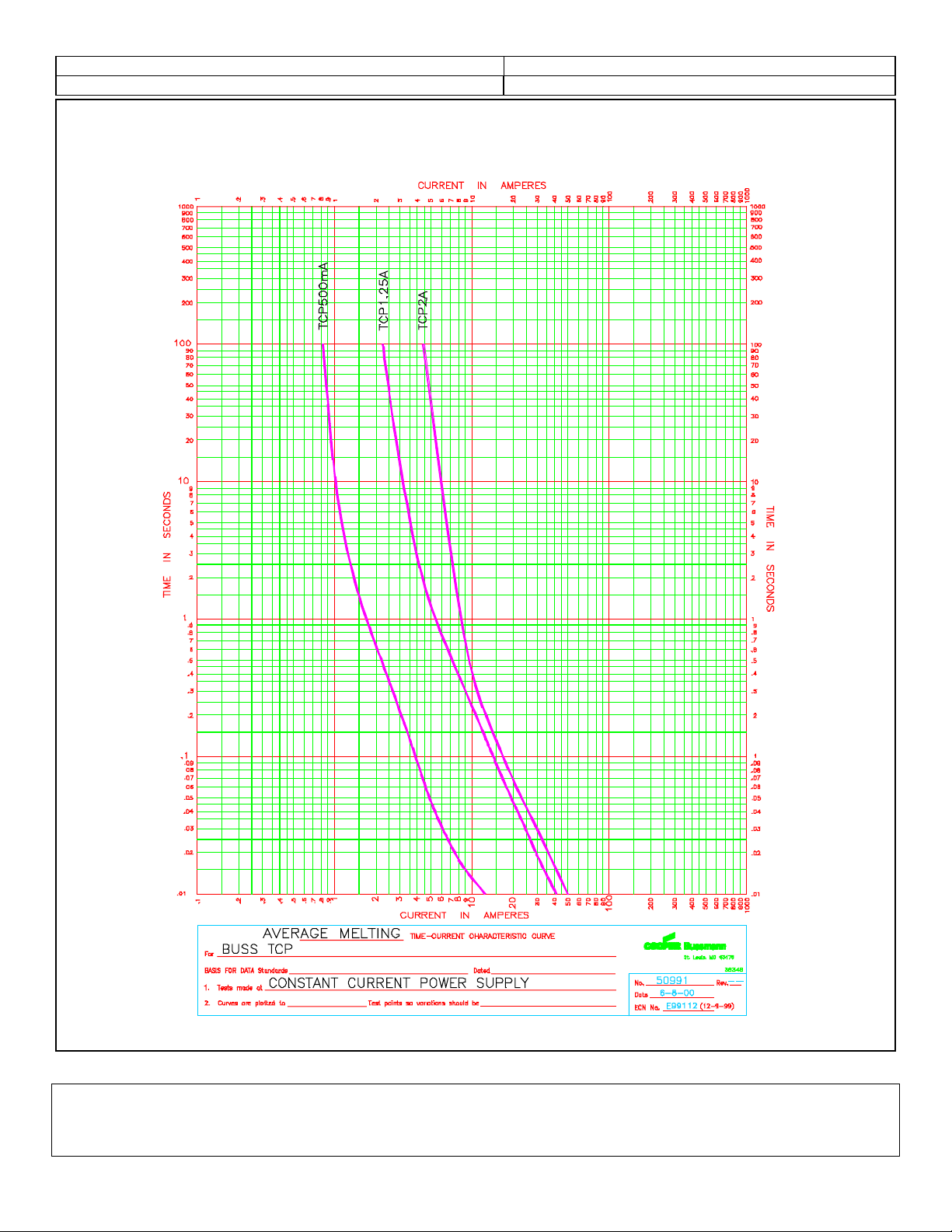

TIME CURRENT CURVE

Brick™Fuses

6125TD Series,Time Delay

250mA and 375mA

to be determined

Visit us on the Web at www.cooperET.com

3601 Quantum Boulevard Boynton Beach, Florida 33426-8638

Tel: +1-561-752-5000 Toll Free: +1-888-414-2645 Fax:+1-561-742-1178

This bulletin is intended to present product design solutions and technical information that will help the end user with design applications. Cooper

Electronic Technologies reserves the right, without notice, to change design or construction of any products and to discontinue or limit distribution of

any products. Cooper Electronic Technologies also reserves the right to change or update, without notice, any technical information contained in this

bulletin. Once a product has been selected, it should be tested by the user in all possible applications.

OC-2530 Rev. M 5/03

© Cooper Electronic

Technologies 2003

PACKAGING CODE

Packaging Code Description

SP2 50 piece sample

TR1 Standard Package:(This is an insert)

1000 pieces of fuses on 12mm tape-and-reel on a 7 inch (177mm) reel per EIA Standard 481

Page 3

Description

• The first and most reliable surface mount telecom circuit

protector designed to protect against power cross faults

and comply with all surge requirements.

• Allows compliance with telecom regulatory standards

including Bellcore GR 1089, UL 1950/60950, and FCC part

68. Application circuit testing is recommended.

• Eliminates the need for a current limiting resistor.

• Protects against overcurrent conditions found in telecom tip

and ring applications.

• RoHS Compliant version available (-R option)

* If the device does not open at 250% within 120 seconds, increase

current to 300% of amp rating.Device must open in 10 seconds max.

Agency Information

• UL Recognition Card:JDYX2/E19180

• CSA Component Certification Record and Class No.:

053787C000, 1422 30

Environmental Data

•Life Test: MIL-STD-202, Method 108A, Test Condition D

• Load Humidity:MIL-STD-202, Method 103B

• Moisture Resistance:MIL-STD-202, Method 106E

• Thermal Shock: MIL-STD-202, Method 107D, air-to-air

• Case Resistance:EIA/IS-722

• Resistance to Dissolution of Metallization:

ANSI J-STD-002, Test D

• Mechanical Shock:MIL-STD-202, Method 213B, Test

Condition A

• High Frequency Vibration:MIL-STD-202, Method 204D,

Test Condition D

• Resistance to Solvents:MIL-STD-202, Method 215A

Soldering Method

• Wave Immersion:260°C, 3 sec max.

• Infrared:240°C, 30 sec max.

Land Pattern

Dimensions

mm

⁄(inches)

ELECTRICAL CHARACTERISTICS

% of Amp Rating Opening Time

100% 4 Hours Minimum

250% 1 Second Minimum

250% 4-10 Seconds Typical

250%* 120 Seconds Maximum

300% 10 Seconds Maximum

ELECTRICAL AND POWER CROSS SPECIFICATIONS

Product Voltage Interrupting DC Cold Typical Maximum Typical Alpha Code

Code Rating Rating* Resistance** (ohms) Melting Total Voltage Marking

AC 250VAC 600VAC min. typ. max. I2t† Clearing Drop‡ 1st Code 2nd Code

TCP500mA 250 V 50 A 40 A 0.420 0.530 0.640 1.3 A2s 100 A2s 471mV F

TCP1.25A 250 V 50 A 60 A 0.070 0.090 0.110 22.2 A2s 100 A2s 150mV J

TCP2A 250 V 50 A 60 A 0.050 0.075 0.100 30 A

2

s 100 A2s 205mV N

*AC Interrupting Rating (Measured at designated voltage, 100% power factor)

** DC Cold Resistance (Measured at 10% of rated current)

***On RoHS Compliant Version (-R option)

†Typical Melting I2t (Measured with a battery bank at 60V DC, 10x-rated current, time constant of calibrated circuit less than 50 microseconds)

‡Typical Voltage Drop (Measured at rated current after temperature stabilizes)

R***

LIGHTNING SURGE SPECIFICATIONS

Surge Specification Surge Repetitions Waveform Current (A) Voltage (V) Performance

(µSec.) Requirement

TCP 500mA tested

FCC 47 Part 68 Longitudinal Type B 2 5x320 37.5 N/A Fuse cannot open

FCC 47 Part 68 Metallic Type A 2 10x560 100 800 Fuse must open safely

Surge out 25 10x160 65 N/A Fuse cannot open

TCP 1.25A and TCP2A tested

FCC 47 Part 68 Longitudinal Type A 2 10x160 100 per fuse 1500 Fuse cannot open

FCC 47 Part 68 Metallic Type B 2 10x560 100 800 Fuse cannot open

Bellcore GR-1089-CORE

First Level Lightning 50 10x1000 100 1000 Fuse cannot open

Bellcore GR-1089-CORE

First Level Lightning 50 2x10 500 2500 Fuse cannot open

Surge out 1 10x160 160 N/A Fuse cannot open

Surge out 1 10x560 115 N/A Fuse cannot open

TCP™Series

Telecom Circuit Protector

5.2 3.7

(0.204) (0.145)

