Cooper-Atkins MFM300 Installation Manual

MFM300

Multi-Function Instrument

User Guide and Instrument Warranty

MFM300 Instrumento Multifuncional

Gaurantía de Guía del usuario e Instrumento

MFM300 Instrument Multifuncional

Le Guide d’utilisateur et la garantie d’instrument

MFM300 Button and Jack Locations ................................................................3

Power up the MFM300 .....................................................................................4

Power down the MFM300 .................................................................................4

Display Modes .................................................................................................4

Display MIN, MAX, and AVG Values .................................................................4

Measure Temperature .......................................................................................4

Measure Temperature Difference (Delta T) ................................................... 4-5

Measure Pressure .............................................................................................5

Measure System Superheat / Sub-Cooling .......................................................5

Calculate Superheat / Sub-Cooling ...................................................................5

Measure Dynamic System Superheat / Sub-Cooling .................................... 5-6

Measure Relative Humidity and Dry-Bulb Temperature ....................................6

Display Psychometrics ......................................................................................6

Measure Air Flow ..............................................................................................6

Air Balancing .....................................................................................................6

Navigate the Menu ............................................................................................6

Menu Functions ............................................................................................ 6-7

Using the MFM300 with a GL Data Logger ................................................... 7-8

Capture or Store Snapshots .......................................................................... 8-9

MFM300 Specifications ....................................................................................9

MFM300 Toolbox ............................................................................................10

MFM300 Warranty / Obtaining Service ...........................................................10

MFM300 Instrument Service Information .......................................................10

Product Registration .......................................................................................10

