Page 1

LXT 980 and LXT 981

TORQUE SENSOR

USER’S GUIDE

www.cooperinstruments.com

PH: (540) 349-4746 • FAX: (540) 347-4755

Page 2

CONTENTS

1.0 INTRODUCTION ..................................................................................................................................................................................... 3

2.0 MODEL LXT 980 / LXT 981 ................................................................................................................................................................... 3

3.0 TECHNICAL CHARACTERISTICS OF THE SENSOR ................................................................................................................. 4

4.0 VERSIONS AND ORDE R OPTI ONS ................................................................................................................................................... 5

5.0 AVAILABLE OPTIONS .......................................................................................................................................................................... 6

5.1 Optional Signal Outputs ...................................................................................................................................... 6

5.2 Optical angle sensor ........................................................................................................................................... 6

6.0 DIMENSIONS ............................................................................................................................................................................................ 7

7.0 CONNECTION PLAN .............................................................................................................................................................................. 9

8.0 OPERATING INSTRUCTIONS ............................................................................................................................................................. 9

8.1 Field of Application .............................................................................................................................................. 9

8.2 Scope of Delivery ................................................................................................................................................ 9

8.3 Installation and Removal ................................................................................................................................... 10

8.4 Offset Adjustment ............................................................................................................................................. 10

8.5 Interface Description ......................................................................................................................................... 10

8.6 Operation (in regular case or in optimal case) .................................................................................................. 10

8.7 Irregular Operation, Measures against Disturbance ......................................................................................... 10

8.8 Commissioning ................................................................................................................................................. 10

8.9 Service / Maintenance ...................................................................................................................................... 11

8.10 Disposal .......................................................................................................................................................... 11

8.11 Handling and Transport .................................................................................................................................. 11

8.12 Precautions ..................................................................................................................................................... 11

9.0 CALIBRATION AND ACCURACY CLASS .................................................................................................................................... 11

10.0 WARRANTY REPAIR POL ICY ...................................................................................................................................................... 13

CF 189 ii Rev. E; Dec. 12, 2011

Page 3

1.0 INTRODUCTION

With this torque sensor the effective torque on the gauge bar can be measured bi-directionally

independent from rotational speed. The sensor is delivered as a complete unit with corresponding

connecting cable and key stones. The transmitting shaft, the contact-free signal pick-up and the analog

signal processing are integrated into the sensor structure. No external amplifier is needed. Based on

magnetic field and therefore completely non-contact measurement principle, the sensor works totally

maintenance-free over a wide temperature range.

