Page 1

PH-12

Pipe Hangers & Supports

Beam Clamps, Pipe Hangers, Pipe Clamps, Pipe Rollers & Roller

Supports, Pipe Supports-Guides-Shields-Saddles, Seismic Fittings,

Upper Attachments, Threaded Accessories, Concrete Inserts,

Brackets, Vibra Trol

™

, Roof-Top Supports, KwikWire

™

Page 2

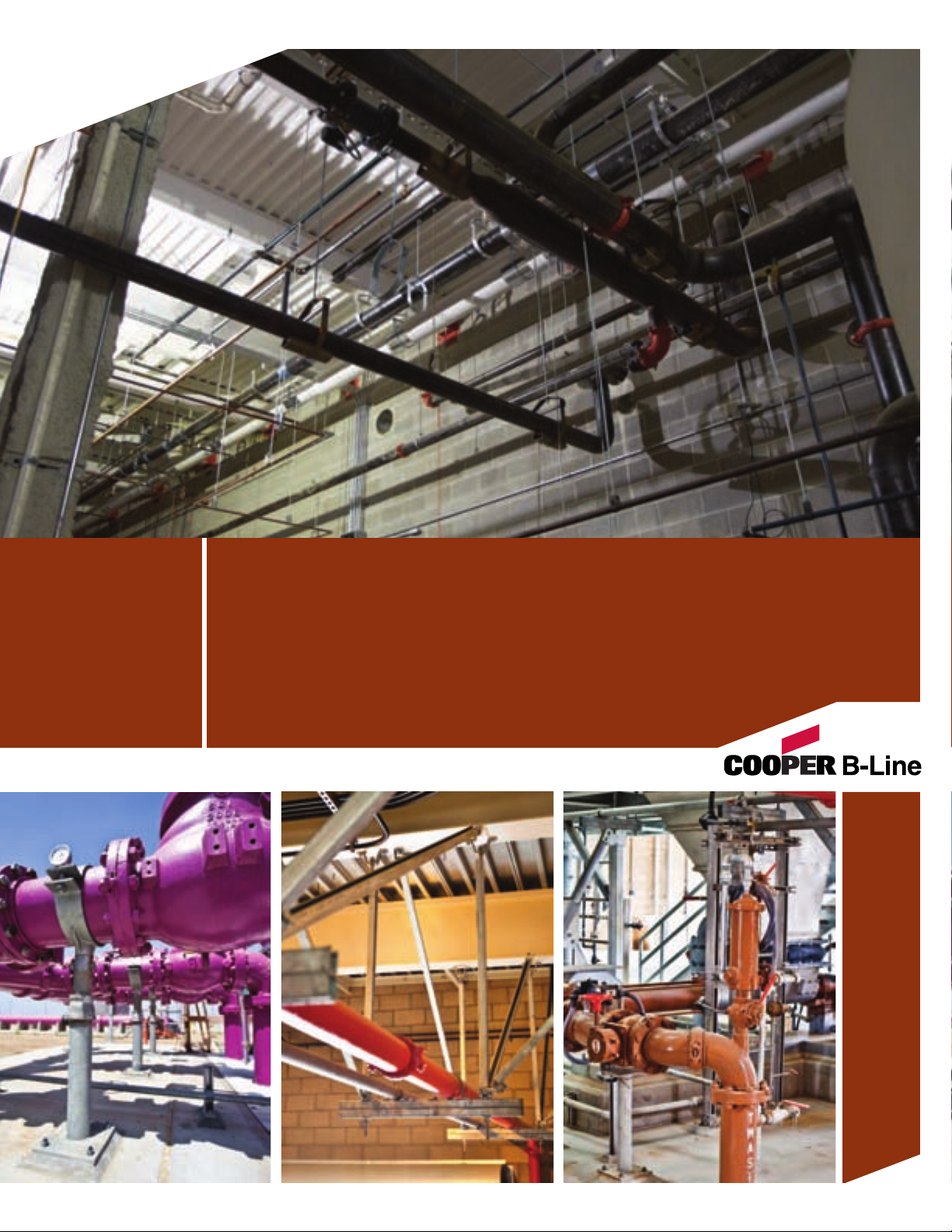

Introduction

Cooper B-Line™, Inc. is a leading manufacturer and fabricator of metal products used in the support of pipe

and equipment for industrial, residential, commercial, utility, and OEM installations. Cooper B-Line is proud

of the exacting standards of research, design, engineering, and manufacturing that go into each and every

product that comprise our pipe hanger product line. Our customers have access to the most complete

support systems offered in the industry, including pipe hangers, metal framing, cable tray, slotted angle,

seismic bracing, fasteners, telecom, enclosures and anchors.

Many of Cooper B-Line's products are listed by Underwriters' Laboratories, Inc. and FM Global approved for

fire sprinkler system installations. All Cooper B-Line products are manufactured to meet or exceed industry

standards set for their design and manufacture.

Cooper B-Line products are produced in five modern plants consisting of over 1,000,000 square feet. These

facilities are located in Highland, Illinois; Troy, Illinois; Reno, Nevada; Corona, California and Sherman, Texas.

Regional sales and distribution centers are located throughout the United States stocking standard Cooper

B-Line products for quick service and delivery.

This catalog is designed to be helpful to engineers and contractors in the application and selection of pipe

hangers, supports and seismic bracing for construction and maintenance.

If a unique application requires a special product not included in this catalog, Cooper B-Line engineering

personnel are ready to furnish design consultation and realistic material estimates. In addition, sales

representatives with engineering expertise are located throughout the United States and abroad for your

convenience.

WARNING

All hanger products in this catalog are intended for installation and service as illustrated or described. Do not

use them for any purposes other than those described in this catalog. Products that are used for unintended

purposes could fail, resulting in severe personal injury or death.

Examples of misapplications which could cause severe personal injury or death include, but are not limited to:

Using a beam clamp on a beam other than those described in the catalog;

•

• Using concrete inserts as anchors for pulling pipe up to the required elevation;

• Suspending clevis hangers, one under another, which could result in an accumulative load that is greater

than that which the pipe hanger will support.

Cooper B-Line pipe hanger and support products are manufactured in accordance with industry standards.

Our customers should exercise care to use these products properly so as to avoid potential accidents.

Contact Cooper B-Line for assistance with proper installation and use of the products in this catalog.

NOTICE

Cooper B-Line reserves the right to change the specifications, materials, equipment, prices or the

availability of products at any time without prior notice. While every effort has been made to assure the

accuracy of information contained in this catalog at the time of publication, Cooper B-Line is not

responsible for inaccuracies resulting from undetected errors or omissions.

SINCE

1924

Manufacturers Standardization Society

of the

Valve and Fitting Industry, Inc.

ISO 9001:2008

Cooper B-Line

509 West Monroe Street

Highland, Illinois 62249-0326

Phone: 800-851-7415

Fax: 618-654-1917 www.cooperbline.com

Page 3

Table of Contents

Pictorial Index ........................................................................... 3-15

Strut Systems Information

.......................................... 16-17

Technical Data

Materials & Corrosion

Finishes & General Information

Recommended Specifications

.......................................................... 18

.......................... 18-19

............................. 20-25

Beam Clamps

C-Clamps

Bottom Beam Clamps

Top Beam Clamps

Trus Joist & Angle Iron Beam Clamps

................................................................................ 27-33

................................................. 34-41

................................................................... 42

.......... 43-44

Pipe Hangers

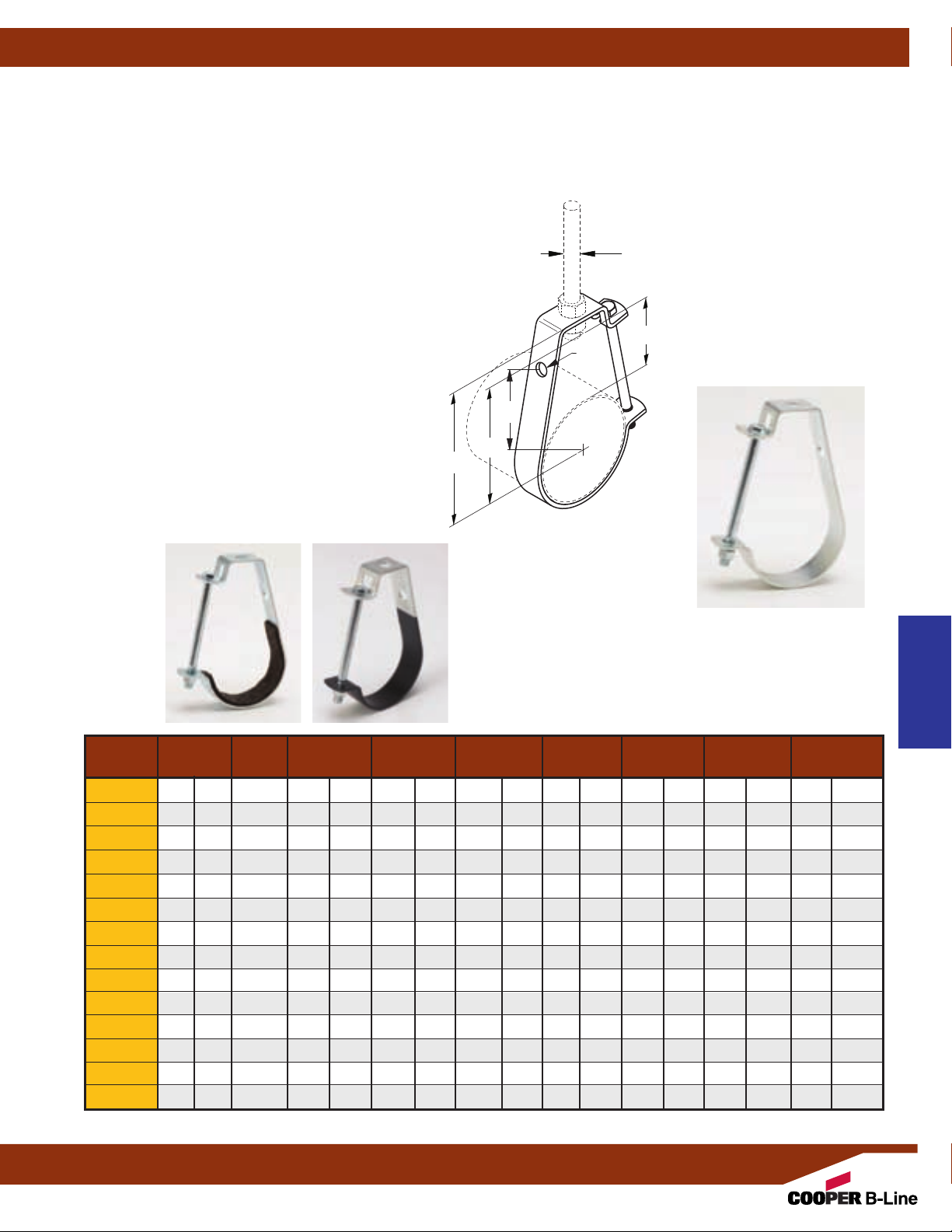

Clevis Hangers

‘J’ Hangers

Band Hangers

Split Clamps & Hangers, Rings

Wall Mount Lay-In Hangers

Wire Hangers

Spring Hangers

................................................................... 47-58

..................................................................................... 53

..................................................................... 59-62

................. 63-66, 72

............................................ 67

....................................................................... 68-70

.......................................................................... 71

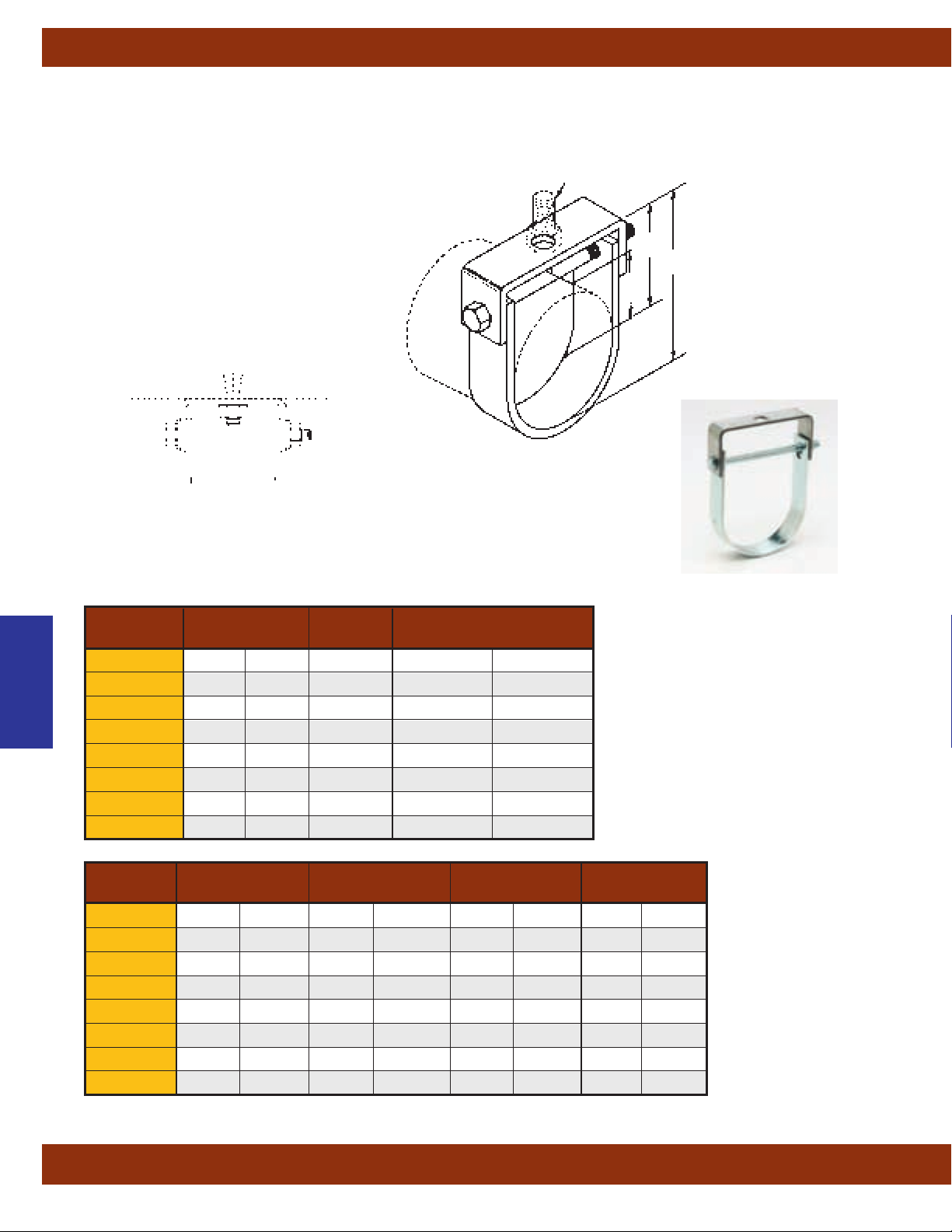

Pipe Clamps

Risers

Underground Clamps

Clamps

Straps

CPVC Hangers

Plastic KWIK-CLIP™

.......................................................................................... 75-76

................................................... 77-78

...................................................................................... 79-88

......................................................................................... 89-92

................................................................. 93-101

.............................................. 102-103

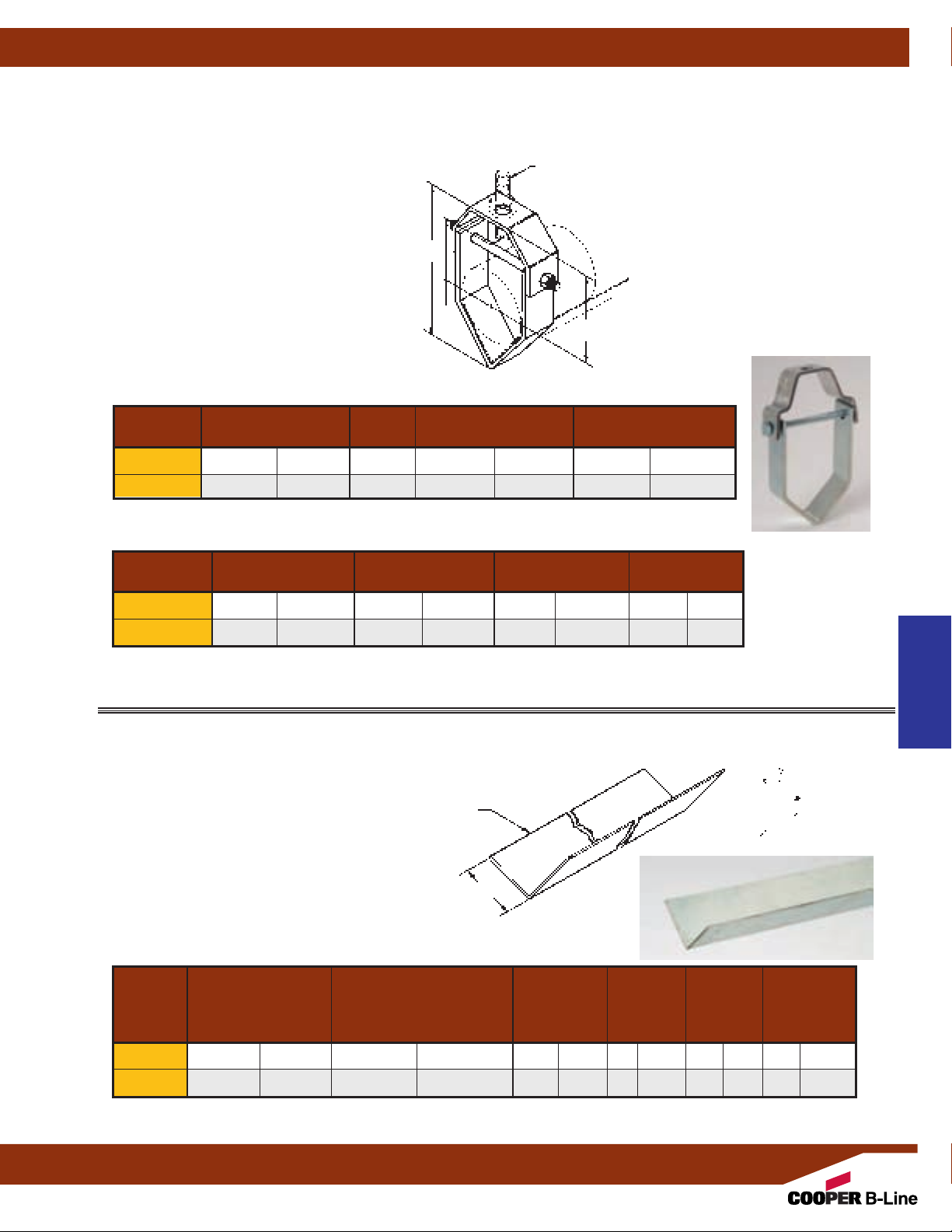

Pipe Rollers & Roller Supports

Roller Hangers

Roller Supports

Roller Stands

Spring Cushion Roller Hanger

Rollers

.................................................................................. 120-121

............................................................. 105-106

............................................................ 107-115

................................................................. 116-118

.................................. 119

Pipe Supports, Guides, Shields & Saddles

Calcium Silicate Shields

Stands & Supports

Isolators, Guides & Anchors

Slides, Shields, Saddles

................................................. 123

................................................... 124-138

............................ 139-145

....................................... 146-165

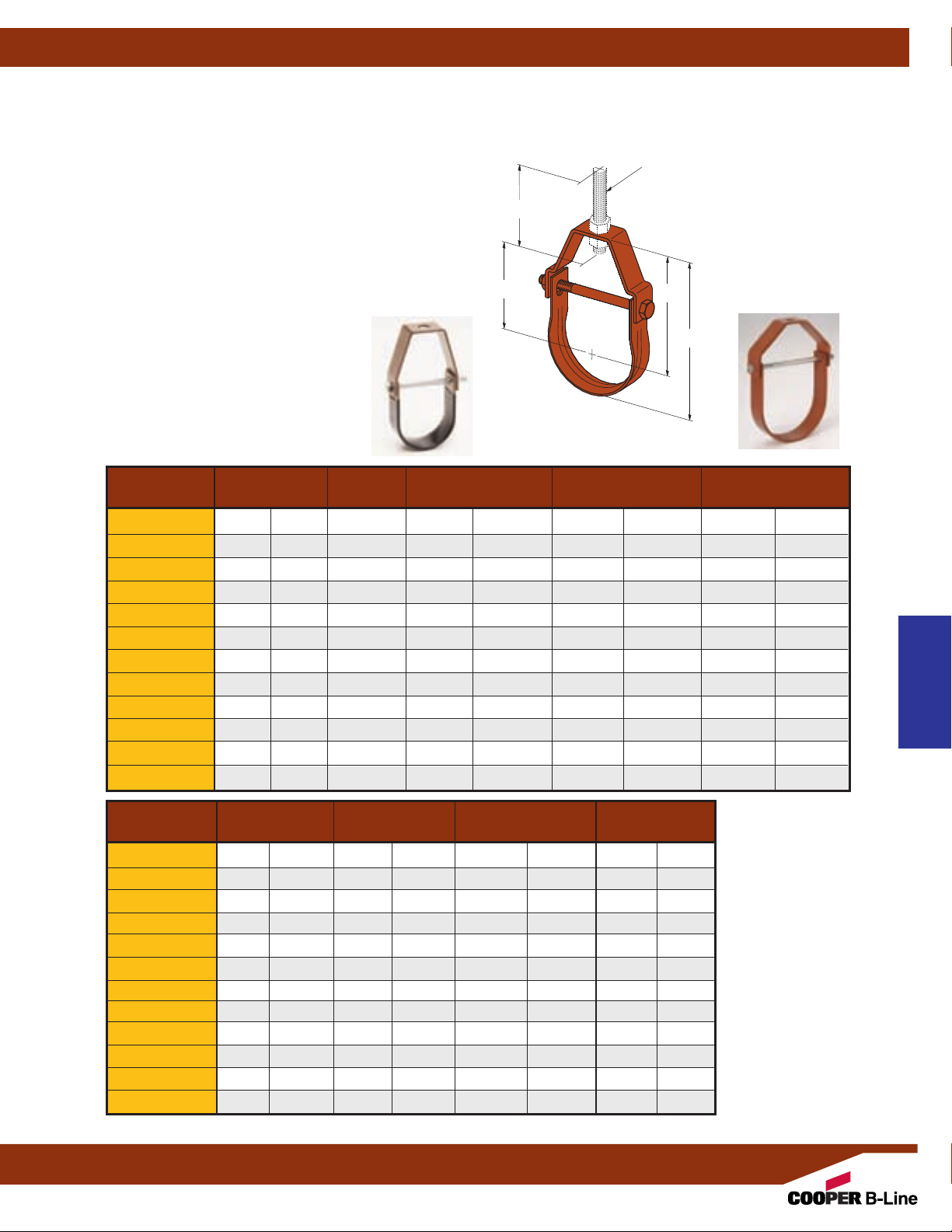

Seismic Bracing

Sway Bracing Pipe Clamps

Sway Bracing Attachments

Mechanical Fast Clamps

Cable Sway Brace Attachments

Sway Brace Main Pipe Attachments

.............................. 167-169

.............................. 170-180

.................................... 181-182

.................. 183-184

....... 185-187

Concrete Inserts

Concrete Deck Inserts

Spot Inserts & Insert Nuts

Continuous Concrete Inserts

Anchor Clips

.............................................................................. 200

.......................................... 189-190

................................. 191-196

.......................... 197-199

Brackets

Light Duty

Medium Duty

Heavy Duty

Brackets w/ U-Bolts

......................................................................... 203-205

............................................................................. 206

.................................................................................. 207

........................................................... 208

Upper Attachments

Ceiling Flange

Angle Supports

Swivel Attachment

Bolted & Welded

Concrete Plates

Rod Beam Attachments

.......................................................................... 211

............................................................ 212-215

............................................................... 216

......................................................... 217-219

........................................................... 220-222

.................................................. 223

Threaded Accessories

Eye Sockets & Nuts

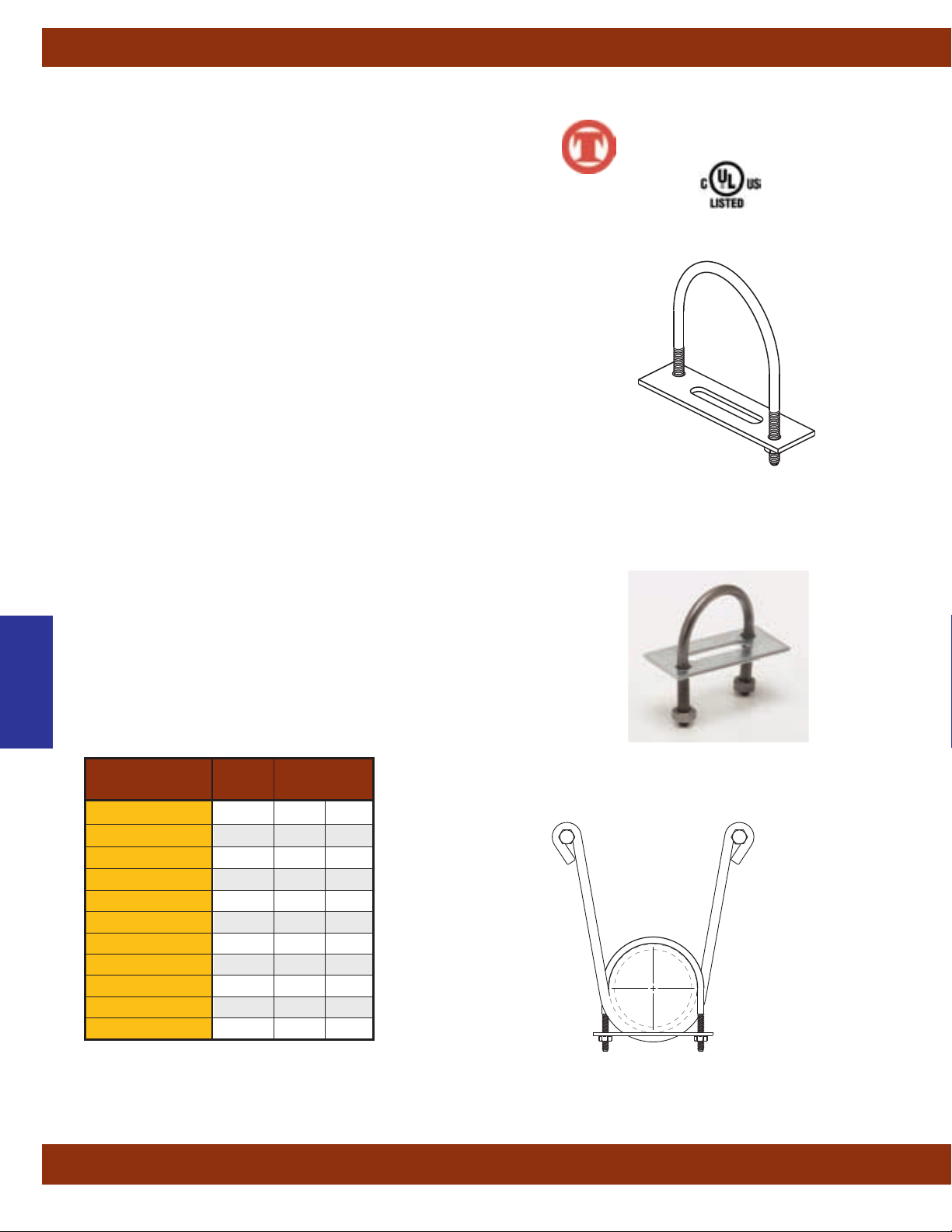

U-Bolts

................................................................................ 227-229

Miscellaneous Accessories

Rods, Couplings, Washers & Hardware

Vibra Trol

™

................................................. 225-226

.............................. 230-232

.......... 233-244

Pads ....................................................................................... 248-250

Molded Mounts

Cup Mounts

Spring Mounts

Vibration Hangers

Spring Hangers

VibraClamp

Isolation Products

DURA-BLOK

....................................................................... 250

................................................................................ 251

.............................................................. 252-257

...................................................... 258-259

............................................................ 260-266

™

.................................................................. 267-268

................................................................ 269

™

Base .................................................................................................. 271

Base & Channel

Base & Clamp Riser

Base & Harness

Base & Rollers

Base Stand

Load Distribution Plate

KwikWire

™

........................................................... 272-274

........................................................... 275

........................................................... 276-277

.............................................................. 278-279

.................................................................................. 279

.................................................... 280

Clamps ........................................................................................... 283

Wire Rope

KwikPak

Cable Cutter

KwikWire Hangers

.................................................................................... 283

™

Kits ......................................................................... 284

.............................................................................. 284

............................................................... 285

Accessories

(Loop, Hook, Bracket Termination)

........ 286-290

Reference Data

Metric Conversions

............................................................. 292

Miscellaneous Charts

Piping, Tubing, Threaded Rod, etc.

