Page 1

Pipe Hangers

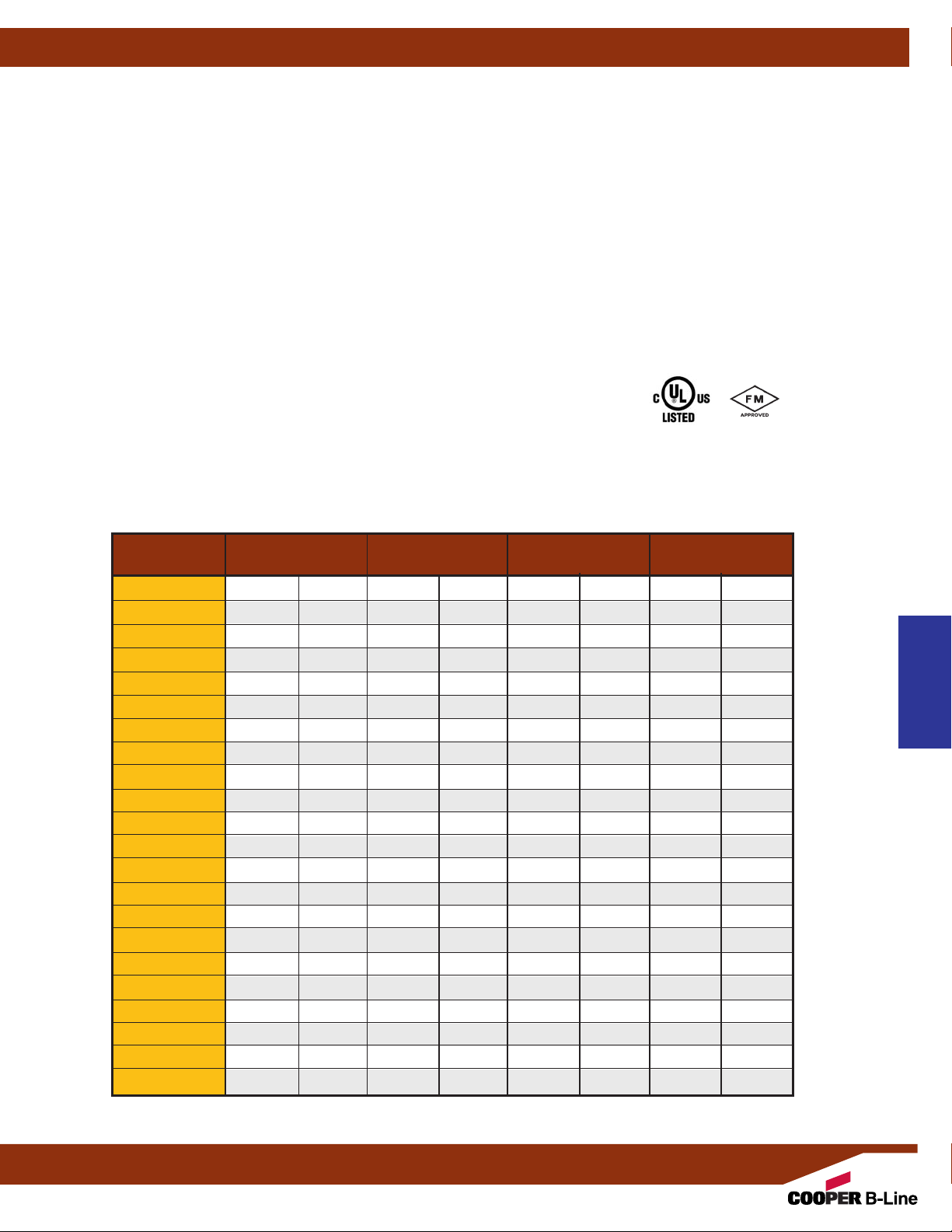

Fig. B3100 - Standard Clevis Hanger (TOLCO Fig.1)

Size Range:1/2” (15mm) to 36” (900mm)

Material: Steel

Function: Recommended for the suspension of non-insulated pipe or insulated pipe with a B3151 shield.

Note: When an oversized clevis is used, a pipe spacer should be placed over the cross bolt to assure that the

lower U-strap will not move in on the bolt. When attaching seismic bracing to the clevis hangers, a B3100PS

(cross bolt spacer) must be installed. See Seismic Restraints Approval Guidelines.