TABLE OF CONTENTS

2

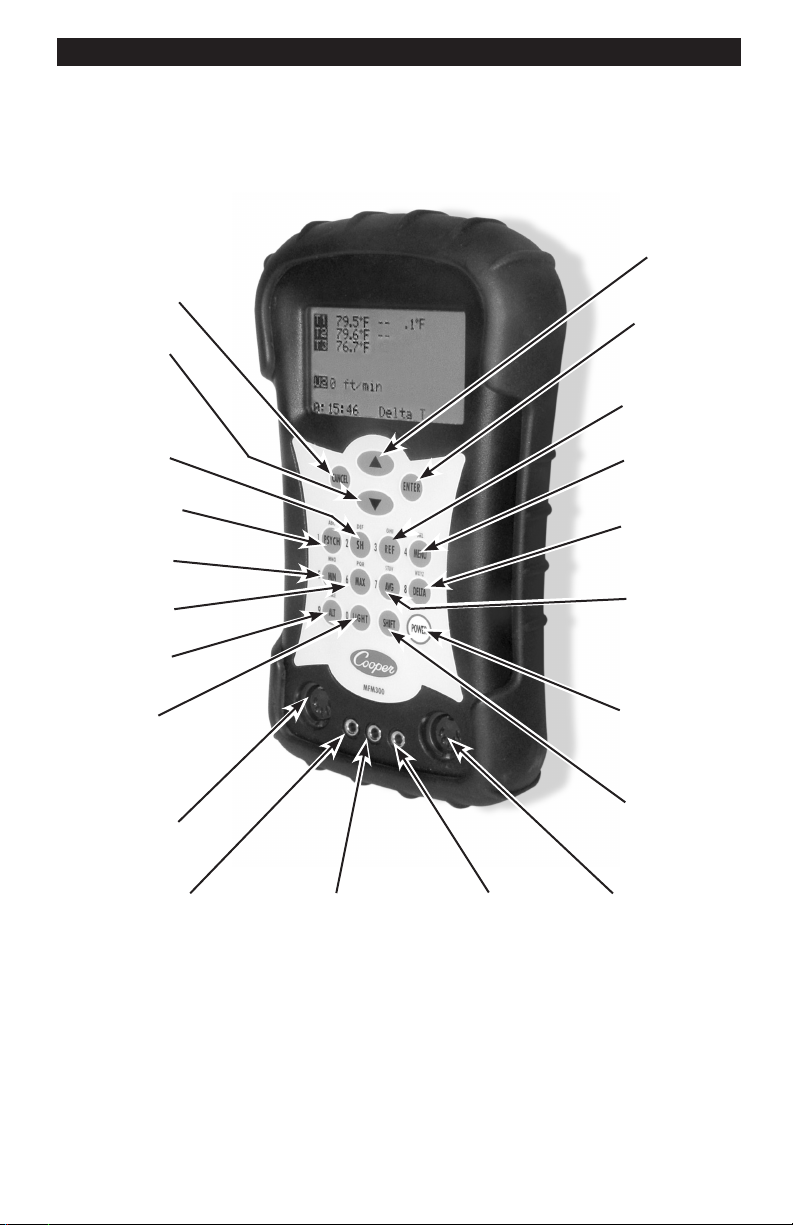

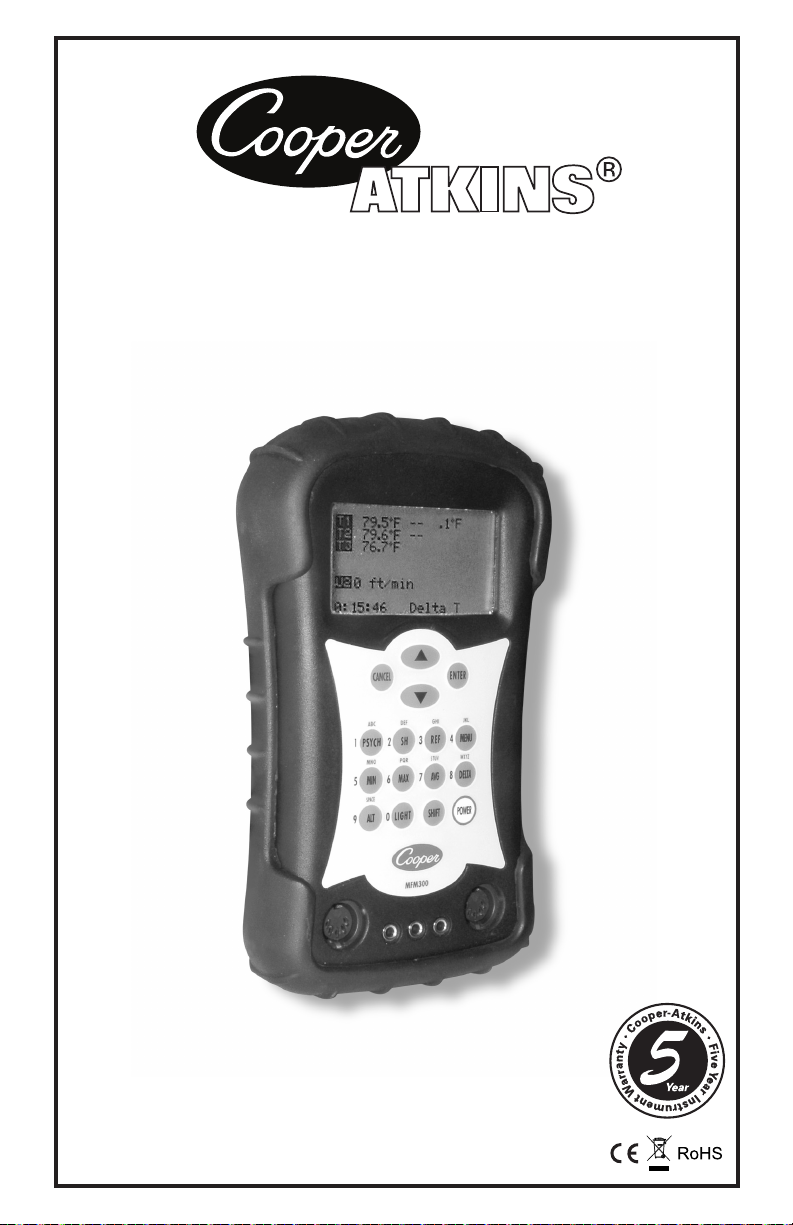

MFM300 BUTTON AND JACK LOCATIONS

THIS UNIT IS CALIBRATED TO STANDARDS

TRACEABLE TO THE NATIONAL INSTITUTE OF STANDARDS AND TECHNOLOGY (NIST)