......... 293-303

MSS & Federal Specifications to

B-Line Cross References

B-Line Compliances & Approvals

Trapeze Hanger Chart

.............................. 304-305

............... 306-307

...................................................... 308

Cross References

TOLCO to Cooper B-Line

Cooper B-Line to TOLCO

Anvil/Grinnell to

Erico to

PHD to

Cooper B-Line/TOLCO

Cooper B-Line/TOLCO

Super Strut to

Cooper B-Line/TOLCO

Cooper B-Line/TOLCO

C & P* to Cooper B-Line/TOLCO

Empire to

Cooper B-Line/TOLCO

......................................... 309

.............................. 310-311

........ 312

............................. 313

............................... 314

............. 315

............................... 316

........................ 317

Index ........................................................... 318-320

* C & P is Carpenter & Paterson

1

Page 4

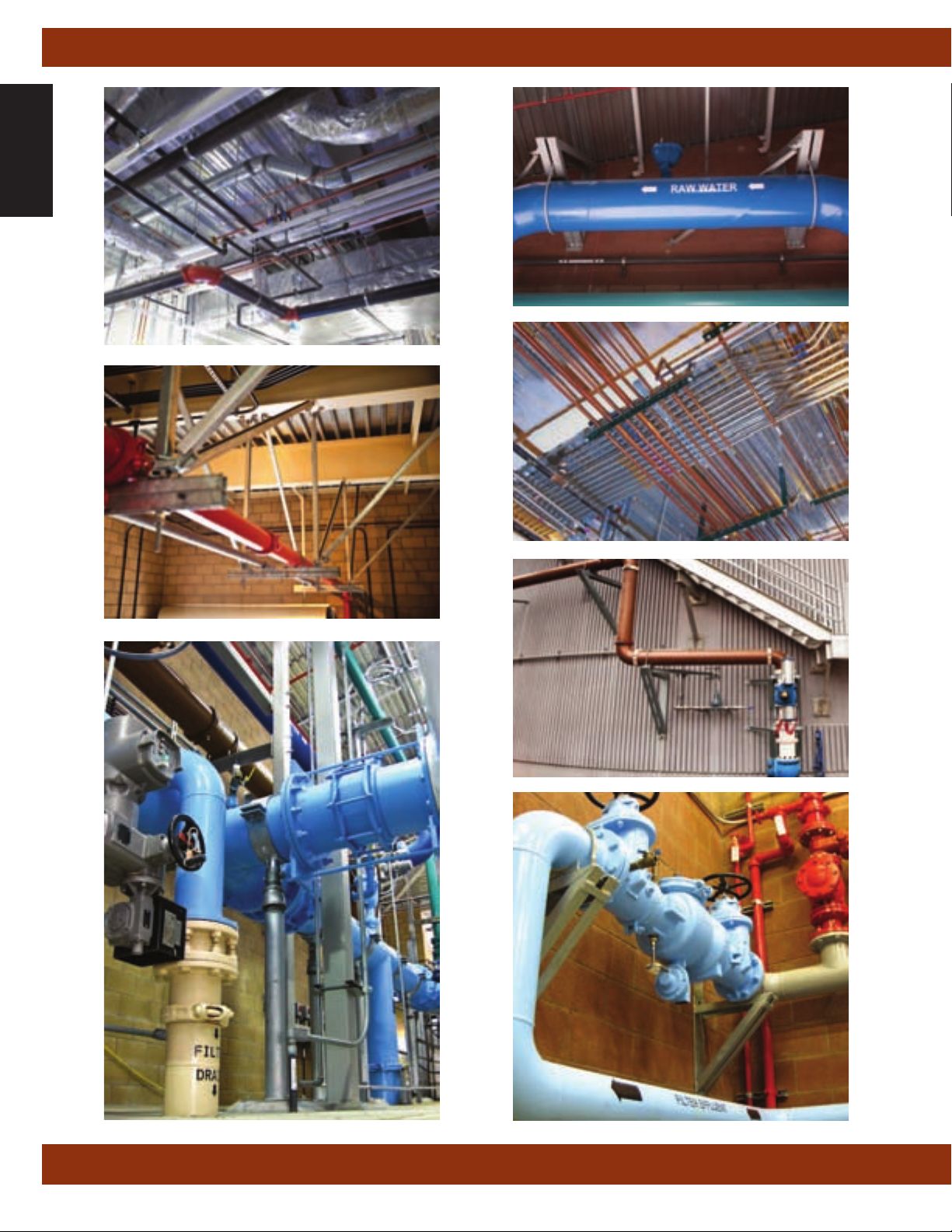

Application Photos

Pictorial Index

2

Page 5

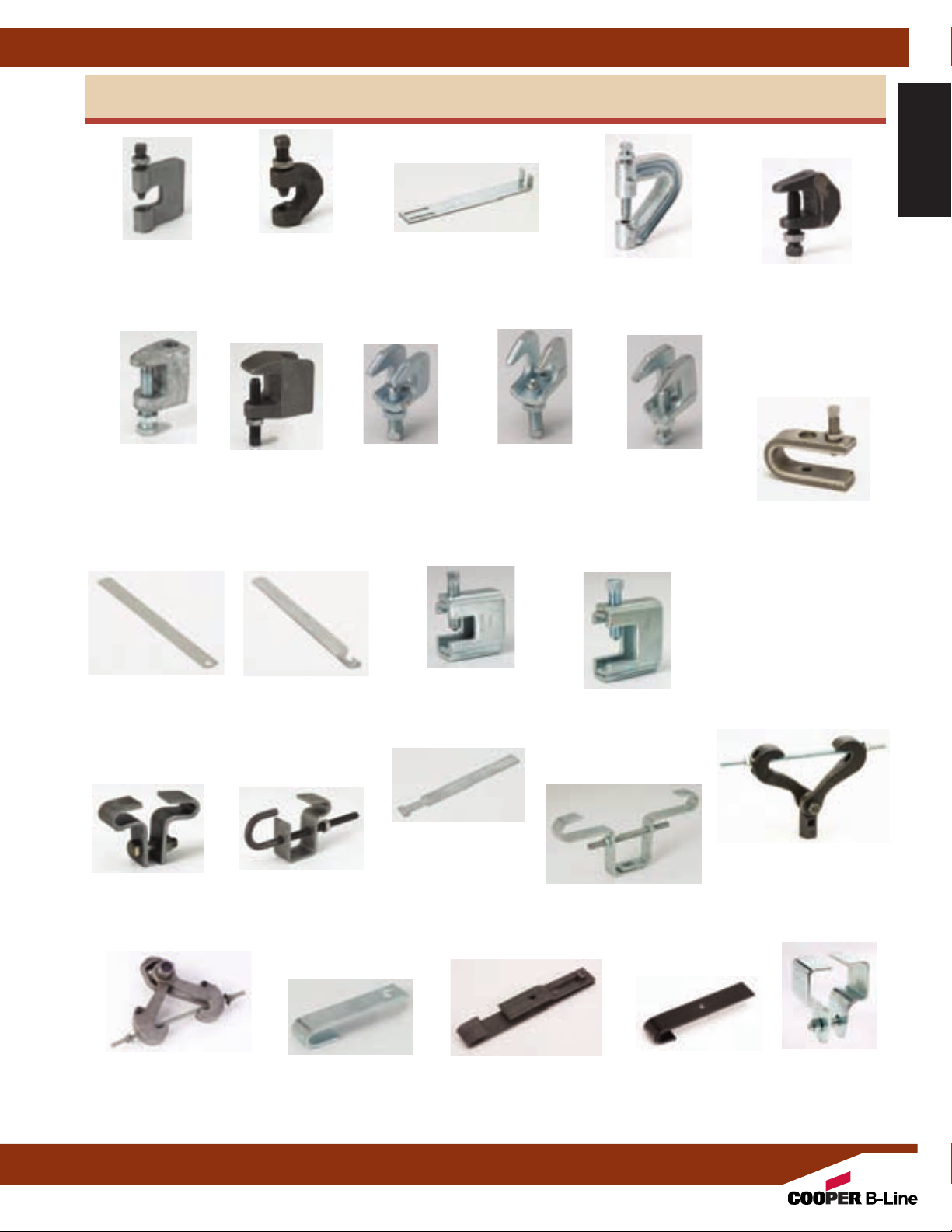

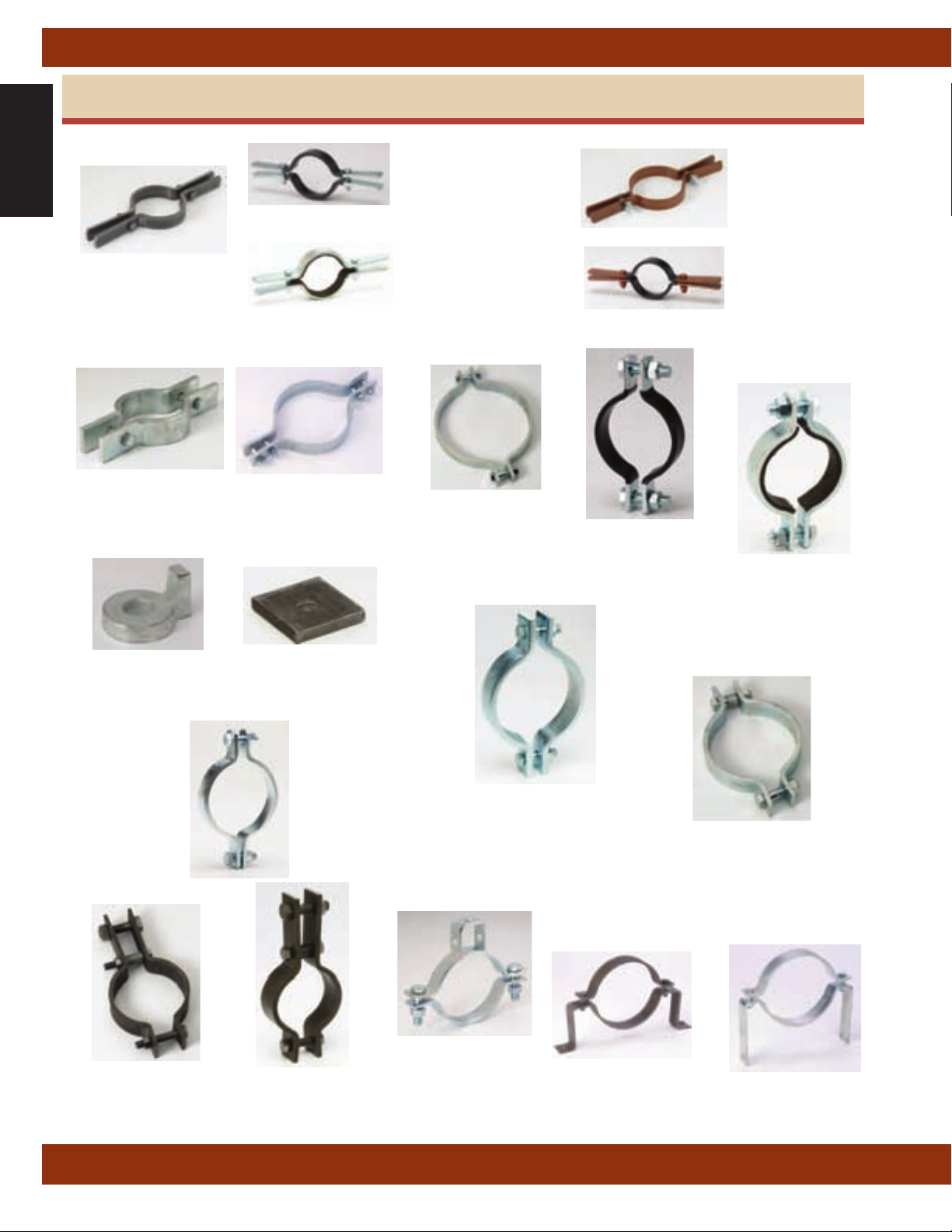

Beam Clamps

Pictorial Index

Pictorial Index

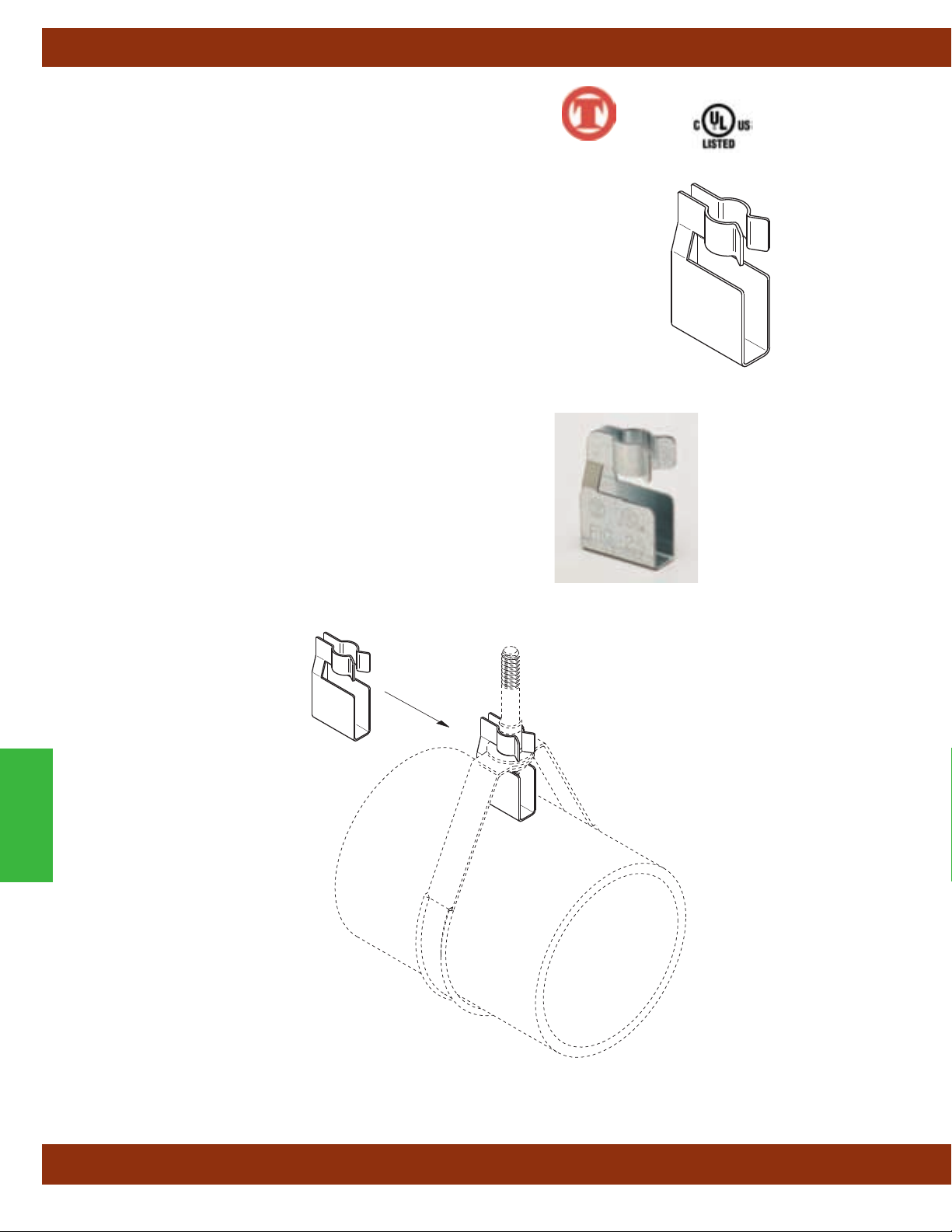

Figure B351L

Steel C-Clamp

With Locknut

Page 27

Figure B3033

Wide Jaw

Top Flange

C-Clamp

Page 29

Figure 69

Retaining Strap

Page 35

Figure B3036L

Malleable Iron

C-Clamp

With Locknut

Page 27

Figure B3034

Top Flange

C-Clamp

Page 30

Figure 69R

Retrofit

Retaining Strap

Page 36

B3362 thru B3365

Retaining Strap

Figure 65

Reversible

Steel C-Clamp

With Locknut

3

/4” Throat

Page 31

Figure B303-B309

Beam Clamp

Figure

Page 28

Figure 65XT-3/8

Steel C-Clamp

With Locknut

Page 34

Reversible

3

/4” Throat

Page 31

Figure B3037

Z-Purlin Beam Clamp

Page 28

Figure 66

Reversible

Steel C-Clamp

With Locknut

1

/4” Throat

1

Page 32

Figure B321 Series

Beam Clamp

Page 34

Figure B3031-3/8

Light Duty

Malleable C-Clamp

Page 29

Figure 67SS

3

(

/4” Throat)

Figure 68SS

1

(1

/4” Throat)

Reversible

Stainless Steel

C-Clamp

With Locknut

Page 33

Figure B3050

Beam Clamp

Page 38

Figure B3291 thru B3298

UFS Forged Steel

Beam Clamp

Page 41

Adjustable Beam Clamp

Figure B3040

Page 38

Figure B3042

Top Beam Clamp

Page 42

Figure B312

Retaining Strap

Page 37

Figure B3045

Side Beam Clamp

3

Page 42

Figure B3055

Steel Beam Clamp

Page 39

Figure B3042T

Bar Joist Hanger

Page 43

Figure B3054

Malleable Iron

Beam Clamp

Page 40

Figure B3052

Trus Joist

Beam Clamp

Page 44

Page 6

Pictorial Index

Pictorial Index

Figure 1CBS

Clevis Pipe Spacer

Figure B3690

Adjustable 'J'

Hanger

Page 53

PIPE HANGERS (Continued)

Figure B3102

AWWA

Clevis Hanger

Page 50

✸

Figure B3690C

Plastic Coated

Adjustable 'J' Hanger

Page 53

Page 47

Figure B3100

Standard

Clevis Hanger

Pages 48 & 49

Figure B3690F

Felt Lined

Adjustable 'J' Hanger

Page 53

Figure B3108

Extended

Clevis Hanger

Page 51

Figure B3109

Flat Top Clevis

Hanger

Page 54

Figure B3100C

Plastic Coated

Standard

Clevis Hanger

Page 52

Figure B3106

Vee Bottom

Clevis Hanger

Page 55

Figure B3100F

Felt Lined

Standard

Clevis Hanger

Page 52

Figure B3106V

Plastic Pipe

Support Channel

Page 55

Figure B3104

Light Duty

Clevis Hanger

Page 56

Adjustable Band Hanger

Figure B3104F

Clevis Hanger

✸

Figure B3170

Page 59

Felt Lined

Light Duty

Page 56

✸ Available in DURA-GREEN

Figure B3104C

Plastic Coated

Light Duty

Clevis Hanger

Page 56

Figure B3170F

Felt Lined

Adjustable Band Hanger

Page 59

◆ DURA-COPPER

™

Finish (Other hangers may be available with the DURA-GREEN finish, contact factory)

Figure B3104CT

Copper Tubing

Light Duty Clevis

Hanger

Page 57

Adjustable Swivel Ring

™

Finish

Figure B3104CTC

Plastic Coated

Copper T

Light Duty Clevis

◆

Figure B3170CT

Copper Tubing

Page 60

Hanger

Page 57

◆

ubing

Figure B3100U

Ultra Clevis Hanger

◆

Figure B3170CTC

Copper Tubing

Plastic Coated

Adjustable Swivel Ring

Page 60

Page 58

4

◆

Page 7

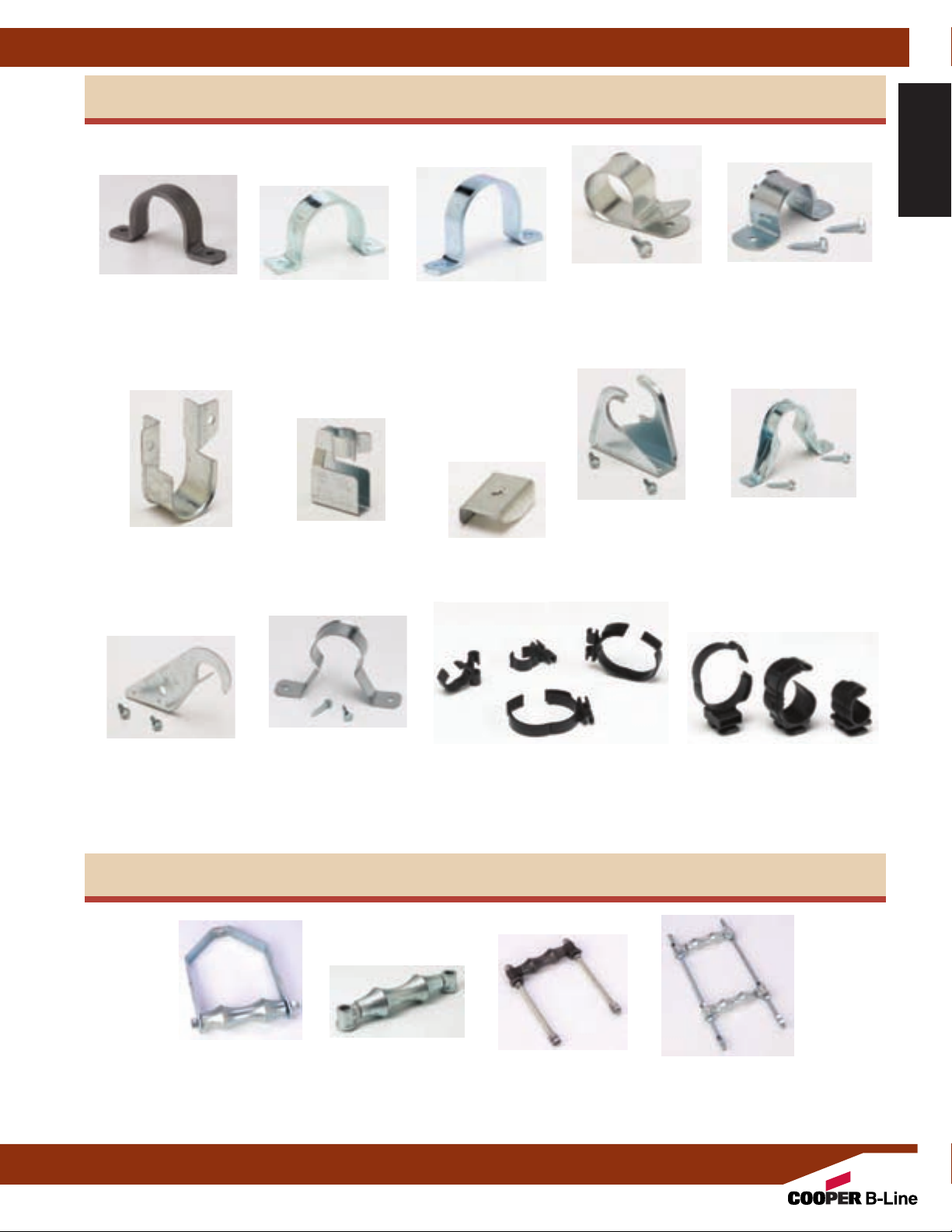

PIPE HANGERS (Continued)

Pictorial Index

Trimline Adjustable

Figure 200F

Felt Lined

rimline Adjustable

T

Band Hanger

Page 61

Figure 200

Band Hanger

Page 61

Figure 200C

Plastic Coated

rimline Adjustable

T

Band Hanger

Page 61

Figure B3198H

Hinged Extension

Split Pipe Clamp

Page 63

Figure B3198HCT

Copper Tubing

Hinged Extension

Split Pipe Clamp

Page 63

◆

Figure 200 H

Heavy Duty

Band Hanger

Page 62

Figure B3198R

Extension

Split Pipe Clamp

Page 64

Figure B3198RCT

Copper Tubing

Extension

Split Pipe Clamp

Page 64

◆

Pictorial Index

Figure B3175

Ring and Bolt Hanger

Page 65

Figure 120

‘U’ Hanger

Page 68

Parallel Strap Hanger

Figure B3175CT

Copper Tubing

Ring and Bolt Hanger

Figure 120MF

Mutt & Jeff

Hanger

‘U’

Page 69

Figure BH-2-4

BH-5-8

BH-9-12

Page 72

Page 65

◆

Figure B3171

Adjustable Split

Ring Swivel Hanger

Page 66

Figure 120W

Wrap Around

Hanger

‘U’

Page 69

Figure BH-2-4-R

BH-5-8-R

BH-9-12-R

Right Angle Strap Hanger

Page 72

Figure B3190

Offset 'J' Hook

Page 67

Figure 120RWA

Retrofit Wrap Around

“u Hanger Clamp

Page 70

Figure B3191

Straight 'J' Hook

Page 67

Figure B3262

Light Duty

Spring Hanger

Page 71

Figure BL1400

thru BL1490

Hanger

Page 72

◆ DURA-COPPER

5

™

Finish

Page 8

Pictorial Index

Pictorial Index

Figure B3373

Standard Riser Clamp

Figure B3132

Two-Bolt

Underground Clamp

Page 77

PIPE CLAMPS

Page 75

Figure B3134

Underground Clamp

Four-Bolt

Page 78

Figure B3373C

Plastic Coated

Standard Riser Clamp

Page 75

Figure B3373F

Felt Lined

Standard Riser Clamp

Page 75

Figure B3140

Standard Pipe Clamp

Page 79

Figure B3140C

Plastic Coated

Standard Pipe Clamp

Page 79

Figure B3373CT

Page 76

Page 76

Page 79

ubing

◆

◆

Copper T

Riser Clamp

Figure B3373CTC

Copper Tubing

Plastic Coated

Riser Clamp

Figure B3140F

Felt Lined

Standard Pipe Clamp

Figure B3132W

Lug Washer

Page 77

Figure B3146

Heavy Duty Double

Bolt Pipe Clamp

Page 83

Figure B3134W

Washer

Page 78

Figure 4A

Pipe Clamp for

Sway Bracing

Page 80

Figure B3144

Double Bolt Pipe Clamp

Pages 84 & 85

Figure B3141

A.W.W.A. Pipe Clamp

Figure 4B

Pipe Clamp For

Sway Bracing

Page 86

◆ DURA-COPPER

Page 81

™

Finish

Figure B3148

Offset Pipe Clamp

Page 87

Figure B3142

Heavy Duty Pipe Clamp

Page 82

Figure B3149

Marine Hanger

Page 88

6

Page 9

PIPE CLAMPS (Continued)

Pictorial Index

Pictorial Index

Figure B3180FL

Flush Mount

Pipe Strap

Page 89

Figure 24

Double Fastener

Side Mounted

CPVC Strap

Page 95

Figure B2400

Standard Pipe Strap

Pages 90-91

Figure 25

Surge Restrainer

Page 96

Figure B3180

Extended Leg

Pipe Strap

Page 92

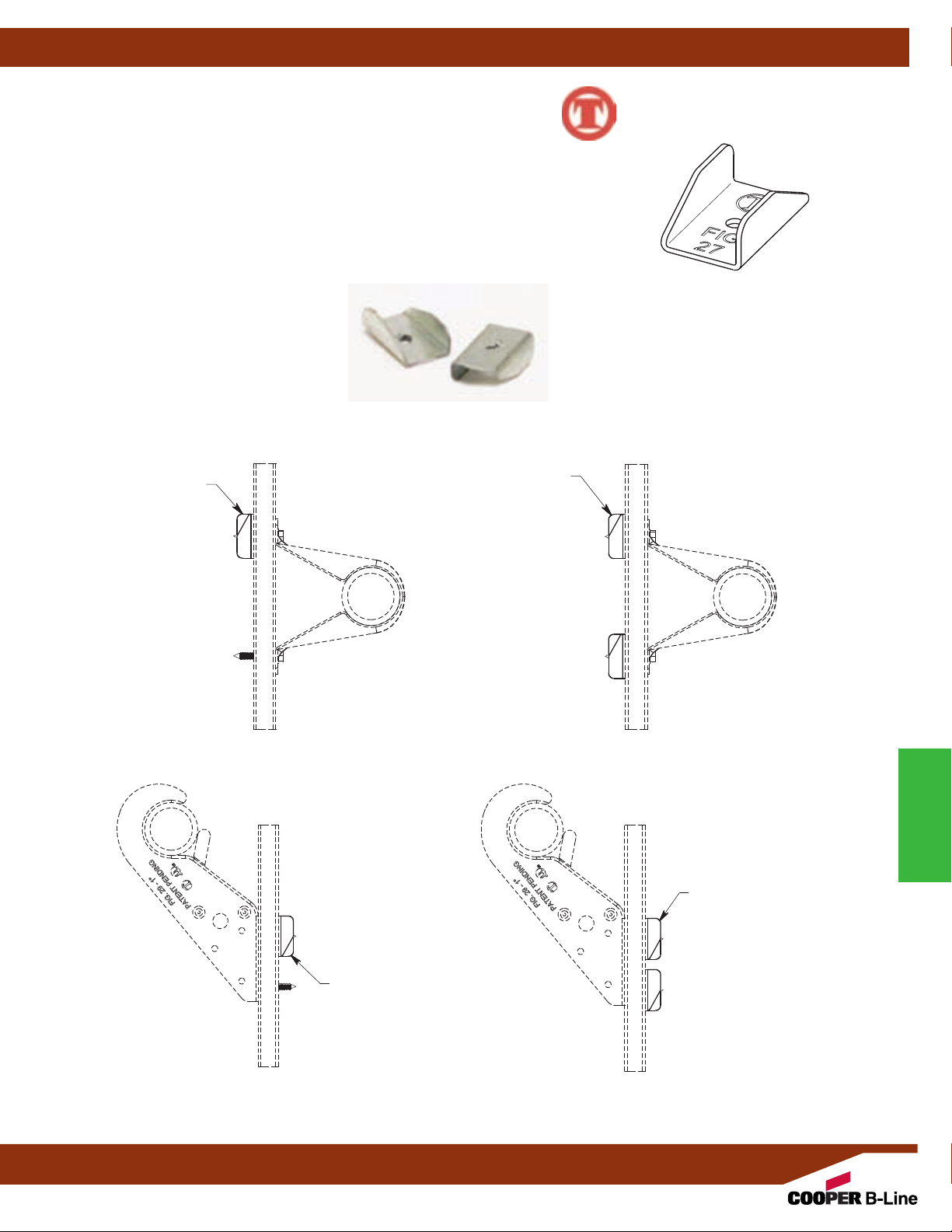

Figure 27

Speed Nut

Page 97

Figure 22

Single Fastener

CPVC Strap

Page 93

Figure 28

Stand-Off Hanger &

Restrainer for

CPVC Pipe

Page 98

Figure 23

Double Fastener

Strap

CPVC

Page 94

Figure 28M

Offset Hanger &

Restrainer for

CPVC & IPS Pipe

Page 99

Figure 29

Double Offset

Hanger & Restrainer

for CPVC Pipe

Page 100

Figure B3184

Light Duty

fset Hanger &

Of

Restrainer for

CPVC & IPS Pipe

Page 101

Figure BPRC Series

PIPE ROLLERS & ROLLER SUPPORTS

Figure B3110

Adjustable Steel

Yoke Pipe Roll

Page 105

✸

Figure B3114

Pipe Roll With Sockets

Page 106

✸ Available in DURA-GREEN

7

Rod Mount

KWIK-CLIP

Page 102

Figure B3122

Adjustable Roller Support

Page 107

™

Finish

Figure BPIC Series

Figure BPSC Series

Channel Mount

KWIK-CLIP

Page 103

Figure B3122A

Adjustable Double

Roller Guide

Page 108

Page 10

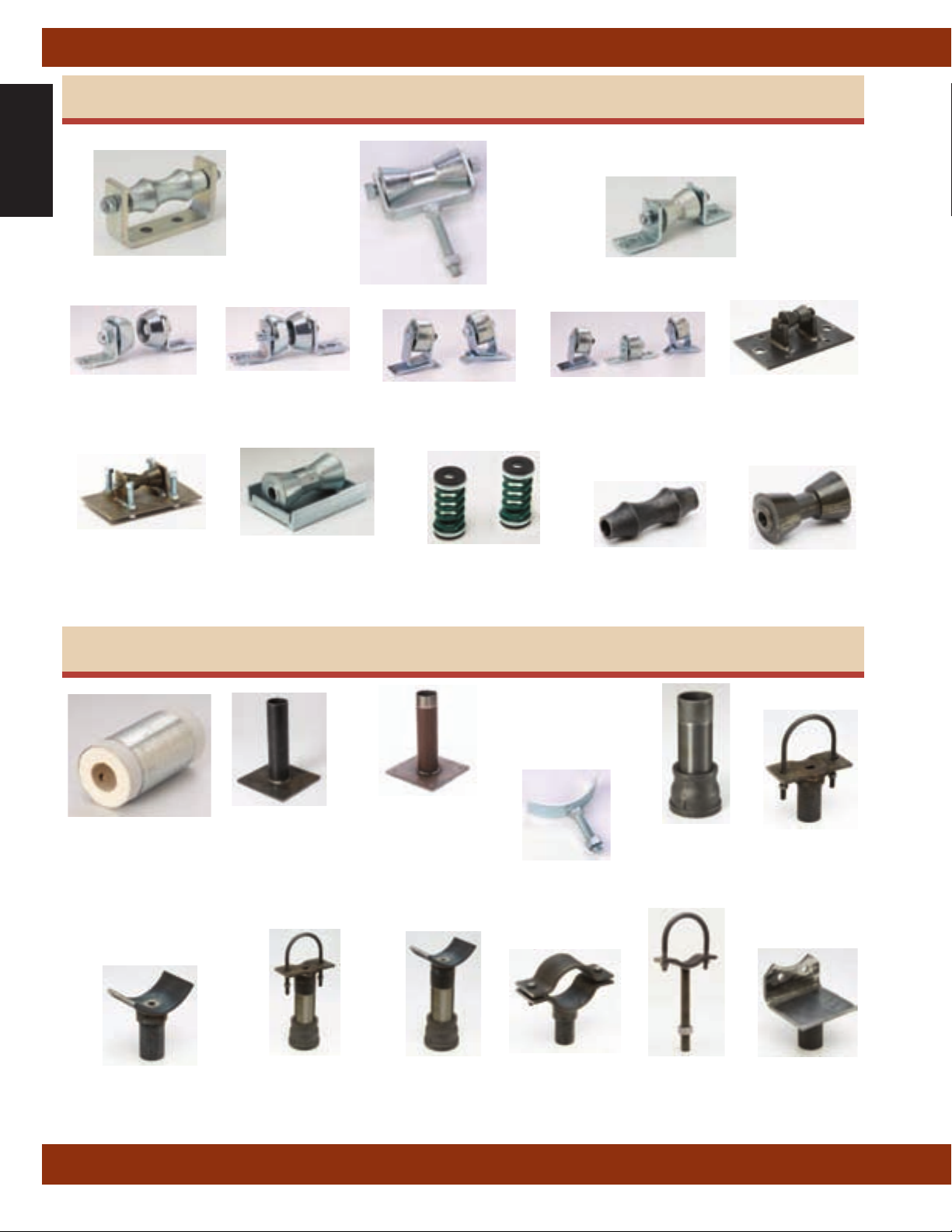

Pictorial Index

Pictorial Index

Adjustable Roller Stand

PIPE ROLLERS & ROLLER SUPPORTS (Continued)