Order pipe sleeves Fig. 1CBS-(pipe size) separately.

Approvals:

Factory Mutual Engineering Approved (FM) for 3/4” (20mm) thru 8” (200mm) pipe.

WW-H-171E & A-A-1192A, Type 1 and Manufacturers Standardization Society ANSI/MSS SP-69 & SP-58, Type 1.

Also available to accommodate rod schedule per per National Fire Protection Association (NFPA) Pamphlet 13.

Maximum Temperature: 650°F (343°C).

Standard Finish: Plain, Electro-Galvanized, DURA-GREEN™, or Hot-Dip Galvanized

also available in Stainless Steel

Order By:

For AWWA - Ductile Iron Clevis Hangers, see B3102, page 50.

Underwriter's Laboratories Listed in the USA (UL) and Canada (cUL) for sizes 1/2" (15) thru 12" (300).

Conforms to Federal Specification

Figure

number and finish.

** Note: Do not use the dimensions shown in the B3100 chart for NFPA hanger sizes.

Contact Cooper B-Line for NFPA rod sizing on

1

/2” (15mm) thru 12” (300mm) pipe.

Part numbers will be 1NFPA-pipe size.

E Adjustment F Design Load Approx. Wt./100

Part No.

B3100-1/2 21/2" (63.5)

B3100-3/4 21/2" (63.5)

B3100-1 21/2" (63.5)

B3100-11/4 21/2" (63.5)

in. (mm) in. (mm) Lbs. (kN) Lbs. (kg)

7

/16" (11.1) 730 (3.25) 25 (11.3)

1

/2" (12.7) 730 (3.25) 29 (13.1)

5

/8" (15.9) 730 (3.25) 35 (15.9)

7

/8" (22.2) 730 (3.25) 40 (18.1)

B3100-11/2 21/2" (63.5) 13/16" (30.2) 730 (3.25) 42 (19.0)

B3100-2 * 21/2" (63.5) 15/8" (41.3) 730 (3.25) 52 (23.6)

B3100-21/2 * 21/2" (63.5) 2" (50.8) 1350 (6.00) 90 (40.8)

B3100-3 * 21/2" (63.5) 2" (50.8) 1350 (6.00) 110 (49.9)

B3100-31/2 21/2" (63.5) 2" (50.8) 1350 (6.00) 142 (64.4)

B3100-4 * 21/2" (63.5) 2" (50.8) 1430

B3100-5 * 21/2" (63.5) 2" (50.8) 1430

B3100-6 * 3" (76.2) 2" (50.8) 1940

B3100-8 31/2" (88.9) 25/16" (58.7) 2000

B3100-10 31/2" (88.9) 25/16" (58.7) 3600

B3100-12 31/2" (88.9) 25/8" (66.7) 3800

B3100-14 4" (101.6) 27/8" (73.0) 4200

B3100-16 4" (101.6) 211/16" (68.3) 4600

B3100-18 41/2" (114.3) 315/16" (100.0) 4800

B3100-20 5" (127.0) 53/8" (136.5) 4800

B3100-24 5" (127.0) 53/8" (136.5) 4800

B3100-30 5" (127.0) 61/4" (158.7) 6000

B3100-36 5" (127.0 57/16" (138.1) 6000

Clevis Hanger design, as shown above, for sizes 2, 2

*SLIDE-RITE

™

All dimensions in charts and on drawings are in inches. Dimensions shown in parentheses are in millimeters unless otherwise specified.

1

/2, 3, 4, 5 & 6.

(6.36) 132 (59.9)

(6.36) 215 (97.5)

(8.63) 320 (145.1)

(8.89) 485 (220.0)

(16.01) 846 (383.7)

(16.90) 1083 (491.2)

(18.68) 1432 (649.5)

(20.46) 2200 (997.9)

(21.35) 2500 (1134.0)

(21.35) 4400 (1995.8)

(21.35) 5000 (2268.0)

(26.69) 6600 (2993.7)

(26.69) 8474 (3843.8)