CANCEL

DOWN

ARROW

REFRIGERANT

SUPERHEAT /

SUB-COOLING

(SH)

UP ARROW

ENTER

(REF)

MENU

PSYCHROMETRICS

(PSYCH)

MINIMUM

(MIN)

MAXIMUM

(MAX)

ALTERNATE

(ALT)

LIGHT

UNIVERSAL

JACK U1

TEMPERATURE

JACK T1

TEMPERATURE

JACK T2

TEMPERATURE

JACK T3

TEMPERATURE

DIFFERENCE

(DELTA)

AVERAGE

(AVG)

POWER

SHIFT

UNIVERSAL

JACK U2

3

POWER-UP THE MFM300

Press the POWER button until the display shows the Cooper logo, the remaining battery life and

the installed firmware. Press the LIGHT button to illuminate the screen in low light conditions.

POWER-DOWN THE MFM300

Press the POWER button until the display goes blank.

DISPLAY MODES

Normal mode:

Superheat mode: Displays superheat or sub-cooling values. Requires a temperature probe be

installed in either T1 or T2 (or both) and optionally a pressure probe in U1 or U2 (or both).

Press the SH button to enter Superheat Mode. Press the SH button again, or CANCEL, to return

to Normal Mode. See the section on measuring system Superheat / Sub-cooling for further

information.

Psychrometrics mode: Displays psychrometric values. Requires a relative humidity probe to be

installed in either U1 or U2 (or both). Press the PSYCH button to enter the Psychrometric Mode.

Press the PSYCH button again, or CANCEL, to return to Normal Mode.

The MFM300 will attempt to operate in the last mode it was in when powered off. If it can not, the

Normal Mode is the default. If no probes are connected, the “No Probes” message will appear on

the display.

When in Normal Mode press:

MIN button to display the lowest readings sensed by each probe.

MAX button to display the highest readings sensed by each probe.

AVG button to display the average readings sensed by each probe.

The active mode, MIN, MAX or AVG, will be indicated near the bottom of the display. Pressing

the same button again, or CANCEL, turns off the selected mode. Disconnecting a probe will

clear that probe’s MIN, MAX, and AVG memory, but all probes still connected will continue to

be updated. All MIN, MAX and AVG memory is lost when the MFM300 is powered down.

Displays the measured values of all the probes currently connected.

DISPLAY MIN, MAX AND AVG VALUES

MEASURE TEMPERATURE

Install one, two, or three Cooper 10K thermistor probes into any of the three temperature jacks:

T1, T2 or T3. The MFM300 will sense the probe and display the temperature measurement with

the appropriate label.

MEASURE TEMPERATURE DIFFERENCE (DELTA T)

With two probes connected, press the DELTA button until “Delta T” appears on the display. The

absolute temperature difference appears to the right of the horizontal bars that point to the two

temperature inputs being measured. Press the DELTA button again, or CANCEL, to turn off the

“Delta T” display. If three temperature probes are connected, press the DELTA button again to

display the next “Delta T”. With three temperature probes connected, the “Delta T” sequence is

as follows:

4

MEASURE TEMPERATURE DIFFERENCE (Delta T) Continued

FIRST PRESS: T1 – T2;

SECOND PRESS: T1 – T3;

THIRD PRESS: T2 – T3;

FOURTH PRESS: DELTA T DISPLAY OFF.