12.6

(0.496)

4.0

(0.157)

Page 4

PACKAGING CODE

Packaging Code Description

TR2 2500 pieces of fuses on 24mm tape-and-reel on 13 inch (330mm) reel per EIA Standard 481, 8mm pitch

OPTIONS

Option Code (Suffix) Description

-R RoHS Compliant Version (Sn plating w/ Ni barrier)

TIME CURRENT CURVE

Cooper Electronic Technologies

3601 Quantum Boulevard

Boynton Beach, FL 33426-8638

Tel: 1-561-752-5000

Fax:1-561-742-0134

Toll Free: 1-888-414-2645

Cooper Bussmann

P.O. Box 14460

St. Louis, MO 63178-4460

Tel: 1-636-394-2877

Fax:1-800-544-2570

Europe

Cooper Electronic Technologies

Cooper (UK) Limited

Burton-on-the-Wolds

Leicestershire • LE12 5TH UK

Tel: +44 (0) 1509 882 737

Fax:+44 (0) 1509 882 786

Asia Pacific

Cooper Electronic Technologies

1 Jalan Kilang Timor

#06-01 Pacific Tech Centre

Singapore 159303

Tel: +65 278 6151

Fax:+65 270 4160

Visit us on the web at:

www.CooperET.com

Datasheet: 98076

6/15/04 - SB04124

© Cooper Electronic

Technologies 2004

North America

TCP™Series

Telecom Circuit Protector

Page 5

Description

• Designed to IEC 127-4

• Surface Mount fuse, time lag

• Solder Immersion Compatible

• Overcurrent protection of systems up to 250VAC

Approvals

• Designed to IEC 127, Sheet 4 (approval pending)

Environmental Data

•Termination Strength: IEC 127-4 Clause 8.3.2

• Soldered Joints: IEC 127-1 Clause 8.5

• Solderability: IEC 127-4 Clause 8.6.2 subjected to Test

Td of IEC-68-2-58 with the following conditions; Aging:

none. Immersion conditions: exceeds IEC 127-4.

Depth of immersion: entire metal surface. Flux type:

non-activated. Solder type:60% tin and 40% lead

according to IEC 68-2-20, Appendix B.

• Resistance to Soldering Heat: IEC 127-4 Clause 8.7

subjected to Test Td of IEC 68-2-58 with the following

conditions; Aging: none. Immersion conditions: 260°C

± 5°C, 10 seconds ± 1 sec. Depth of immersion:

10mm. Flux type: activated. Solder type: 60% tin and

40% lead

• Insulation Resistance: IEC 127-4, Clause 9.3.3

(resistance ≥ 0.1Mohms)

Ordering

• Specify product code and packaging code

Soldering Method

• Wave Immersion:260°C, 10 sec max.

• Infrared:260°C, 30 sec max.

3.07 ± 0.15

(0.121 ± 0.006)

2.77 ± 0.15

3.07 ± 0.15

(0.109 ± 0.006)

(0.121 ± 0.006)

2.77 ± 0.15

(0.109 ± 0.006)

3.30

(0.130)

4.38

(0.172)

6.79

(0.267)

1.4 ± 0.25

1.4 ± 0.25

(0.055 ± 0.010)

(0.055 ± 0.010)

2.77 ± 0.15

(0.109 ± 0.006)

3.07 ± 0.15

(0.121 ± 0.006)

10.29 ± 0.20

(0.405 ± 0.008)

1.4 ± 0.25

1.4 ± 0.25

(0.055 ± 0.010)

(0.055 ± 0.010)

2.77 ± 0.15

(0.109 ± 0.006)

3.07 ± 0.15

(0.121 ± 0.006)

10.29 ± 0.20

(0.405 ± 0.008)

Land Pattern

Dimensions

mm

⁄(inches)

Drawing Not to Scale

Top View

Side View

End View

Brick

™

Fuses 1025T Series

Time Lag, Low Breaking Capacity

ELECTRICAL CHARACTERISTICS

% of Amp Rating Opening Time

125% 1 Hours Minimum

200% 2 Minutes Maximum

200% 1 Second Minimum

1000% 0.01 -- 0.1 Seconds

SPECIFICATIONS

Voltage Interrupting DC Cold Typical Typical Max. Marking

Product Code Rating Rating* Resistance** (ohms) Melting Voltage Voltage Code

AC DC 250VAC 125VDC min. typ. max. I2t† Drop‡ Drop‡

1025T250mA 250V 125V 100A 50A TBD TBD TBD TBD TBD 800 Dt

1025T500mA 250V 125V 100A 50A TBD TBD TBD TBD TBD 600 Ft

1025T800mA 250V 125V 100A 50A TBD TBD TBD TBD TBD 400 KKt

1025T1A 250V 125V 100A 50A TBD TBD TBD TBD TBD 300 Ht

1025T1.6A 250V 125V 100A 50A 0.064 0.074 0.083 12.26 155 mV 300 MMt

1025T2A 250V 125V 100A 50A TBD TBD TBD TBD TBD 300 Nt

1025T2.5A 250V 125V 100A 50A 0.045 0.048 0.051 32.91 TBD 300 Ot

1025T3.15A 250V 125V 100A 50A 0.030 0.034 0.038 54.98 184 mV 300 Qt

1025T4A 250V 125V 100A 50A TBD TBD TBD TBD TBD 300 St

1025T5A 250V 125V 100A 50A TBD TBD TBD TBD TBD 300 Tt

1025T6.3A 250V 125V 100A 50A TBD TBD TBD TBD TBD 300 OOt

*AC Interrupting Rating (Measured at designated voltage, greater than 95% power factor);DC Interrupting Rating (Measured at designated voltage, time constant of

the calibrated circuit is less than 1 millisecond, battery source)

** DC Cold Resistance (Measured at ≤10% of rated current)

†Typical Melting I2t (Measured with a battery bank at rated DC voltage, 10x-rated current, not to exceed IR, time constant of calibrated circuit less than 50 microseconds)

‡Typical Voltage Drop (Measured at rated current after temperature stabilizes)

• Device designed to carry rated current for four hours minimum.An operating current of 80% or less of rated current is recommended, with further derating required at

elevated ambient temperatures.

Page 6

PACKAGING CODE

Packaging Code Description

TR2 2,500 pieces of fuses on 24mm tape-and-reel on 13 inch (330mm) reel per EIA Standard 481

TR3 50 pieces of fuses on 24mm tape packaged in a plastic box per EIA Standard 481

TIME CURRENT CURVE

Brick

™

Fuses 1025T Series

Time Lag, Low Breaking Capacity

Visit us on the Web at www.cooperET.com

3601 Quantum Boulevard Boynton Beach, Florida 33426-8638

Tel: +1-561-752-5000 Toll Free: +1-888-414-2645 Fax:+1-561-742-1178

This bulletin is intended to present product design solutions and technical information that will help the end user with design applications. Cooper

Electronic Technologies reserves the right, without notice, to change design or construction of any products and to discontinue or limit distribution of

any products. Cooper Electronic Technologies also reserves the right to change or update, without notice, any technical information contained in this

bulletin. Once a product has been selected, it should be tested by the user in all possible applications.

OC-2536 Rev. XF 5/03

© Cooper Electronic

Technologies 2003

Page 7

Description

• Surface mount fuse, fast acting

• Designed to IEC 127-4

• Surface Mount

• Solder Immersion Compatible

• Overcurrent protection of systems up to 250 VAC

Approvals

• Designed to IEC 127, Sheet 4 (approval pending)

Environmental Data

•Termination Strength: IEC 127-4 Clause 8.3.2

• Soldered Joints: IEC 127-1 Clause 8.5

• Solderability: IEC 127-4 Clause 8.6.2

• Resistance to Soldering Heat: IEC 127-4 Clause 8.7

• Insulation Resistance: IEC 127-4 Clause 9.3.3

Soldering Method

• Wave Immersion:260°C, 10 sec max.

• Infrared:260°C, 30 sec max.

