Page 1

TOLCO™Seismic Bracing

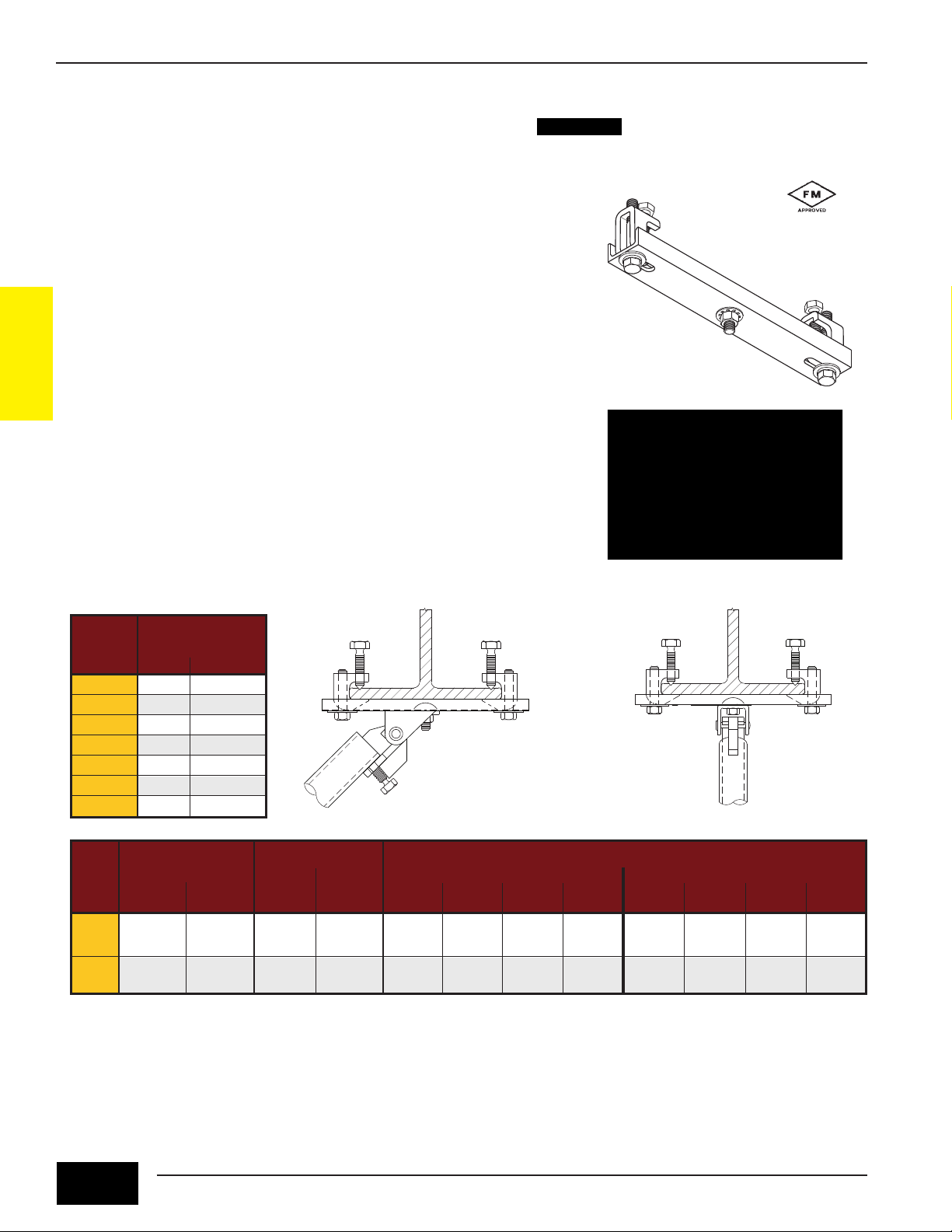

Fig. 800 - Adjustable Sway Brace Attachment to Steel

Size Range: 4" (101.6mm) thru 18" (457.2mm) beam width

Material: Steel

Function: Seismic brace attachment to steel.