Figure B218

Pipe Rollers

Page 1

Figure B3118SL

With Base Plate

Page 117

12

Figure

B3120

Roller Chair

Page 109

Figure B219

Pipe Rollers

Page 1

Figure B3119SL

Roller With Steel

Base Plate

Page 1

13

18

Figure B3124

Roller Support

Page 1

Figure B379

Pipe Rollers

14

Page 1

Figure B3264

Spring Cushion Hanger

19

Page 1

10

Figure B479

Pipe Rollers

Page 1

Figure B3114R

Long Pipe Roll Only

Page 120

15

Figure B3126

Roller Support

11

Page 1

Figure B3117SL

Steel Roller Stand

16

Page 1

Figure B3117R

Short Pipe Roll Only

Page 121

PIPE SUPPORTS, GUIDES, SHIELDS & SADDLES

Figure B3088T

Threaded Base Stand

Figure B3088ST

Seismic Threaded

Base Stand

Pages 124 & 125

Figure B3093

Adjustable Pipe

Saddle Support

Pages 134 & 135

Figure B3096

Adjustable Pipe

Saddle Support

Page 126

Figure B3097

Pipe Saddle

With Strap

Page 136

Figure B3380

thru B3384

360° Calcium

Silicate Shield

Page 123

Figure B3095

Pipe Saddle Support

Pages 130 & 131

Figure B3088

Base Stand

Figure B3088S

Seismic Base Stand

Pages 124 & 125

Figure B3092

Adjustable Pipe Saddle

Support With Yoke

Pages 132 & 133

Figure B3089

Pipe Support

Adjuster

Page 127

Figure B3098

Adjustable Pipe

Support w/U-Bolt

Page 137

Figure B3090

Pipe Saddle

Support

With U-Bolt

Pages 128 & 129

Figure B3094

Flange Support

Page 138

8

Page 11

Pictorial Index

PIPE SUPPORTS, GUIDES, SHIELDS & SADDLES (Continued)

Figure B3256

Hold-Down

Anchor Clamp

Page 144

Figure B3151

Insulation

Protection Shield

Page 161

Figure B3195

I.P.S. Isolator

Figure B3195CT

Copper Tubing

Isolator

Page 139

Figure B3257

Base Plate

Page 145

Figure B3153

Insulation Protection

Shield With

Page 161

Tabs

Figure B2417

Pipe Guides

Page 142

Figure B3154

Short Insulation

Protection Shield

Page 162

Figure B3891 thru B3897

Pipe Slides

Pages 146 - 149

Figure B3155

Short Insulation

Protection Shield

abs

With T

Page 162

Figure B3281

thru B3287

Pipe Alignment

Guide

Pages

140 & 141

Figure B3991 thru

B3993

Pipe Slides

Pages 150 - 153

Figure BPH Series

Snap N’Shield

Page 163

Clevis

Figure B3147A

Figure B3147B

Anchor Chairs

Pages 142 & 143

Figure B3160 thru

B3165

Pipe Covering

Protection Saddle

Pages 154 - 159

Figure BPS Series

Snap N’Shield

Pages 164 & 165

Pictorial Index

SEISMIC BRACING

Figure 4B

Pipe Clamp For

Figure 4A

Pipe Clamp For

Sway Bracing

Page 167

Figure 825A

Bar Joist Sway

Brace Attachment

Page 172

Sway Bracing

Universal Sway

Brace Attachment

Page 168

Figure 828

Page 173

Figure 4L

Longitudinal “In-Line”

Sway Brace

Attachment

Page 169

Figure 906

Sway Brace Multi-

Fastener Adaptor

Page 174

Figure 800

Adjustable Sway

Brace Attachment

o Steel

T

Page 170

Figure 907

4-Way

Longitudinal Sway

Brace Attachment

Page 175

Figure 825

Bar Joist Sway

Brace Attachment

Page 171

Figure 909

No-Thread Swivel

Sway Brace

Attachment

Page 176

9

Page 12

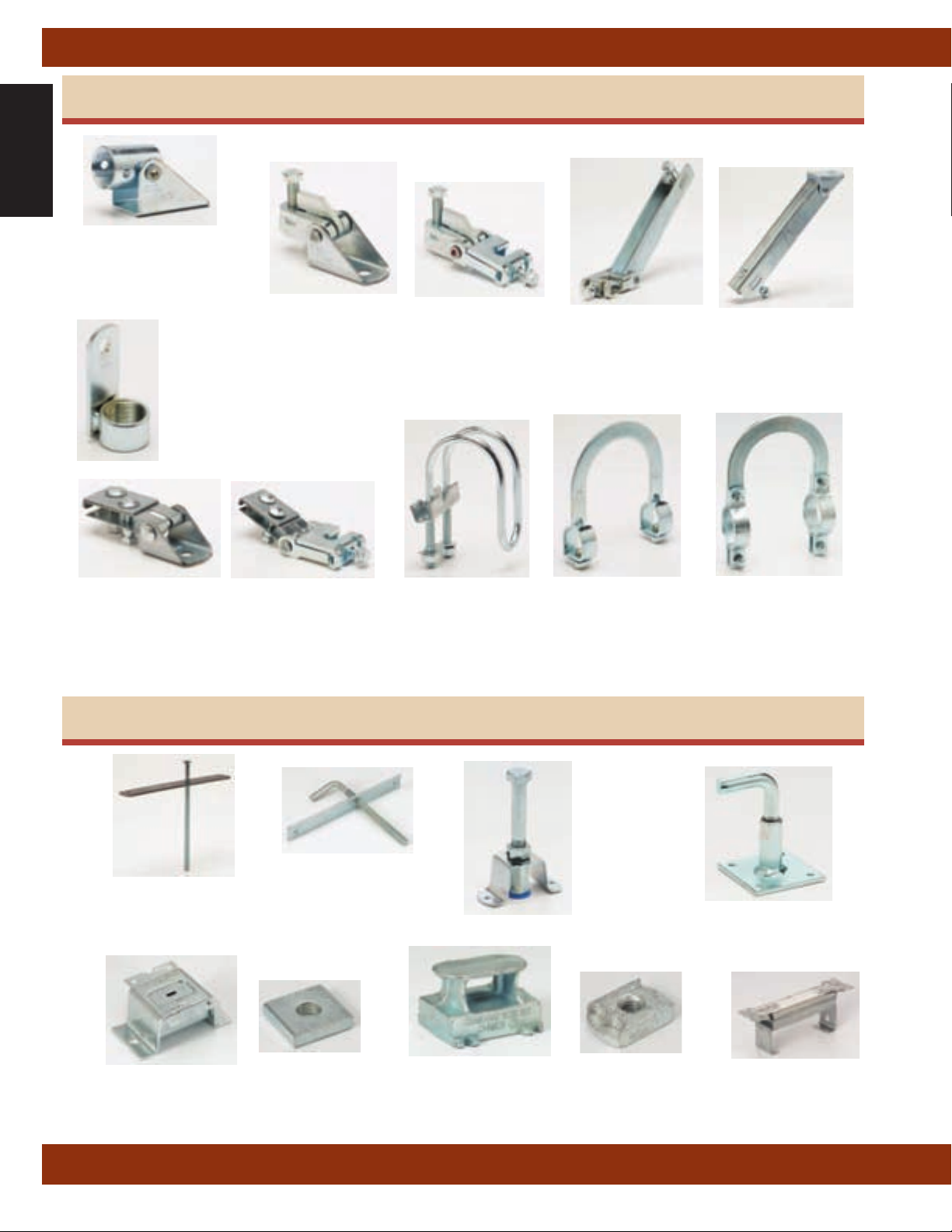

Pictorial Index

Pictorial Index

Swivel Sway Brace

SEISMIC BRACING (Continued)

Figure 910

Attachment

Page 177

Figure 980

Figure 975

Straight Sway

Brace Fitting

Page 178

Universal Swivel

Sway Brace

Attachment

Page 179

Universal Swivel Sway

Figure 981

Fast-Attach

Brace Attachment

Page 180

Figure 985

Mechanical Fast

Clamp

Page 181

Figure 986

Mechanical Fast

Clamp

Page 182

Figure 990

Cable Sway Brace

Attachment

Page 183

Figure 991

Fast Attach

Cable Sway Brace

Attachment

Page 184

CONCRETE INSERTS

Figure 109A

Concrete Deck Insert

Page 189

Figure B3019

Adjustable Metal

Deck Ceiling Bolt

Page 190

Figure 1000

Fast Clamp

Sway Brace

Attachment

Page 185

Figure 1001

Sway Brace

Attachment

Page 186

Figure 109AF

Spot Insert

Page 191

Figure 2002

Sway Brace

Attachment

Page 187

Figure B2499

Heavy Duty Spot Insert

Page 192

Figure B2500

Light Duty Spot Insert

Page 193

Figure N2500

Steel Insert Nut

Page 193

Figure B3014

Malleable Iron

Spot Insert

Page 194

10

Figure B3014N

Malleable Iron Insert Nut

Page 194

Figure B2505

thru B2508

Spot Insert

Page 195

Page 13

CONCRETE INSERTS (Continued)

Pictorial Index

Pictorial Index

Figure B2503

Heavy Duty Spot Insert

Page 196

BRACKETS

Figure B3068

Light Duty Welded

Bracket

Page 203

Figure B22I, B32I, B52I

Continuous Concrete Inserts

Figure B3064

Adjustable Strut Bracket

Page 204

Figure B3069W

Welded Knee Brace

Page 208

Pages 197 - 199

Figure B3065

Light Duty Welded

Bracket

Page 205

Figure BD40

Fastener Clip

Page 200

Figure B3066

Medium Duty Welded

Bracket

Page 206

Figure BE-5-8

Figure BE-9-12

Fastener Clip

Page 201

Figure B3067

Heavy Duty Welded Bracket

Page 207

Figure B3069E

“O” Bracket

Page 208

UPPER ATTACHMENTS

Figure B3199

Ceiling Flange

Page 21

Figure B3070

Reversible Angle Clip

Page 212

1

Figure B3199CT

Dura-Copper Coated

Ceiling Flange

Page 21

Figure B3060

Side Beam Angle Clip

Page 213

1

◆

Figure 78

All Steel Ceiling Plate

Page 21

Figure 51

Side Beam Angle Clip

Page 213

◆ DURA-COPPER

11

1

™

Finish

Figure 50

Side Beam Bracket For

A Rod & Fastener Sizing

NFP

Page 214

Figure B3060L

Side Beam

Angle Clip

Page 212

Figure B3061

Angle Bracket

Page 214

Page 14

Pictorial Index

Pictorial Index

Figure 56

Tapped Side

Beam Connector

Page 214

UPPER ATTACHMNETS (Continued)

Figure 58

Threaded Side

Beam Bracket

Page 215

Figure B3058

Side Beam Connector

Page 217

Figure B3062

Side Beam Bracket

Page 217

Figure B3083

Figure B3083WO

Welded Beam

Page 218

Attachment

Figure 75

Swivel Attachment

Page 216

Figure B3080S (Short)

Figure B3080L (Long)

Structural Welding Lug

Page 219

Figure B3085

Rod Attachment Concrete Plate

Page 220

THREADED ACCESSORIES

Figure B3200

Weldless Eye Nut

Page 226

Figure B3222

Eye Socket

Page 225

Figure B3201

Forged Steel Clevis

Page 230

Figure B3086

Clevis Concrete Plate

Page 221

Figure B501

Light Weight U-Bolt

Page 227

Figure B3203

Extension Piece

Page 231

Figure B3188

Standard U-Bolt

Pages 153 & 154

Pages 228 & 229

Figure B3223

Offset Eye Socket

Page 231

◆ DURA-COPPER

Figure B3084

Single Lug Concrete Plate

Page 222

Figure B3224

Hanger Adjuster

Figure B3224CT

Dura-Copper Coated

Hanger Adjuster

™

Finish

Page 232

Figure B3082

Rod Beam Attachment

Page 223

Figure B3188C

Plastic Coated

Standard U-Bolt

Pages 228 & 229

Figure B3202

Turnbuckle

Page 232

◆

12

Page 15

THREADED ACCESSORIES (Continued)

Pictorial Index

Pictorial Index

Figure B3205

Machine Threaded Rod

Page 233

Figure 98

Rod Stiffener

Page 234

Figure B3212

J-Bolt

Page 238

Figure ATR

All Threaded Rod

Page 233

Figure 98B

Rod Stiffener with

Break Off Bolt Head

Page 234

Figure B3228

Hex Head Lag Bolt

Page 238

Figure B3214

Tie Bolt

Page 235

Figure B3213

Coach Screw Rod

Page 235

Figure DS 16 x 2

#16 x 2"

Drive Screw

Page 238

Figure B3210

Eye Rod

Page 236

Figure B3210X

Linked Eye Rod

Page 237

Figure B3211

Welded Eye Rod

236

Figure B3211X

Linked Welded Eye Rod

Page 237

Figure B655

Steel Rod Coupling

Page 164

Figure B656

Steel Reducer

Rod Coupling

Page 239

Figure B3220

Malleable Iron

Rod Coupling

Page 240

Figure FW

Flat Washer

Page 243

Figure B3248

Steel Washer Plate

Page 241

Figure LW

Lock Washer

Page 243

Figure B200

Square Washer

Page 240

Figure FFW

Flat Fender Washer

Page 243

13

Figure B3234

Bevel Washer

Page 241

Figure ATB

Toggle Bolt

Page 244

Figure HN - Hex Nut

Figure HHN - Heavy

Hex Nut

Page 242

Figure AWA

Wedge Anchor

Page 244

Page 16

Pictorial Index

Pictorial Index

Ribbed Neoprene Pad

Double Deflection

VIBRA TROL

Figure NNP

Page 248

Figure NVD

Page 250

™

Figure CNP

Cork and Ribbed

Neoprene Pad

Page 248

Figure CM

Metal Housing and Neoprene

Page 251

Figure CNNK

Cork, Ribbed Neoprene

and Steel

Page 249

Figure OML/OM

Spring Mount

Pages 252 & 253

Figure VRP

Rubber Cube Pad

Page 249

Figure BVS

Vibra Strip™

15/8" Wide B-Line

channel

Page 250

for

Figure HMLE/HME

Housed 1"

Deflection Mounting

Pages 254 & 255

Figure HMLT/HMT

Housed 1"

Deflection Mounting

Pages 256 & 257

Figure SHE

Isolation Spring Hanger

Pages 264 & 265

DURA-BLOK

DBP & DBM

Bases

Page 271

Figure ANH

Acoustical Hanger

Page 258

™

DB Series

Base & Short Channel

Page 272

Figure RH

Neoprene Hanger

Page 259

Figure BVT

VibraClamp

ubing Sizes

T

Page 267

Figure BVP

VibraClamp

Pipe Sizes

Page 268

DB6 Series

Base & Tall Channel

Page 273

Figure HSL/HS

Vibration Spring Hanger

Pages 260 & 261

Figure B1999

Vibra Cushion

Page 269

Double Base & Long Channel

Figure HESL/HES

Combination Spring

& Neoprene

Pages 262 & 263

Figure ISO

ISO Pipe

Page 269

DB10 Series

Page 274

14

Page 17

Pictorial Index

DURA-BLOK

DBM Series

Base & Clamp Riser

Page 275

CLDP10

Load Distribution Plate

Page 280

™

(Continued)

DBR Series

Base & Adjustable Height

Roller Assembly

Page 279

DBR Series

Base & Fixed Height

Roller Assembly

Page 278

DBE Series

Base & Adjustable

Height Channel

Page 279

Pictorial Index

DB__DS Series

Bases & Harness Assembly

Pages 276 & 277

KWIKWIRE™

KwikWire Clamp

Page 283

Wire Rope Cutter

Page 284

Wire Rope

Page 283

KwikWire Hanger

Page 285

KwikPak Kit

Page 284

KwikWire Accessories

BKL & BKLK

ermination

Loop T

Page 2867

KwikWire Accessories

BKH & BKHK

Single Hook

Termination

Page 288

15

KwikWire Accessories

BKYH & BKYHK

Double Hook

Termination

Page 289

KwikWire Accessories

BKA & BKAK

Angle Bracket

ermination

T

Page 290

Page 18

Strut Systems

Cooper B-Line's metal framing support system is designed with many

time-saving features. Fully adjustable and reusable, with a complete line

of channels, fittings, and accessories for multi-purpose applications.

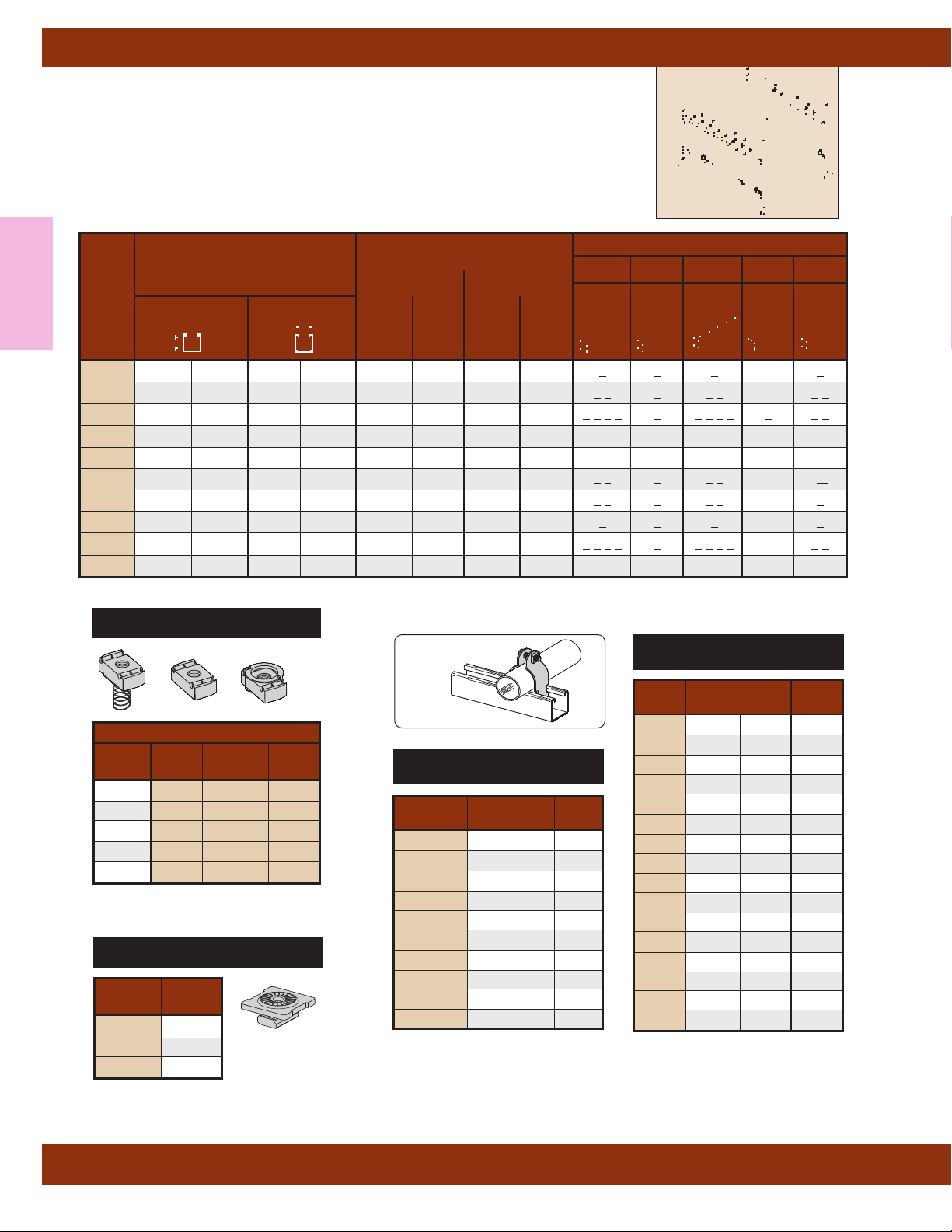

SELECTION CHART

for Channels, Materials and Hole Patterns

Strut Systems

Information

Channel

Type

B11 3

B12 27/16" (61.9) 15/8" (41.3) 12 Ga. .105 -- -- 1 2 1 1 2 -- 1 2

B22 15/8" (41.3) 15/8" (41.3) 12 Ga. .105 12 Ga. 12 Ga. 1 2 3 4 1 1 2 3 4 1 1 2

B24 15/8" (41.3) 15/8" (41.3) 14 Ga. .080 14 Ga. 14 Ga. 1 2 3 4 1 1 2 3 4 -- 1 2

B26 15/8" (41.3) 15/8" (41.3) 16 Ga. -- -- -- 1 1 1 -- 1

B32 13/8" (34.9) 15/8" (41.3) 12 Ga. -- 12 Ga. -- 1 3 1 1 3 -- 1

B42 1" (25.4) 15/8" (41.3) 12 Ga. -- 12 Ga. -- 1 3 1 1 3 -- 1

B52

B54

B56

1

/4" (82.5) 15/8" (41.3) 12 Ga. -- -- -- 1 1 1 -- 1

13

/16" (20.6) 15/8" (41.3) 12 Ga. -- -- -- 1 1 1 -- 1

13

/16" (20.6) 15/8" (41.3) 14 Ga. .080 14 Ga. 14 Ga. 1

13

/16" (20.6) 15/8" (41.3) 16 Ga. -- -- -- 1

Height

Channel

Dimensions

Width

Material & Thickness* Channel Hole Pattern **

Stainless SH S H17/8 TH KO6

Steel

Steel

1

Alum.