• Torque sensor with non-contact principle

• Measurement range from 0 to 2000Nm bi-directionally

• Accuracy classes

o Series 3000: 0,2

o Series 4000: 0,1

• High tolerable dynamic loads

• Maintenance-free operation

• Torque measurement up to 10.000 rpm

• Integrated signal conditioning

• Optional angle sensor

• Optional sensor outputs PWM, 4...20mA

• Temperature range from -30°C to +85°C

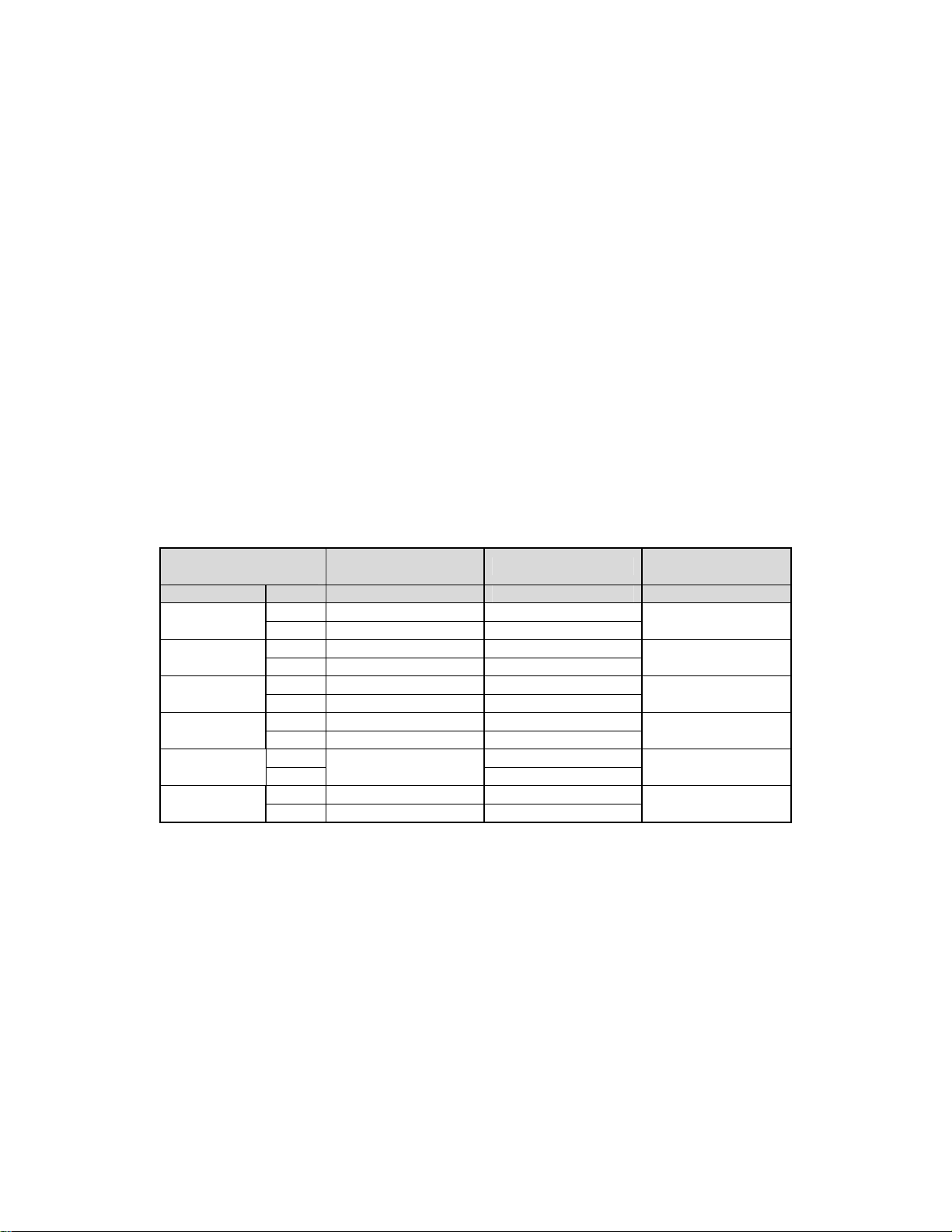

2.0 MODEL LXT 980 / LXT 981

Model

LXT 980 / LXT 981

Shaft Unit Bi-directional (+/-) Bi-directional (+/-) [rpm]

15 mm

15 mm

25 mm

25 mm

40 mm

40 mm

[Nm]

[ft-lb]

[Nm]

[ft-lb]

[Nm]

[ft-lb]

[Nm]

[ft-lb]

[Nm]

[ft-lb]

[Nm]

[ft-lb]