MEASURE PRESSURE

Connect a Cooper Pressure Transducer to either U1 or U2 (or both). The MFM300 will sense

the probe(s) and display the pressure measurement(s) with the appropriate U1 or U2 label.

Before connecting the transducer(s) to the cooling system, zero the pressure reading(s) (refer

to Setup section on zeroing the pressure probes and setting altitude).

NOTE: AT SEA LEVEL, THE PRESSURE READING SHOULD BE 0 PSI (0 KPA) WHEN NOT

CONNECTED TO A COOLING SYSTEM. AT ELEVATIONS ABOVE SEA LEVEL THE

DISPLAY WILL SHOW A NEGATIVE PRESSURE READING (-0.5 PSI / 1000

FEET ALTITUDE). CONNECT THE TRANSDUCER(S) TO THE COOLING SYSTEM ACCESS

PORTS, USING BEST INDUSTRY PRACTICES, TO BEGIN MEASURING SYSTEM

PRESSURE.

MEASURE SYSTEM SUPERHEAT / SUB-COOLING

Select the refrigerant: The selected refrigerant is displayed when in Superheat / Sub-cooling

Mode, or when viewing pressure / temperature charts. To change the refrigerant, press the REF

button. The “Up / Down Arrows” will appear beside the refrigerant name. Use the UP / DOWN

ARROW buttons to scroll to the desired refrigerant and then press the ENTER or REF button.

Press the CANCEL button to abandon changes.

Add and / or change refrigerants: The MFM300 stores P / T data from 15 popular refrigerants

that reside in permanent memory. There is room in the memory for up to five more

refrigerants. New refrigerant P / T data can be downloaded from the Cooper-Atkins website

(www.cooper-atkins.com/mfm.asp) using the MFM300 Toolbox and the optional computer

connection cable.

CALCULATE SUPERHEAT / SUB-COOLING

The MFM300 can be used as a Superheat / Sub-cooling calculator. Connect the temperature

probes to the system and press the SH button. Select the refrigerant and press the ENTER

button. Since there are no pressure transducers connected, system pressure will default to

25 PSI for superheat and 75 PSI for Sub-cooling. You may manually enter the actual pressure

value from the manifold gauge into the MFM300 using the UP / DOWN ARROW buttons. Once

the pressure is entered for Superheat, use the SHIFT button to move to Sub-cooling, where

pressure is manually entered the same way. Remember that the values shown in this mode are

not dynamic.

MEASURE DYNAMIC SYSTEM SUPERHEAT / SUB-COOLING

Measuring dynamic system Superheat or Sub-cooling requires both a temperature probe

and a pressure transducer. The refrigerant type selected on the display must match the

refrigerant type used in the system. Refer to the section Select the Refrigerant. For Superheat

measurement, connect the temperature probe to T1, and the pressure transducer to U1. For

Sub-cooling measurement, connect the temperature probe to T2 and the pressure transducer

to U2. To measure superheat, attach the temperature probe to the system suction line near the

compressor. Attach the pressure transducer to the low side access port. Press the SH button.

5

MEASURE DYNAMIC SYSTEM SUPERHEAT / SUB-COOLING - Continued

The system superheat value is displayed along with the actual temperature and pressure

readings. Sub-cooling is measured in the same way, except the temperature probe is attached

to the liquid line, and the pressure transducer is attached to the high side access port.

NOTE: SUPERHEAT MEASUREMENTS USE T1 AND U1; SUB-COOLING MEASUREMENTS USE

T2 AND U2.

MEASURE RELATIVE HUMIDITY AND DRY-BULB TEMPERATURE

Connect a Cooper relative humidity probe to either U1 or U2 (or both). The MFM300 will sense

the probe and display the relative humidity and dry-bulb temperature measurements with the

appropriate U1 or U2 label.

DISPLAY PSYCHROMETICS

Connect a Cooper relative humidity probe to either U1 or U2 (or both). Press the PSYCH

button to display the psychometrics calculated from the current relative humidity and dry-bulb

measurements. Press the PSYCH button again, or CANCEL to return to Normal Mode.

