Cooper STX-1 User Manual

STX Digital Strap Tension Meter

1.0 SAFETY

WARNING: When using cordless, electronic instruments, always follow basic safety precautions to reduce the risk

of fire, electric shock and personal injury.

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE. Before use, ensure all users read and understand

this manual, as well as any labels packaged with, or attached to the instrument.

1. KNOW YOUR INSTRUMENT. Read this manual carefully to learn your tension meter’s applications and

limitations, as well as the potential hazards associated with this type of instrument.

2. AVOID DANGEROUS ENVIRONMENTS. Do not use your instrument in the presence of explosive

atmospheres (gaseous fumes, dust or flammable materials). Do not submerge your instrument in liquids.

3. USE THE RIGHT TOOL OR INSTRUMENT. Do not use this instrument to do a job for which it is not

recommended.

4. CHECK FOR DAMAGED PARTS. Inspect instrument before use. Check for any binding of moving parts,

improper mountings, broken parts and any other condition that may affect operation. Do not use a damaged

instrument. Tag damaged instrument “DO NOT USE” until repaired. For repair, send instruments directly to

Cooper Instruments.

5. GUARD AGAINST ELECTRIC SHOCK when connecting power supply to voltage source.

6. MAINTAIN INSTRUMENT CAREFULLY. Keep handles dry, clean and free from oil and grease. Do not

lubricate. All roller bearings are sealed.

7. DO NOT USE INSTRUMENT IF it has received a sharp blow, been dropped or damaged in any way. Do not

disassemble. Incorrect reassembly may result in the risk of electric shock, fire or exposure to battery fluids. If

instrument is damaged return it to Cooper Instruments for repair.

8. STANDARD POWER SUPPLY IS RATED FOR 100-240 VAC and includes several “blades” allowing use with

European, US, Australian and other plug configurations.

9. DO NOT USE INSTRUMENT WHEN TEMPERATURE is below 35ºF or above 115ºF. Charging in direct

sunlight or near a heat source will not produce a full charge and may permanently damage battery pack.

10. STORE INSTRUMENT AND CHARGER in a cool, dry place. Do not store where temperatures may exceed

120°F or fall below 35ºF for storage times less than one month. Never let LCD display or battery pack assembly

freeze.

11. WARNING: Only use battery pack assemblies provided by Cooper Instruments with your meter (P/N: STX-15).

Other types of batteries may explode, causing personal or property damage if charged in this device.

2.0 CHARGING INSTRUMENT BATTERIES

1. Connect power supply cable to instrument.

2. Plug the power supply into a 100 – 240 VAC outlet.

3. Full charge of battery assembly takes approximately eight hours.

CF 124 1/19/12

1

4. Battery pack assembly cannot be overcharged, however instrument will remain on while plugged into power

supply.

5. Fully charged battery assemblies will operate approximately six hours +/- 20% depending upon usage and

backlighting intensity.