2

Type

304

Type

316

3

4

2 3 4 1 1 2 3 4 -- 1 2

1 1 -- 1

Channel Nuts

Size and Part Number

Thread

With Without

Twirl

Size Spring Spring Nut

1

/4"-20 N224 N224WO TN224

3

/8"-16 N228 N228WO TN228

1

/2"-13 N225 N225WO TN225

5

/8"-11 N255 N255WO --

3

/4"-10 N275 N275WO --

Available Finishes: Electro-Galvanized

Combo Nut Washers

Part Thread

Number Size

NW5241/4"-20

NW528

NW525

3

/8"-16

1

/2"-13

Available Finishes: Electro-Galvanized

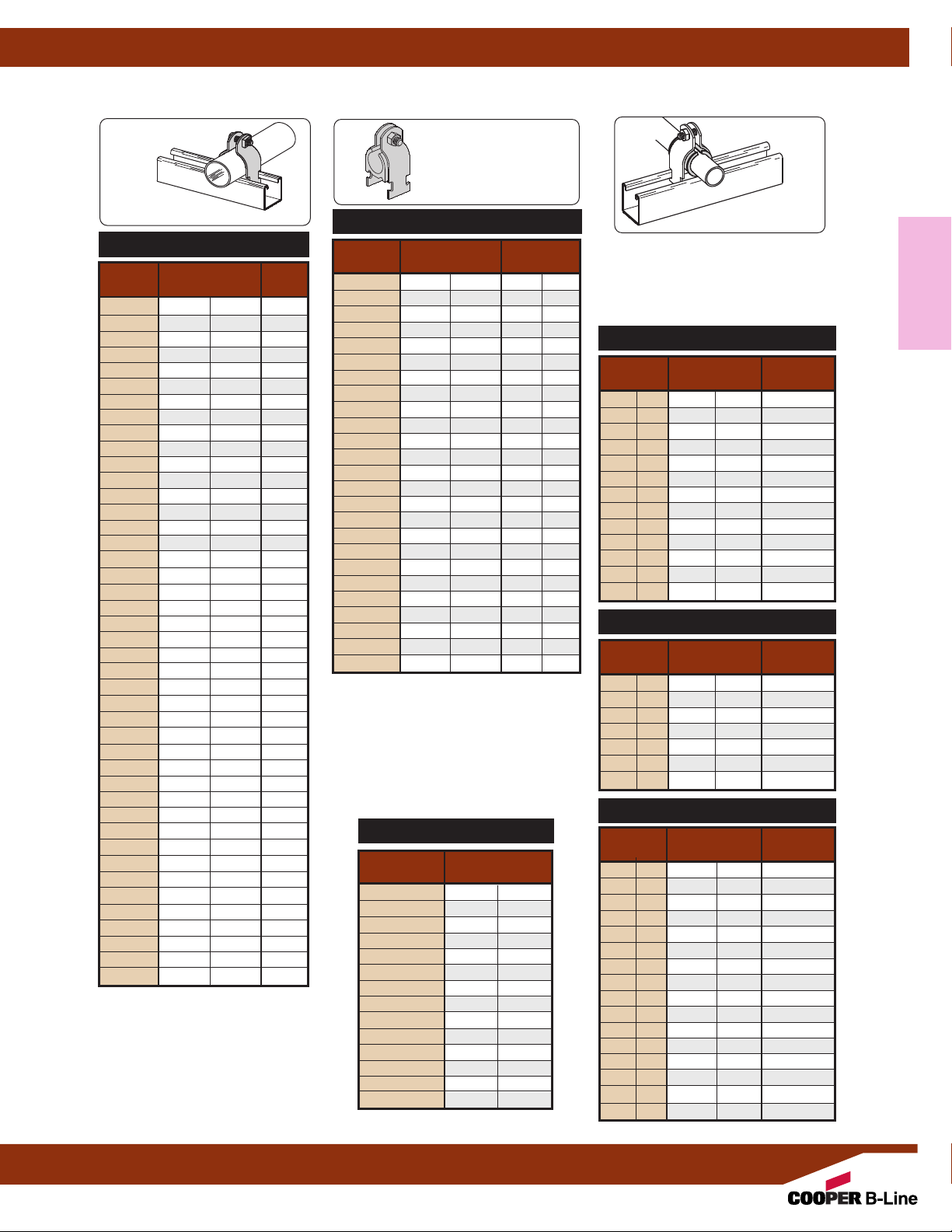

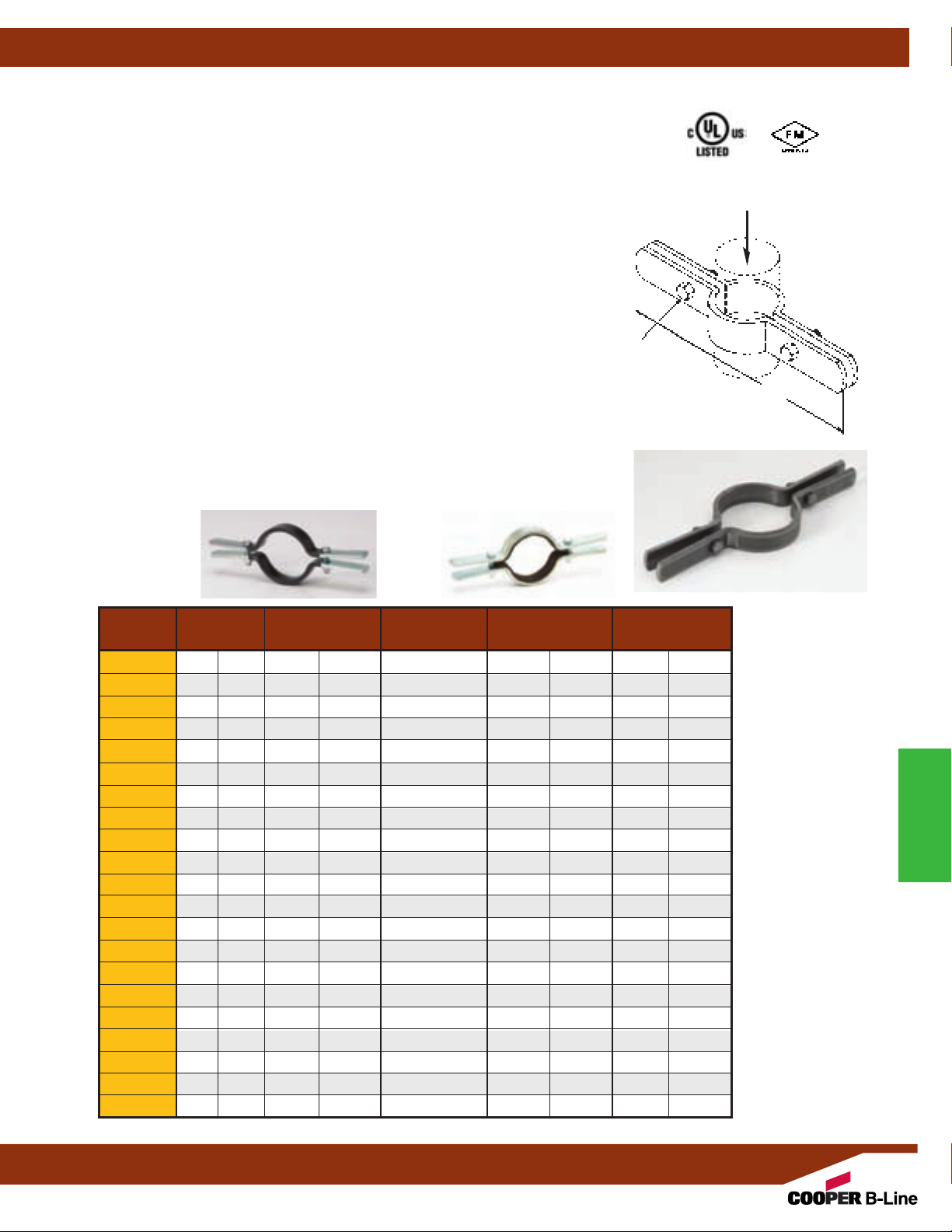

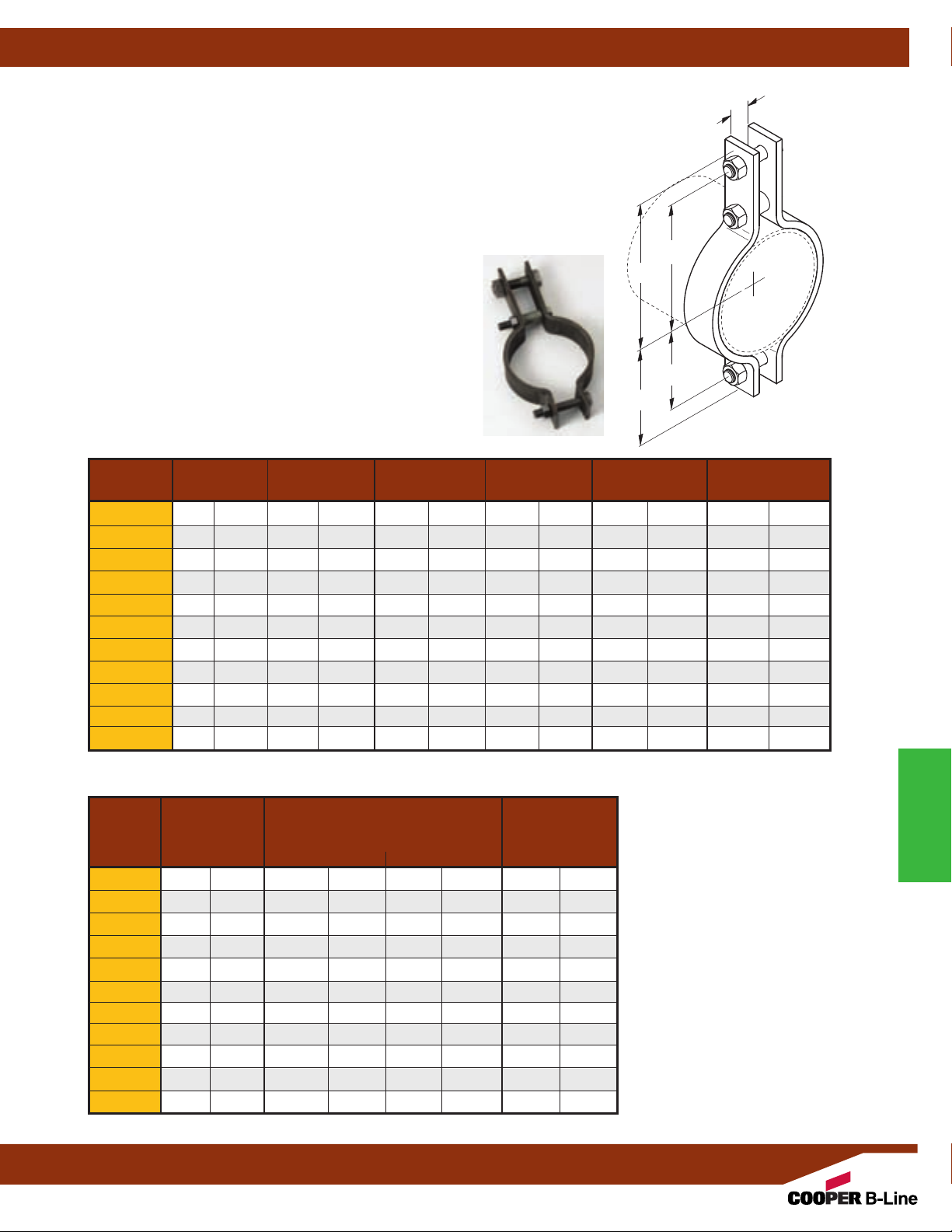

B2000 Series

Schedule 40 Pipe Clamps

Part

Nomina l

No. Pipe Size Ga.

3

/8" (10) 16

1

/2" (15) 16

3

/4" (20) 14

1

/4" (32) 14

1

/2" (40) 12

1

/2" (60) 12

1

/2" (90) 11

1

/2" (115) 11

Copper Tubing Clamps

DURA-COPPER

Part

No. Tubing Size Ga.

B2026DCU1/2" (15) 16

B2008DCU

B2030DCU 1"

B2032DCU 1

B2011DCU 1

B2038DCU 2"

B2042DCU 2

B2046DCU 3"

B2050DCU 3

B2054DCU 4"

Nominal

3

/4" (20) 16

1

/4" (32) 14

1

/2" (40) 14

1

/2" (60) 12

1

/2" (90) 12

™

Mat'l

(25) 14

(50) 12

(80) 12

(100) 11

B2001

B2008

B2009

B2010 1"

B2011 1

B2012 1

B2013 2"

B2014 2

B2015 3"

B2016 3

B2017 4"

B2018 4

B2019 5"

B2020 6"

B2021 7"

B2022 8"

Available Finishes: Electro-Galvanized, Aluminum, Stainless,

Dura-Copper Painted, Hot-Dip Galvanized and PVC coated.

Nut and bolts are included with all two-piece clamps.

** Add “PA” to Part No. for Pre-assembled

Mat'l

(25) 14

(50) 12

(80) 12

(100) 11

(125) 11

(150) 11

(175) 11

(200) 11

All dimensions in charts and on drawings are in inches. Dimensions shown in parentheses are in millimeters unless otherwise specified.

16

Page 19

B-LINEB-LINE

BVP150BVP150

1 1/2” I.P11/2” I.P..

Strut Systems

Below are some basic clamp and cushions to be used with a strut system. For the industry's most complete

line of strut and strut fittings, refer to Cooper B-Line's Strut Systems Engineering Catalog.

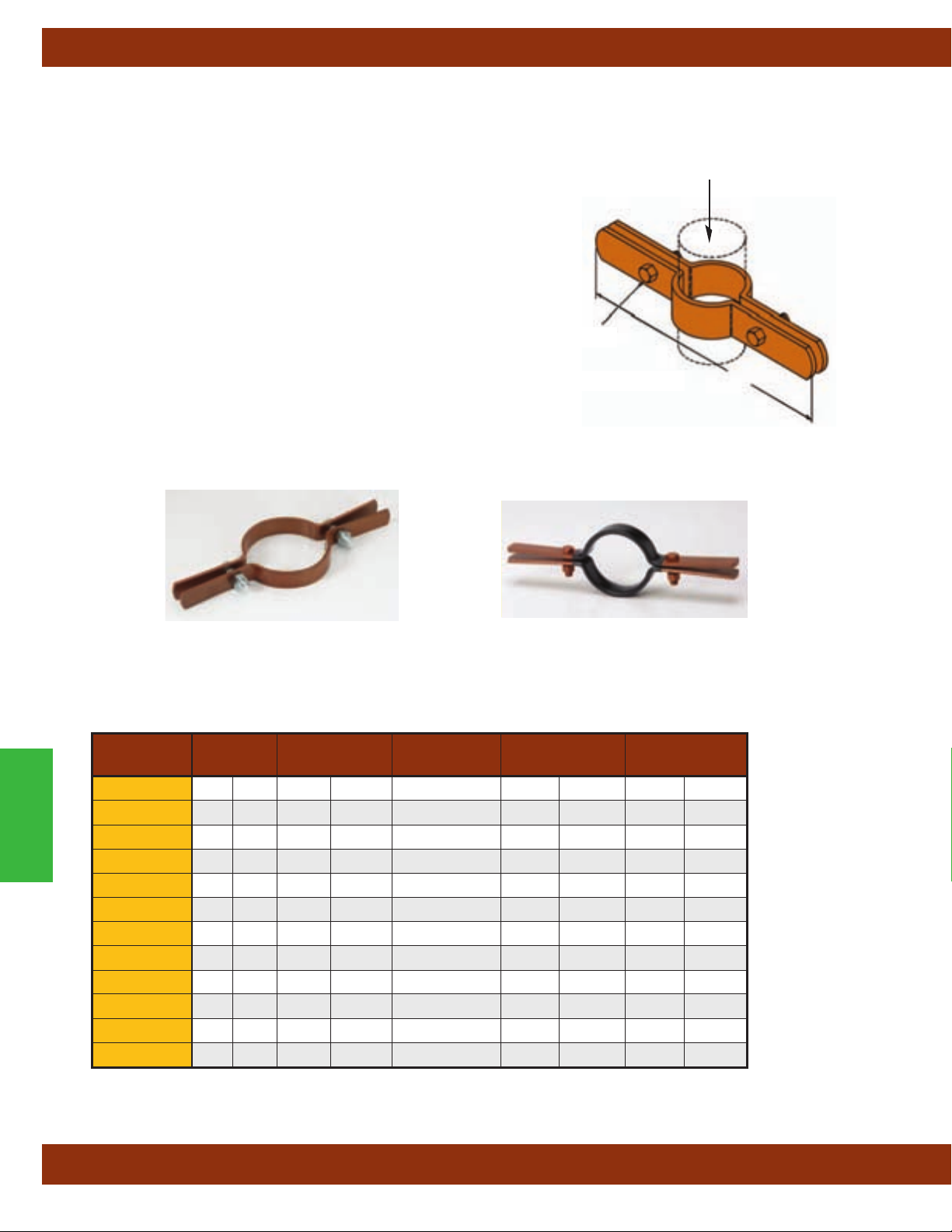

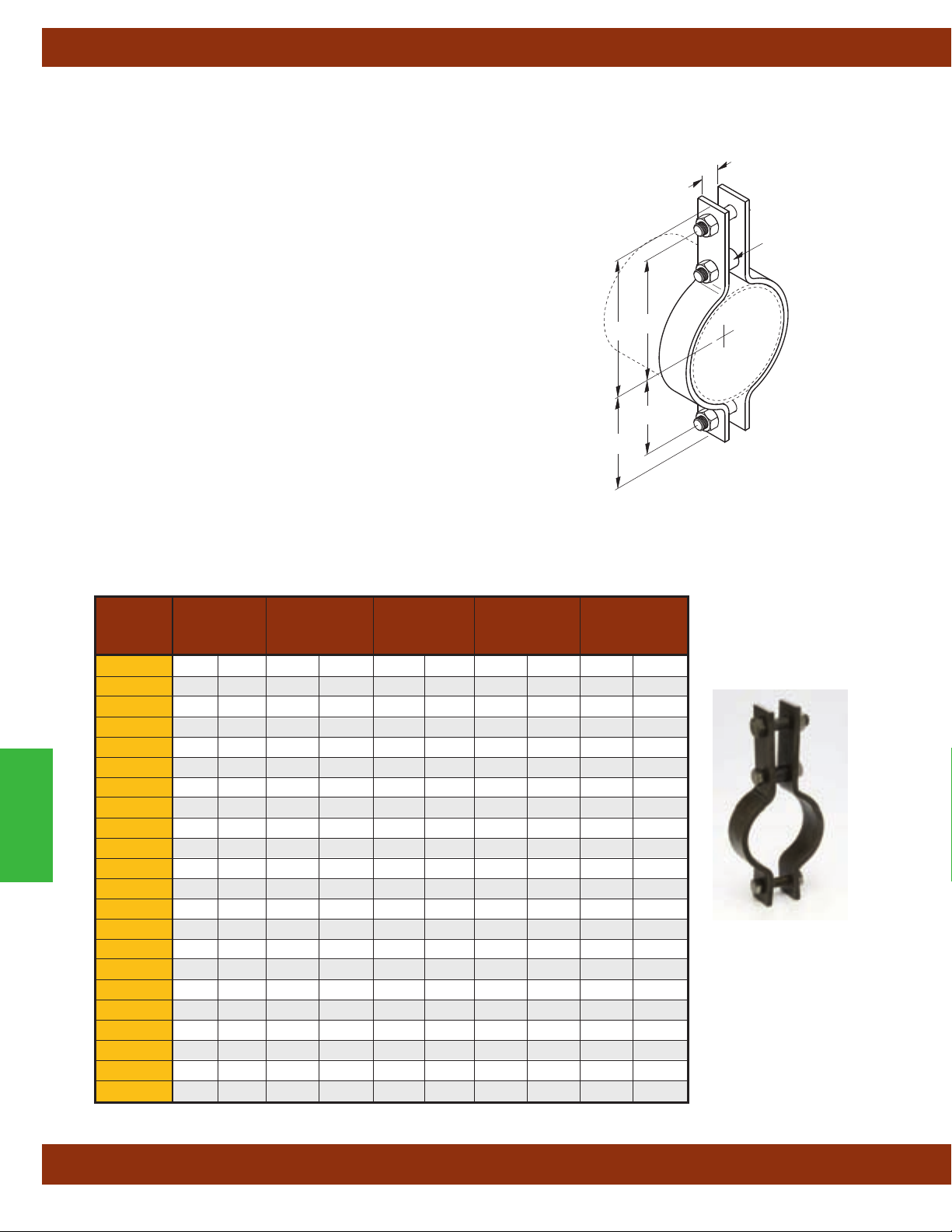

B2000 Series

O.D. Pipe Clamps

Part

No. (Outside Dia.) Ga.

B2023

B2024

B2025

B2026

B2027

B2028

B2029 1"

B2030 1

B2031 1

B2032 1

B2004 1

B2011 1

B2005 1

B2036 1

B2037 2"

B2038 2

B2039 2

B2013 2

B2041 2

B2042 2

B2043 2

B2014 2

B2045 3" (76.2) 12

B2046 3

B2047 3

B2048 3

B2015 3

B2050 3

B2051 3

B2052 3

B2016 4"

B2054 4

B2055 4

B2056 4

B2017 4

B2058 4

B2059 4

B2060 4

B2061 5"

B2062 5

B2063 5

B2064 5

B2065 5

O.D. Size

1

/4" (6.3) 16

3

/8" (9.5) 16

1

/2" (12.7) 16

5

/8" (15.9) 16

3

/4" (19.0) 16

7

/8" (22.2) 16

(25.4) 14

1

/8" (28.6) 14

1

/4" (31.7) 14

3

/8" (34.9) 14

1

/2" (38.1) 14

5

/8" (41.3) 14

3

/4" (44.4) 12

7

/8" (47.6) 12

(50.8) 12

1

/8" (54.0) 12

1

/4" (57.1) 12

3

/8" (60.3) 12

1

/2" (63.5) 12

5

/8" (66.7) 12

3

/4" (69.8) 12

7

/8" (73.0) 12

1

/8" (79.4) 12

1

/2" (82.5) 12

3

/8" (85.7) 12

1

/2" (88.9) 12

5

/8" (92.1) 11

3

/4" (95.2) 11

7

/8" (98.4) 11

(101.6) 11

1

/8" (104.8) 11

1

/4" (107.9) 11

3

/8" (111.1) 11

1

/2" (114.3) 11

5

/8" (117.5) 11

3

/4" (120.6) 11

7

/8" (123.8) 11

(127.0) 11

1

/8" (130.2) 11

1

/4" (133.3) 11

3

/8" (136.5) 11

1

/2" (139.7) 11

All dimensions in charts and on drawings are in inches. Dimensions shown in parentheses are in millimeters unless otherwise specified.

Mat'l

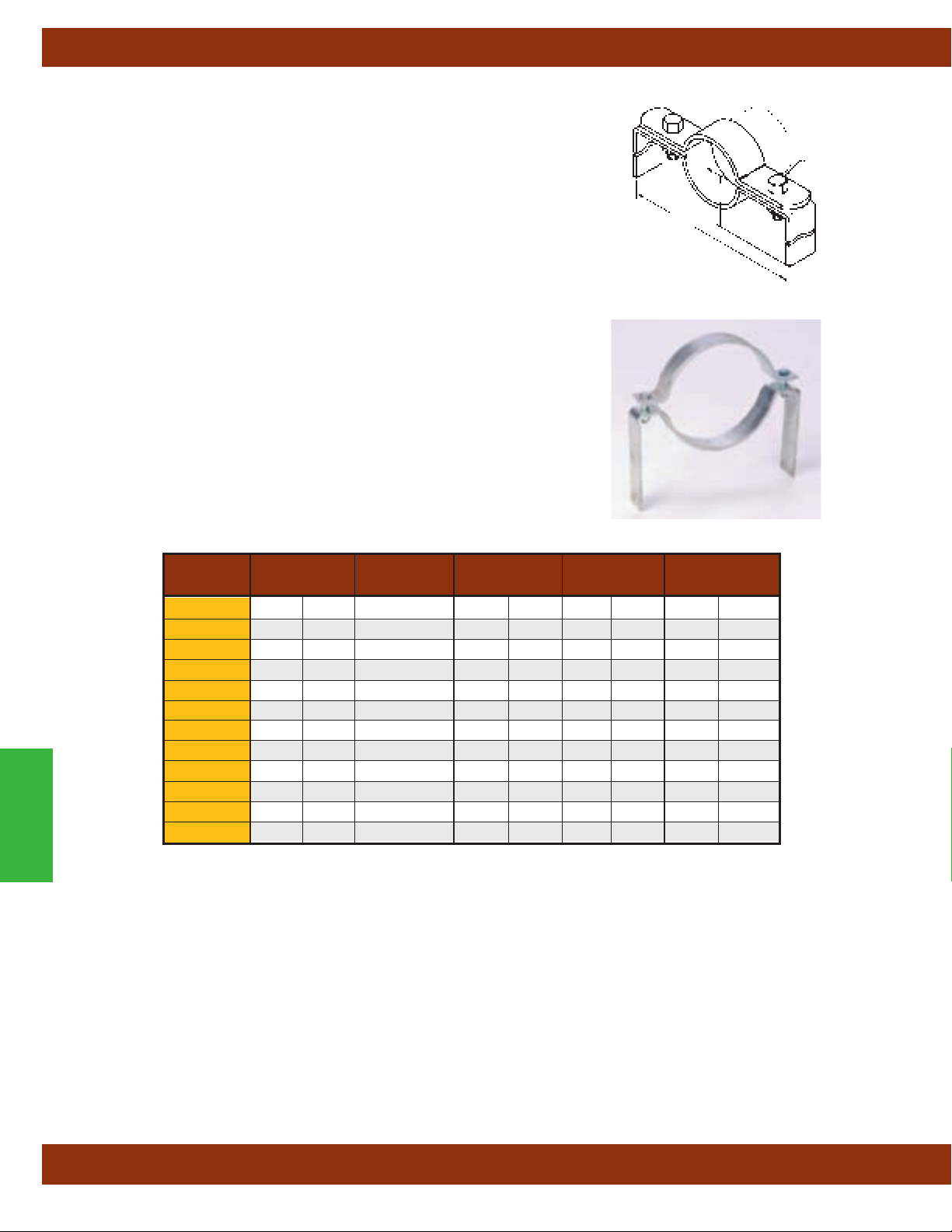

BVT & BVP

Series

Vibra-Clamp

™

For Copper Tubing & OD Sizes

Catalog Copper & Steel Nominal

No. OD Tubing Size Copper Size

BVT025

BVT037

BVT050

BVT062

BVT075

BVT087

1

/4" (6.3) -- --

3

/8" (9.5)1/4" (6)

1

/2" (12.7)3/8" (10)

5

/8" (15.9)1/2" (15)

3

/4" (19.0)5/8" (17)

7

/8" (22.2)3/4" (20)

BVT100 1" (25.4) -- --

BVT112 1

1

/8" (28.6) 1" (25)

BVT125 11/4" (31.7) -- -BVT137 1

3

/8" (34.9) 11/4" (32)

BVT150 11/2" (38.1) -- -BVT162 1

5

/8" (41.3) 11/2" (40)

BVT175 13/4" (44.4) -- -BVT187 1

BVT200 2"

BVT212 2

7

/8" (47.6) -- --

(50.8) -- --

1

/8" (54.0) 2" (50)

BVT225 21/4" (57.1) -- -BVT250 2

BVT262 2

1

/2" (63.5) -- --

5

/8" (66.7) 21/2" (65)

BVT300 3" (76.2) -- --

BVT312 3

1

/8" (79.4) 3" (80)

BVT362 35/8" (92.1) 31/2" (90)

BVT400 4" (101.6) -- --

BVT412 4

1

/8" (104.8) 4" (100)

BVT612 61/8" (155.6) 6" (150)

Available for tubing and pipe sizes

1

/4" to 6", OD sizes 1/4" to 65/8".

Easy one tool installation, dampens

vibration and noise, secures tubing

firmly, and protects against galvanic

reaction.

Stainless Steel available

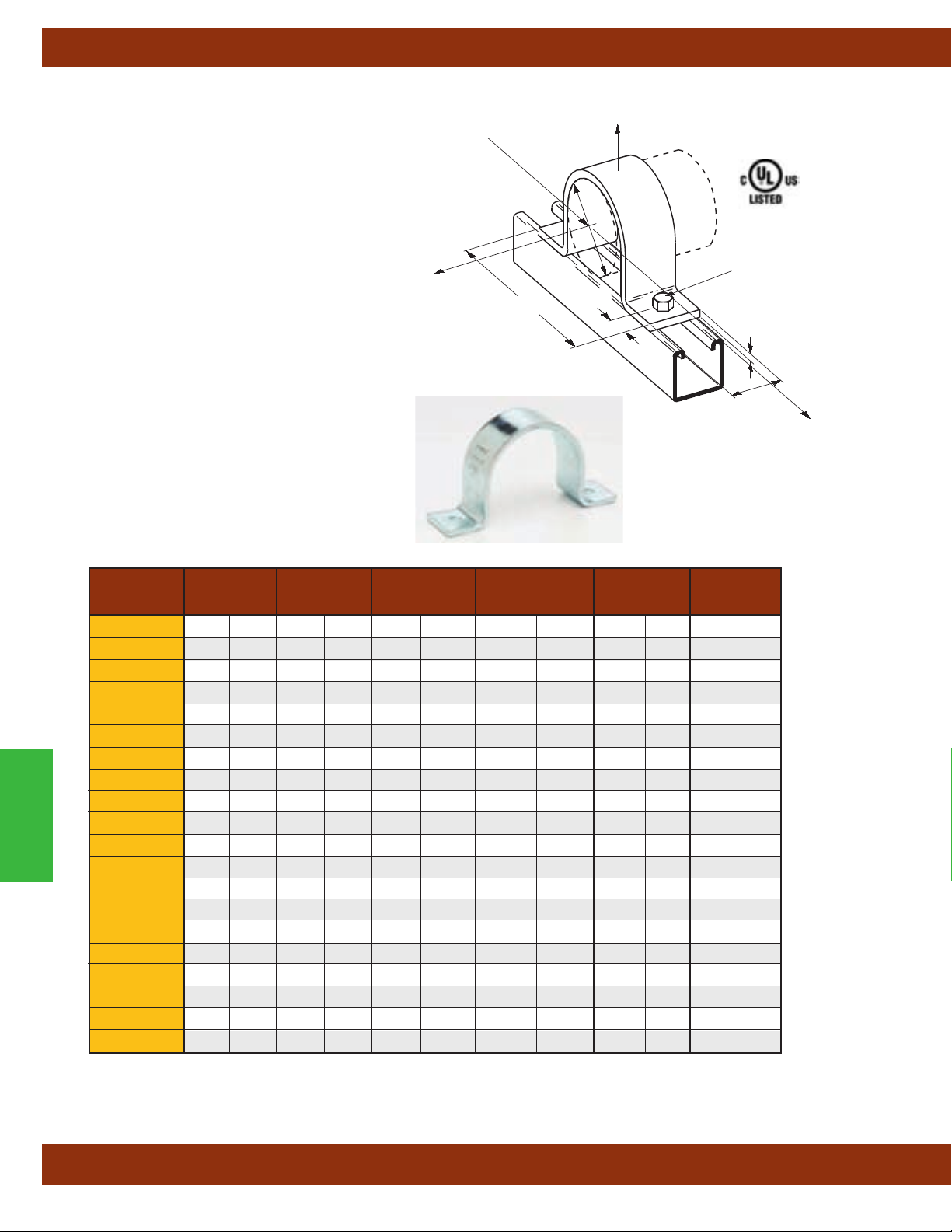

For Pipe Sizes

Catalog Nominal

No. Pipe Size

BVP025

BVP037

BVP050

BVP075

BVP100 1" (25)

BVP125 11/4" (32)

BVP150 11/2" (40)

BVP200 2" (50)

BVP250 21/2" (65)

BVP300 3" (80)

BVP350 31/2" (90)

BVP400 4" (100)

BVP500 5" (125)

BVP600 6" (150)

1

/4" (6)

3

/8" (10)

1

/2" (15)

3

/4" (20)

B1999

Vibra-Cushion

™

• Inhibits Galvanic Reaction

• Reduces Sound & Vibration

• Used on refrigeration, HVAC, copper

tubing, glass pipes & hydraulic lines

Available in 20 Ft. rolls.

For Rigid Conduit or Iron Pipe

Nominal Length of Use

Size Vibra-Cushion Clamp No.

3

/8" (10) 21/8" (54.0) B2002

1

/2" (15) 25/8" (66.7) B2009

3

/4" (20) 31/4" (82.5) B2031

1"

1

1

/4" (32) 53/16" (131.8) B2012

1

1

/2" (40) 515/16" (150.8) B2038

2"

1

2

/2" (65) 9" (228.6) B2046

3"

1

3

/2" (90) 121/2" (317.5) B2055

4"

5"

6"

For Thinwall (EMT) Conduit

Nominal Length of Use

Size Vibra-Cushion Clamp No.

3

/8" (10) 113/16" (46.0) B2027

1

/2" (15) 23/16" (58.7) B2002

3

/4" (20) 27/8" (73.0) B2003

1"

1

1

/4" (32) 43/8" (120.6) B2036

1

/2" (40) 57/16" (138.1) B2012

1

2"

For Copper Tubing Type L & K

Nominal Length of Use

Size Vibra-Cushion Clamp No.

1

/4" (6) 13/16" (30.2) B2026

3

/8" (10) 19/16" (39.7) B2027

1

/2" (15) 17/8" (47.6) B2028

5

/8" (17) 25/16" (58.7) B2029

3

/4" (20) 23/4" (69.8) B2030

1"

1

1

/4" (32) 45/16" (109.5) B2011

1

1

/2" (40) 51/8" (130.2) B2036

2"

1

2

/2" (65) 81/4" (209.5) B2014

3"

1

3

/2" (90) 113/8" (288.9) B2052

4"

(100) 12

5"

(125) 6

6"

(150) 19

8"

(200) 25

1

(25) 4

(50) 7

(80) 11" (279.4) B2051

(100) 14

(125) 17

(150) 20

(25) 3

(50) 6

(25) 3

(50) 6

(80) 9

/8" (104.8) B2004

1

/2" (190.5) B2042

1

/2" (368.3) B2059

7

/16" (442.9) B2067

3

/4" (527.0) B2116

5

/8" (92.1) B2032

7

/8" (174.6) B2013

1

/2" (88.9) B2032

11

/16" (169.9) B2013

13

/16" (249.2) B2048

15

/16" (328.6) B2056

1

/8" (409.6) B2064

1

/4" (488.9) B2112

1

/2" (647.7) B2128

Information

Strut Systems

17

Page 20

Technical Data

MATERIALS

Carbon Steel

Carbon steel is used in the

manufacture of Cooper B-Line pipe

hangers and supports. Excellent

strength characteristics and

adaptability to cold forming provide a

well engineered design. By cold

forming the steel, mechanical

properties are increased, adding to

the structural integrity of the

fabricated hanger.

Stainless Steel

AISI Type 304 and Type 316 are

Technical Data

non-magnetic members of the

austenitic stainless steel group.

Several conditions make the use of

stainless steel ideal. These include

reducing long term maintenance

costs, high ambient temperatures,

appearance, and stable structural

properties such as yield strength,

and high creep resistance.

CORROSION

All metal surfaces exposed to the

environment are affected by

corrosion. Depending on the physical

properties of the metal and its

proximity to other dissimilar metals,

an electrochemical reaction may

occur which causes an attack on the

metal itself, resulting in corrosion.

Chemical corrosion is limited to

highly corrosive environments, high

temperatures, or a combination of

both.

FINISHES

Zinc Coatings

Protective zinc coatings are available

on a number of pipe hangers and

accessories in three basic forms:

Electro-galvanized, pre-galvanized,

and hot-dip galvanized after

fabrication. In all cases, the zinc

protects the steel first as a sacrificial

anode to repair bare areas on cut

edges and gouges.

When exposed to air and moisture,

zinc forms a tough, adherent protective

film consisting of a mixture of zinc

oxides, hydroxides, and carbonates.

The corrosion resistance of zinc is

directly related to its thickness and the

environment. For example a 0.2 mil

(5 µm) coating will last twice as long

as a 0.1 mil (2.5 µm) coating in the

same environment.

Electro-Galvanized

(ASTM B 633 SC1 or SC3)

An electro-galvanized process deposits

a coating of zinc on the steel by

electrolysis from a bath of zinc salts.

This coating is pure zinc and adheres

to the steel with a molecular bond. A

maximum of 0.5 mils (12.7 µm) of zinc

can be applied by this method.

coating is recommended for in-door

use in relatively dry areas.

This

Pre-Galvanized Zinc

(ASTM A 653 Coating

Designation G90)

Pre-galvanized zinc is produced by

continuously rolling the steel coils or

sheets through molten zinc at the steel

mills. This is also known as "mill-galvanized" or "hot-dipped mill galvanized".

Coils are then slit to size for fabrication

of pipe hangers. Coating thicknesses

of G90, is 0.90 ounces per square foot

(0.27 kg/m

Zn

ZnFe

Fe

Protection of cut edges with zinc coatings.

Cut edges and welded areas are

not zinc coated; however, zinc near the

uncoated metal becomes a

sacrificial anode which protects the

bare areas after a short period of time.