Ordering

• Specify product code and packaging code

2.77 ± 0.15

(0.109 ± 0.006)

2.77 ± 0.15

(0.109 ± 0.006)

3.07 ± 0.15

(0.121 ± 0.006)

3.07 ± 0.15

(0.121 ± 0.006)

4.38

(0.172)

3.30

(0.130)

6.79

(0.267)

2.77 ± 0.15

(0.109 ± 0.006)

10.29 ± 0.20

(0.405 ± 0.008)

1.4 ± 0.25

(0.055 ± 0.010)

1.4 ± 0.25

(0.055 ± 0.010)

3.07 ± 0.15

(0.121 ± 0.006)

2.77 ± 0.15

(0.109 ± 0.006)

10.29 ± 0.20

(0.405 ± 0.008)

1.4 ± 0.25

(0.055 ± 0.010)

1.4 ± 0.25

(0.055 ± 0.010)

3.07 ± 0.15

(0.121 ± 0.006)

Land Pattern

Dimensions

mm

⁄(inches)

Drawing Not to Scale

Top View

Side View

End View

Brick

™

Fuses 1025F Series

Fast Acting, Low Breaking Capacity

ELECTRICAL CHARACTERISTICS

% of Amp Rating Opening Time

125% 1 Hour Minimum

200% 2 Minutes Maximum

1000% 0.001 - 0.01 Seconds

SPECIFICATIONS

Voltage Interrupting DC Cold Typical Typical Marking

Product Code Rating Rating* Resistance** (ohms) Melting Voltage Code

AC DC 250VAC 125VDC min. typ. max. I2t† Drop‡

1025F250mA 250V 125V 100A 50A TBD TBD TBD TBD TBD D f

1025F500mA 250V 125V 100A 50A TBD TBD TBD TBD TBD F f

1025F800mA 250V 125V 100A 50A TBD TBD TBD TBD TBD KK f

1025F1A 250V 125V 100A 50A TBD TBD TBD TBD TBD H f

1025F1.6A 250V 125V 100A 50A TBD TBD TBD TBD TBD MM f

1025F2A 250V 125V 100A 50A TBD TBD TBD TBD TBD N f

1025F2.5A 250V 125V 100A 50A TBD TBD TBD TBD TBD O f

1025F3.15A 250V 125V 100A 50A TBD TBD TBD TBD TBD Q f

1025F4A 250V 125V 100A 50A TBD TBD TBD TBD TBD S f

1025F5A 250V 125V 100A 50A TBD TBD TBD TBD TBD T f

1025F6.3A 250V 125V 100A 50A TBD TBD TBD TBD TBD OO f

*AC Interrupting Rating (Measured at designated voltage, greater than 95% power factor);DC Interrupting Rating (Measured at designated voltage,

time constant of the calibrated circuit is less than 1 millisecond, battery source)

** DC Cold Resistance (Measured at ≤10% of rated current)

†Typical Melting I

2

t (Measured with a battery bank at 10x-rated current, not to exceed IR,

time constant of calibrated circuit less than 50 microseconds)

‡Typical Voltage Drop (Measured at rated current after temperature stabilizes)

• Device designed to carry rated current for four hours minimum.An operating current of 80% or less of rated current is recommended, with

further derating required at elevated ambient temperatures.

Page 8

PACKAGING CODE

Packaging Code Description

TR2 2500 pieces of fuses on 24mm tape-and-reel on a 13 inch (330mm) reel per EIA Standard 481

TR3 50 pieces of fuses on 24mm tape packaged in a plastic box per EIA Standard 481

TIME CURRENT CURVE

Brick

™

Fuses 1025F Series

Fast Acting, Low Breaking Capacity

Visit us on the Web at www.cooperET.com

3601 Quantum Boulevard Boynton Beach, Florida 33426-8638

Tel: +1-561-752-5000 Toll Free: +1-888-414-2645 Fax:+1-561-742-1178

This bulletin is intended to present product design solutions and technical information that will help the end user with design applications. Cooper

Electronic Technologies reserves the right, without notice, to change design or construction of any products and to discontinue or limit distribution of

any products. Cooper Electronic Technologies also reserves the right to change or update, without notice, any technical information contained in this

bulletin. Once a product has been selected, it should be tested by the user in all possible applications.

OC-2548 Rev. X2 5/03

© Cooper Electronic

Technologies 2003

4000

3000

2000

1000

800

600

500

400

300

200

100

80

60

50

40

30

20

10

8

6

5

4

3

2

TIME IN SECONDS

1

.8

.6

.5

.4

.3

.2

.1

.08

.06

.05

.04

.03

.02

50 %

100 %

166 %

200 %

300 %

1000 %

2000 %

4000

3000

2000

1000

800

600

500

400

300

200

100

80

60

50

40

30

20

10

8

6

5

4

3

2

1

.8

.6

.5

.4

.3

.2

.1

.08

.06

.05

.04

.03

.02

.01

.008

.006

.005

.004

.003

.002

.001

.1

50 %

100 %

166 %

200 %

300 %

1000 %

2000 %

.01

.008

.006

.005

.004

.003

.002

.001

CURRENT IN PERCENT

Page 9

Description

• Surface Mount

• Environmentally rugged, complies with the EIA-IS-722

Standard

• Solder Immersion Compatible

• Targeted for Consumer Electronics

• Overcurrent protection of systems up to 125VAC/DC

• Wire-in-air design

Agency Information

• UL Listed Guide and File Numbers (250mA-12A):

JDYX & E195337

• UL Recognized Guide and File Numbers (15A):

JDYX2 & E195337

• CSA Component Acceptance: 053787 C 000 &

Class No: 1422 30

Environmental Data

• Shock: MIL-STD-202, Method 213, Test Condition 1

(100 G’s peak for 6 milliseconds)

• Vibration: MIL-STD-202, Method 201 (10-55 Hz, 0.06

inch, total excursion)

• Salt Spray:MIL-STD-202, Method 101, Test Condition

B (48 hrs)

• Insulation Resistance: MIL-STD-202, Method 302, Test

Condition A (After Opening) 10,000 ohms minimum

• Resistance to Solder Heat: MIL-STD-202, Method 210,

Test Condition F (20 sec, at 260° C)

• Thermal Shock: MIL-STD-202, Method 107, Test

Condition B (-65° C to +125° C)

Ordering

• Specify product code and packaging code

Soldering Method

• Wave Solder: 260°C, 10 sec max.

(MIL-STD-202, Method 210)

• Infrared Reflow:260°C, 30 sec max.

Brick™Fuses

6125FA Series, Fast Acting

2.59+.250

(0.102+

.010)

2.59+

.250

(0.102+

.010)

2.6 3.0

(0.102) (0.118)

4.0

(0.157)

8.6

(0.339)

*AC Interrupting Rating (Measured at designated voltage, 100% power factor);DC Interrupting Rating (Measured at designated voltage, time constant of less than 50

microseconds, battery source)

** DC Cold Resistance (Measured at 10% of rated current)

†Typical Melting I

2

t (Measured with a battery bank at rated DC voltage, 10x-rated current, time constant of calibrated circuit less than 50 microseconds)

‡Typical Voltage Drop (Measured at rated current after temperature stabilizes)

Device designed to carry rated current for four hours minimum.An operating current of 80% or less of rated current is recommended, with further derating required at elevated

ambient temperatures.

1.35+.25 1.35+.25

(0.053+

.010) (0.053+ .010)

2.59+

.25

(0.102+

.010)

6.10+

.25

(0.240+

.010)

1.35+.25 1.35+.25

(0.053+

.010) (0.053+.010)

2.59+

.25

(0.102+

.010)

6.10+

.25

(0.240+

.010)

Land Pattern

Dimensions

mm

⁄(inches)

Drawing Not to Scale

Top View

Side View

End View

ELECTRICAL CHARACTERISTICS

% of Amp Rating Opening Time

100% 4 Hours Minimum

200% 5 Seconds Maximum

SPECIFICATIONS

Product Voltage Interrupting Resistance Typical Typical

Code Rating Rating* (ohms)** Melt Voltage

AC DC DC 125V AC 125V DC 86V DC Typ. I2t† Drop (V)‡

6125FA250mA 125V 125V 86V 50A 300A 10,000A 0.65 0.01 0.30

6125FA375mA 125V 125V 86V 50A 300A 10,000A 0.36 0.03 0.25

6125FA500mA 125V 125V 86V 50A 300A 10,000A 0.24 0.06 0.22

6125FA750mA 125V 125V 86V 50A 300A 10,000A 0.15 0.07 0.17

6125FA1A 125V 125V 86V 50A 300A 10,000A 0.11 0.14 0.17

6125FA1.25A 125V 125V 86V 50A 300A 10,000A 0.09 0.24 0.16

6125FA1.5A 125V 125V 86V 50A 300A 10,000A 0.07 0.41 0.15

6125FA2A 125V 125V 86V 50A 300A 10,000A 0.05 0.80 0.15

6125FA2.5A 125V 125V 86V 50A 300A 10,000A 0.038 1.4 0.14

6125FA3A 125V 125V 86V 50A 300A 10,000A 0.028 2.4 0.13

6125FA3.5A 125V 125V 86V 50A 300A 10,000A 0.025 3.3 0.13

6125FA4A 125V 125V 86V 50A 300A 10,000A 0.022 4.4 0.13

6125FA5A 125V 125V 86V 50A 300A 10,000A 0.016 7.8 0.12

6125FA6.3A 125V 125V 86V 50A 300A 10,000A 0.012 14.0 0.12

6125FA7A 125V 125V 86V 50A 300A 10,000A 0.011 19.0 0.114

6125FA10A 125V N/A 86V 50A N/A 10,000A 0.007 44 0.107

6125FA12A 125V N/A 86V 50A N/A 10,000A 0.006 69 0.103

6125FA15A N/A N/A 86V N/A N/A 10,000A 0.004 124 0.098

Page 10

PACKAGING CODE

Packaging Code Description

SP2 50 piece sample

TR2 5000 pieces of fuses on 12mm tape-and-reel on a 13 inch (330mm) reel per EIA Standard 481