Features: This product’s design incorporates a concentric attachment point which is

critical to the performance of structural seismic connections. NFPA 13 indicates the

importance of concentric loading of connections and fasteners. Permits secure

connection to steel where drilling and/or welding of brace connection could present

structural issues.

Installation Instructions: Fig. 800 is the structural attachment component of a

Seismic Bracing

longitudinal or lateral sway brace assembly. It is intended to be combined with a

Cooper B-Line/TOLCO

B-Line/TOLCO

"braced pipe" attachment to form a complete bracing assembly.

NFPA 13 and/or OSHPD guidelines should be followed.

To Install: Place the Fig. 800 on the steel beam, tighten the cone point set screws

on flange until the heads break off. Tighten hex head bolts into clamp body until lock

washers are fully flat. Attach other

910, 980 or 986. Transitional fitting attachment can pivot for adjustment to proper

brace angle.

Approvals: Underwriters Laboratories Listed in the USA (UL) and Canada (cUL).

Approved by Factory Mutual Engineering (FM). Included in our Seismic Restraints

Catalog approved by the State of California Office of Statewide Health Planning and

Development (OSHPD). For additional load, spacing and placement information

relating to OSHPD projects, please refer to the

Guidelines.

Finish: Plain. Contact B-Line for alternative finishes and materials.

Order By: Figure number, type number and size number.

transitional attachment, "bracing pipe" and a

TOLCO

transitional attachment fitting, Fig. 909,

TOLCO

Seismic Restraint Systems

Cooper

Component of State of

California OSHPD Approved

Seismic Restraints System

Set Screws & Hardware

Included

Fits Beam

Part No. Flange Width

in. (mm)

800-1 4”- 6” (101.6-152.4)

800-2 6”-8” (152.4-203.2)

800-3 8”-10” (203.2-254.0)

800-4 10”-12” (254.0-304.8)

800-5 12”-14” (304.8-355.6)

800-6 14”-16” (255.6-406.4)

Shown with Fig. 980

brace fitting to

pipe brace

(Across Beam)

Shown with

Fig. 980 brace

fitting to pipe brace

(Along Beam)

800-7 16”-18” (406.4-457.2)

Fits Beam Flange

Type

Thickness

in. (mm) lbs./(kN) lbs./(kN) lbs./(kN) lbs./(kN) lbs./(kN) lbs./(kN) lbs./(kN) lbs./(kN) lbs./(kN) lbs./(kN)

1 Up to 3/4” (Up to 19.0)

23/4” to 11/4” (19.0 to 31.7)

Eaton’s B-Line Business seismic bracing components are designed to be compatible only with other B-Line bracing components,

resulting in a listed seismic bracing assembly. B-Line’s warranty for seismic bracing components will be the warranty provided in

B-Line’s standard terms and conditions of sale made available by B-Line, except that, in addition to the other exclusions from

B-Line’s warranty, Eaton’s B-line Business makes no warranty relating to B-Line’s seismic bracing components that are combined

with products not provided by Eaton’s B-Line Business.

Max. Design Loads (cULus) Max. Design Load (FM)

Along Beam Across Beam Lateral - Parallel to Structural Member Longitudinal - Perpendicular to Structural Member

30°-44° 45°-59° 60°-74° 75°-90° 30°-44° 45°-59° 60°-74° 75°-90°

1265 2015 1430 1970 1980 NR 930 1310 1610 1800

(5.62) (8.96) (6.36) (8.76) (8.81) (NR) (4.13) (5.82) (7.16) (8.00)

1265 2015 NR NR NR NR NR NR NR NR

(5.62) (8.96) (NR) (NR) (NR) (NR) (NR) (NR) (NR) (NR)

All dimensions in charts and on drawings are in inches. Dimensions shown in parentheses are in millimeters unless otherwise specified.

173

Pipe Hangers & Supports

Loading...

Loading...