Pre-galvanized steel is not

generally recommended for use

outdoors in industrial environments,

2

) of steel surface.

ZnO

but is suitable for extended exposure in

dry or mildly corrosive atmospheres.

Hot-Dip Galvanized After

Fabrication (ASTM A 123)

After a pipe hanger or fitting has been

fabricated, it is completely immersed in

a bath of molten zinc. A metallurgical

bond is formed, resulting in a zinc

coating that completely coats all

surfaces, including edges. Zinc

coatings of this specification have a

minimum thickness of 1.50 ounces per

square foot (0.45 kg/m

or a total of 3.0 ounces per square foot

(0.9 kg/m2) of steel.

Hot-dip galvanized after fabrication is

recommended for outdoor exposure.

For best results, a zinc rich paint

(available from Cooper B-Line) should

be applied to field cuts. The zinc rich

paint will provide immediate protection

for field cuts and eliminate the short

time period for galvanic action to "heal"

the damaged coating.

2

) on each side

Plastic Coating

Some products offered by Cooper

B-Line are plastic or vinyl coated for

prevention of galvanic reaction between

materials or for noise reduction. These

coated products can also be used

where contact between glass pipe and

hanger is not desirable. Felt lined

hangers may be substituted for same

purpose.

Red Primer

A corrosion resistant metal primer

containing rust inhibitive pigments.

18

Page 21

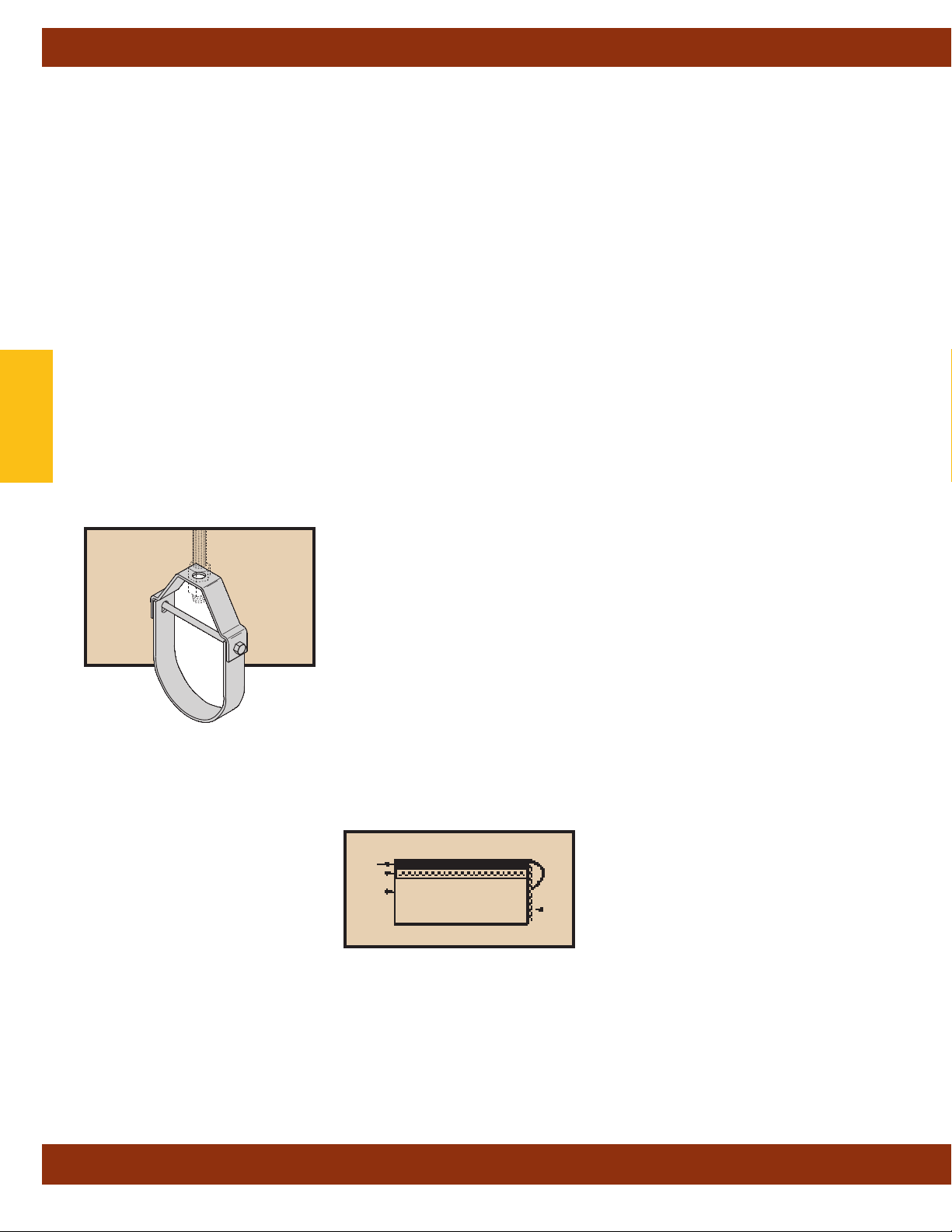

Technical Data

DURA-COPPER™and

™

DURA-GREEN

Dura-Copper and Dura-Green are

water borne epoxy coatings applied to

Cooper B-Line products by a precisely

controlled cathodic electro-deposition

process. This process is accomplished

using a conveyor to transport parts

through several cleaning, phosphatizing

and application stages prior to being

baked (See diagram below).

This custom designed paint system is

used for painting all copper painted

hanger parts and all green channel,

Epoxy Coatings

Samples are selected on a routine

basis for Salt Spray (fog) testing to

verify the quality of the finish. These

tests are performed in accordance with

ASTM B 117-73 and evaluated and

rated according to ASTM D 1654-79

(Tables 1 & 2). The Dura-Copper and

®

Dura-Green

Epoxy coatings have

been tested and listed by Underwriters

Laboratories in accordance with

"Standard for Pipe Hanger Equipment

for Fire Protection Service, UL 203"

and meet or exceed all requirements of

Federal Specification TT-C-490B

Paragraph 3.

slotted angle and fittings.

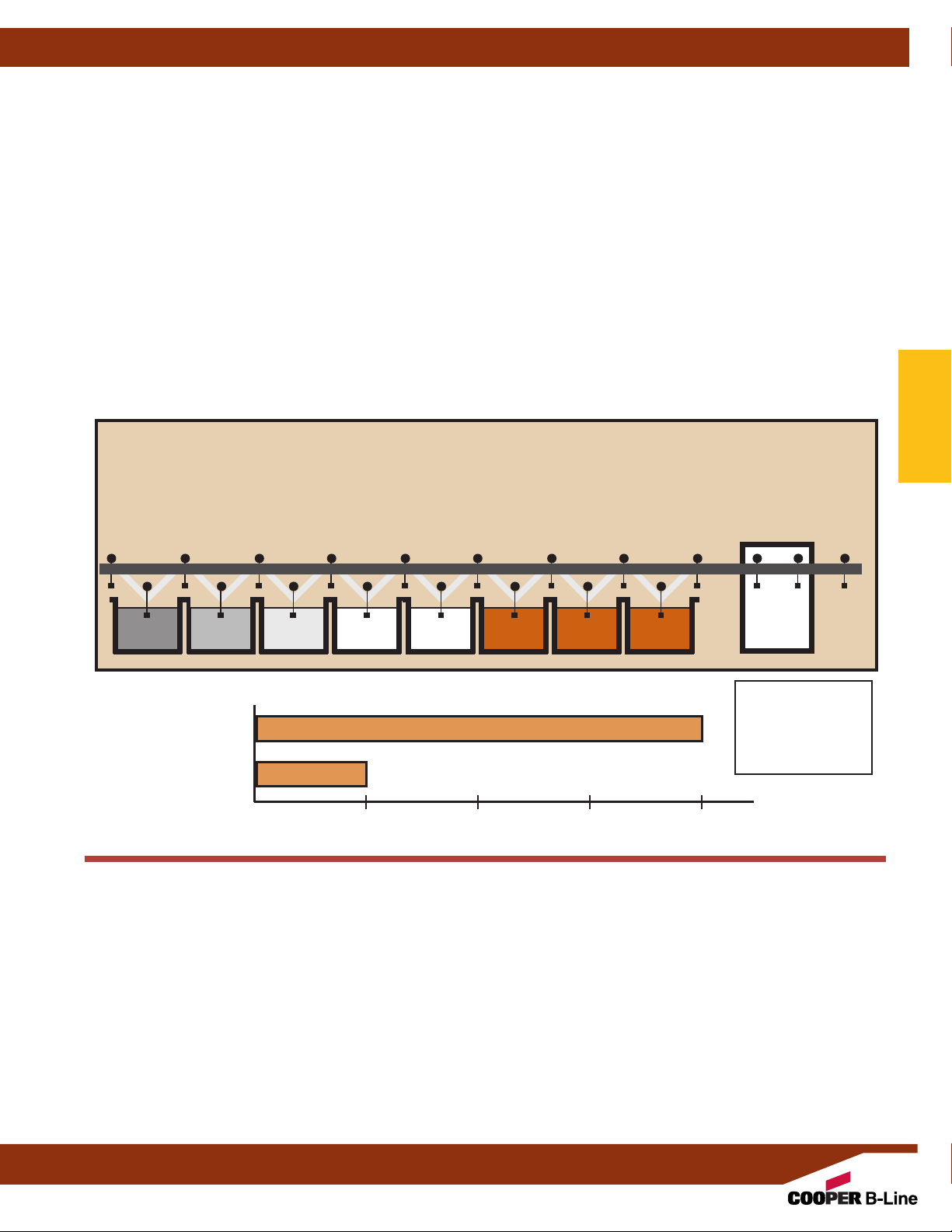

DURA-COPPER™ & DURA-GREEN™EPOXY COATING PROCESS

TANK 1

Parts are thoroughly cleaned

and phosphatized.

TANK 2

Rinse is

applied to

remove

insoluble salts

and unreacted

phosphates.

TANK 3

Phosphatized

sealer is applied

to insure

corrosion resistance and paint

adhesion.

TANK 4

The material

moves through

clear water

rinse to remove

excess phosphates.

TANK 5

Deionized rinse

prepares the

metal for the

cathodic

electro-coating.

TANK 6

The electrocoating tank

applies a

uniform coat of

epoxy paint to

the entire surface.

Quality Assurance

Cooper B-Line System's Quality

Assurance Program has been

developed and implemented for

compliance to various industry

standards and specifications.

TANK 7

The first

post rinse

removes any

unelectrically

attracted

solids.

TANK 8

The final rinse

insures a

smooth,

nonblemish

finish.

BAKE OVEN

The curing

process takes

20 minutes at a

baking

temperature of

375°F (199°C).

Technical Data

SALT SPRAY TEST RESULTS

Dura-Copper

Epoxy

Dura-Copper

out performs

Copper Plating

4 to 1

Copper Plating

Elapsed Time

(1) All salt spray (fog) tests conducted in accordance with ASTM B 117-73 and evaluated and rated

according to ASTM D 1654-79 Tables 1 & 2. Tests were performed and certified by an independent testing laboratory.

General Information

Torque

The torque values in this catalog are to be used as a guide only. The relationship between the applied torque or

torque wrench reading and the actual tension created in the bolt may be substantially different. Important factors

affecting torque-tension relationships include friction under the bolt head or nut, hole tolerances, and torque

wrench tolerances.

Charts and Tables

Charts and tables in this section are compiled from information published by nationally recognized organizations

and are intended for use as a guide only

the validity of such information as applied to their own applications.

Cooper B-Line, Inc. reserves the right to make specification changes without notice.

Accuracy of many commercial torque wrenches may vary as much as plus or minus 25%.

. Cooper B-Line recommends that users of this information determine

19

Page 22

Technical Data

SECTION 15140 - PIPE HANGERS AND SUPPORTS

Part I - GENERAL

1.01 SECTION INCLUDES

A. The work covered under this section consists of the furnishing of all necessary labor,

supervision, materials, equipment, and services to completely execute the pipe hanger and

supports as described in this specification.

1.02 REFERENCES

A. ASTM B 633 - Specification for Electrodeposited Coatings of Zinc on Iron and Steel.

B. ASTM A 123 - Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

Technical Data

C. ASTM A 653 - Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron

Alloy-Coated (Galvannealed) by the Hot-Dip Process.

D. ASTM A 1011 - Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural,

High-Strength Low-Alloy, and High-Strength Low-Alloy with Improved Formability.

E. ANSI/MSS SP-58 - Manufacturers Standardization Society: Pipe Hangers and Supports -

Materials, Design, and Manufacture.

F. ANSI/MSS SP-69 - Manufacturers Standardization Society: Pipe Hangers and Supports -

Selection and Application.

G. NFPA 13 - Installation of Sprinkler Systems.

1.03 QUALITY ASSURANCE

A. Hangers and supports used in fire protection piping systems shall be listed and labeled by

Underwriters Laboratories.

B. Steel pipe hangers and supports shall have the manufacturers name, part number, and

applicable size stamped in the part itself for identification.

C. Hangers and supports shall be designed and manufactured in conformance with MSS SP-58.

D. Supports for sprinkler piping shall be in conformance with NFPA 13.

1.04 SUBMITTALS

A. Submit product data on all hanger and support devices, including shields and attachment

methods. Product data to include, but not limited to materials, finishes, approvals, load

ratings, and dimensional information.

Part II - PRODUCTS

2.01 ACCEPTABLE MANUFACTURERS

A. Manufacturer: Subject to compliance with these specifications, pipe hanger and support

systems shall be as manufactured by Cooper B-Line, Inc.

2.02 PIPE HANGERS AND SUPPORTS

A. Hangers

1. Uninsulated pipes 2 inch and smaller:

a. Adjustable steel swivel ring (band type) hanger, Cooper B-Line B3170, Fig. 200.

b. Adjustable steel swivel J-hanger, Cooper B-Line B3690.

c. Malleable iron ring hanger, Cooper B-Line B3198R or hinged ring hanger,

B3198H.

d. Adjustable steel clevis hanger, Cooper B-Line B3104, B3100 or 1U.

20

Page 23

Technical Data

2. Uninsulated pipes 21/2 inch and larger:

a. Adjustable steel clevis hanger, Cooper B-Line B3100.

b. Pipe roll with sockets, Cooper B-Line B3114.

c. Adjustable steel yoke pipe roll, Cooper B-Line B3110.

3. Insulated pipe - Hot or steam piping:

a. 2 inch and smaller pipes: use adjustable steel clevis with galvanized sheet metal

shield, Cooper B-Line B3100 with B3151 or B3153 series.

1

b. 2

/2 inch and larger pipes:

i. Adjustable steel yoke pipe roll with pipe covering protection saddle, Cooper

B-Line B3110 with B3160 - B3165 series.

ii. Pipe roll with sockets with pipe covering protection saddle, Cooper B-Line

B3114 with B3160 - B3165 series.

4. Insulated pipe - Cold or chilled water piping:

a. 5 inch and smaller pipes: use adjustable steel clevis with galvanized sheet metal

shield, Cooper B-Line B3100 with B3151 or B3153 series.

b. 6 inch and larger pipes:

i. Adjustable steel yoke pipe, Cooper B-Line B3110, with B3380CW - B3384CW

calcium silicate shield.

ii. Pipe roll with sockets, Cooper B-Line B3114, with B3380CW - B3384CW calcium

silicate shield.

Technical Data

B. PIPE CLAMPS

1. When flexibility in the hanger assembly is required due to horizontal movement, use

pipe clamps with weldless eye nuts, Cooper B-Line B3140 or B3142 with B3200. For

insulated lines use double bolted pipe clamps, Cooper B-Line B3144 or B3146 with B3200.

C. MULTIPLE OR TRAPEZE HANGERS

1. Trapeze hangers shall be constructed from 12 gauge roll formed ASTM A 1011 SS Gr. 33

structural steel channel, 1

required.

2. Mount pipes to trapeze with two piece pipe straps sized for outside diameter of pipe,

Cooper B-Line B2000 series.

3. For pipes subjected to axial movement:

a. Strut mounted roller support, Cooper B-Line B3126. Use pipe protection shield or

saddles on insulated lines.

b. Strut mounted pipe guide, Cooper B-Line B2417.

D. WALL SUPPORTS

1. Pipes 4 inch and smaller:

a. Carbon steel hook, Cooper B-Line B3191.

b. Carbon steel J-hanger, Cooper B-Line B3690.

2. Pipes larger than 4 inch:

a. Welded strut bracket and pipe straps, Cooper B-Line B3064 and B2000 series.

b. Welded steel brackets, Cooper B-Line B3066 or B3067, with roller chair or adjustable

steel yoke pipe roll. Cooper B-Line B3120 or B3110. Use pipe protection shield or

saddles on insulated lines.

5

/8” x 15/8” minimum, Cooper B-Line B22 strut or stronger as

21

Page 24

Technical Data

E. FLOOR SUPPORTS

1. Hot piping under 6 inch and all cold piping:

a. Carbon steel adjustable pipe saddle and nipple attached to steel base stand sized

for pipe elevation, Cooper B-Line B3093 and B3088T or B3090 and B3088. Pipe saddle

shall be screwed or welded to appropriate base stand.

2. Hot piping 6 inch and larger:

a. (Adjustable) Roller stand with base plate, Cooper B-Line B3117SL (or B3118SL).

b. Adjustable roller support and steel support sized for elevation, Cooper B-Line B3124

F. VERTICAL SUPPORTS

1. Steel riser clamp sized to fit outside diameter of pipe, Cooper B-Line B3373.

Technical Data

G. COPPER TUBING SUPPORTS

1. Hangers shall be sized to fit copper tubing outside diameters.

a. Adjustable steel swivel ring (band type) hanger, Cooper B-Line B3170CT.

b. Malleable iron ring hanger, Cooper B-Line B3198CT or hinged ring hanger B3198HCT.

c. Adjustable steel clevis hanger, Cooper B-Line B3104CT.

H. PLASTIC PIPE SUPPORTS

1. V-bottom clevis hanger with galvanized 18 gauge continuous support channel, Cooper

B-Line B3106 and B3106V, to form a continuous support system for plastic pipe or flexible

tubing.

I. SUPPLEMENTARY STRUCTURAL SUPPORTS

1. Design and fabricate supports using structural quality steel bolted framing materials

as manufactured by Cooper B-Line. Channels shall be roll formed, 12 gauge ASTM

A 1011 SS Grade 33 steel, 1

Submit designs for pipe tunnels, pipe galleries, etc., to engineer for approval. Use

clamps and fittings designed for use with the strut system.

5

/8” x 15/8” or greater as required by loading conditions.

2.04 UPPER ATTACHMENTS

A. BEAM CLAMPS

1. Beam clamps shall be used where piping is to be suspended from building steel.

Clamp type shall be selected on the basis of load to be supported, and load configuration.

2. C-Clamps shall have locknuts and cup point set screws, Cooper B-Line B351L, B3036L or Fig. 65XT

Top flange C-clamps shall be used when attaching a hanger rod to the top flange of

structural shapes, Cooper B-Line B3034 or B3033. Refer to manufacturers’

recommendation for setscrew torque. Retaining straps shall be used to maintain the

clamp’s position on the beam where required (Fig. 69, Fig. 69R).

3. Center loaded beam clamps shall be used where specified. Steel clamps shall be Cooper

B-Line B3050 or B3055. Malleable iron or forged steel beam clamps with cross bolt shall

be Cooper B-Line B3054 or B3291 - B3297 series as required to fit beams.

B. CONCRETE INSERTS

1. Cast in place spot concrete inserts shall be used where applicable, either steel or

malleable iron body, Cooper B-Line B2500 or B3014. Spot inserts shall allow for lateral

adjustment and have means for attachment to forms. Select insert nuts to suit

threaded hanger rod sizes, Cooper B-Line N2500 or B3014N series.

22

Page 25

Technical Data

2. Continuous concrete inserts shall be used where applicable. Channels shall be 12

gauge, ASTM A 1011 SS Grade 33 structural quality carbon steel, complete with

styrofoam inserts and end caps with nail holes for attachment to forms. The

continuous concrete insert shall have a load rating of 2,000 lbs/ft. in concrete,

Cooper B-Line B22I, B32I, or B52I (B52I is limited to 1,500 lbs/ft.). Select channel nuts

suitable for strut and rod sizes.

2.05 VIBRATION ISOLATION AND SUPPORTS

A. For refrigeration, air conditioning, hydraulic, pneumatic, and other vibrating system

applications, use a clamp that has a vibration dampening insert and a nylon inserted

locknut. For copper and steel tubing use Cooper B-Line BVT series VibraClamps, for pipe

sizes use BVP series.

B. For larger tubing or piping subjected to vibration, use neoprene or spring hangers

as required.

C. For base mounted equipment use vibration pads, molded neoprene mounts, or spring

mounts as required.

D. Vibration isolation products as manufactured by Cooper B-Line, VibraTrol systems.

Technical Data

2.06 ACCESSORIES

A. Hanger rods shall be threaded both ends, Cooper B-Line B3205, or continuous threaded rods

of circular cross section. Use adjusting locknuts at upper attachments and hangers.

No wire, chain, or perforated straps are allowed.

B. Shields shall be 180° galvanized sheet metal, 12 inch minimum length, 18 gauge minimum

thickness, designed to match outside diameter of the insulated pipe, Cooper B-Line B3151.

1

C. Pipe protection saddles shall be formed from carbon steel,

sized for insulation thickness. Saddles for pipe sizes greater than 12 inch shall have a

center support rib.

/8 inch minimum thickness,

2.07 FINISHES

INDOOR FINISHES

A. Hangers and clamps for support of bare copper piping shall be coated with copper colored

epoxy paint, Cooper B-Line Dura-Copper. Additionally a plastic coating or a felt lining in

hanger can be used.

B. Hangers for other than bare copper pipe shall be zinc plated in accordance with ASTM

B 633 - SC3 or shall have an electro-deposited green epoxy finish, Cooper B-Line Dura-Green.

C. Strut channels shall be pre-galvanized in accordance with ASTM A 653 G90 or have

an electro-deposited green epoxy finish, Cooper B-Line Dura-Green.

OUTDOOR AND CORROSIVE AREA FINISHES

D. Hangers and strut located outdoors shall be hot dip galvanized after fabrication in

accordance with ASTM A 123. All hanger hardware shall be hot-dip galvanized or

stainless steel. Zinc plated hardware is not acceptable for outdoor or corrosive use.

E. Hangers and strut located in corrosive areas shall be Type 304 (316) stainless steel

with stainless steel hardware.

23

Page 26

Technical Data

Part III - EXECUTION

3.01 PIPE HANGERS AND SUPPORTS

A. Pipe shall be adequately supported by pipe hanger and supports specified in PART II -

PRODUCTS. Hangers for insulated pipes shall be sized to accommodate insulation

thickness.

B. Horizontal steel piping shall be supported in accordance with ANSI/MSS SP-69 & SP-58

Tables 3 and 4, excerpts of which follow below:

NOMINAL PIPE SIZE ROD DIAMETER MAXIMUM SPACING

Technical Data

3

/8” - 11/4”

1

/2”

1

2”

1

/2”

2

3”

1

/2”

3

4”

5”

6”

8”

10”

12”

3

/8” 7’-0”

3

/8” 9’-0”

3

/8” 10’-0”

1

/2” 11’-0”

1

/2” 12’-0”

1

/2” 13’-0”

5

/8” 14’-0”

5

/8” 16’-0”

3

/4” 17’-0”

3

/4” 19’-0”

7

/8” 22’-0”

7

/8” 23’-0”

14” 1” 25’-0”

16” 1” 27’-0”

C. Horizontal copper tubing shall be supported in accordance with ANSI/MSS SP-69 & SP-58

Tables 3 and 4, excerpts of which follow below:

NOMINAL TUBING SIZE ROD DIAMETER MAXIMUM SPACING

1

/4” - 3/4”

1”

1

/4”

1

1

/2”

1

2”

1

/2”

2

3”

1

/2”

3

4”

5”

6”

8”

3

/8” 5’-0”

3

/8” 6’-0”

3

/8” 7’-0”

3

/8” 8’-0”

3

/8” 8’-0”

1

/2” 9’-0”

1

/2” 10’-0”

1

/2” 11’-0”

1

/2” 12’-0”

1

/2” 13’-0”

5

/8” 14’-0”

3

/4” 16’-0”

D. Provide means of preventing dissimilar metal contact such as plastic coated hangers,

copper colored Cooper B-Line Dura-Copper epoxy paint, or non-adhesive isolation tape

(Cooper B-Line Iso-Pipe). Galvanized felt isolators sized for copper tubing may also be used,

Cooper B-Line B3195CT.

24

Page 27

Technical Data

E. Support horizontal cast iron pipe adjacent to each hub, with 10 feet maximum spacing

between hangers.

1

F. Install hangers to provide a minimum of

adjacent work.

G. Place a hanger within 12 inches of each horizontal elbow.

H. Support vertical piping independently of connected horizontal piping. Support vertical

pipes at every (other) floor. Wherever possible, locate riser clamps directly below pipe

couplings or shear lugs.

I. Where several pipes can be installed in parallel and at the same elevation, provide trapeze

hangers as specified in Section 2.02 C. Trapeze hangers shall be spaced according to the

smallest pipe size, or install intermediate supports according to schedule in Section 3.01 B.

J. Do not support piping from other pipes, ductwork or other equipment which is not

building structure.

3.02 CONCRETE INSERTS

A. Provide inserts for placement in formwork before concrete is poured.

/2 inch space between finished covering and

Technical Data

B. Provide inserts for suspending hangers from reinforced concrete slabs and sides of

reinforced concrete beams.

C. Where concrete slabs form finished ceilings, provide inserts to be flush with slab surface.

D. For inserts carrying 5” nominal pipe and larger, provide hooked rod to concrete

reinforcement.

25

Page 28

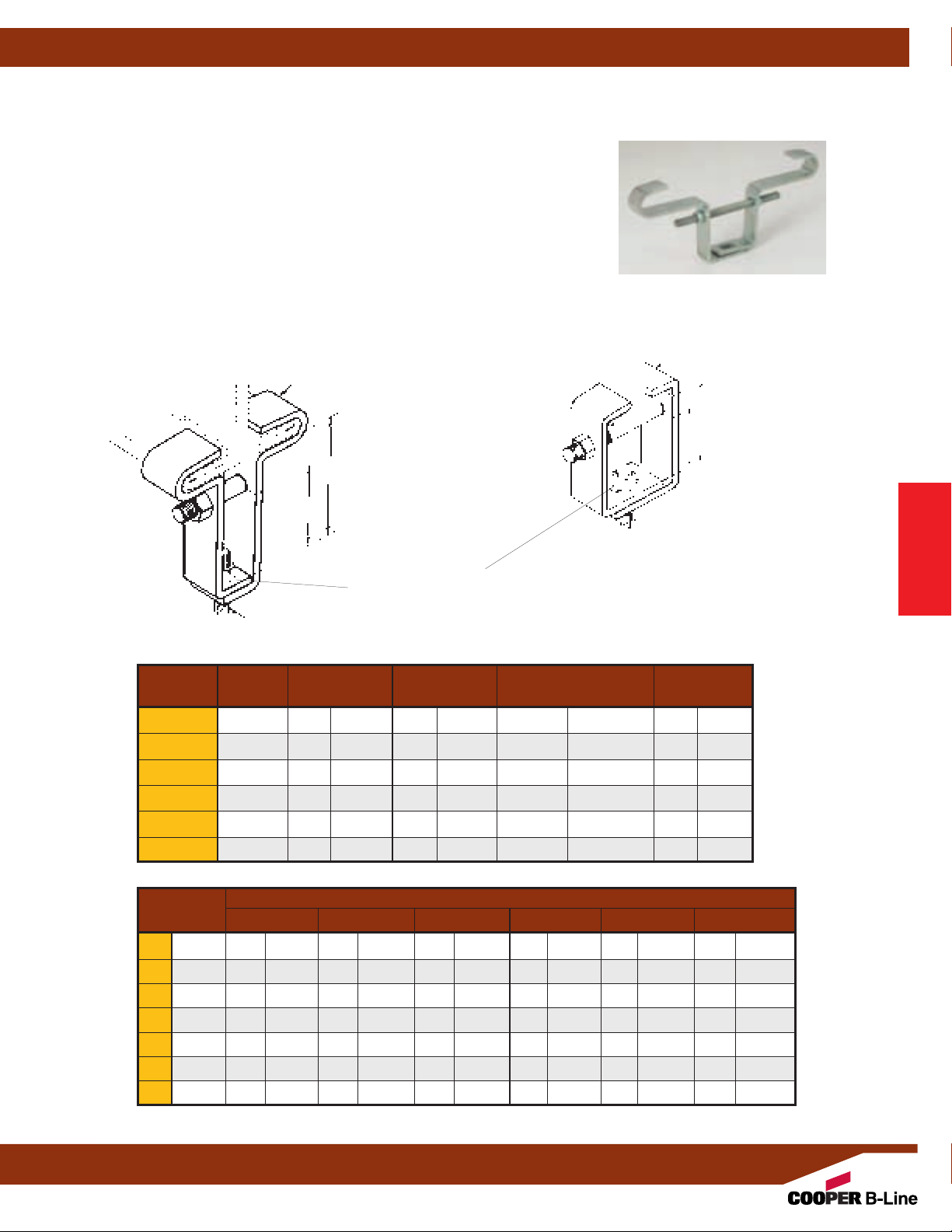

Beam Clamps

Beam Clamps

Beam clamps offered in this section are designed to provide attachment of hanger rods to structural members without

drilling or welding. A wide range of types and sizes are available for various applications.

Materials

Carbon Steel, Malleable Iron and Forged Steel are used in the manufacturing of beam clamps and accessories. Stainless

steel and other materials are available.

Finishes

The standard finishes for mechanical supports are plain steel (oil coated) sometimes referred to as black and ElectroGalvanized Zinc (ASTM B 633 SC3). Hot-Dip Galvanized After Fabrication (ASTM A 123), Red Primer, Plastic Coating and

DURA-GREEN

™

. Other special coatings are available upon request.

Note: Due to the design of some products, (threads, connecting hardware, swivels, etc.) items may

or may not be uniformly coated with special finishes. In some cases, the hanger itself may be coated, however, the

hardware may be supplied Electro-Plated, copper plated, or in stainless steel.

Recommended Set screw Torque

1

/4”-20

4 ft/lbs

(5 Nm)

5 ft/lbs

(unless otherwise specified)

3

/8”-16

(7 Nm)

11 ft/lbs

1

/2”-13

(15 Nm)

5

/8”-11

21 ft/lbs

(28 Nm)

3

/4”-10

34 ft/lbs

(46 Nm)

Over torqued set screws will damage beam clamps in this section.