TIME CURRENT CURVE

Brick™Fuses

6125FA Series, Fast Acting

Visit us on the Web at www.cooperET.com

3601 Quantum Boulevard Boynton Beach, Florida 33426-8638

Tel: +1-561-752-5000 Toll Free: +1-888-414-2645 Fax:+1-561-742-1178

This bulletin is intended to present product design solutions and technical information that will help the end user with design applications. Cooper

Electronic Technologies reserves the right, without notice, to change design or construction of any products and to discontinue or limit distribution of

any products. Cooper Electronic Technologies also reserves the right to change or update, without notice, any technical information contained in this

bulletin. Once a product has been selected, it should be tested by the user in all possible applications.

OC-2531 Rev. I 5/03

© Cooper Electronic

Technologies 2003

Page 11

Description

• Surface Mount

• Environmentally rugged, satisfies the EIA/IS-722

Standard

• Solder Immersion Compatible

• Targeted for Consumer Electronics

Note: 30vde constant current source required for 200%

overload tests on 250ma-1a.

Agency Information

• UL Recognition Guide & File numbers:

JDYX2 & E19180 (250mA - 15A)

• CSA Component Acceptance:

File # 053787 C000, Class # 1422 30

Environmental Data

•Life Test: MIL-STD-202, Method 108A, Test Condition D

• Load Humidity: MIL-STD-202, Method 103B

• Moisture Resistance: MIL-STD-202, Method 106E

•Terminal Strength: MIL-STD-202, Method 211A

• Thermal Shock: MIL-STD-202, Method 107D, air-to-air

• Case Resistance: EIA/IS-722

• Resistance to Dissolution of Metallization:

ANSI J-STD-002, Test D

• Mechanical Shock: MIL-STD-202, Method 213B with

exceptions per EIA/IS-722 Standard

• High Frequency Vibration: MIL-STD-202, Method 204D,

Test Condition D

• Resistance to Solvents: MIL-STD-202, Method 215A

Soldering Method

• Wave Solder: 260°C, 10 sec max.

• Infrared Reflow:260°C, 30 sec max.

Ordering

• Specify product code and packaging code

3.30

(0.130)

4.38

(0.172)

6.79

(0.267)

Land Pattern

Dimensions

mm

⁄(inches)

Drawing Not to Scale

Brick™Fuses

1025FA Series, Fast Acting

ELECTRICAL CHARACTERISTICS

% of Amp Rating Opening Time

100% 4 Hours Minimum

200% (250mA-5A) 5 Seconds Maximum

250% (250mA-5A fuse) 1 Second Maximum

200% (7A-15A fuse) 20 Seconds Maximum

250% (7A-15A fuse) 4 Seconds Maximum

SPECIFICATIONS

Voltage Interrupting DC Cold Typical Typical Marking

Product Code Rating Rating* Resistance** (ohms) Melting Voltage Code‡‡

AC DC 250VAC 125VDC 60VDC Typical I2t† Drop‡

1025FA250mA 250V 125V 50A 50A - 5.0000 0.1212 2019 mV AD

1025FA500mA 250V 125V 50A 50A - 1.2000 0.0415 1500 mV AF

1025FA750mA 250V 125V 50A 50A - 0.6000 0.143 880 mV AG

1025FA1A 250V 125V 50A 50A - 0.3000 1.750 560 mV AH

1025FA1.5A 250V 125V 50A 50A - 0.1040 1.460 260 mV AK

1025FA2A 250V 125V 50A 50A - 0.0800 6.086 258 mV AN

1025FA2.5A 250V 125V 50A 50A - 0.0510 8.48 232 mV AO

1025FA3A 250V 125V 50A 50A - 0.0390 18.15 205 mV AP

1025FA3.5A 250V 125V 50A 50A - 0.0300 17.83 185 mV AR

1025FA4A 250V 125V 50A 50A - 0.0270 23.32 190 mV AS

1025FA5A 250V 125V 50A 50A - 0.0200 38.74 180 mV AT

1025FA7A 250V 60V 50A 50A - 0.0116 138 150 mV AU

1025FA10A 250V 60V 50A 50A - 0.0076 457 146 mV AW

1025FA12A 250V 60V 50A - 50A 0.0550 498 120 mV AX

1025FA15A 250V 60V 50A - 50A 0.0041 1451 110 mV AY

*AC Interrupting Rating (Measured at designated voltage, 100% power factor random closing);DC Interrupting Rating (Measured at designated voltage, time constant of

less than 50 microseconds, battery source)

** DC Cold Resistance (Measured at ≤10% of rated current)

†Typical Melting I

2

t (Measured with a battery bank at rated DC voltage, 10x-rated current, but not exceeding the interrupting rating. Time constant of calibrated circuit less

than 50 microseconds).Test current not to exceed interrupting rating of 50A.

‡Typical Voltage Drop (Measured at rated current after temperature stabilizes)

‡‡Marking Code - 3

rd

(U = USA, T = Taiwan and S = China)

• Device designed to carry rated current for four hours minimum.An operating current of 80% or less of rated current is recommended, with further derating required at

elevated ambient temperatures.

U,

T

or

S

1

st

& 2

nd3rd

Page 12

PACKAGING CODE

Packaging Code Description

SP1 50 piece sample

TR2 2,500 pieces of fuses on 24mm tape-and-reel on 13 inch (330mm) reel per EIA Standard 481

TIME CURRENT CURVE

Brick™Fuses

1025FA Series, Fast Acting

Visit us on the Web at www.cooperET.com

3601 Quantum Boulevard Boynton Beach, Florida 33426-8638

Tel: +1-561-752-5000 Toll Free: +1-888-414-2645 Fax:+1-561-742-1178

This bulletin is intended to present product design solutions and technical information that will help the end user with design applications. Cooper

Electronic Technologies reserves the right, without notice, to change design or construction of any products and to discontinue or limit distribution of

any products. Cooper Electronic Technologies also reserves the right to change or update, without notice, any technical information contained in this

bulletin. Once a product has been selected, it should be tested by the user in all possible applications.

OC-2538 Rev. X6 5/03

© Cooper Electronic

Technologies 2003

Page 13

Description

• Surface Mount

• Environmentally rugged, satisfies the EIA/IS-722

Standard

• Solder Immersion Compatible

• Targeted for Consumer Electronics

* If fuse does not open @ 200% in 60 seconds, raise current to 250%

and the fuse must open in 10 seconds maximum.

Agency Information

• UL Recognition Guide & File numbers:

JDYX2 & E19180 (250mA - 5A)

• CSA Component Acceptance:

File # 053787 C000, Class # 1422 30

Environmental Data

•Life Test: MIL-STD-202, Method 108A, Test Condition D

• Load Humidity: MIL-STD-202, Method 103B

• Moisture Resistance: MIL-STD-202, Method 106E

•Terminal Strength: MIL-STD-202, Method 211A

• Thermal Shock: MIL-STD-202, Method 107D, air-to-air

• Case Resistance: EIA/IS-722

• Resistance to Dissolution of Metallization:

ANSI J-STD-002, Test D

• Mechanical Shock: MIL-STD-202, Method 213B with

exceptions per EIA/IS-722 Standard

• High Frequency Vibration: MIL-STD-202, Method 204D,

Test Condition D

• Resistance to Solvents: MIL-STD-202, Method 215A

Ordering

• Specify product code and packaging code

Soldering Method

• Wave Immersion:260°C, 10 sec max.

• Infrared:260°C, 30 sec max.