MEASURE AIRFLOW

Connect a Cooper anemometer to either U1 or U2 (or both). The MFM300 will display airflow

in feet per minute (FPM) and temperature. To display airflow in cubic feet per minute (CFM),

press the ALT button. To insure that the correct cubic feet per minute values are displayed,

you must enter the shape and size of the duct opening where airflow is being measured. To do

this, press the MENU button while viewing CFM. Use the on-screen directions to enter the duct

shape and size and press the ENTER button when done.

AIR BALANCING

To perform basic Air Balancing, the MFM300 will calculate the average CFM and FPM using all

entered readings. While viewing CFM, press the AVG button while measuring airflow. Each time

the AVG button is pressed, new average values are calculated based upon the measurement

being taken. The display will show the average CFM and FPM and the number of individual

readings taken. To clear all average values, press the MENU button and then press the AVG

button.

NAVIGATE THE MENU

Additional functions and settings are available through the MFM300 MENU. Press the MENU

button to display the top-level menu and use the UP / DOWN ARROW buttons to select a menu

option, then press the ENTER button.

MENU FUNCTIONS

Adjust contrast: Allows display contrast to be changed to suit lighting situation. Use the

UP / DOWN ARROW buttons to set contrast and press the ENTER button to complete. Press

the CANCEL button to abandon changes.

View GL100 Log: Manage up to five data logger downloads stored in MFM300 memory.

Pressure / temp chart(s): Select the desired refrigerant by pressing the REF button, then use

the UP / DOWN ARROW buttons to scroll to the desired refrigerant and press the ENTER button

6

MENU FUNCTIONS - Continued

to save. Press the CANCEL button to abandon changes. While viewing pressure / temperature

charts, use the UP / DOWN ARROW buttons to scroll through the chart.

Hide / show elapsed time: In Normal Mode, the elapsed time is shown in the lower-left corner

of the display. The elapsed time may be turned off by selecting this menu item and Pressing the

ENTER button. If disabled, the menu item will be shown as “Show Elapsed Time”. If enabled,

the menu item will be shown as “Hide Elapsed Time”.

Disable / enable auto shut-off: When Auto Shut-off is enabled, the MFM300 will power-off

in 15 minutes if no buttons have been pressed. To disable Auto Shut-off, use the UP / DOWN

ARROW buttons to highlight this menu item and press the ENTER button. Auto Shut-off is the

default setting when turning the MFM300 on.

Setup: Press the MENU button, highlight the “Setup” option and press the ENTER button.

Setup Items include set altitude, set units of measure, temperature calibration, and zero-out

pressure transducers. Use the UP / DOWN ARROW buttons and press ENTER to select the

highlighted option. To return to the main menu, press CANCEL at any time.

• Set altitude: Use the UP / DOWN ARROW buttons to enter the current altitude in 500-foot

increments.

• Units of measure: Select either English or Metric units of measure.

• Temperature calibration: Place a temperature probe connected to T1 into an

environment with a known temperature and adjust the reading to calibrate and match.

• Zero-out probe P1, Zero-out probe P2: When a pressure transducer is attached to U1 or

U2, select this option before connecting to the system if the transducer reading is not “0

PSI” after setting the altitude.

USING THE MFM300 WITH A GL DATA LOGGER

Connect the Data Logger Reader to U1 using the GL300 data logger cable.

NOTE: THE GL300 DATA LOGGER CABLE IS NOT SUPPORTED ON U2.

Attach the GL100 Data Logger Tag to the reader. The MFM300 detects the Data Logger and

displays the GL100 Data Log Menu. If the Data Logger has been previously programmed for

a mission, the mission description is displayed. Below the mission description are the menu

options. Use the UP / DOWN ARROW buttons to scroll to the desired menu option and press the

ENTER button.

Check settings: Select this menu option to view the current mission status.