We are aware that torque wrenches are not used or not available in many instances. In the absence of a torque wrench, the

set screw should be finger tightened to the I-beam and then an additional

1

/4 to 1/2 turn applied to the set screw.

Approvals (as noted)

Items in this section are Underwriters Laboratories Listed, Factory Mutual Approved, and comply with Federal Specification

WW-H-171E & A-A-1192A or Manufacturers Standardization Society ANSI/MSS SP-69 & SP-58.

All dimensions in charts and on drawings are in inches. Dimensions shown in parentheses are in millimeters unless otherwise specified.

26

Page 29

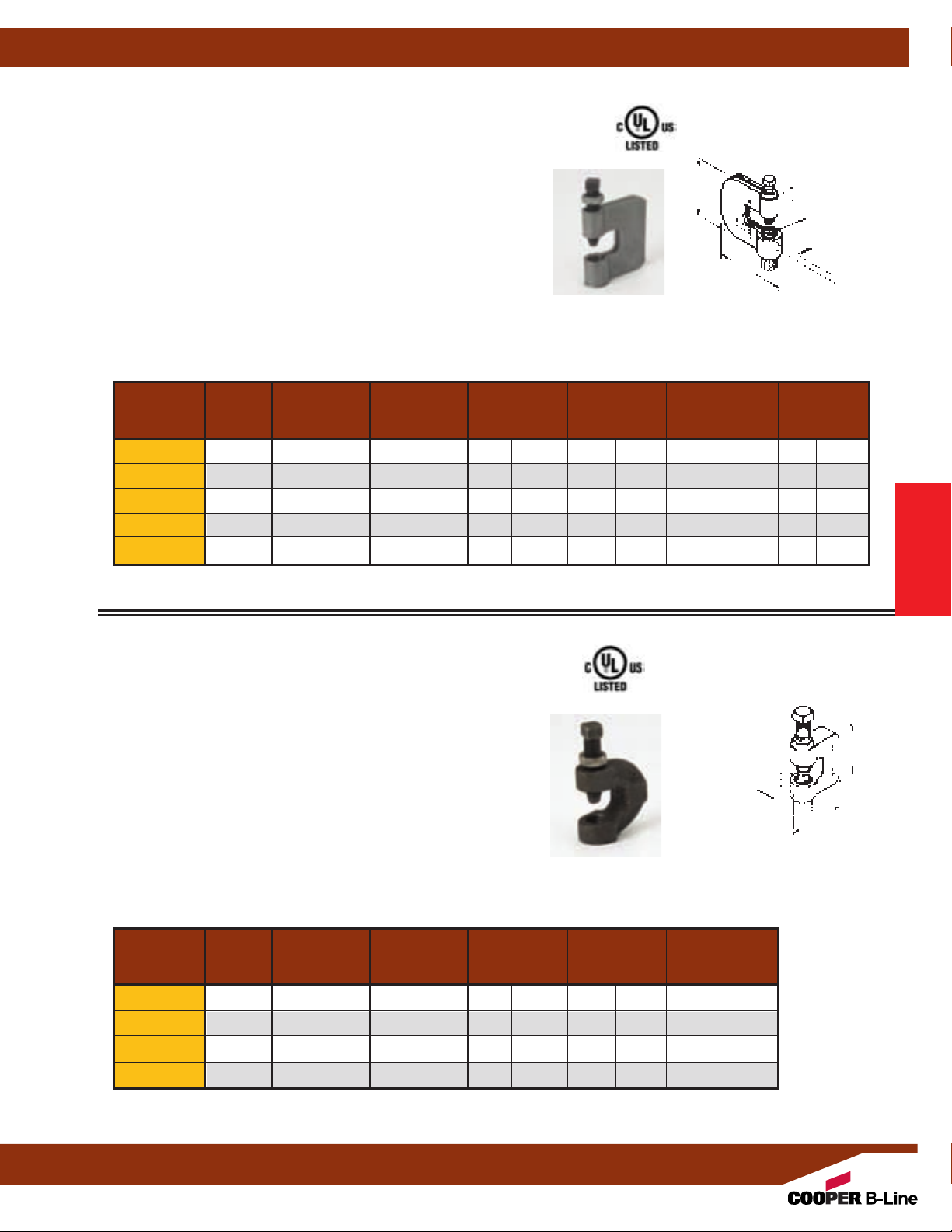

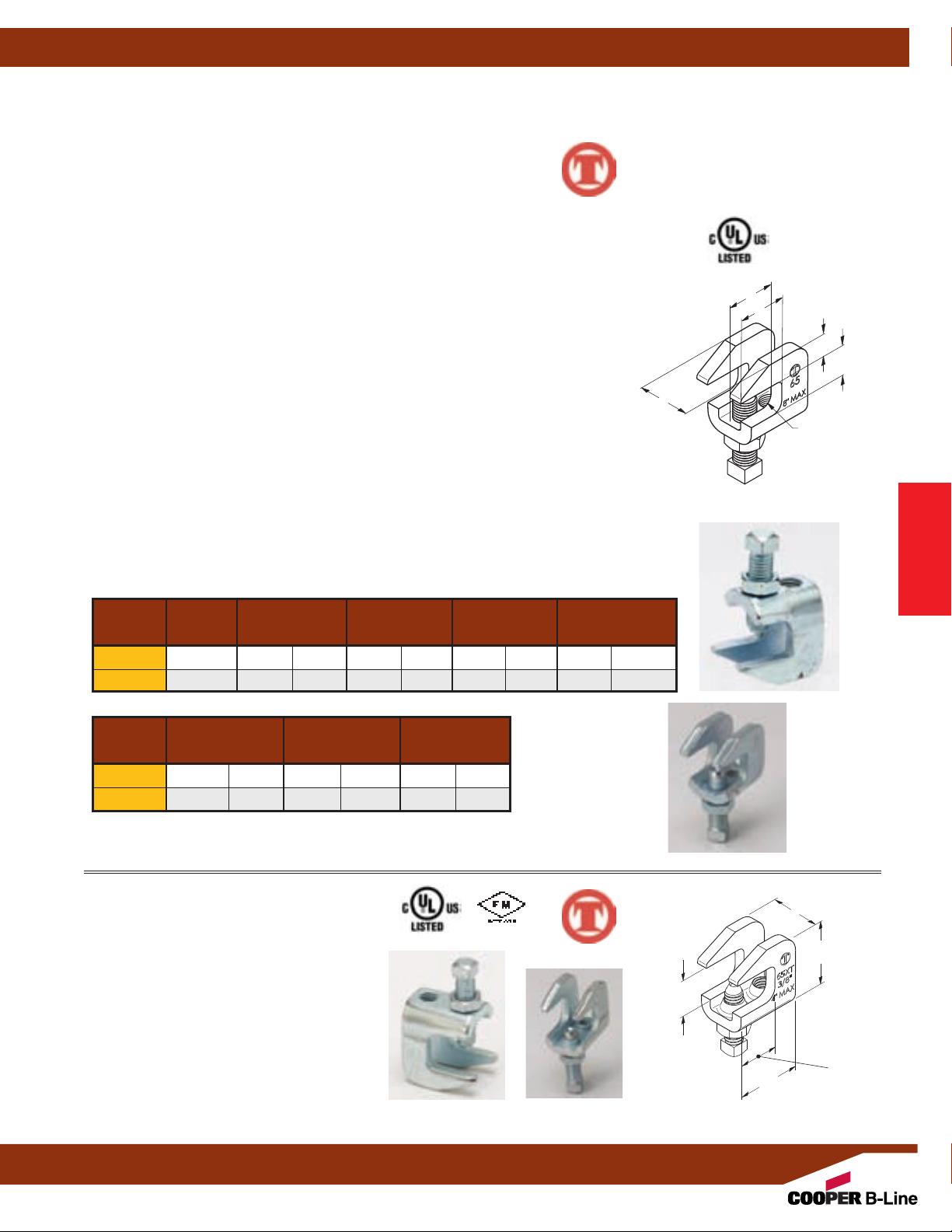

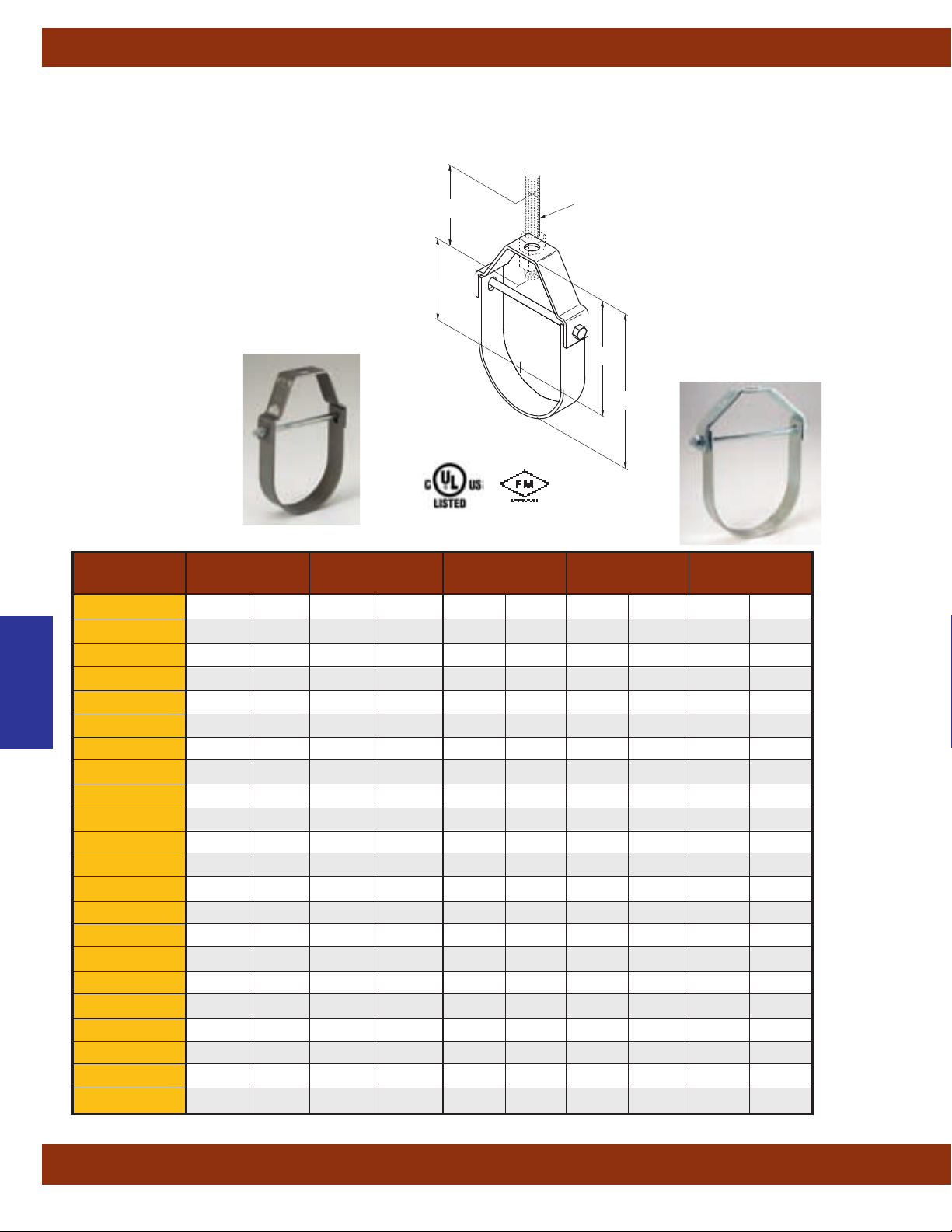

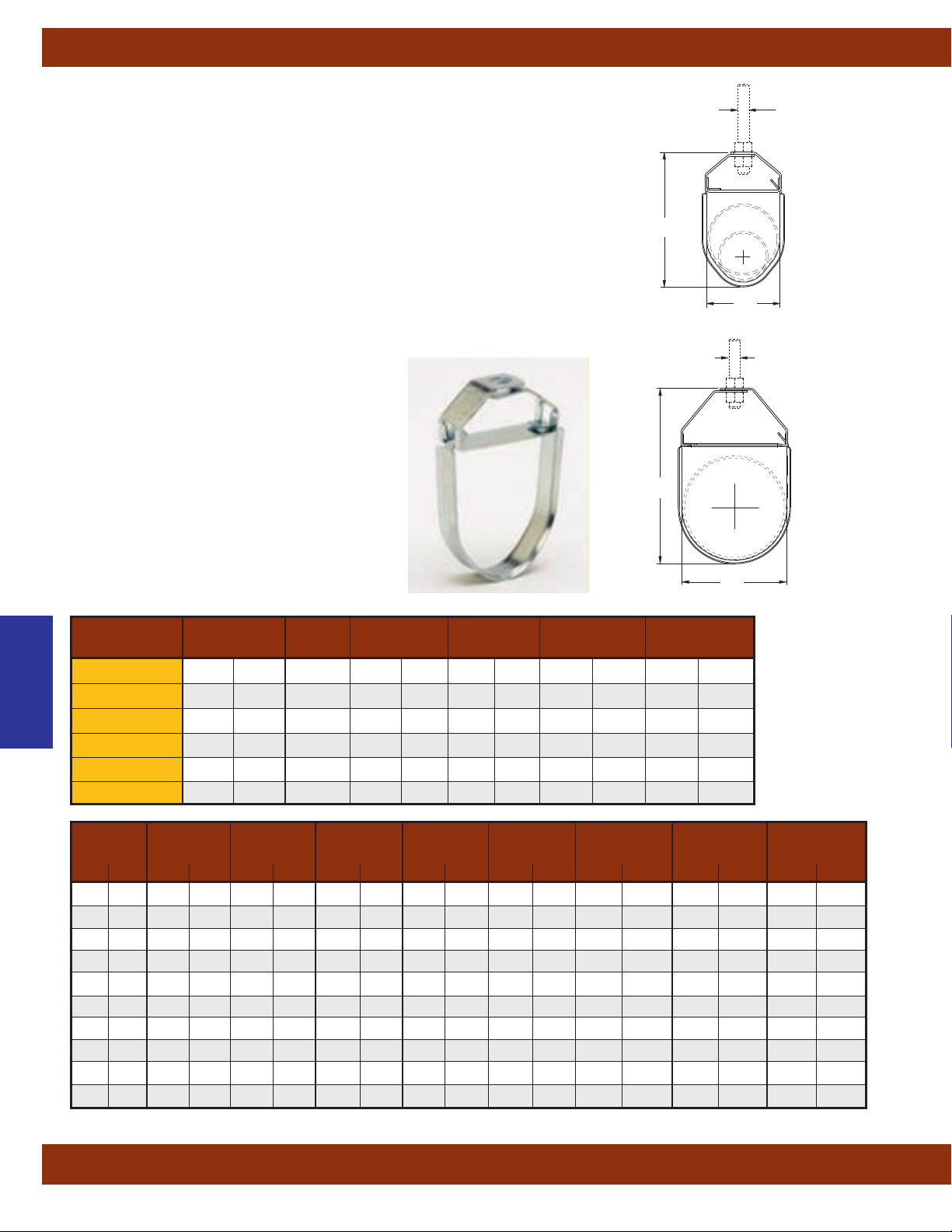

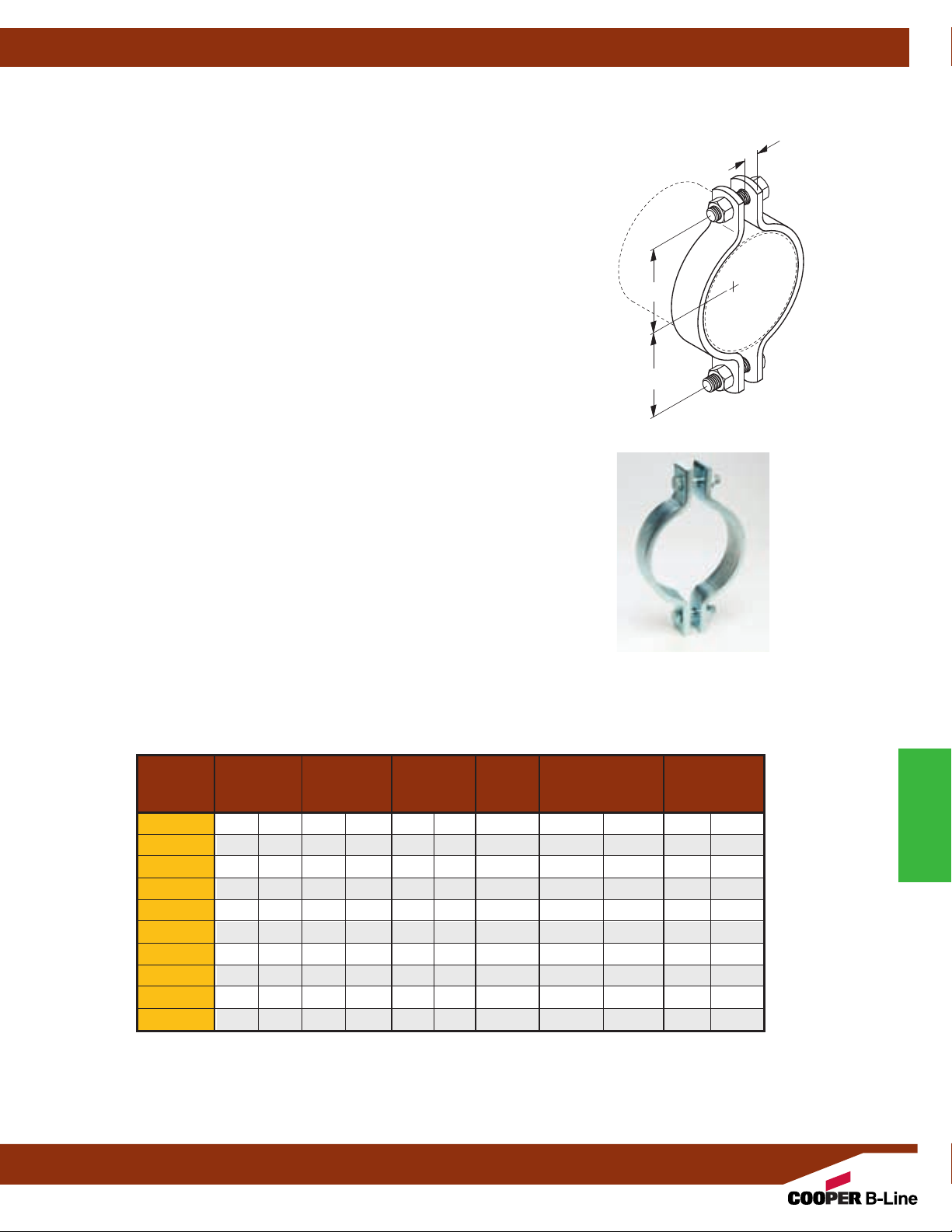

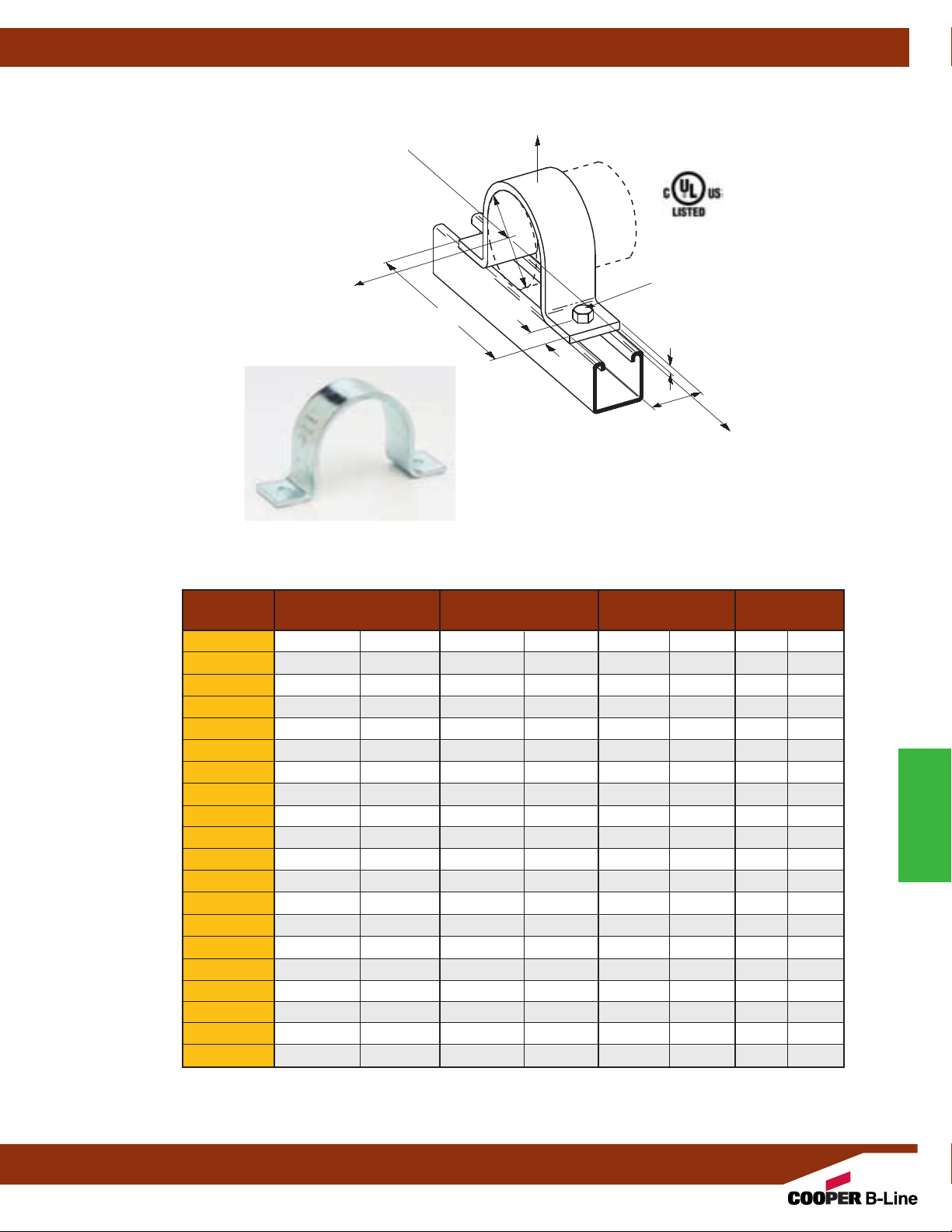

Fig. B351L - Steel C-Clamp With Locknut (TOLCO Fig. 64)

Size Range:3/8"-16 thru 7/8"-9 rod

Material: Steel

Function: For attachment to I-beams, channels, and wide flange beams

where the thickness does not exceed

secures “C” Clamp to beam.

3

Approvals: B351L (

/8”-16 - 3/4”-10), is Underwriters Laboratories Listed.

Conforms to Federal Specification WW-H-171E & A-A-1192A, Type 23 and

Manufacturers Standardization Society ANSI/MSS SP-69 & SP-58, Type 23.

Finish: Plain. Contact Cooper B-Line for alternative finishes and materials.

Note: When retaining strap is required, order B3362 thru B3365 separately.

See page 28.

Order By: Figure number and finish

Part Rod Design Maximum Iron

No. Size B C D Load Pipe Size Per UL

A in. (mm) in. (mm) in. (mm) Lbs. (kN) in. (mm) Lbs. (kg)

B351L-3/8

B351L-1/2

B351L-5/8

B351L-3/4

B351L-7/8

3

/8"-16 23/8" (60.3) 23/8" (60.3)3/4" (19.0) 300 (0.89) 4" (100) 41 (18.6)

1

/2"-13 23/8" (60.3) 23/8" (60.3)3/4" (19.0) 380 (1.69) 6" (150) 41 (18.6)

5

/8"-11 23/8" (60.3) 21/4" (57.1)3/4" (19.0) 550 (2.44) 6" (150) 60 (27.2)

3

/4"-10 23/8" (60.3) 21/4" (57.1)3/4" (19.0) 630 (2.80) 6" (150) 71 (32.2)

7

/8"-9 3" (76.2) 31/4" (82.5) 1" (25.4) 1200 (5.34) -- -- 184 (83.4)

3

/4" (19.0mm). Hardened set screw

Beam Clamps

Set Screw and

D

B

C

Locknut Included

A

(Rod Size)

Hanger Rod

Not Included

Approx. Wt./100

Note: See page 26 for recommended setscrew torque.

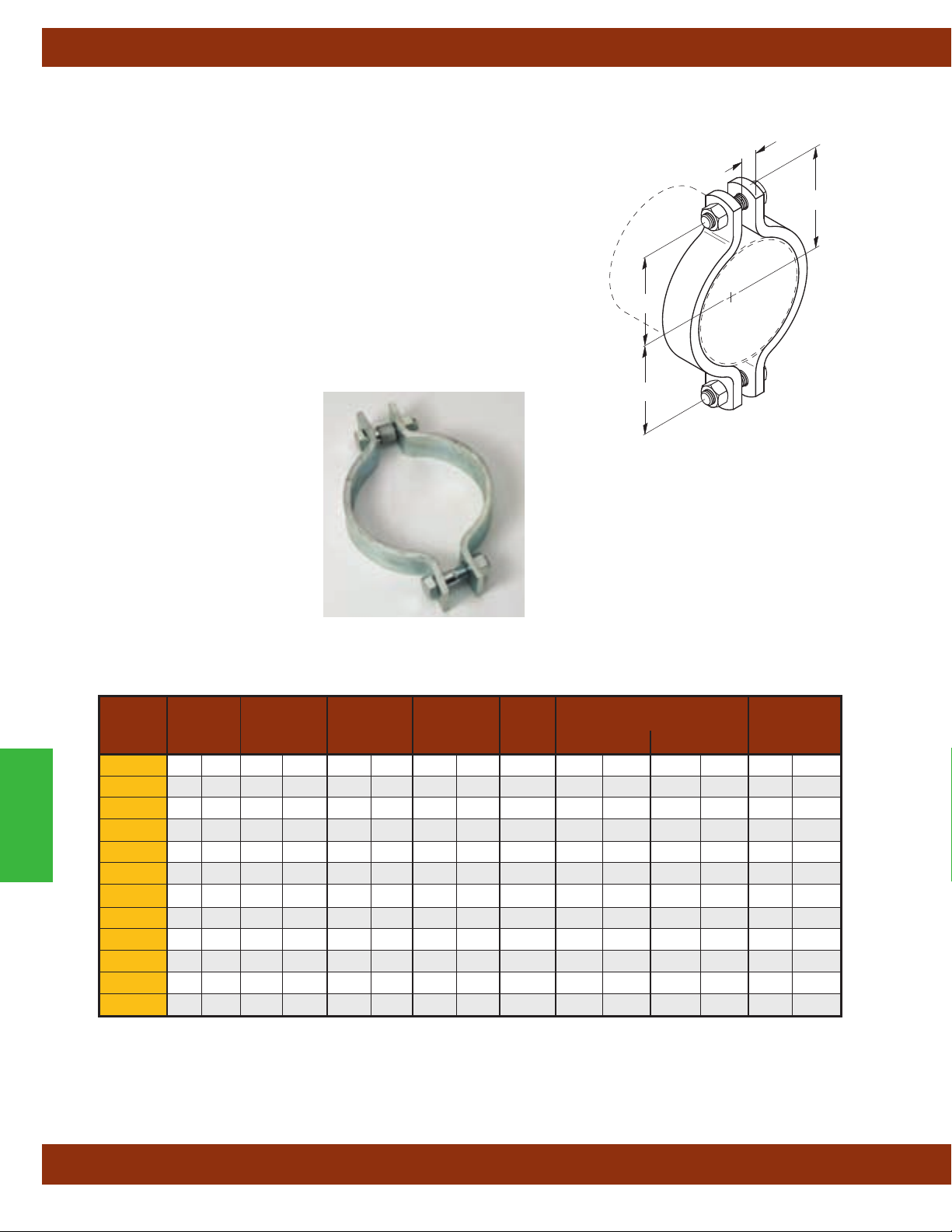

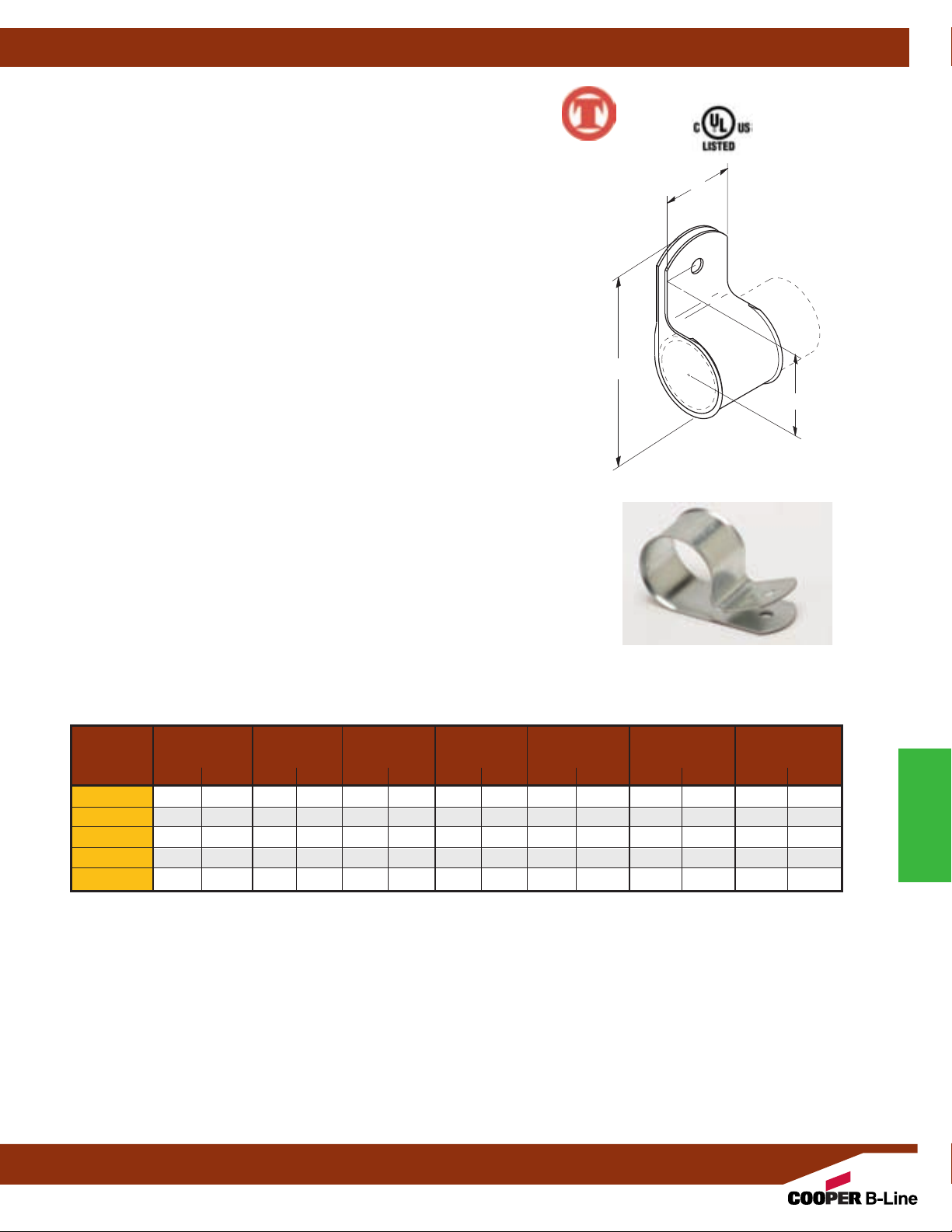

Fig. B3036L - Malleable Iron C-Clamp With Locknut

3

Size Range:

Material: Malleable Iron

Function: Designed for attaching a hanger rod to the flange of a beam.