6. Battery charge level is indicated in the upper, right-hand corner of the display.

3.0 OPERATION: QUICK START

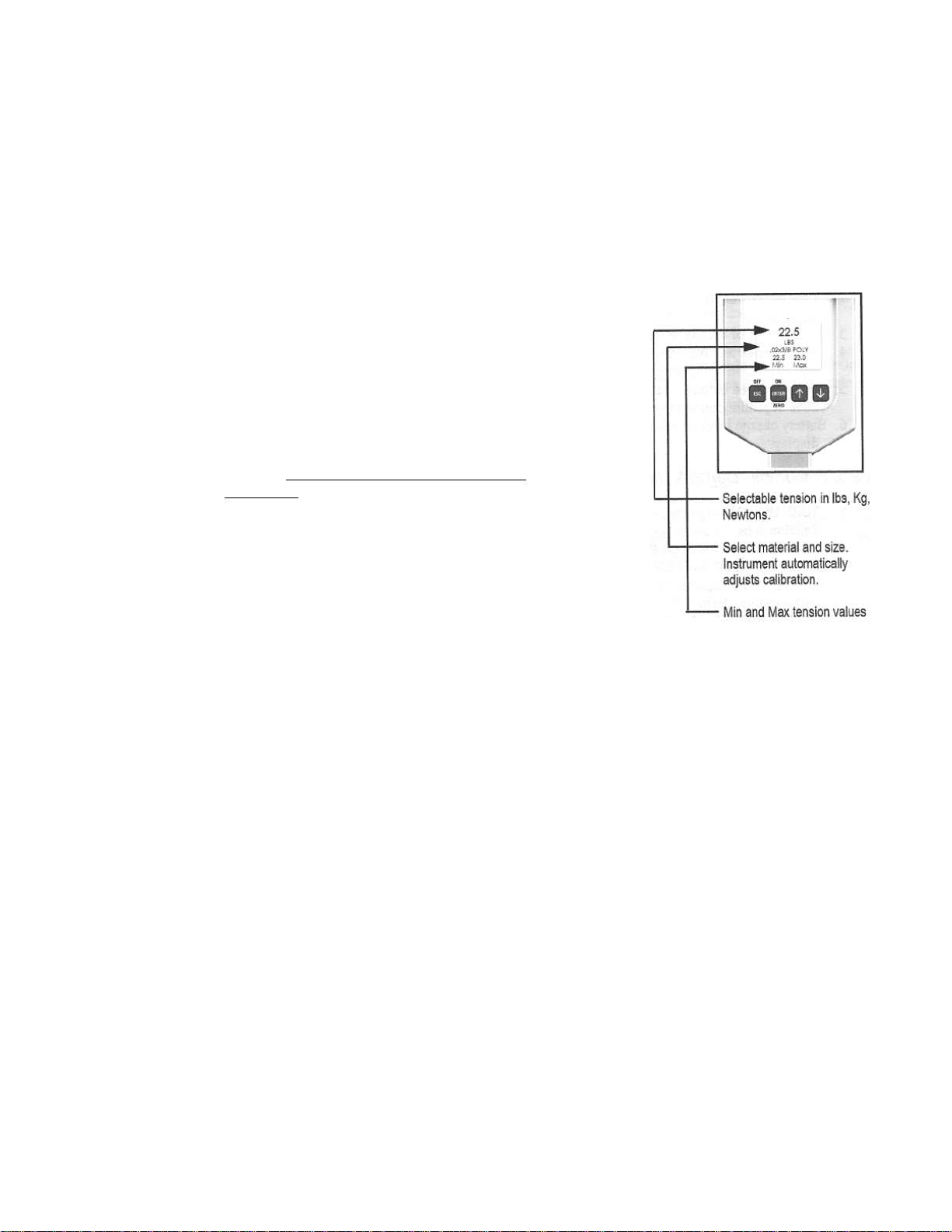

1. TURN UNIT ON by pressing ON button. Display shows: Tension (Lbs, Newtons, or Kilograms), Cable size

selected and battery charge level.

2. MEMORY FUNCTION. Depress the MEMORY button to store and display up

to five separate tension readings, plus the average (AVG) of these stored

values.

3. MOVE BETWEEN SCREENS by pressing either the ↑ or ↓ arrows. To make,

or enter a selection, depress the ENTER key. To exit a setting, depress the

ESCAPE key.

4. ZERO THE INSTRUMENT before taking readings by holding the instrument

in the attitude in which it will be used, and with no load applied press the

button marked ZERO.

5. READING OF TENSION. Variations in materials and sizes affect tension

readings. It is essential to select the correct material and size

calibration menu before use

6. SELECT MATERIAL. From the Main Display (first screen seen when unit is

turned on) use the ↑ or ↓ keys until SELECT MATERIAL is displayed. Press

ENTER. Next toggle through the various selections using the ↑ or ↓ arrows

until correct strap size is highlighted, and press ENTER to make your

selection. If your specific material is not listed, follow the calibration

instructions included at the end of these instructions, or send a sample and

the instrument to Cooper Instruments for a custom calibration.

7. SELECTING TENSION UNITS IN LBS, KILOGRAMS or NEWTONS. Press the ↑ or ↓ keys until TENSION

UNITS is displayed. Press ENTER. Next, select: Lbs, Kilograms or NEWTONS and ENTER selection.

8. ENGAGE INSTRUMENT TO TENSIONED MATERIAL. For best accuracy hold the instrument in the attitude

the measurement will be taken in and press ZERO. Then engage the tensioned material by slipping or guiding

the instrument’s three contact elements onto the strap. Proper routing of the strapping material is: under the

two, outside guide pins, and over the center contact element.

, or values may be incorrect.

from the

4.0 ADDITIONAL TECHNICAL INFORMATION

1. SPEEDING UP OR SLOWING DOWN DISPLAY LCD REFRESH RATES -DAMPENING ADJUSTMENT. To

either speed up or slow down the rate at which tension values refresh on the display. Use the ↑ or ↓ keys,

select SETUP, and press ENTER. Next select Dampening and after entering this selection, choose the refresh

rate from: 1Hz, 2Hz or 5Hz. When new rate is highlighted, press ENTER.

2. AUDIO. Turn on or off audio beep (with key inputs) by selecting: SETUP, then select Audio, and finally either

select ON or OFF.

3. BACKLIGHTING INTENSITY. Increase or decrease backlighting intensity by selecting: SETUP, then

BACKLIGHT, and finally intensity level.

4. DATA LOGGING. (Optional feature). From the Main display use the UP or DOWN keys until Data Logging is

displayed. Press ENTER. Next, select Logging Rate and select Hz rate which your data will be collected in

(choices are from 1Hz to 100Hz). Next select Duration and select the time period the data will be collected

over by using the UP or DOWN keys. Finally select Begin Logging when you are ready to collect your data.

Note: You can stop collecting data at any time by simply depressing ESC (escape). Collected data will remain

in memory, regardless if instrument is turned off, and will only be overwritten once new data is collected. To

view collected data select View Data Log and press ENTER. Logged Data can also be uploaded to your

computer via the RS-232, serial port. Refer to Sec 4.12, Uploading logged data, for specific instructions.

5. DISPLAY CONTRAST. Increase or decrease LCD display contrast by selecting: SETUP, then select

CONTRAST, and finally manipulate contrast using the ↑ or ↓ keys. Remember to ENTER your new setting.