3.30

(0.130)

4.38

(0.172)

6.79

(0.267)

Land Pattern

Dimensions

mm

⁄(inches)

Drawing Not to Scale

Brick™Fuses

1025TD Series,Time Delay

ELECTRICAL CHARACTERISTICS

% of Amp Rating Opening Time

100% 4 Hours Minimum

200% 1 Second Minimum

200% 60 Seconds Maximum

250% * 10 Seconds Maximum

SPECIFICATIONS

Voltage Interrupting DC Cold Typical Typical Marking

Product Code Rating Rating* Resistance** (ohms) Melting Voltage Code‡‡

AC DC 250VAC 125VDC Typical I2t† Drop‡

1025TD250mA 250V 125V 50A 50A 4.200 0.128 1900 mV DD

1025TD500mA 250V 125V 50A 50A 0.5500 1.47 455 mV DF

1025TD750mA 250V 125V 50A 50A 0.317 0.93 400 mV DG

1025TD1A 250V 125V 50A 50A 0.2030 9.91 387 mV DH

1025TD1.5A 250V 125V 50A 50A 0.1025 11.79 310 mV DK

1025TD2A 250V 125V 50A 50A 0.0680 17.27 250 mV DN

1025TD2.5A 250V 125V 50A 50A 0.0420 16.51 201 mV DO

1025TD3A 250V 125V 50A 50A 0.0330 42.74 184 mV DP

1025TD3.5A 250V 125V 50A 50A 0.0270 43.33 180 mV DR

1025TD4A 250V 125V 50A 50A 0.0220 66.96 152 mV DS

1025TD5A 250V 125V 50A 50A 0.0160 88.38 145 mV DT

*AC Interrupting Rating (Measured at designated voltage, 100% power factor random closing);DC Interrupting Rating (Measured at designated voltage, time

constant of the calibrated circuit is less than 50 microseconds, battery source)

** DC Cold Resistance (Measured at ≤10% of rated current)

†Typical Melting I2t (Measured with a battery bank at rated DC voltage, 10x-rated current, time constant of calibrated circuit less than 50 microseconds)

‡Typical Voltage Drop (Measured at rated current after temperature stabilizes)

‡‡Marking Code - 3

rd

(U = USA, T = Taiwan and S = China)

• Device designed to carry rated current for four hours minimum.An operating current of 80% or less of rated current is recommended, with further derating required at

elevated ambient temperatures.

U,

T

or

S

1

st

& 2

nd

3

rd

Page 14

PACKAGING CODE

Packaging Code Description

SP1 50 piece sample

TR2 2,500 pieces of fuses on 24mm tape-and-reel on 13 inch (330mm) reel per EIA Standard 481

TIME CURRENT CURVE

Brick™Fuses

1025TD Series,Time Delay

Visit us on the Web at www.cooperET.com

3601 Quantum Boulevard Boynton Beach, Florida 33426-8638

Tel: +1-561-752-5000 Toll Free: +1-888-414-2645 Fax:+1-561-742-1178

This bulletin is intended to present product design solutions and technical information that will help the end user with design applications. Cooper

Electronic Technologies reserves the right, without notice, to change design or construction of any products and to discontinue or limit distribution of

any products. Cooper Electronic Technologies also reserves the right to change or update, without notice, any technical information contained in this

bulletin. Once a product has been selected, it should be tested by the user in all possible applications.

OC-2537 Rev. XH 5/03

© Cooper Electronic

Technologies 2003

Page 15

Engineering Product Specification

TM

TCP

Telecom Circuit Protector

- The information contained in this document is the property of Cooper Industries, Inc. It is not for public disclosure. Possession of the information

does not convey any right to loan, sell or disclose the

prohibited. This document is to be returned to Cooper Industries, Inc. Upon completion of the purposes for which it is loaned or upon request.

Rev. # Revision Description Date Author Appr

L Redraw the Maximum Offset of Tube to make it legible. Correct the minimum tube size from .103”SQ to .101”SQ. Add

comment to indicate the cap and tub e SQ si zes are minimum dimensions. Update UL card to indicate 2A. Remove the ink

color from the alpha mark spec. Add the alpha mark designations for the China and Costa Rica facilities. Update mfgr info.

K Rename TCP1.251A product to TCP2A. No change in electrical characteristics. Add China facility. 8/23/00 VK DB

J Add 1.251A version. Add ISO registration information. Change alpha code: 500mA from A to F and 1.25A from B to J. 6/8/00 DR EC

I Detail marking specification in section 7. 4/28/00 DR EC

H Add maximum total clearing I2t in section 5.5. 1/19/00 DR EC

G Added nickel flash. Added cold resistance for TCP-500mA (min 0.541, typ 0.614, max. 0.686) Added typ. Melt I2t

(500mA=1.3a

205mV. Added TCC for both ratings. Changed max. temp from 85°C to 125°C. Added max. tube offset drawing.

F 5.2.1 Changed .500mA 600v int. rating to 40A; 5.4 Added DC cold resistance for TCP1.25 min-0.107, type -0.128, max. -

0.150; 5.6 Added 0.205 typ voltage drop to TCP 1.25A; 6.1 Added UL Recognition card; 6.2 Added CSA component

acceptance card; 12 Removed copper from wire, plate end plates and mark in flow chart.

E Changed area code, removed Nickel flash on post plating, removed marking of fuse 6/99 CR EC

D Changed Interrupting Rating to 60A, changed Time vs. Current requirement for 1.25A, & removed specification data results. 4/99 DG EC

C Added new logo and disclaime r 1/99 DG EC

B Final for prerelease 3/98 EC EC

A Original 2/18 EC EC

2

sec, 1.25A=22.2 a2sec). Added typ. Voltage drop on 500mA(471mV), changed voltage drop of 1.25A to

CONFIDENTIAL information. Unauthorized reproduction or use of the information is

2/21/01 VK DB

10/99 CR EC

9/99 CR EC

Page 16

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 2 of 18

Table of Contents

Section Title Page

1. Scope 3

2. Manufacturer and Production Facility 3

3. Catalog Symbol and Part Numbering System 3

4. Mechanical Specifications 4

5. Electrical Specifications 6

6. Standards and Agency information 11

7. Marking Specification 13

8. Soldering Method 13

9. Land Pattern 14

10. Temperature Derating Curve 14

11. Packaging Specification 15

12. Process Flow Chart 15

13. Environmental (Reliability / Qualification) Data 16

14. End 18

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 17

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 3 of 18

1.SCOPE

1.1 This Specification applies to Bussmann TCP series protectors.

2. MANUFACTURER AND PRODUCTION FACILITY

2.1 Manufacturer Cooper Electronic Technologies

3601 Quantum Boulevard

Boynton Beach, FL 33426

Phone: (561) 752-5000

Fax: (561) 742-0134

2.2 Production Facility 1) Bussmann 2) NO. 59-12, 9 Lin

114 Old State Road Ta Tsuo Li, Chu Nan Chen

Ellisville, MO 63021 (USA) Mia LiHsien, Taiwan, R.O.C

3) Xin Min Industrial Estate 4) 1K M Al Este Del Aeropurto

Changan DongGuan Juan Santamarita, Zona Franca

Guangdong Province China Saret, Edificio B-05

Rio Segundo Alajuela, Costa Rica

2.3 ISO Registration 1) ISO 9002, File Number A4916 2) ISO 9001, File Number A6444

3) ISO 9002, Certificate No. Q2273 4) ISO 9002, File Number A7346

3. CATALOG SYMBOL AND PART NUMBERING SYSTEM

3.1 Catalog Symbol

3.1.1 Example TR1/TCP500mA

TR1/

TCP 500mA

↓ ↓ ↓

1 2 3

1. Packaging Code: TR1/

2. Series Number: TCP

3. Ampere Rating: 500mA

3.2 Part Numbering System

3.2.1 Packaging Code

Pack aging Code Desc ript i on

SP1/ 10 Fuses in Tape in a Pl as tic Bag (Engineeri ng S am pl es)

SP2/ 50 Fuses in Tape with a Leader and Trailer in a P l as tic Box (En gineering S am pl es)

TR1/ 1000 Fuses i n Tape and Reel (13 inc h [ 330 m m ] reel)

TR2/ 2500 Fuses i n Tape and Reel (13 inc h [ 330 m m ] reel)