The status screen displays the following data:

• Mission description or “Name”

• Sampling status: Active or stopped

• Sample interval: Time between samples

• Mission start time and date

• Action when Data Logger is full: Stop or rollover

• Record count

Press any key to return to the GL100 Data Log Menu.

Program a mission: Enter up to 20 alphanumeric characters to describe the pending mission.

The symbol in the lower-left corner of the display indicates whether letters or numbers are

entered. “ABC” indicates upper case letters, “abc” indicates lower case letters and “1 2 3”

indicates numbers.

7

USING THE MFM300 WITH A GL DATA LOGGER - Continued

Switch between letters and numbers by pressing the SHIFT button. When entering letters,

press the letter button repeatedly until the desired character is displayed. After 2 seconds the

cursor will advance to the next position. Press the UP ARROW button to move the cursor to the

right, or press the DOWN ARROW button to move the cursor to the left. Use the SPACE (ALT)

button to insert a space in the description. When the mission description is complete, press the

ENTER button.

Sampling interval: Use the number buttons to enter the desired sampling interval (the time

between samples). The minimum interval is 1 minute, the maximum is 255 minutes. Press the

ENTER button when done.

When full instructions: Select the action to take when the data logger has reached the end

of its storage memory. Select “Roll-over” (continue to take readings) or “stop”. Use the UP /

DOWN ARROW buttons to scroll. Press the ENTER button when done.

Set clock: Use the number buttons and the UP / DOWN ARROW buttons to set the current date

and time. Press the ENTER button when done.

Delay start: The Data Logger will begin recording at the end of the delay time. Use the

NUMBER buttons to enter the Delay Start in minutes up to 255 minutes.

Confirm: Press the ENTER button to complete the mission programming, or press the CANCEL

button to abandon. Once finished, remove the Data Logger from the cable and place it where

temperatures are to be measured.

Download data: Select this “menu” option to store the Data Logger contents in the MFM300,

and view at a later time.

View data: Select this “menu” option to view the records contained in the Data Logger. The

data is displayed in two ways: as a graph of the temperature data points, and as discrete data at

the bottom of the display. Use the UP / DOWN ARROW buttons to move the cursor (the short

vertical line near the bottom of the display). As the cursor moves, the temperature, date and

time data pointed to by the cursor is displayed below the cursor line.

NOTE: WHEN VIEWING TEMPERATURE DATA ON THE MFM300, UP TO 16 PAGES, OR

SCREEN VIEWS, MAY BE SHOWN. PRESS THE MAX BUTTON TO VIEW THE NEXT

PAGE. PRESS THE MIN BUTTON TO VIEW THE PREVIOUS PAGE. PRESS THE CANCEL

BUTTON WHEN DONE AND DISCONNECT THE DATA LOGGER FROM THE DATA LOG

READER.

CAPTURE OR STORE SNAPSHOTS

The MFM300 can capture and store data that is currently being measured and displayed. Select

the “Capture Snapshots” option in the main menu and press the ENTER button. Select the

“Take Snapshots” option and press the ENTER button to display the snapshot set up screen.

The description, date and time are entered here using the UP / DOWN ARROW buttons. Once

set up is complete, a flashing camera icon appears on the screen.

Take a snapshot: Press the ENTER button, and then press the ENTER button again to save. Use

the Buttons to enter an identifying tag for future reference. Up to 50 snapshots can be stored

in the MFM300. To stop using the snapshot feature, return to the main menu, select “Capture

Snapshots” and select “Stop Snapshots”.

8

CAPTURE OR STORE SNAPSHOTS - Continued

View stored snapshots: Select the capture snapshots option in the main menu and press

the ENTER button. Highlight “View Snapshots” and press the ENTER button to display stored

snapshots. Use the UP / DOWN ARROW buttons to scroll through the stored snapshots. To

stop reviewing snapshots, press CANCEL.