Pipe Hangers

49

Page 2

Pipe Hangers

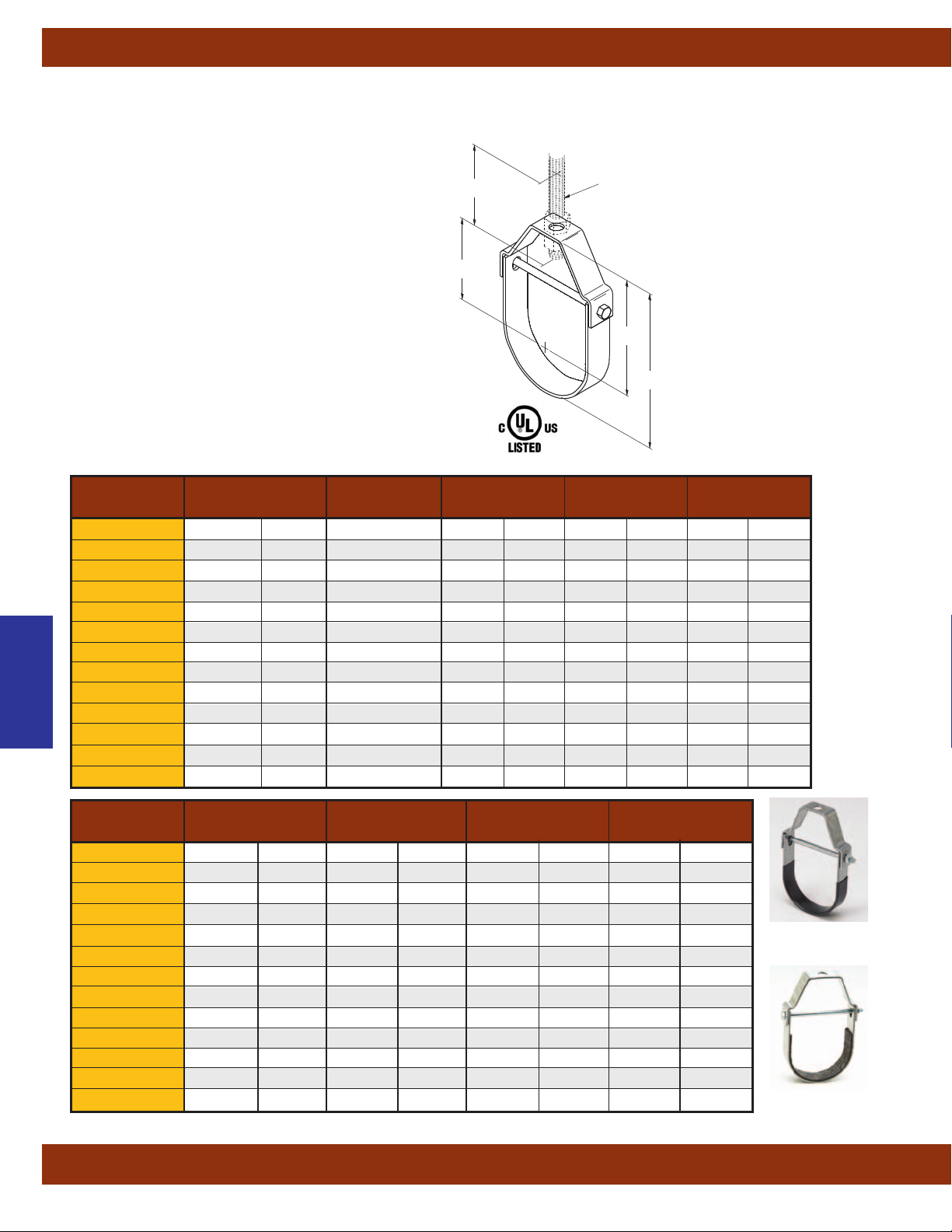

Fig. B3100C - Standard Clevis Hanger - Plastic Coated (TOLCO Fig.1PVC)

Fig. B3100F - Standard Clevis Hanger - Felt Lined (TOLCO Fig.1F)

Size Range:1/2” (15mm) to 8”

(200mm)

pipe

Material: Steel

Insulation Material:3/16” (4.8mm) Felt

Service: The B3100F is designed for the suspension of

copper tube so as to prevent electrolysis between tubing

and hanger. The B3100C is designed for steel or other

pipe types of the same O.D. Both B3100F and B3100C

act to reduce noise and vibration in pipe or tubing

systems

Approvals:

.