Approvals: B3036L is Underwriters Laboratories Listed. Complies

with Federal Specification WW-H-171E & A-A-1192A

Manufacturers Standardization Society ANSI/MSS SP-69 & SP-58 Type 23.

Finish: Plain or Electro-Galvanized

Order By: Figure number and finish. When retaining strap is

required, order B3362 thru B3365 separately

B3036L-3/8

B3036L-1/2

B3036L-5/8

B3036L-3/4

Note: See page 26 for recommended setscrew torque.

/8"-16 thru 3/4"-10 rod

Type 23 and

. See page 28.

Part Rod Design

No. Size B C Load

A

3

/8"-16 13/4" (44.4) 13/4" (44.4) 300 (0.89) 4" (100) 41 (18.6)

1

/2"-13 13/4" (44.4) 13/4" (44.4) 380 (1.69) 5" (125) 41 (18.6)

5

/8"-11 2" (50.8) 17/8" (47.6) 530 (2.36) 6" (150) 60 (27.2)

3

/4"-10 2" (50.8) 2" (50.8) 530 (2.36) 6" (150) 71 (32.2)

in. (mm) in. (mm) Lbs. (kN) in. (mm) Lbs. (kg)

Maximum Iron

Pipe Size Per UL

Set Screw and

Locknut Included

A

(Rod Size)

Hanger Rod

Not Included

Approx. Wt./100

Beam Clamps

3

/4"

(19.0)

B

C

All dimensions in charts and on drawings are in inches. Dimensions shown in parentheses are in millimeters unless otherwise specified.

27

Page 30

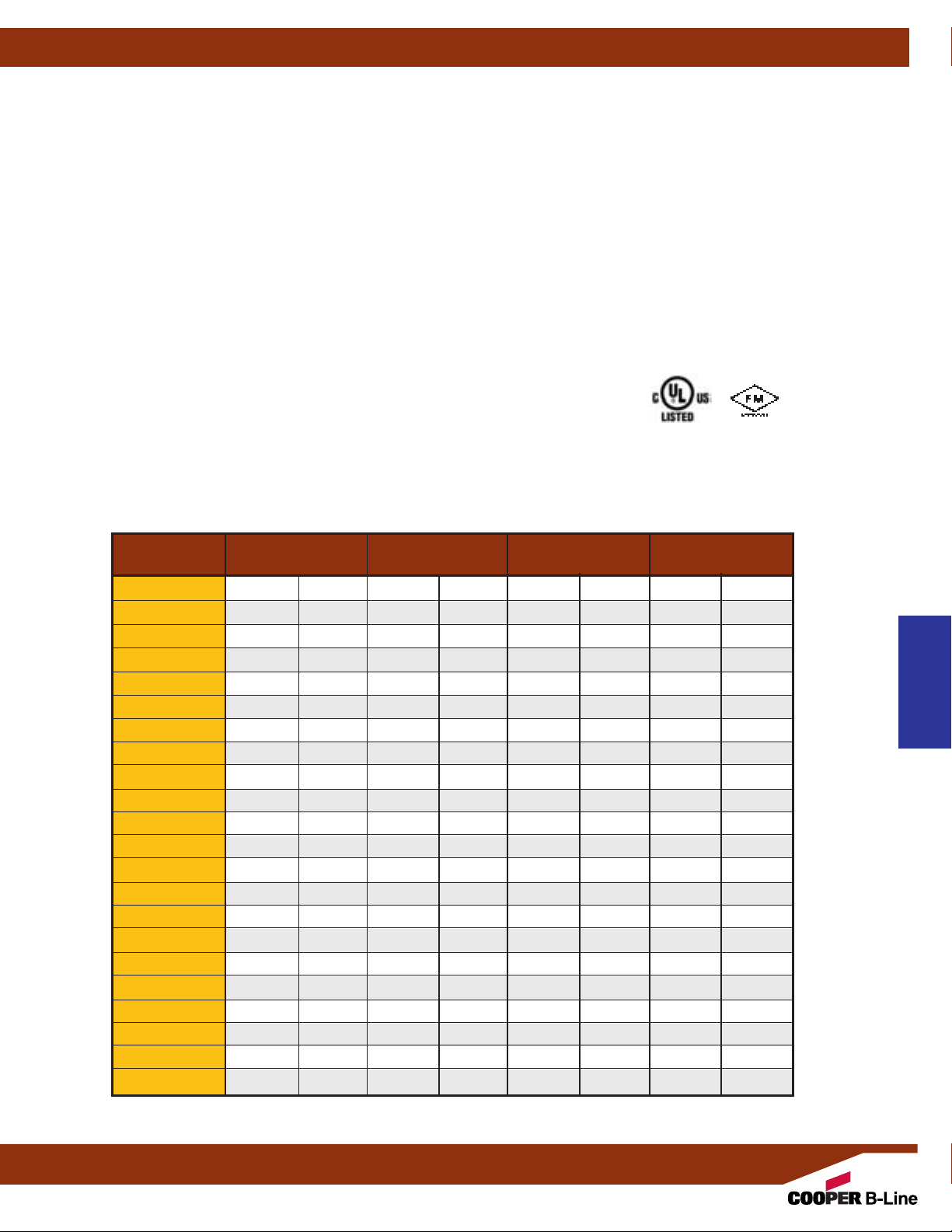

Beam Clamps

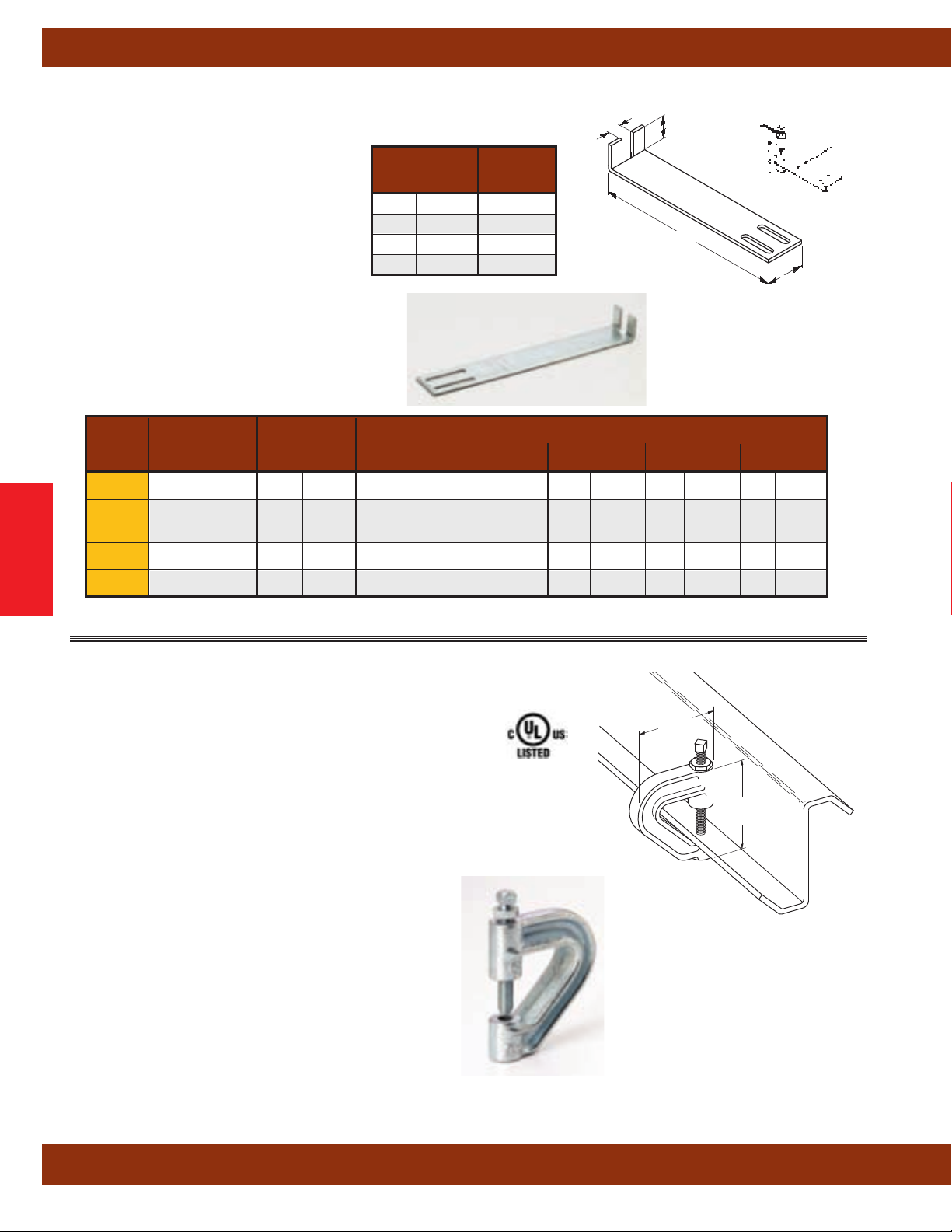

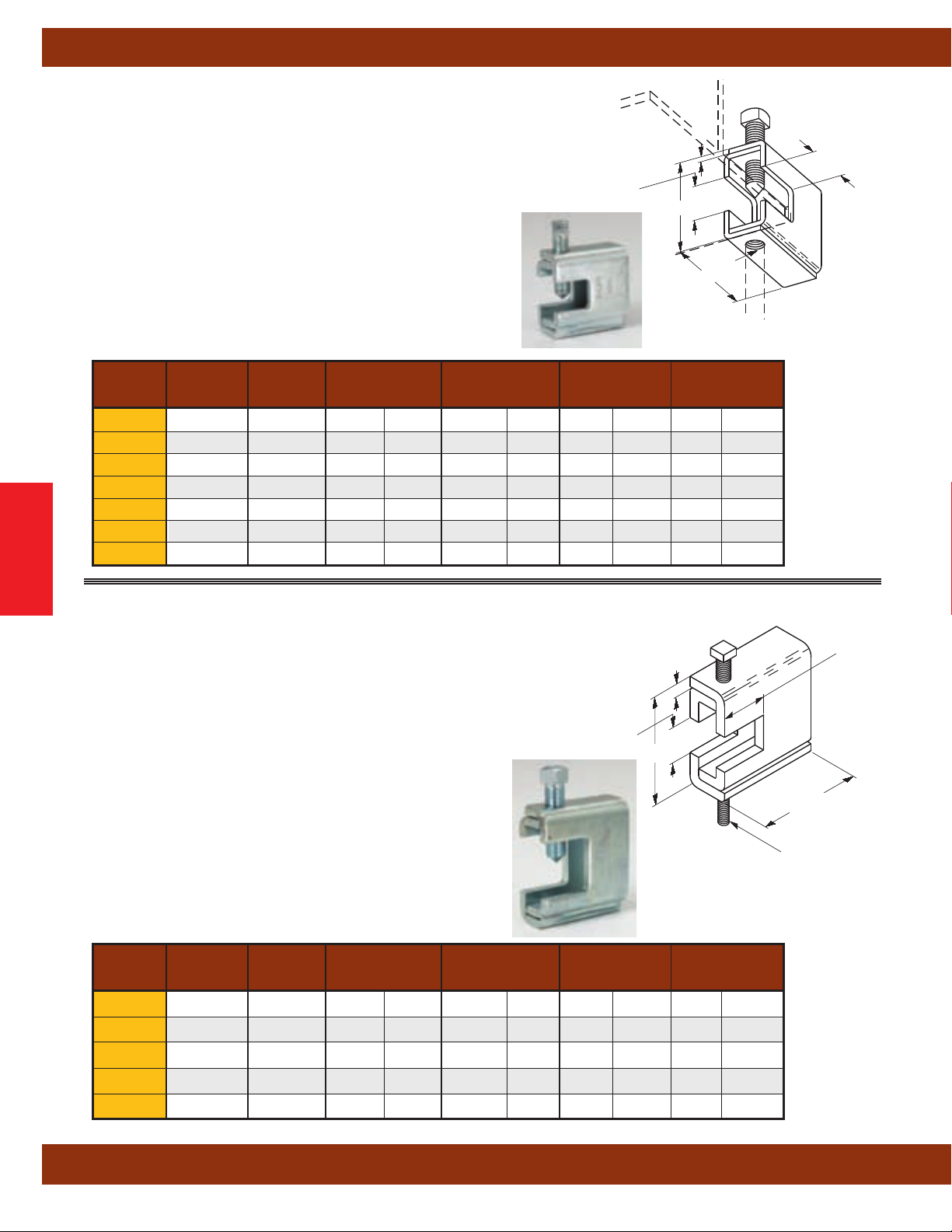

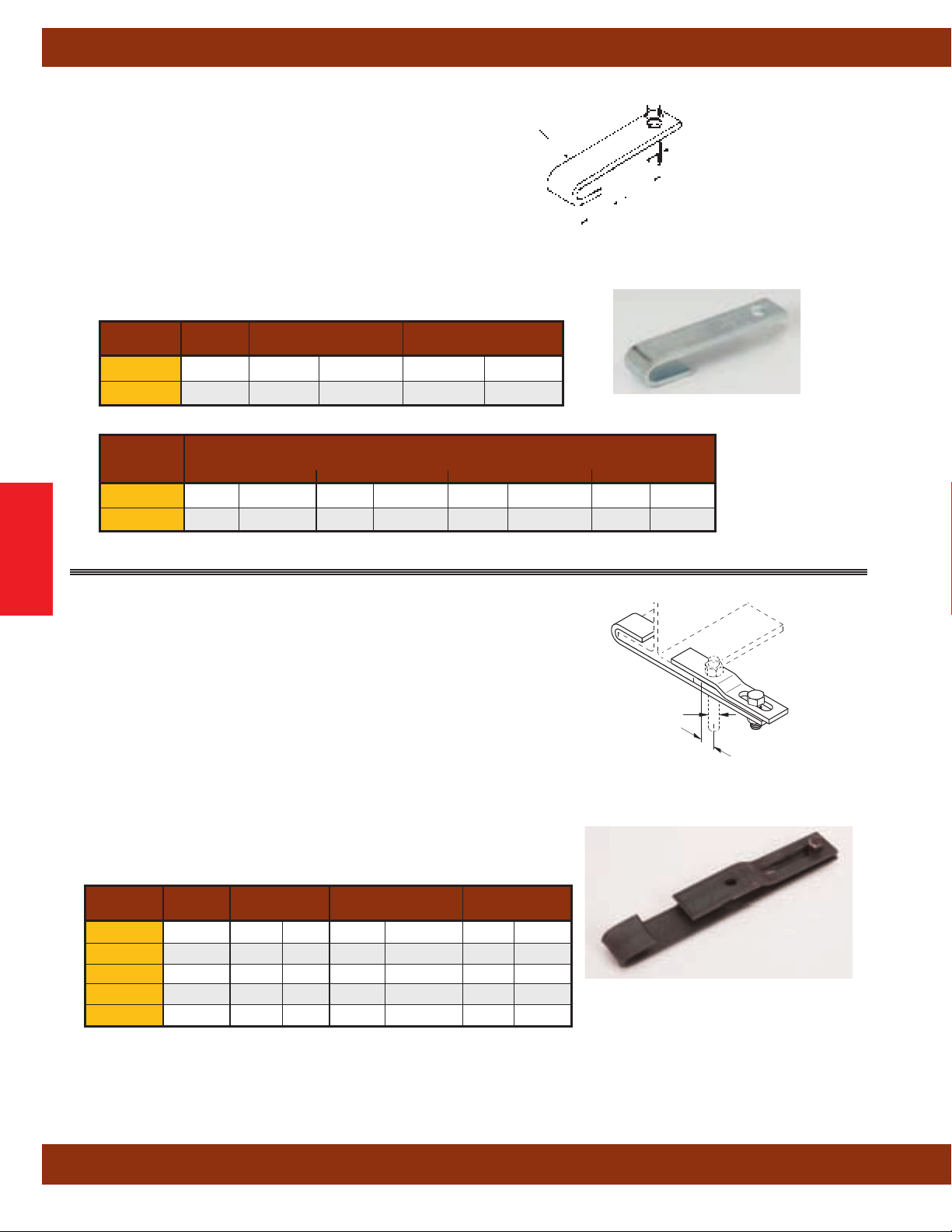

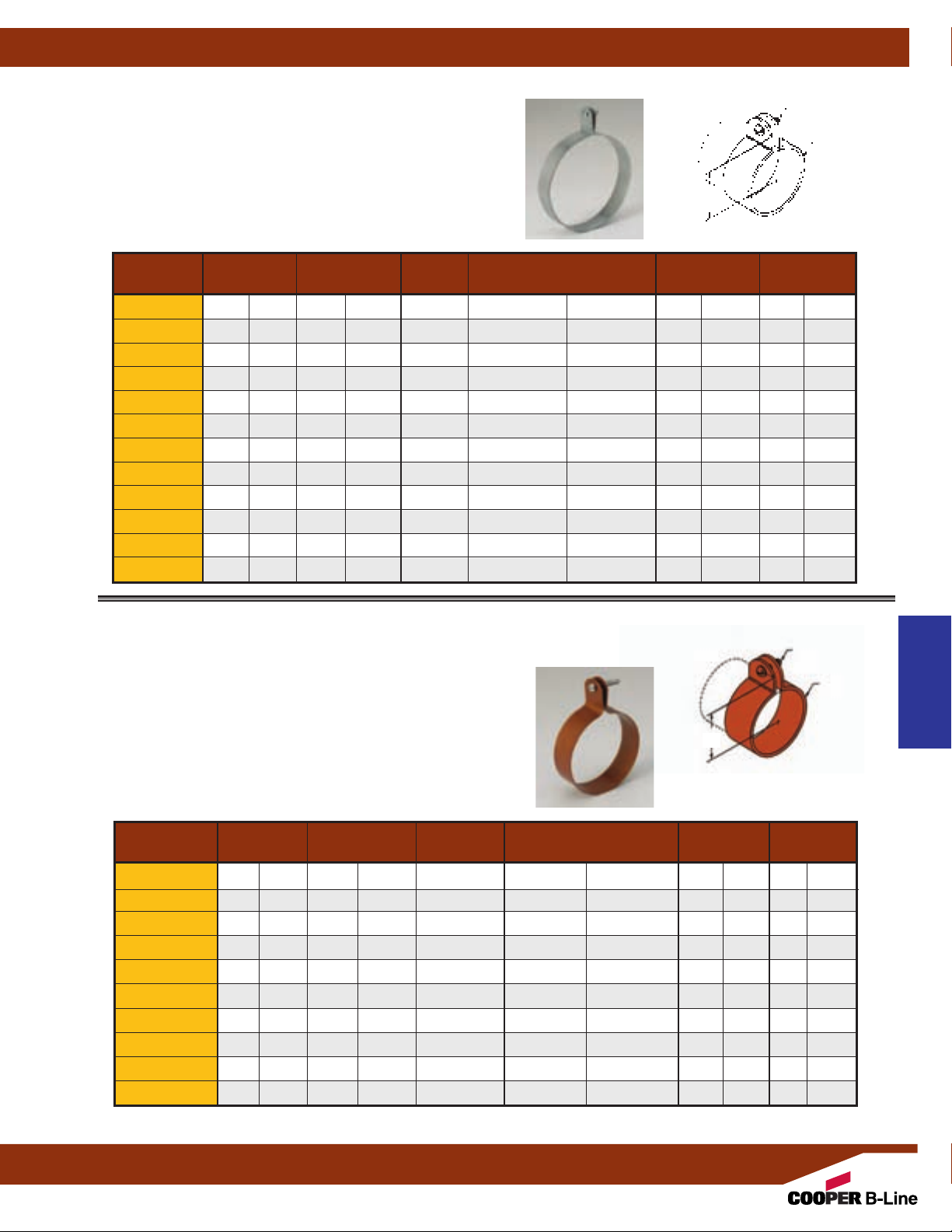

Fig. B3362, B3363, B3364, B3365 - Retaining Strap

Size Range: 6” (152.4mm) to 12” (304.8mm)

lengths

Material: Steel (Stainless Steel available)

Finish: Pre-Galvanized

Function: Designed for use with B351L

and B3036L

C-Clamps.

Order By: Figure number, length 'L', (add

1"

(25.4) minimum to flange width), and

finish.

Note: Requires field forming on beam.

Part For Use With A B 6"

No. in. (mm) in. (mm) Lbs. (kg) Lbs. (kg) Lbs. (kg) Lbs. (kg)

B3362-L B351L-3/8 & 1/2

Beam Clamps

B3363-L B351L-5/8 &3/4,

B3036L-3/8 &1/2

B3364-L B3036L-5/8 & 3/4

B3365-L B351L-7/8

11/4

" (31.7)7/16" (11.1) 27 (12.2) 35 (15.9) 44 (19.9) 52 (23.6)

11/4" (31.7)

11/4

" (31.7)

11/2

" (38.1)

Flange Width Length L

in. (mm) in. (mm)

3”-5” (76-127) 6” (152.4)

5”-7” (127-178) 8” (203.2)

7”-9” (178-228) 10” (254.0)

9”-11” (228-279) 12” (304.8)

5

/8" (15.9) 26 (11.8) 35 (15.9) 43 (19.5) 52 (23.6)

11

/16" (17.4) 26 (11.8) 35 (15.9) 43 (19.5) 52 (23.6)

3

/4

" (19.0) 32 (14.5) 42 (19.0) 52 (23.6) 62 (28.1)

B

3

/4"

(19.0)

L

A

Material Thickness

12 Gauge

(2.7)

Approx. Wt./100 for Length 'L' of

(152.4) 8" (203.2) 10" (254.0) 12" (304.8)

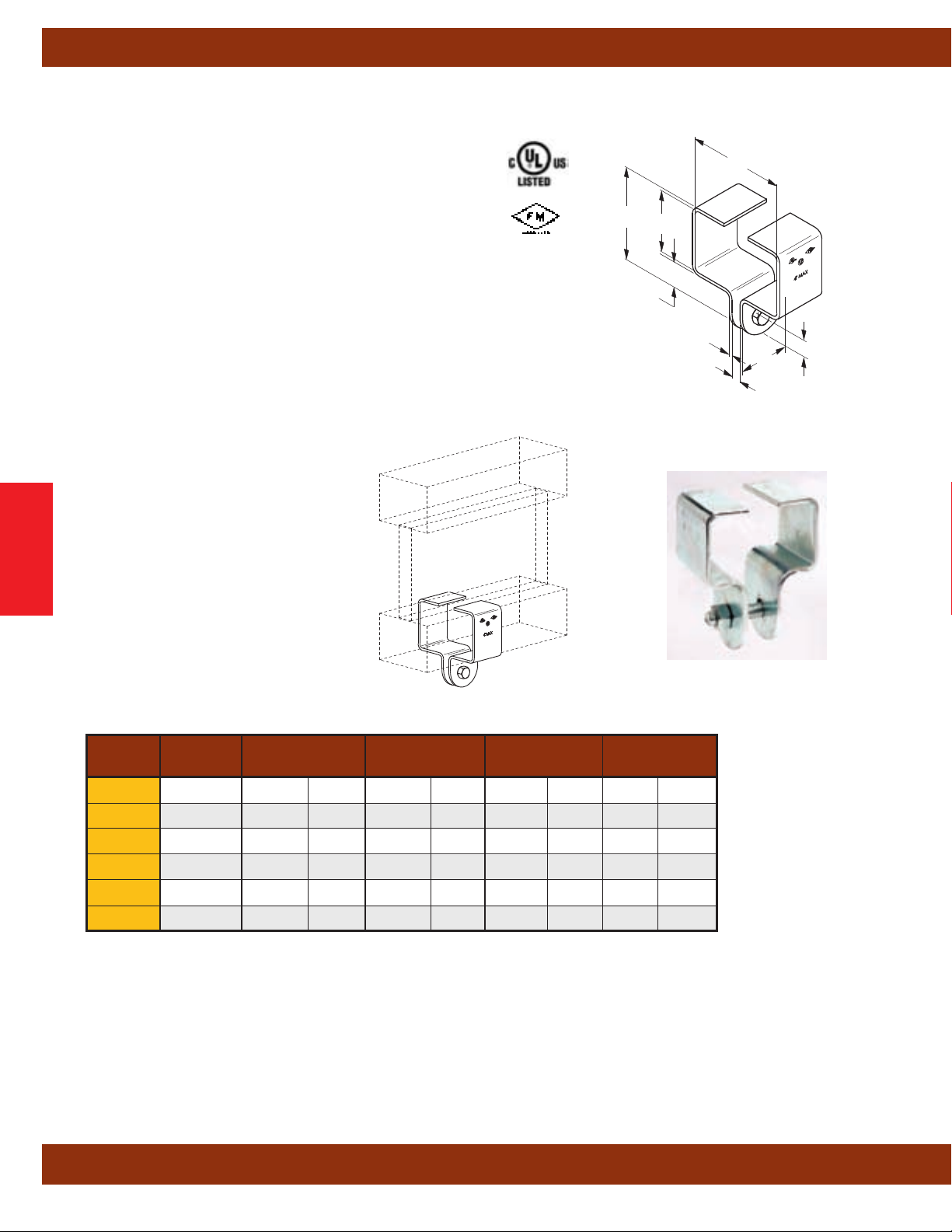

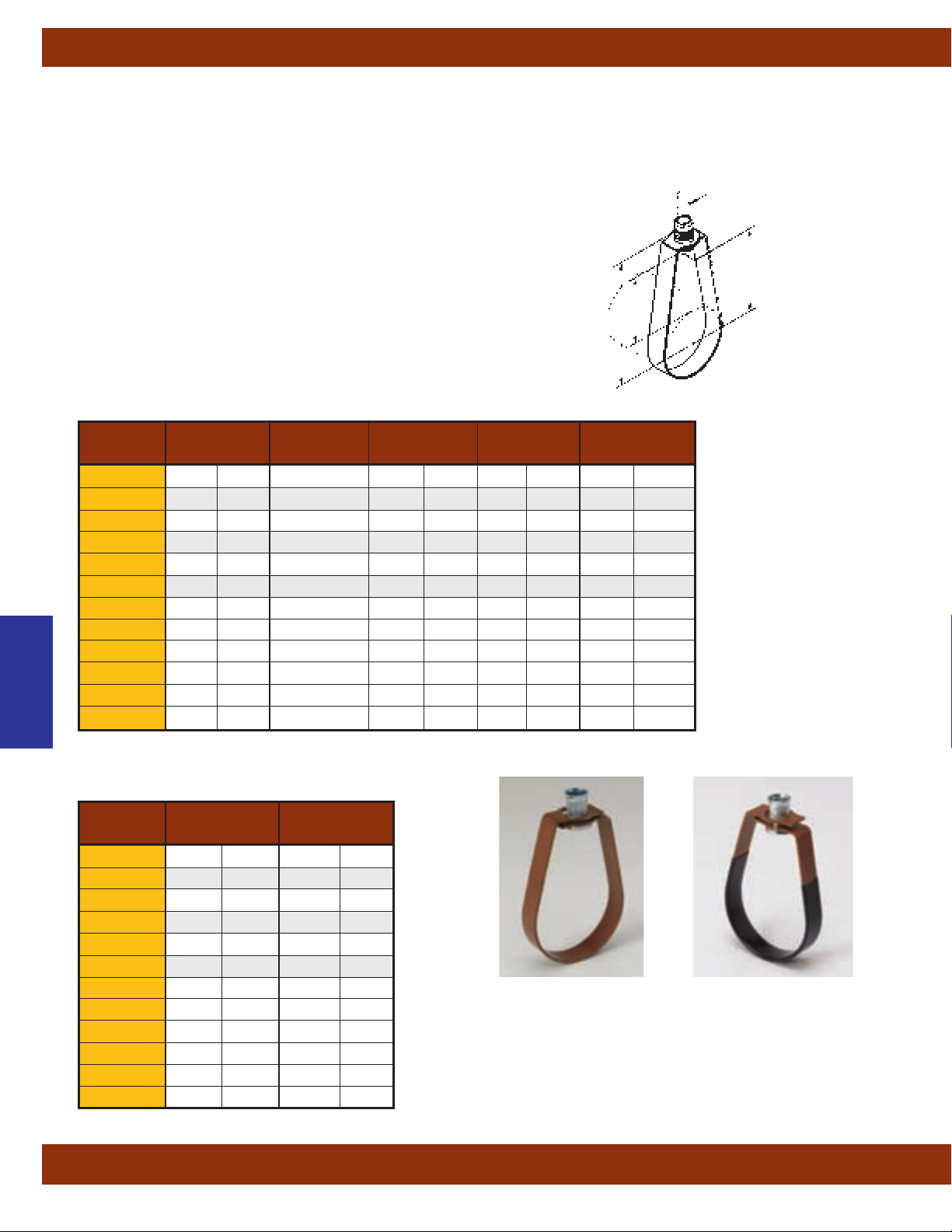

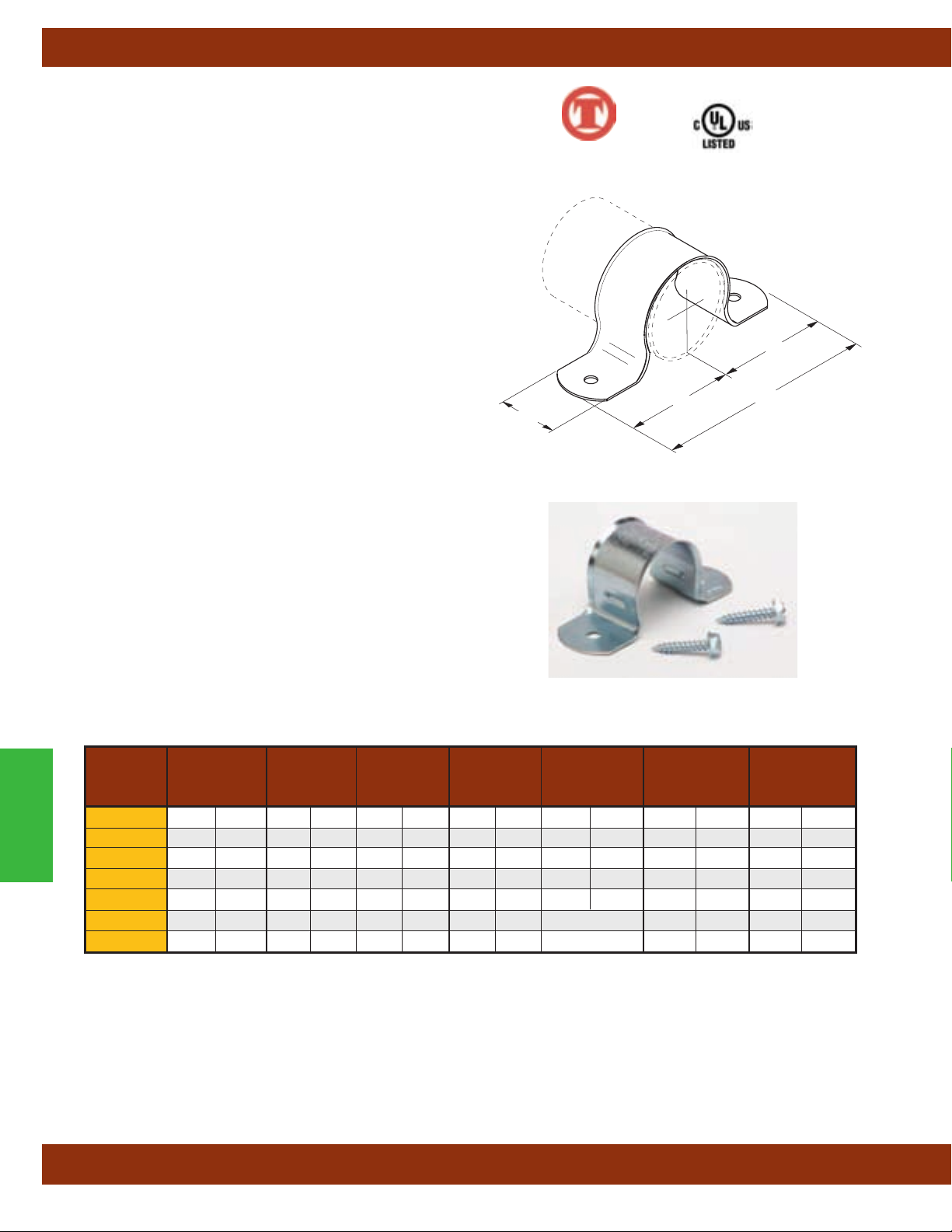

Fig. B3037 - Z-Purlin Malleable C-Clamp

Material: Malleable Iron

3

Function: Designed for attaching a

bottom flange of a Z-purlin.