Delete snapshots: Select the “Capture Snapshots” option in the main menu and press the ENTER

button. Highlight “Delete all Snapshots” and press the ENTER button. Confirm that all snapshots

should be deleted and press the ENTER button again.

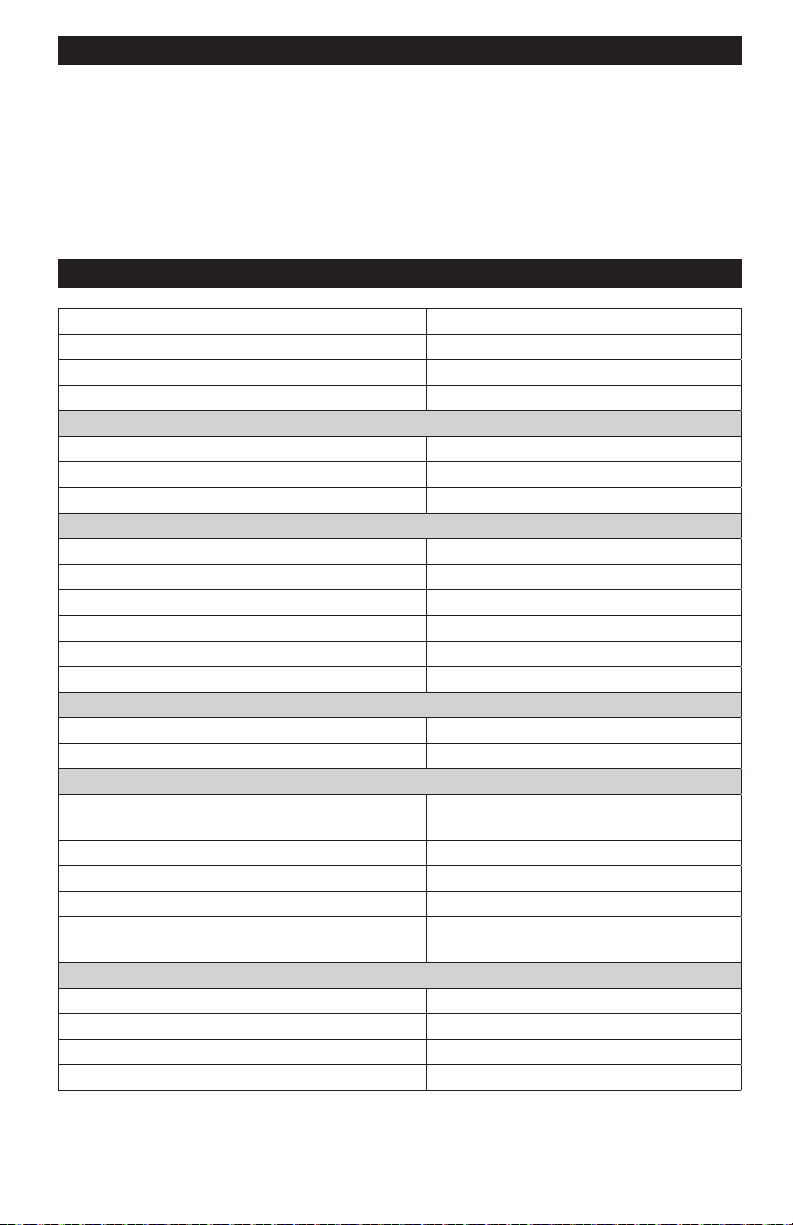

MFM300 SPECIFICATIONS

Ambient Temperature Operating Conditions

Ambient Humidity Operating Conditions

Power Source

Battery Life

Temperature Probes

Temperature Measurement Range

Temperature Accuracy

Temperature Display Resolution

Relative Humidity (RH) Probe

Relative Humidity Measurement Range

Relative Humidity Accuracy

Relative Humidity Display Resolution

Dry-Bulb Temperature Measurement Range

Dry-Bulb Accuracy

Dry-Bulb Display Resolution

Pressure Transducers

0 - 500 PSI Accuracy

0 - 1000 PSI Accuracy

Anemometer

Temperature Range

Temperature Accuracy

Velocity Range 100 - 6,000 FPM (0.5 - 30.48 MPS)