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 18

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000

Printed on: 7/14/2003 Sheet 4 of 18

3.2.2 Ampere Rating

Catalog Description

Symbol

TCP500m A 500m A Fuse

TCP1.25A 1.25A Fuse

TCP2A 2A Fuse

4. MECHANICAL SPECIFICATIONS

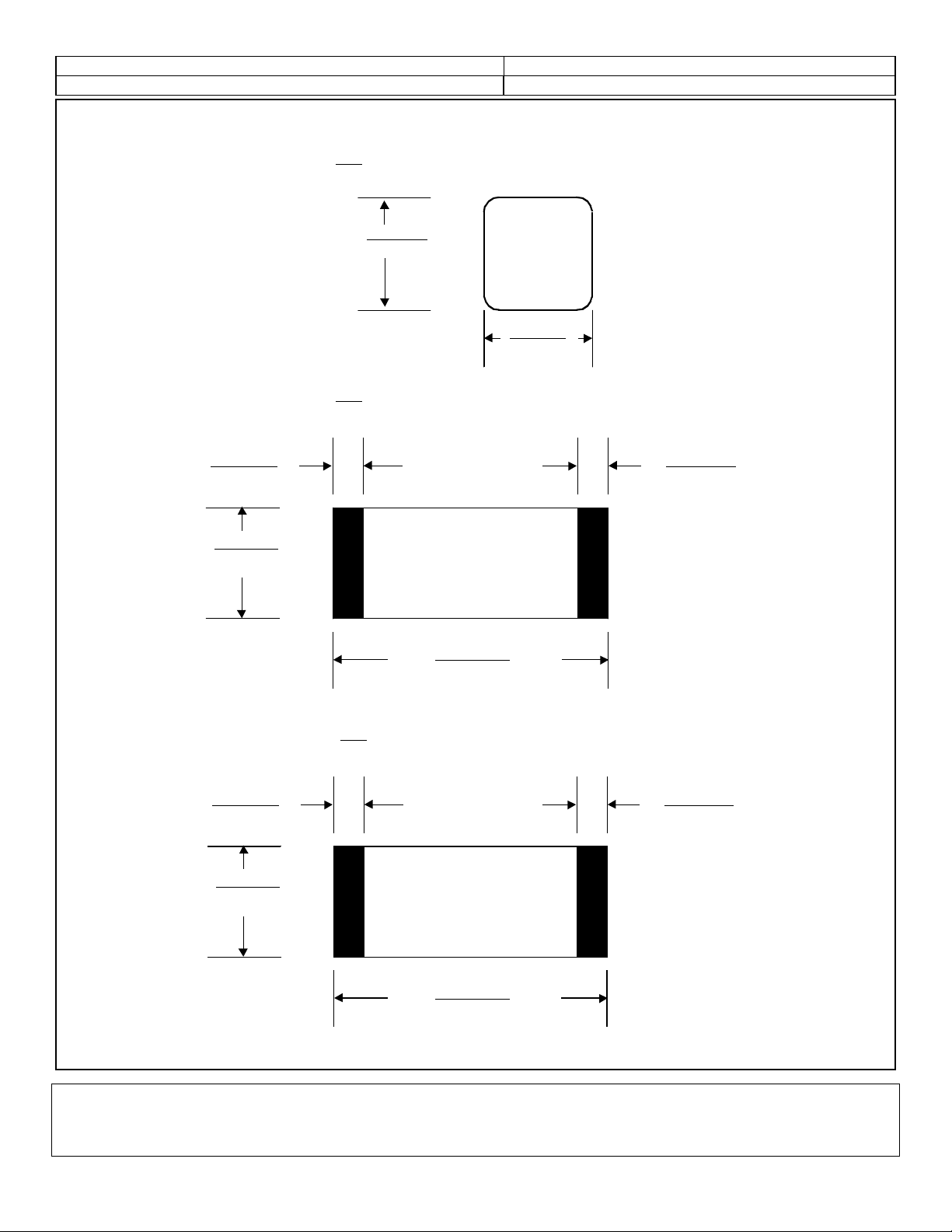

4.1 Construction (drawing not to scale)

1 2 3 4 5 6

1. End plate

2. High temperature solder preform

3. Metallization of ceramic body

4. Ceramic body

5. Fuse element

6. End termination overcoat on both ends (Nickel Flash, Tin/Lead Overcoat)

4.1.2 Maximum Offset of Tube

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 19

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 5 of 18

4.2 Dimensions (drawings not to scale)

4.2.1 End View mm

(inches)

2.77± 0.15

(0.109± 0.006)

2.77± 0.15

(0.109± 0.006)

4.2.2 Top View mm

(inches)

1.40± 0.25 1.40± 0.25

(0.055± 0. 010) (0.055± 0.010)

2.77± 0.15

(0.109± 0. 006)

10.29± 0. 2 0

(0.405± 0.008)

4.2.3 Side View mm

(inches)

1.40± 0. 25 1.40± 0.25

(0.055± 0. 010) (0.055± 0. 010)

2.77± 0. 15

(0.109± 0. 006)

10.29± 0.2 0

(0.405± 0.008)

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 20

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Vol tage Rat ing

Printed on: 7/14/2003 Sheet 6 of 18

4.2.4 Orthogonal View

5. ELECTRICAL SPECIFICATIONS

5.1 Voltage Rating

Catalog Sy m bol

AC

TCP500mA 250 V

TCP1.25A 250 V

TCP2A 250 V

5.2 Interrupting Rating

5.2.1 AC Interrupting Rating (Measured at designated voltage, 100% power factor)

C a ta log Sym bol

Inte rrupting R ating

AC

250 V 600 V*

TC P5 00mA 5 0 A 4 0A

TC P1 .25A 50 A 60 A

TC P2 A 50 A 60 A

*600V, 60A Interrupting ratings test were performed by closing the circuit between 50

° and 70° on the voltage wave.

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 21

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 7 of 18

5.3 Time vs. Current Characteristic (Measured with a Kepco constant current power supply)

5.3.1 For TCP500mA and TCP1.25A

% of Am p Rat ing Opening Time

100% 4 Hours M inim um

250% 1 Second Min im um

250% 4 -10 Sec onds Typic al

250% 120 Seconds Maxim um

300%* 10 S ec onds M ax im um

*If the device does not open at 250% within 120 seconds, increase current to 300% of amp rating.

Device must open in 10 seconds maximum.

5.3.2 For TCP2A

Current Level Opening Time

2.2A * * 30 mi nut es mi nim um

7A opens before Bussmann M DL-2

25A opens before Bus s m ann M DL-2

40A opens before Bus s m ann M DL-2

% of Amp Rating O pening Time

1 00% 4 Hours Minimum

2 50% 1 Second Minimum

2 50% 4 - 10 Seconds Typica l

2 50% 120 Seconds Maxim um

3 00%* 10 S econds Maximum

*If the device does not open at 250% within 120 seconds, increase current to 300% of amp rating.

Device must op en in 10 seconds maximum.

** The TCP2 A may have a maximum t emperature rise of 100°C after carrying 2.2A for thirty minutes.

5.4 DC Cold Resistance (Measured at 10% of rated current)

Catalog Sy m bol Resistance (ohms)

Min. Typ. Max.

TCP500mA 0.420 0.530 0.640

TCP1.25A 0.107 0.128 0.150

TCP2A 0.050 0.075 0.100

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 22

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 8 of 18

5.5 I

2

t

5.5.1 Typical Melt I

2

t is measured with a battery bank at 60V DC, 10x-rated current, time constant

of calibrated circuit less than 50 microseconds.

5.5.2 Maximum Total Clearing is measured on a 40A, 600V AC, unity power factor circuit.

C atalog Symbol Typical Maximum

2

Melt I

t Total C learing I2t

TCP500mA 1.3 A

TCP1.25A 22.2 A

TCP2A 30 A

2

s100 A

2

s100 A

2

s100 A

2

s

2

s

2

s

5.6 Typical Voltage Drop (Measured at rated current after temperature stabilizes)

Catalog Symbol Typical Voltage Drop

TCP500mA 471mV

TCP1.25A 205mV

TCP2A 205mV

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 23

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Waveform

Metallic

Waveform

Longitudi nal Type A

Printed on: 7/14/2003 Sheet 9 of 18

5.7 Surge Specifications

a) TCP 500mA tested to surge requirements listed below

Surge S pecific at i on Surge Repet i t ions

(µSec.) Current (A) Volt age (V)

Longitudinal

FCC 47 Part 68

FCC 47 Part 68

Type B 2 5x320 37.5 N/A Fus e cannot open

Type A 2 10x 560 100 800

Performance

Requirement

Fus e m ust open

safely

Surge Out 25 10x160 65 N/A F us e cannot open

b) TCP1.25A and TCP2A tested to surge specifications listed below

Performance

Surge S pecific at i on Surge Repetitions

FCC 47 Part 68

2 10x160 100 per fuse 1500 Fus e cannot open

( µSec.) Current (A ) V ol t age (V )

Requirements

FCC 47 Part 68 Met al li c Type B 2 10x560 100 800 Fuse c annot open

Bel lcore GR-1089-CORE Fi rs t Level Lighting 50 10x1000 100 1000 F us e cannot open

Bel lcore GR-1089-CORE Fi rs t Level Lighting 50 2x10 500 2500 F us e cannot open