Approvals: Underwriters Laboratories Listed for up to 4”

pipe. Conforms to Federal Specification WW-H-171E & A-A-1192A,

Type 23 and Manufacturers Standardization Society ANSI/MSS

SP-69 & SP-58, Type 23.

Finish: Plain or Electro-Galvanized

Order By: Figure number and finish.

Weight: Approx. Wt./100 90 Lbs.

Design Load: 400 Lbs. (1.78kN)

Note: See page 26 for recommended setscrew torque.

/8"-16 hanger rod to the

(100mm)

(40.8kg)

3"

(76.2)

Throat Opening

31

/32" (24.6)

Bottom Hanger Rod

Threads

3

/8"-16

313/32"

(86.5)

Set Screw and

Locknut Included

All dimensions in charts and on drawings are in inches. Dimensions shown in parentheses are in millimeters unless otherwise specified.

28

Page 31

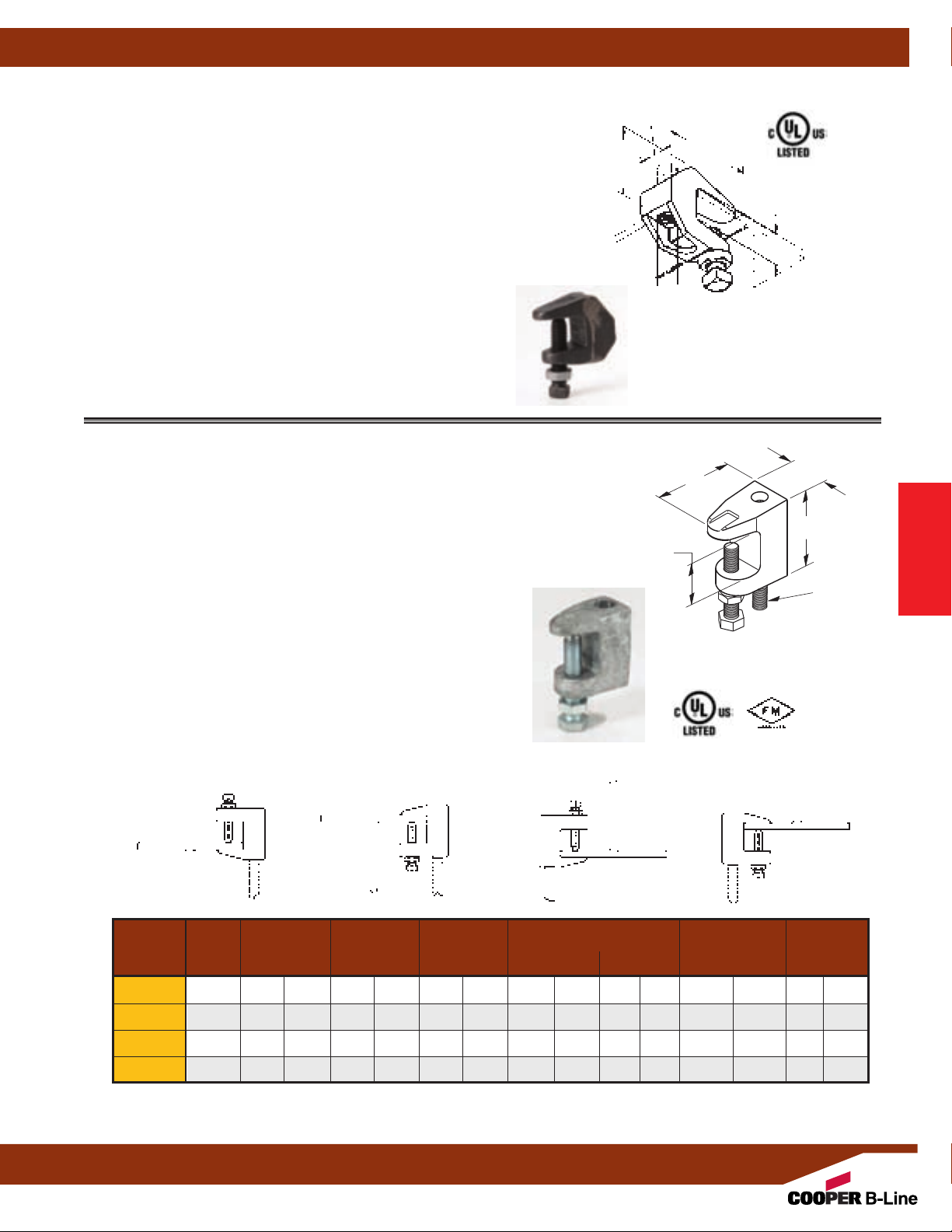

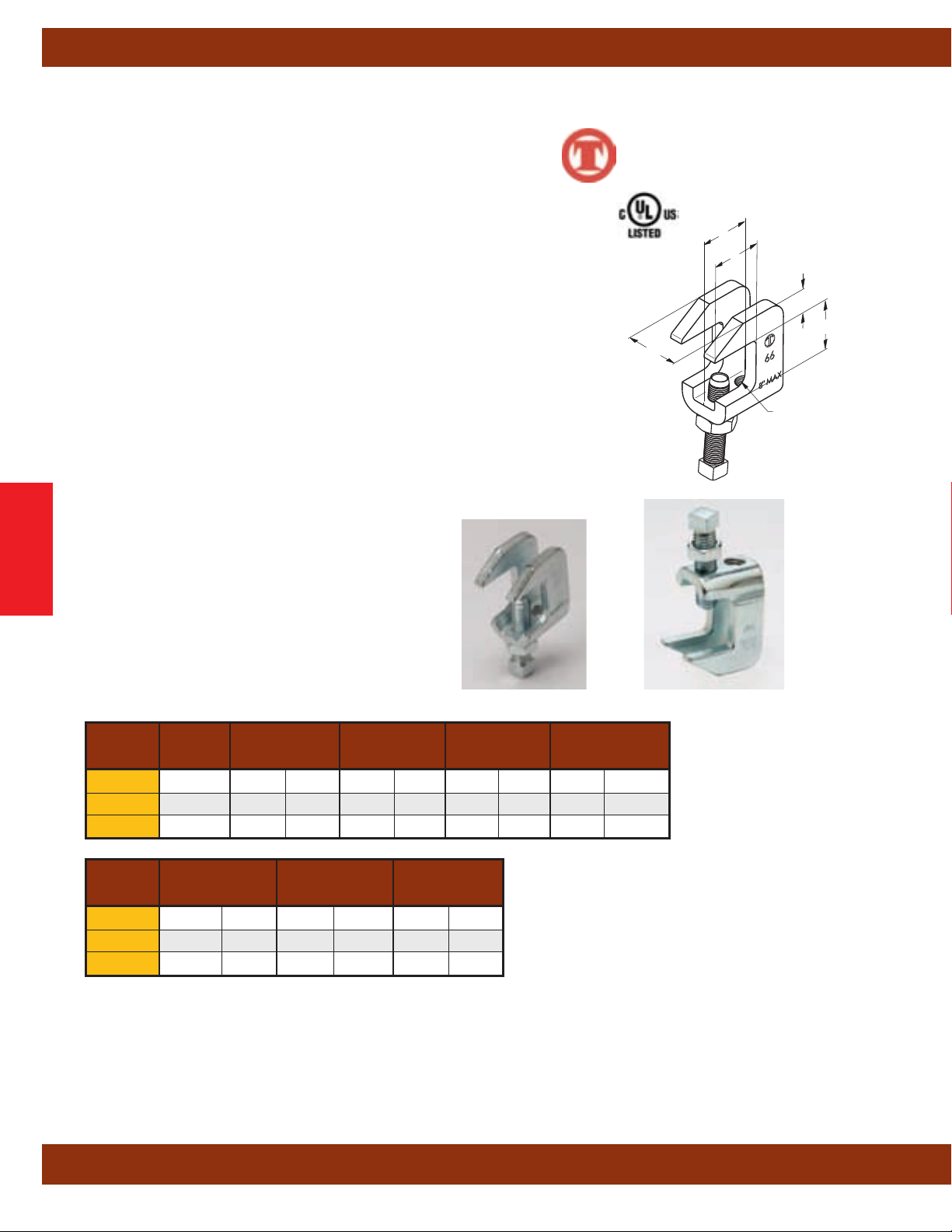

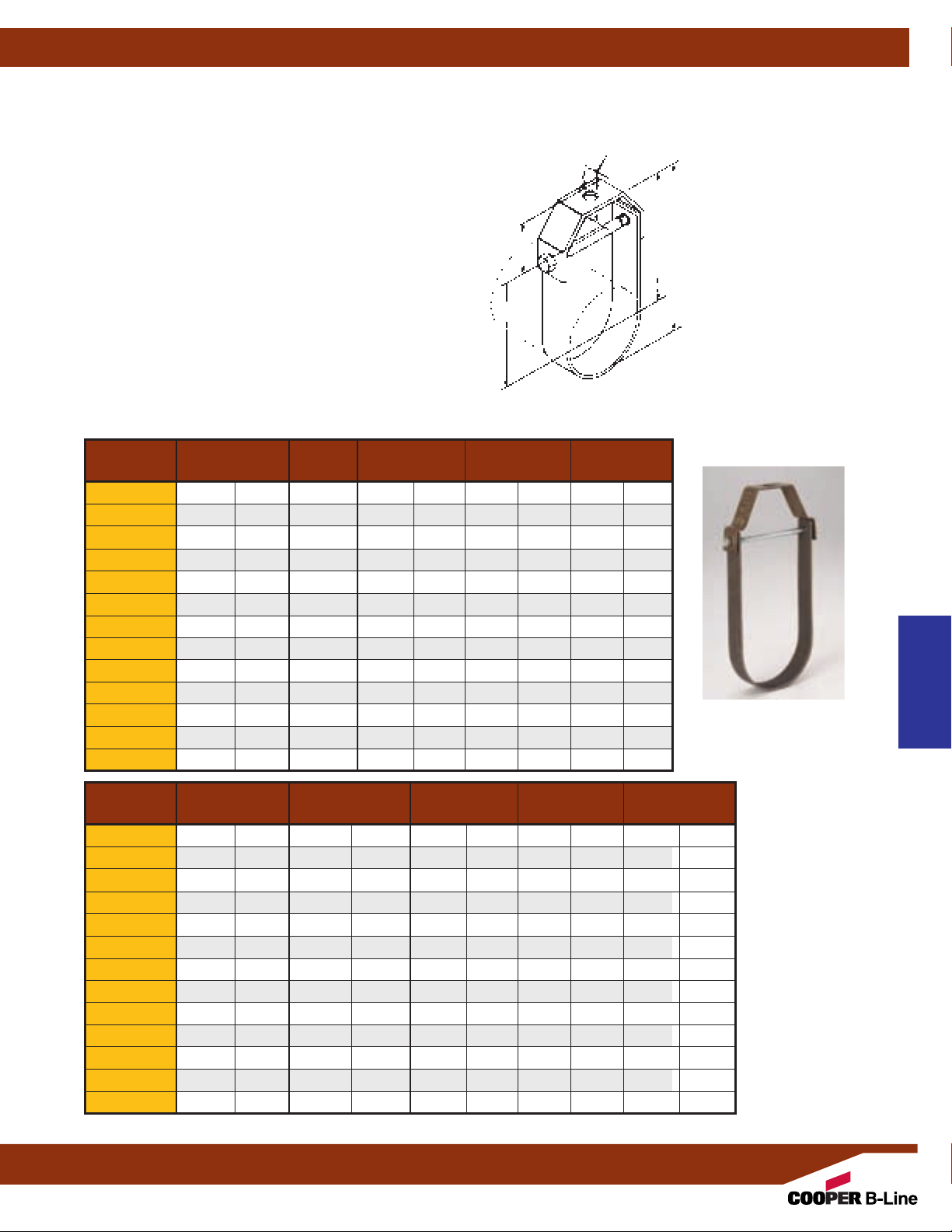

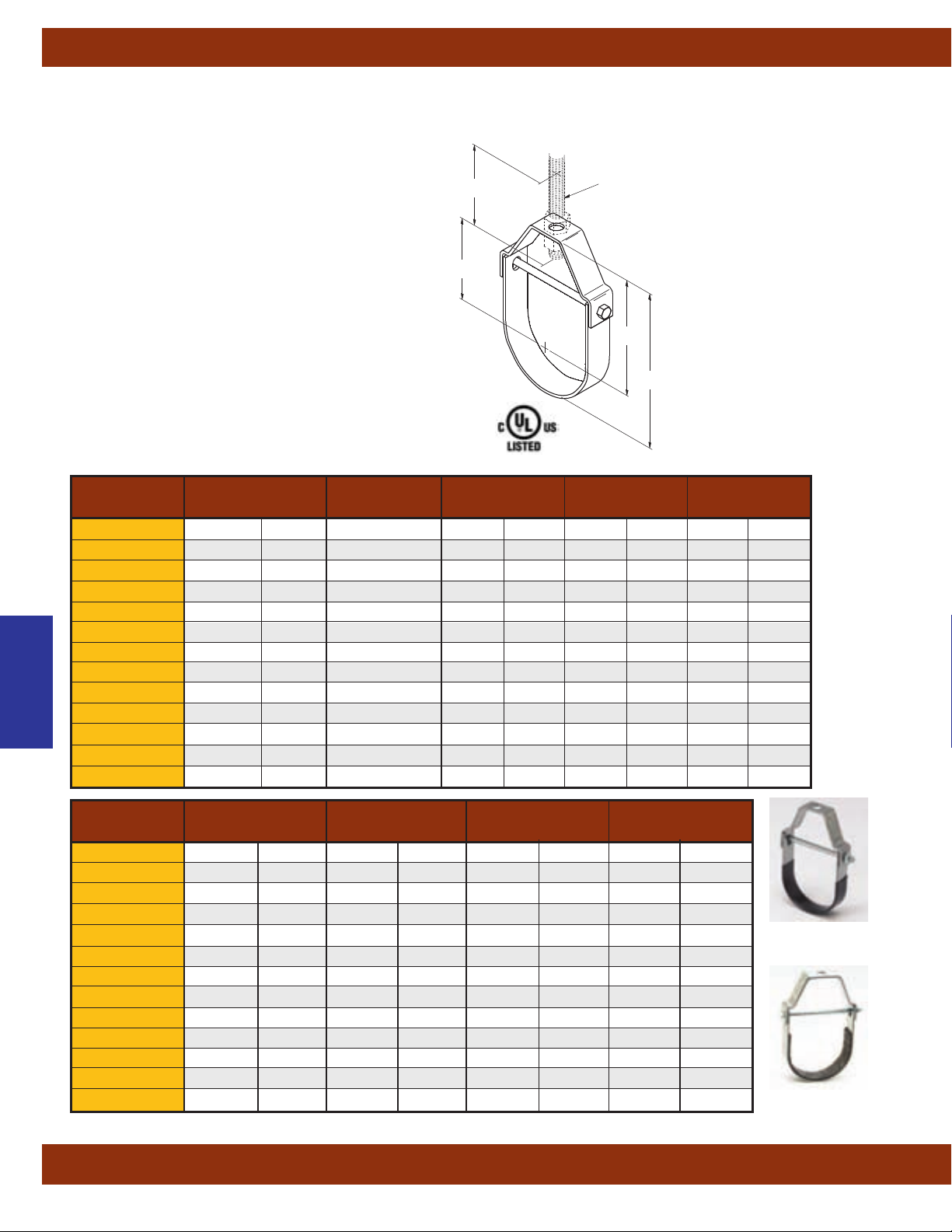

Beam Clamps

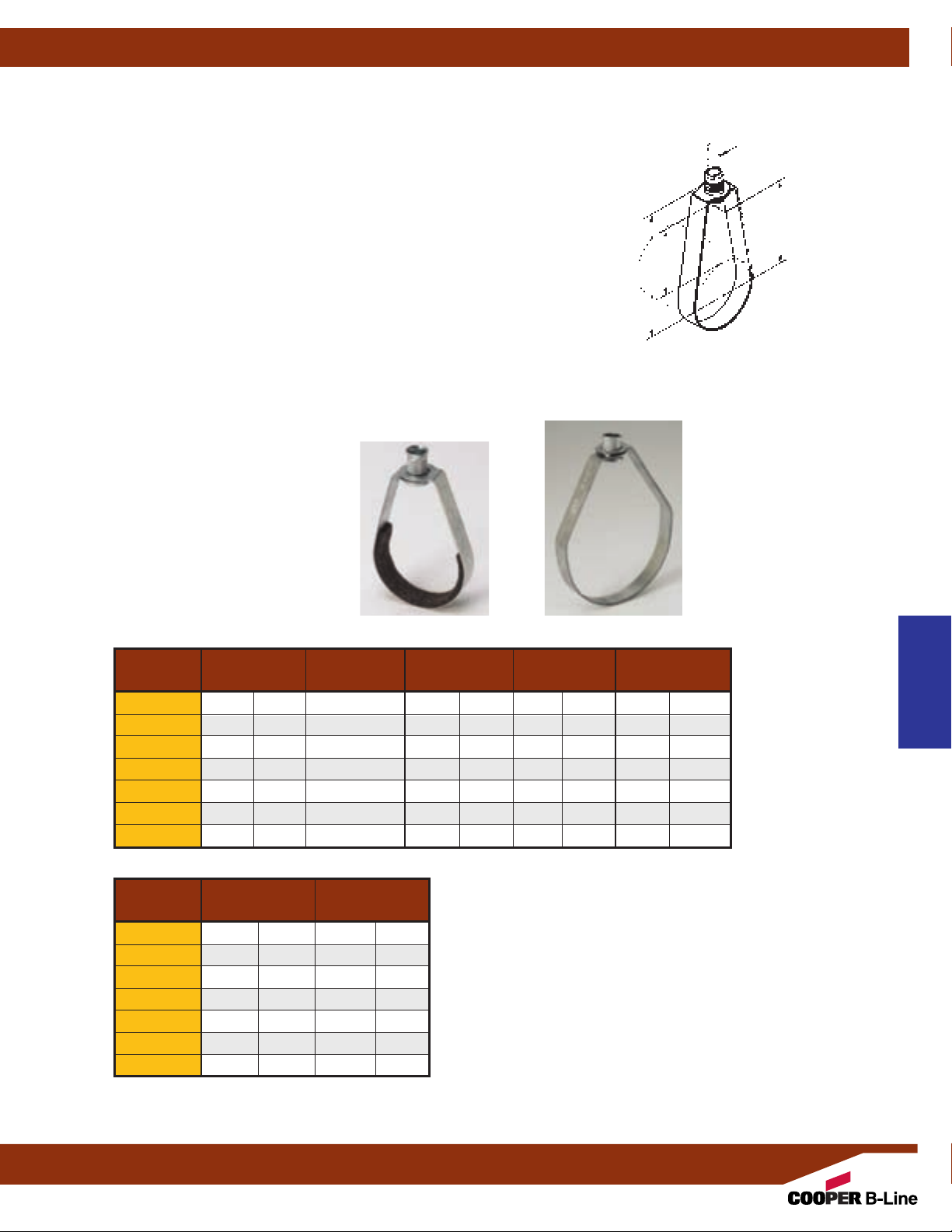

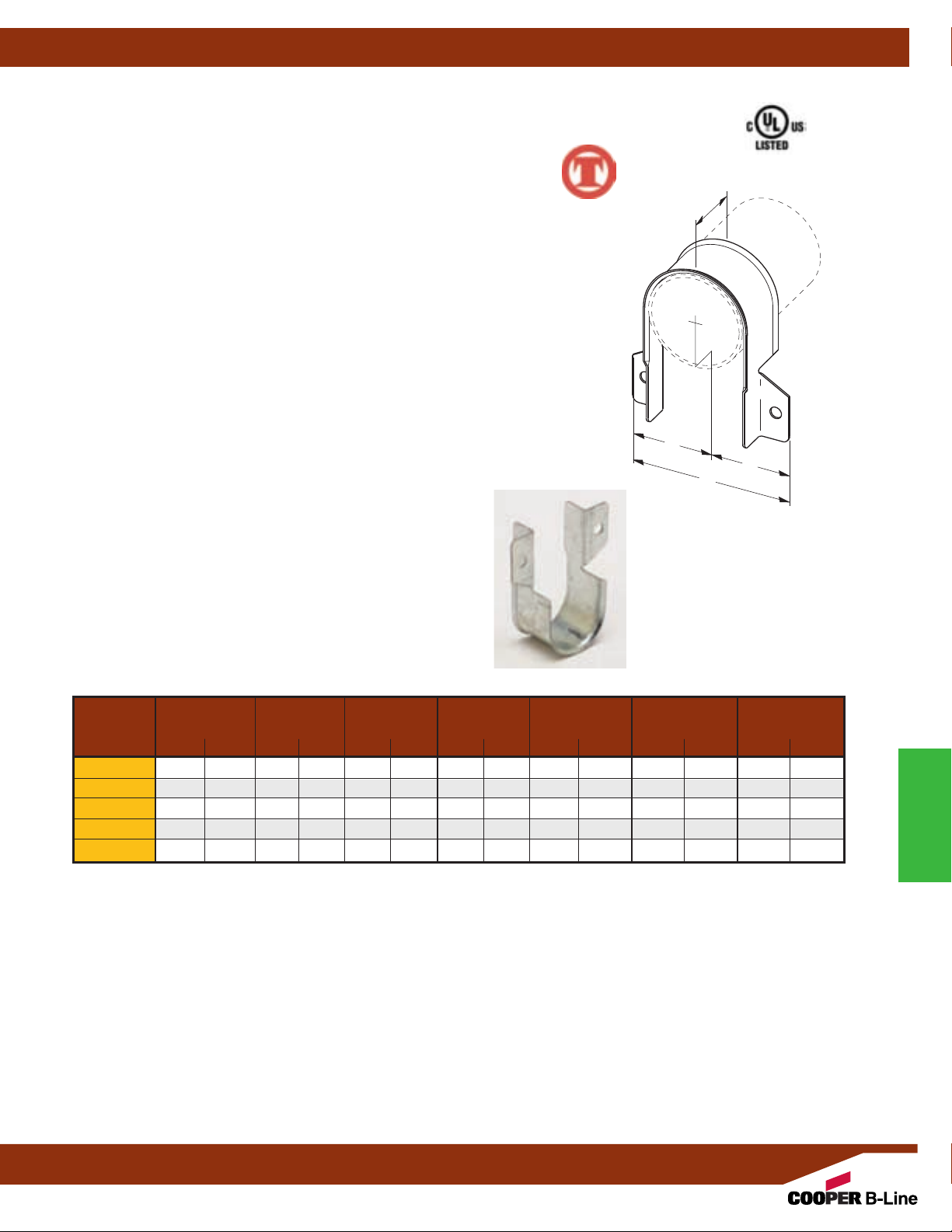

Fig. B3031-3/8 - Light Duty Malleable C-Clamp

Material: Malleable Iron

3

Function: Designed for attaching a

/8"-16 hanger rod to the top or

bottom flange of a beam or bar joist when setscrew is in the down position

as shown.

Approvals: Underwriters Laboratories Listed for up to 4” pipe. Conforms to

Federal Specification WW

-H-171E & A-A-1192A, Type 19 and Manufacturers

Standardization Society ANSI/MSS SP-69 & SP-58, Type 19.

Finish: Plain or Electro-Galvanized

Order By: Figure number and finish. When retaining strap is required,

order Fig. 69 separately

Weight: Approx. Wt./100 25 Lbs.

. See Page 35.

(11.3kg)

Design Load: 350 Lbs. (1.55kN)

Note: See page 26 for recommended setscrew torque.

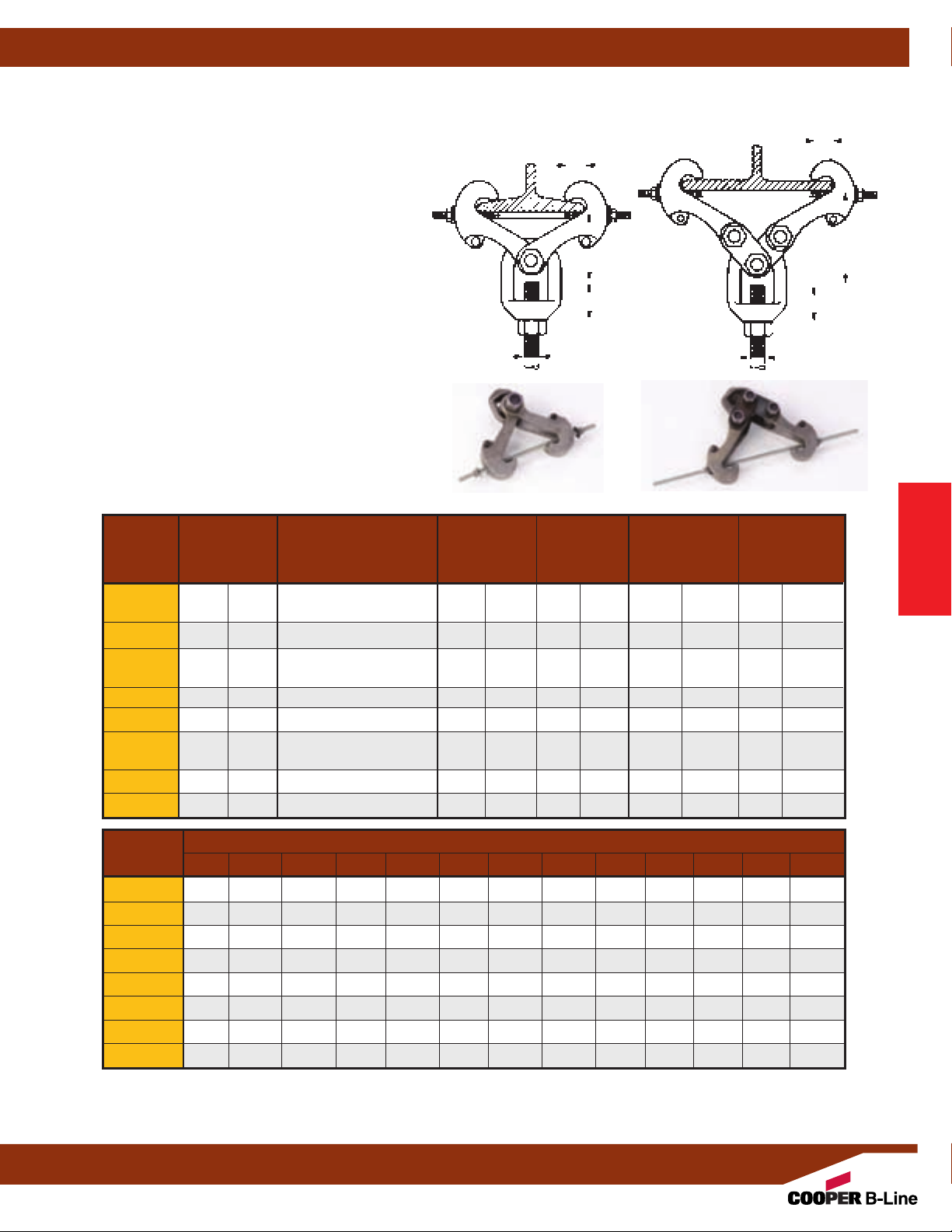

Fig. B3033 - Wide Jaw Reversible C-Clamp (TOLCO Fig. 68 & Fig. 68W)

Size Range:3/8"-16 thru 3/4"-10 rod

Material: Cast Malleable Steel with hardened cup point set screw

and jam nut

Function: For attachment to structural shapes requiring wider throat

especially under roof with bar joist construction.

This clamp may be used with the set screw in the up or down position.

Approvals: Underwriters Laboratories Listed (cULus) and Factory

3

Mutual Engineering

Approved (FM) for

/8”-16 and 1/2”-13 rod sizes.

Conforms to Federal Specification WW-H-171E Type 19 & A-A-1192A,

Type 19 & 23 and Manufacturers Standardization Society ANSI/MSS

SP-69 & SP-58, Type 19 & 23. Factory Mutual Engineering Approved