Underwriter's Laboratories Listed in the USA

(UL) and Canada (cUL).

Maximum Temperature: 650°F (343°C).

Standard Finish: Plain, Electro-Galvanized, or Hot-Dip

Galvanized. Contact Cooper B-Line for alternative finishes

and materials.

Order By: Figure number and finish.

Pipe Size Rod Size B CD

Part No.

B3100-1/2

B3100-3/4

in. (mm) A in. (mm) in. (mm) in. (mm)

1

/2" (15)

3

/4" (20)

B3100-1 1" (25)

B3100-11/4 11/4" (32)

B3100-11/2 11/2" (40)

Pipe Hangers

B3100-2 2" (50)

B3100-21/2 21/2" (65)

B3100-3 3" (80)

B3100-31/2 31/2" (90)

B3100-4 4" (100)

B3100-5 5" (125)

B3100-6 6" (150)

B3100-8 8" (200)

A

E

D

3

/8"-16 21/8" (54.0) 111/16" (42.9)

3

/8"-16 27/16" (61.9) 17/8" (47.6) 11/8" (28.6)

3

/8"-16 213/16" (71.4) 21/8" (54.0) 13/8" (34.9)

3

/8"-16 37/16" (87.3) 29/16" (65.1) 113/16" (46.0)

3

/8"-16 4" (101.6)` 3" (76.2) 21/4" (57.1)

3

/8"-16 41/2" (114.3) 31/4" (82.5) 21/2" (63.5)

1

/2"-13 59/16" (141.3) 4" (101.6) 31/16" (77.8)

1

/2"-13 63/4" (171.4) 47/8" (123.8) 315/16" (100.0)

1

/2"-13 7" (177.8) 5" (127.0) 41/16" (103.2)

5

/8"-11 713/16"

5

/8"-11 91/16"

3

/4"-10 107/16"

3

/4"-10

12

(198.4)

(230.2)

(265.1)

3

/4"

(323.8)

(Rod Size)

Hanger Rod Not

Included

C

B

51/2" (139.7) 43/8" (111.1)

61/8" (155.6) 5" (127.0)

615/16" (176.2) 511/16" (144.5)

83/8" (212.7) 71/8" (181.0)

Bottom of pipe to top of hanger

Center of pipe to top of hanger.

Center of pipe to bottom of

Minimum thread length of

op of cross bolt to bottom of hanger

T

rod nut inside the hanger.

15

/16" (23.8)

B

C

D

ake-Out

Rod T

hanger rod.

E

hanger rod

F

Adjustment

.

E

Part No.

in. (mm) in. (mm) Lbs. (kN) Lbs. (kg)

B3100-1/2 21/2" (63.5)

B3100-3/4 21/2" (63.5)

B3100-1 21/2" (63.5)

B3100-11/4 21/2" (63.5)

Adjustment F

7

/16" (11.1) 730 (3.25) 25 (11.3)

1

/2" (12.7) 730 (3.25) 29 (13.1)

5

/8" (15.9) 730 (3.25) 35 (15.9)

7

/8" (22.2) 730 (3.25) 40 (18.1)

Design Load Approx. Wt./100

B3100-11/2 21/2" (63.5) 13/16" (30.2) 730 (3.25) 42 (19.0)

B3100-2 21/2" (63.5) 15/8" (41.3) 730 (3.25) 52 (23.6)

B3100-21/2 21/2" (63.5) 2" (50.8) 1350 (6.00) 90 (40.8)

B3100-3 21/2" (63.5) 2" (50.8) 1350 (6.00) 110 (49.9)

B3100-31/2 21/2" (63.5) 2" (50.8) 1350 (6.00) 142 (64.4)

B3100-4 21/2" (63.5) 2" (50.8) 1430

B3100-5 21/2" (63.5) 2" (50.8) 1430

B3100-6 3" (76.2) 2" (50.8) 1940

B3100-8 31/2" (88.9) 25/16" (58.7) 2000

All dimensions in charts and on drawings are in inches. Dimensions shown in parentheses are in millimeters unless otherwise specified.

(6.36) 132 (59.9)

(6.36) 215 (97.5)

(8.63) 320 (145.1)

(8.89) 485 (220.0)

52

B3100C

B3100F

Loading...

Loading...