Surge Out 1 10x160 160 N/A Fuse c annot open

Surge Out 1 10x560 115 N/A Fuse c annot open

5.8 Maximum Temperature Rise (Measured at rated current after temperature stabilizes)

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

C atalog Sym bol Maximum Temperature Rise

TCP500mA <

TCP1.25A <

TCP2A <

75 °C (13 5°F)

75 °C (13 5°F)

75 °C (13 5°F)

Page 24

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 10 of 18

5.9 Time Current Curve:

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 25

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 11 of 18

6. STANDARDS and APPROVALS

6.1 UL Recognition Card (JDYX2 / E19180)

6.1.1 Marking The UL Recognition symbol appears on the label affixed to the packaging container.

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 26

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 12 of 18

6.2 CSA Component Acceptance Card (500mA and 1.25A)

2A is approved, but the card has not been updated

6.2.1 Marking The CSA symbol appears on the label affixed to the packaging container

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 27

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 13 of 18

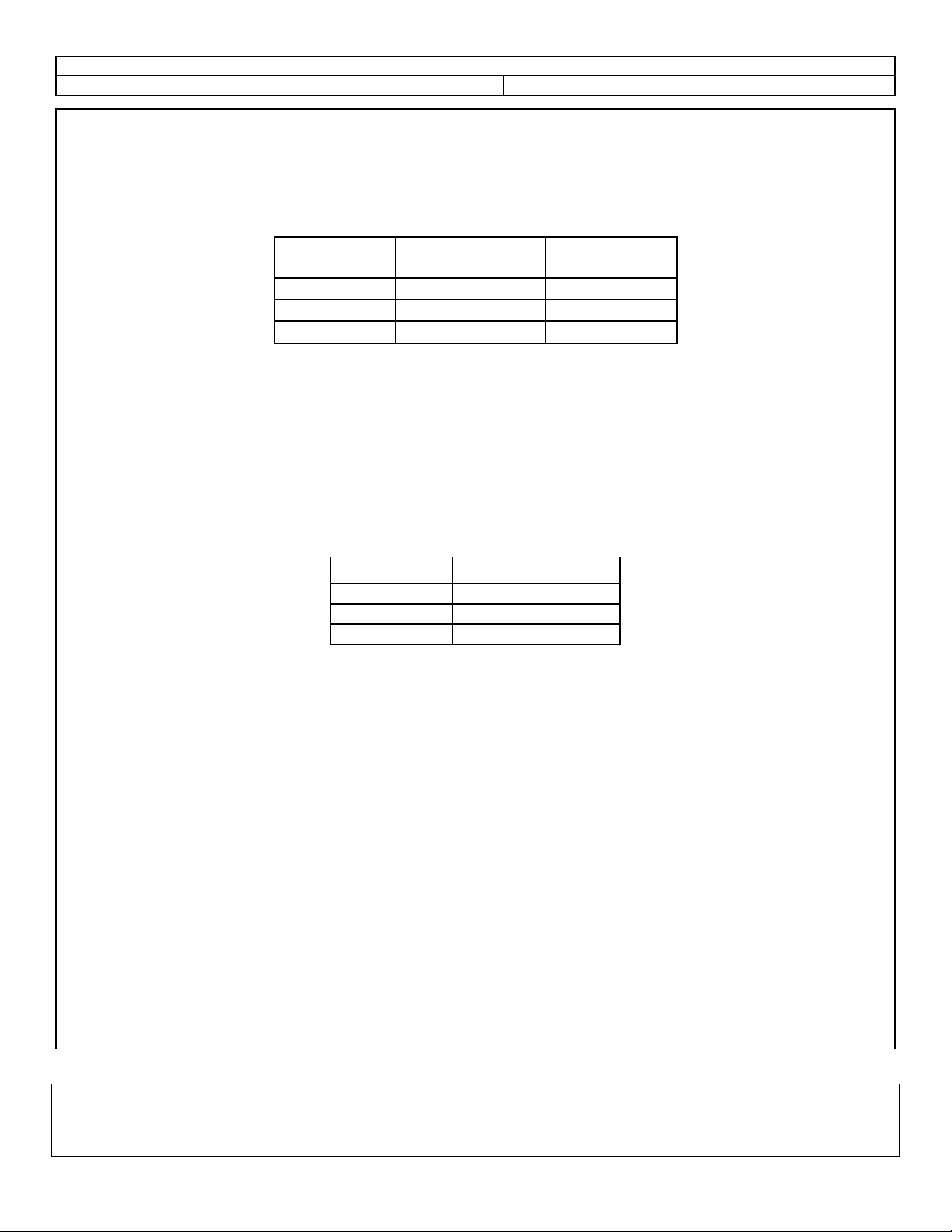

7. MARKING SPECIFICATION

7.1 A two letter alpha code will be marked on the body of the fuse.

The first letter will indicate the ampere rating. The second letter will indicate the manufacturing facility.

7.1.1 Table of alpha code marking

Am pere 1st pos i t ion Manufact uring 2nd posit i on

Rating alpha code Faci l it y Loc at i on alpha c ode

TCP500mA F USA u

TCP1.25A J Taiwan t

TCP2A N China s

Cos t a Rica c

7.1.2 Example of a TCP1.25A manufactured in the USA.

Ju

J = 1.25A

u = manufactured in USA

8. SOLDERING METHOD

8.1 Wave Immersion

8.1.1 Reservoir Temperature: 260° C (500°F)

8.1.2 Time in Reservoir: 3 Seconds Maximum

8.2 Infrared

8.2.1 Temperature: 240° C (464 °F)

8.2.2 Time: 30 Seconds Maximum

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 28

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 14 of 18

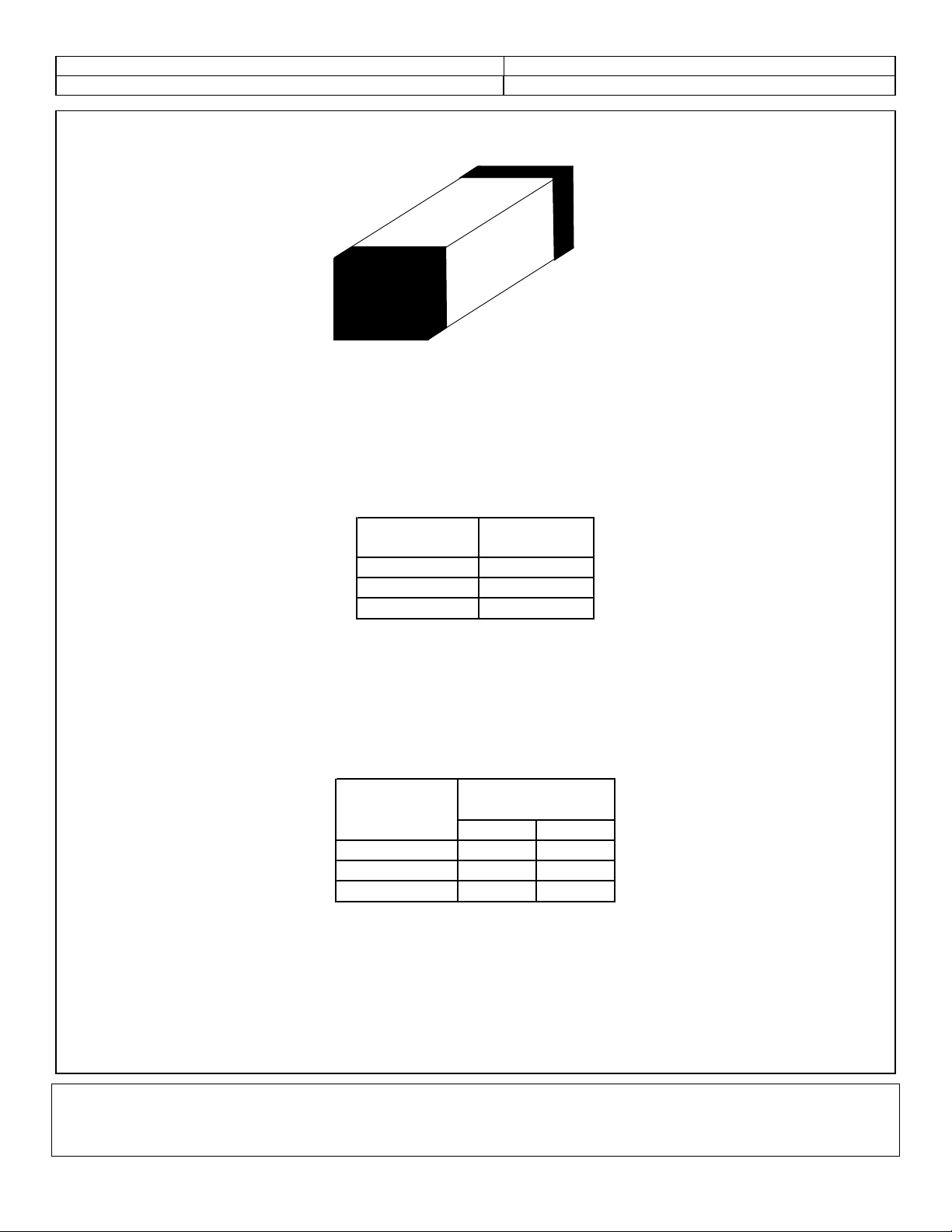

9. LAND PATTERN mm

(inches)