CF 124 1/19/12

2

6. VERSION. Instrument Model No. along with software version information can be viewed under SETUP and

then selecting Version.

7. CUSTOM CALIBRATIONS. Calibrations are password-protected to prevent unintended changes. See Section

7.0 for step-by-step instructions, or contact your Metrology Department or Cooper Instruments for assistance. If

you only want to verify your instrument’s accuracy refer to: How To Check Accuracy, Section 7.0.

8. CUSTOM CALIBRATION NAMES. Custom Calibrations (usually listed as Custom 0 - 9) can be renamed so

that the Main Display indicates your name for the calibration instead of Custom 1, 2, etc. From the Main Display

use the ↑ and ↓ keys until SETUP is selected. Press ENTER. Using the ↑ and ↓ keys select Custom Names.

Press ENTER. Next, using the ↑ and ↓ arrows select calibration number, or previous name you wish to rename.

Press ENTER. Using the ↑ and ↓ keys select the number, letter or character for the beginning of your new

name. Press ENTER. Follow the same procedure for each sequential letter or space of your new description.

Continue pressing ENTER until all spaces in the description have entered values. Once your new name has

been entered you will be returned to the SETUP screen. To select your new calibration follow the procedures

outlined in Sec.3.6.

9. MONITORING TENSION THROUGH THE ANALOG OUTPUT (Optional feature). Output values are: 0 – 5

VDC or 4 – 20 mA. Connect Analog Output Cable to receptacle located on the bottom side of instrument.

Connect output cable leads to the analog input of your measurement or control device. The RED lead is

Voltage +, the WHITE lead is mA, and the BLACK lead is ground. From the main display use the ↑ and ↓ keys

until you reach SETUP. Press ENTER. Next using the ↑ and ↓ arrows select ANALOG OUTPUT. Press

ENTER. Using the ↑ and ↓ arrows select from: ANALOG TENSION CURRENT OR ANALOG TENSION

VOLTAGE. Once correct selection is made, press ENTER.

10.

CALIBRATION OF ANALOG OUTPUT. (Optional feature) From Main Display press the ↑ and ↓ keys until you

reach SETUP. Press ENTER. Press the ↑ and ↓ keys until you reach CALIBRATE ANALOG. Press ENTER.

Using the ↑ and ↓ keys adjust display to show the value at which the instrument reads maximum current or

voltage. Press ENTER.

11. SERIAL DATA COLLECTION (RS-232 option). (Optional feature) Instruments outfitted with the optional RS-

232 feature (designated with a –E in the part number) support serial communications as follows:

A. The baud rate is 9600 with no parity bit, 8 data bits and 1 stop bit (9600 8N1).

B. Serial communications will work with most PCs with a cable up to 15 feet long.

C. Setting the dampening rate on the instrument to “1 Hz + Serial”, “2 Hz + Serial” or “5 Hz + Serial” will

cause the instrument to output the tension values at a rate of once, twice or five times per second,

respectively. The dampening rate can be set by going to the SETUP menu, selecting DAMPENING,

adjusting the value of the dampening rate with the ↑ and ↓ buttons and then pressing the ENTER button.

D. The units output serially will be the same units that are selected in the “Tension Units” menu. The currently

selected tension units (such as Lbs, Kilograms or Newtons) are also displayed on the main tension screen.

E. Perform the following steps in order to log serial data from the instrument using Hyper Terminal on a PC

and put it into a Microsoft Excel spreadsheet:

1) Ensure that the dampening rate is set to “1 Hz + Serial”, “2 Hz + Serial” or “5 Hz + Serial”.

2) Connect the serial cable from the instrument to a serial port on your PC.

3) Go to the Windows® Start Menu and choose Programs->Accessories->Communications->Hyper

Terminal®

4) In the Connection Description dialog box that pops up, type in a name for the new connection (you can

use any name you wish to describe this file) and press the OK button.

5) In the Connect To dialog box that pops up next, go to the drop down menu labeled “Connect Using:”

and select the serial port you connected the cable to in step 2. It is most likely that you are connected

to COM1.

6) In the COMx Properties dialog box that pops up next, set the “Bits per second:” to 9600, the “Data bits:”

to 8, the “Parity:” to None, the “Stop bits:” to 1 and the “Flow Control:” to None.

7) Click the Apply button and then click the OK button.

8) You should now see tension values appearing in the Hyper Terminal window.

9) When you are finished collecting data, close Hyper Terminal.

10) To save the data in Microsoft Excel® format, use Microsoft Excel® to open the file you saved the data

log in and save it as an Excel® file.

12. UPLOADING LOGGED DATA (Optional Feature) via RS-232, SERIAL COMM UNICATIONS.

a. Refer to the previous section, Sec. 4.11, Serial Data Collection (RS-232 option) and configure

communication protocols as outlined. Note: Step c has no effect on transferring stored data and can be

adjusted to any setting.

b. To retrieve, or upload logged data from the instrument, send a lower case ’d’ .

CF 124 1/19/12

3

Loading...

Loading...