Velocity Display Resolution

Velocity Accuracy

Data Logger

Data Logger Temperature Range

Temperature Accuracy

Record Capacity

Sampling Intervals

32° to 122°F (0° to 50°C)

10% to 90% RH Non-Condensing

4 “Double A” (AA) Alkaline Batteries

100 hours Minimum

-58° to 302°F (-50° to 150°C)

±0.3F° (±0.2C°) or ±0.5% of Reading (whichever is greater)

0.1 Degree

0% to 99% RH

±2% RH 20 to 80% RH, 3% < 20% and > 80%

1% RH

-40° to 185°F (-40° to 85°C)

±0.3% Reading

0.1 Degree

±1% Full-Scale

±1% Full-Scale

32° to 150°F (0° to 65°C)

90% RH non-condensing

±2F° (±1C°)

1 FPM (.01 MPS)

3% RDG + .5% Full Scale at 77°F (25°C)

Up to 256 point averaging for airflow

-40° to 185°F (-40° to 85°C)

±2F° (±1C°)

2048

1 minute to 255 minutes

9

MFM300 TOOLBOX

To update the MFM300 firmware, download new refrigerant data, download snapshot or data

log information: connect the MFM300 to a PC that has the MFM300 Toolbox application

installed. To install the MFM300 Toolbox application, go to the Cooper-Atkins website (www.

cooper-atkins.com/downloads.asp), and click on MFM300 Toolbox. The MFM300 Toolbox

contains the latest firmware and refrigerants available for the MFM300 as well as various data

logging / management utilities (Contact Cooper-Atkins Corporation for more information).

MFM300 WARRANTY / OBTAINING SERVICE

The MFM300 Instrument is warranted against defects in material or workmanship for

five (5) years from date of purchase. Cooper-Atkins Corporation will replace or repair the

defective instrument, at their option, subject to verification of defect. All MFM300 probes and

accessories are warranted against defects in material or workmanship for one (1) year from

date of purchase. Cooper-Atkins Corporation has the option to replace or repair the defective

accessory, subject to verification of defect. These warranties exclude all incidental and

consequential damages. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the foregoing limitation may not apply. Except for the warranty set

forth above, Cooper-Atkins Corporation, by this disclaimer, gives notice that any statements or

representations made by it will not create a warranty that this product is fit for any particular

purpose. Such statements, representations or descriptions are informational only, and are

not made or given as a warranty of this product in any way. In addition, Cooper-Atkins

Corporation does not warrant expressly, or by implication, that the electronic instrument will

meet or comply with the requirements of any safety code or regulation of any country, or any

municipality, State, Federal or other jurisdiction. Furthermore, Cooper-Atkins Corporation shall

not be responsible for any loss or damage to customer, directly or indirectly, and whether

arising in contract or tort.

MFM300 INSTRUMENT SERVICE INFORMATION

If your MFM300 requires service, send the instrument freight prepaid to Cooper-Atkins

Corporation. For warranty service, also send proof of date and location of purchase. The

instrument will be repaired or replaced, at the option of Cooper-Atkins Corporation, and

returned via least cost transportation.

For non-warranty service, send instrument freight prepaid to Cooper-Atkins. An estimate

to repair the instrument will be provided before repairs are initiated. The instrument will

be returned via least cost transportation. There is a 90-day warranty on repaired MFM300

instruments.

PRODUCT REGISTRY

Please register your Cooper-Atkins product today. It is the only way to notify you of future

software / product up-grades. There is no fee to register. Go to: www.cooper-atkins.com/

registry.asp, and complete the on-line form.

10

MFM300

Instrumento Multifuncional

MFM300 Gaurantía de Guía del usuario e Instrumento

11

Loading...

Loading...