5.2 3.7

(0.204) (0.145)

4.0

(0.157)

12.6

(0.496)

10. TEMPERATURE DERATING CURVE

10.1 Normal Operating Temperature: 25°C ± 2°C (77 °F ± 3.6 °F)

10.2 Maximum Operating Temperature: -55°C to 125°C with proper correction factor applied

10.2.2 Chart of correction factor for TCP500mA and TCP1.25A

150

140

130

120

110

100

90

80

70

60

Percent of Rating

50

40

30

-55 -40 -20 0 20 40 60 80 100 125

Ambient °C

Effe ct o n Cur r ent

Rating

10.2.3 Chart of correction factor for TCP2A to be created

10.3 Storage Temperature: -55°C to 125°C (-67° F to 185°F)

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 29

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 15 of 18

11. PACKAGING SPECIFICATION

11.1 SP1/: 10 pieces of fuses on 24mm tape, 8 mm pitch per EIA Standard 481, packaged in a

plastic bag

11.2 SP2/: 50 pieces of fuses on 24mm tape, 8 mm pitch per EIA Standard 481, packaged in a

plastic box

11.3 TR1/: 1000 pieces of fuses on 24mm tape and reeled on a 13 inch (330 mm) reel per EIA

Standard 481, 8 mm pitch

11.4 TR2/: 2500 pieces of fuses on 24mm tape and reeled on a 13 inch (330 mm) reel per EIA

Standard 481, 8 mm pitch

12. PROCESS FLOW CHART

Purchase

Tubes

Purchase

End Plates

Clean End

Plates

Overcoat

Terminations

Test

and Pack Fu ses

Purchase

Wire (T)

Plate

Wire (T)

Purchase Ceramic

Yarn (T)

Wind Wire

Around Yarn (T)

Cut Element

To Length

Met allize

Tube Ends

Plate

Metalized

Ends’

Assemble Fu s e Compon ents

and Reflow Solder

Purchase

Solder Disk

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 30

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 16 of 18

13. ENVIRONMENTAL (RELIABILITIY / QUALIFICATION) DATA

13.1 Life Test:

MIL-STD-202, Method 108A, Test Condition D

13.2 Load Humidity Test:

MIL-STD-202, Method 103B except:

13.2.1 Environmental chamber 85%+

2% relative humidity at 85°C+2°C

13.2.2 100% of rated DC current, at any voltage less than or equal to rated voltage for 1000 hours

13.2.3 At 168h, 504h, and completion of test, the power is turned off. Resistance readings are taken

after temperature stabilization. Change in resistance from the original value is calculated

and recorded. ∆R<10%.

13.2.4 After 1000 hours is completed, samples are split into two equal lots.

13.2.5 One group is tested to the non-destructive 100% Current Carry Test. After current carry test is

complete, half of the samples are subjected to the Maximum Current Carry Test with the

remaining samples subjected to the Time Current Characteristic Curve Generation.

13.2.6 The other group is tested to the destructive Current Overload Test.

13.3 Moisture Resistance Test:

MIL-STD-202, Method 106E except:

13.3.1 Samples are placed in a temperature/moisture chamber and subjected to 50 cycles.

13.3.2 Temperature and humidity measurements are recorded at 0 cycles, 25 cycles, and 50 cycles.

13.3.3 At the completion of 50 cycles.

Samples are stabilized at 25°C+

5°C for a minimum of 15 minutes and a maximum of 24 hours.

The change in resistance from the original value is calculated and recorded. ∆R<10%,

13.3.4 One cycle is:

1) Start at 90-100% RH and 25°+

2) Ramp up to 65°C+

3) Remain at 65°C+

4) Ramp down to 25°C+

2°C within 2 ½ hours

2°C for 3 hours

2C within 2 ½ hours with 80-100% RH

5) Ramp back up to 65°C+

6) Remain at 65°C+

7) Ramp down to 25°C+

8) Remain at 25°C+

2°C for 3 hours

2°C within 2 ½ hours with 80-100% RH

2°C for 8 hours with 90-100% RH

2°C

2°C within 2 ½ hours with 90-100% RH

13.3.5 Samples are split into two equal lots

13.3.6 One set is tested to the non-destructive 100% Current Carry Test. After completion, the samples

are subjected to the Time Current Characteristic Curve Generation.

13.3.7 The other set is subjected to the destructive Current Overload Test

13.4 Terminal Strength Test:

Downward force is applied to cause a 1mm deflection for 1 minute (no physical evidence of mechanical

or physical damage, change in resistance < 5%)

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 31

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 17 of 18

13.5 Thermal Shock Test:

MIL-STD-202, Method 107D, air-to-air except:

13.5.1 Samples are placed in a temperature chamber and subjected to 200 air-to-air cycles of the

following:

1) Hold -55°C+

2) Transfer to 125°C+

2°C for 30+5 minutes

2°C within 0.5 minutes

3) Hold 125°C±2°C for 30±5 minutes

4) Transfer to -55°C±2°C within 0.5 minutes

5) Repeat cycle 200 times

13.5.2 At completion of 200 cycles, resistance readings taken after temperature stabilization (25°C±5°C

for 15 minutes minimum to 24 hours maximum)

13.5.3 Samples divided into two equal lots of twenty

13.5.4 One set is tested to the non-destructive 100% current carry test. After completion, the samples

are subjected to the Time Current Characteristic Curve Generation.

13.5.5 The other set is subjected to the destructive Current Overload Test.

13.6 Maximum Current Carry Test

13.6.1 Performed after the non-destructive Load Humidity and 100% Current Carry Tests (same samples

used)

13.6.2 At the completion of the 100% Current Carry Test, the current is increased by 10% of the current

rating of the fuse. Increase occurs every 15 minutes until the fuse opens. Temperature is

monitored constantly.

13.7 Case Resistance Test

EIS/IS-722

13.8 Resistance to Dissolution of Metallization Test

ANSI J-STD-002, Test D

13.9 Mechanical Shock Test

MIL-STD-202, Method 213B, Test Condition A, except:

13.9.1 Test boards mounted to a shock test fixture, which in turn was mounted to the table of the shock

machine.

13.9.2 Shock machine calibrated for the required shock pulse.

13.9.3 Samples subjected to eighteen impacts, three impacts in each of the three mutually

perpendicular axis. Each shock pulse approximated a half-sine wave shape with a magnitude

of 50 g’s for 11±1 milliseconds.

13.9.4 High frequency vibration test is performed after the mechanical shock test is completed.

After the high-frequency vibration test, the samples undergo the 100% current carry test and the

Current overload tests.

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Page 32

Title: Engineering Product Specification Telecom Circuit Protector Revision: L

Printed on: 7/14/2003 Sheet 18 of 18

13.10 High Frequency Vibration Test

MIL-STD-202, Method 204D, Test Condition D, except:

13.10.1 Test boards mounted to a shock test fixture, which in turn was mounted to the table of the shock

machine.

13.10.2 Samples subjected to a simple harmonic motion having an amplitude of 20g peak ± 20%.

13.10.3 Vibration frequency is varied logarithmically from 10 to 2,000 Hz.

13.10.4 Cycle is performed 12 times in each of the three mutually perpendicular directions.

13.10.5 At the completion of the last cycle, resistance readings are taken after temperature stabilization.

The change in resistance from the original value is calculated and recorded.

13.10.6 After the vibration test is completed, the samples undergo the non-destructive 100% current

carry test and then the destructive Current Overload Test.

13.11 Resistance to Solvents Test

MIL-STD-202, Method 215A

Note:

Due to the similarities of constructions for TCP1.25A and TCP2A, environmental tests were

performed on TCP1.25A only.

14. END

This bulletin is intended to clearly present c omprehensive product data and provide technical information that will help the end user with des i gn

applications. Bussmann reserves the right, without notic e, to change design or construction of any products and to discontinue or limi t distribution of

any products. Bussmann also reserves the right to change or update, without notice, any technical information contained in this bulletin. Onc e a

product has been selected, i t should be tested by the user in all possi bl e appl i cations.

Loading...

Loading...