Nominal-Torque Max. overload Rotational Speed

50 150

37 111

100 150

74 111

250 750

184 553

500 750

369 553

1000 3000

738 2213

2000 3000

1475 2213

10.000

10.000

8.000

8.000

5.000

5.000

CF 189 3 Rev. E; Dec. 12, 2011

Page 4

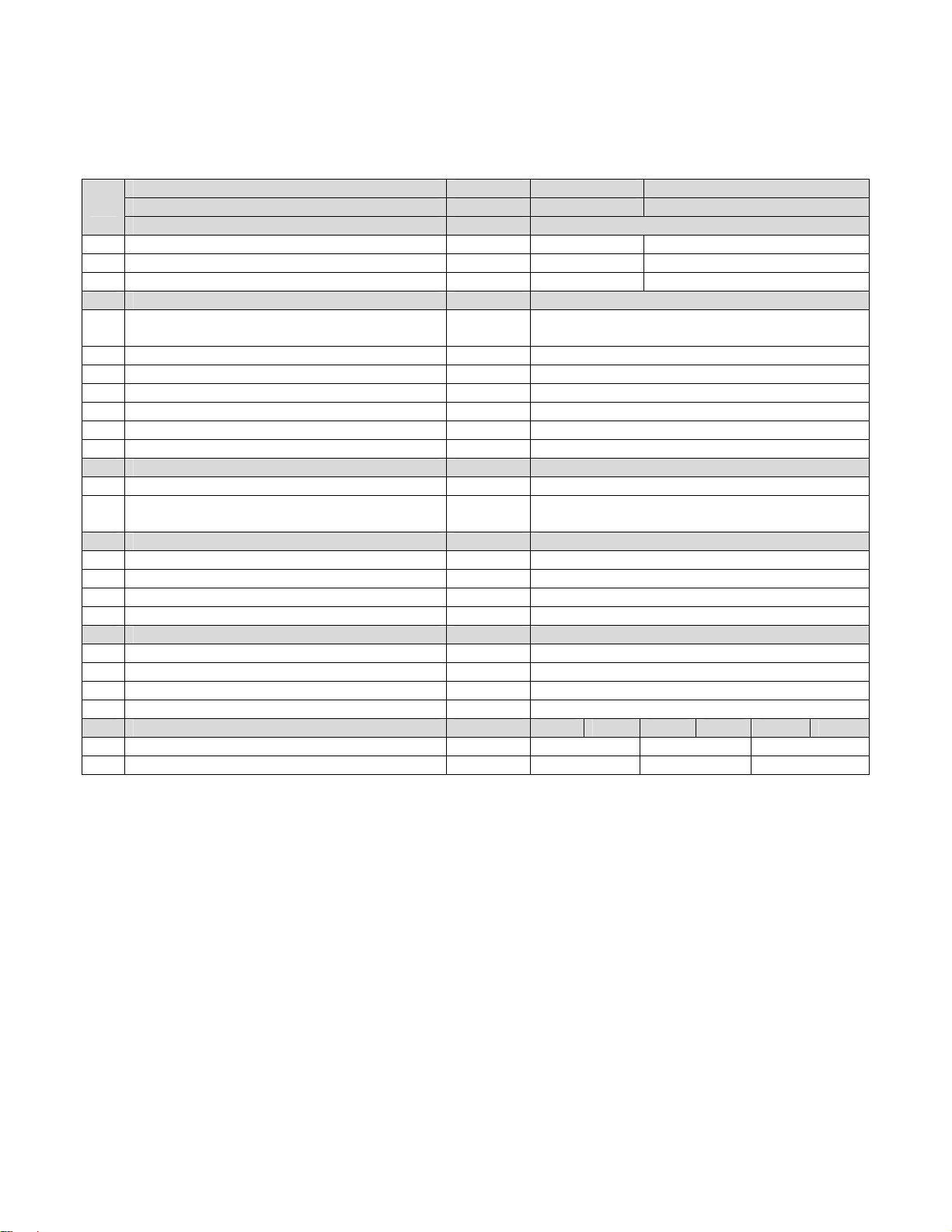

3.0 TECHNICAL CHARACTERISTICS OF THE SENSOR

LXT 980 LXT 981

No.

Accuracy class1) 0.1 0.2

Unit Value

1 Linearity deviation incl. hysteresis

2 Rotational Signal Uniformity (RSU)

3 Repeatability

%ME*

%ME*

%ME*

Output signal in general Unit Value

4 Frequency range, -3dB point, Bessel

Hz 0…2500

characteristics

5 Analog signal V 0… 10

6 Signal at torque +/- Zero2) V ≈ 5

7 Signal at positive nominal torque V ≈ 9

8 Signal at negative nominal torque V ≈ 1

9 Calibration parameter mV/Nm ≈4000mV / Measurement range

10 Output resistance Ω 62

Effect of temperature Unit Value

11 Zero point drift over temperature %/10K <0.2

12 Signal drift over temperature within

operational temperature range

Power supply Unit Value

3)

%/10K <0.5

13 Supply voltage VDC 11…28

14 Current consumption (max.) mA 150

15 Start-up peak mA < 200

16 Absolute max. supply voltage VDC 30

General information Unit Value

17 Degree of protection acc. to EN 60529 IP 50 (64 if required)

18 Reference temperature °C +15…+35

19 Operational temperature range °C -30…+85

20 Storage temperature range °C -30…+100

Nominal torque M (bi-directional) Nm 50 100 250 500 1000 2000

21 Weight g 1280 2030 5800

22 Moment of inertia round shaft kg*mm2 5,9 59,5 626

%ME: related to a full scale measurement range

1) The accuracy class implies that taken separately both the linearity deviation as well as the rotational

signal uniformity is either lower than or equal to the value of the accuracy class. The accuracy class is

not to be identified with the classification following DIN 51309 or EA-10/14.

2) Zero point can be set to 5V by pressing the Tera-button.

3) The factor of transmission declines linearly up to a maximum of 0.5% / 10K with rising temperature

due to the reduction of the elasticity.

<± 0.2 <± 0.1

<± 0.2 <± 0.1

<± 0.5 <± 0.5

CF 189 4 Rev. E; Dec. 12, 2011

Page 5

5)

6)

EMI / EMC Unit Value

Tested Standards

23 EN 61000-6-3: 2007 - PASSED

24 EN 55011: 2009 + A1: 2010 class B - PASSED

25 EN 61000-6-2: 2005 - PASSED

26 EN 61000-4-2 (ESD) : 2009 - PASSED

27 EN 61000-4-3 (HF) : 2006 + A1: 2008 + A2: 2010 - PASSED

28 EN 61000-4-4 (BURST): 2004 + A1: 2010 - PASSED

29 EN 61000-4-5 (Surge): 2006 - PASSED

30 EN 61000-4-6: 2009 - PASSED

31 EN 61000-4-8: 2010 - PASSED

32 EN 61000-4-11: 2004 - PASSED

Load limits4) Unit Value

33 Maximum measurable torque % 110

34 Maximum torque, related to nominal torque % 300

35 Ultimate torque % 500

36 Maximum load of key stone (Application factor 1,5) % 180 200 200

4) Based on the non-contact measurement principle the torque sensor is quite insensitive to bending

and shearing forces. Self-aligning couplings are recommended in case of dynamic loads.

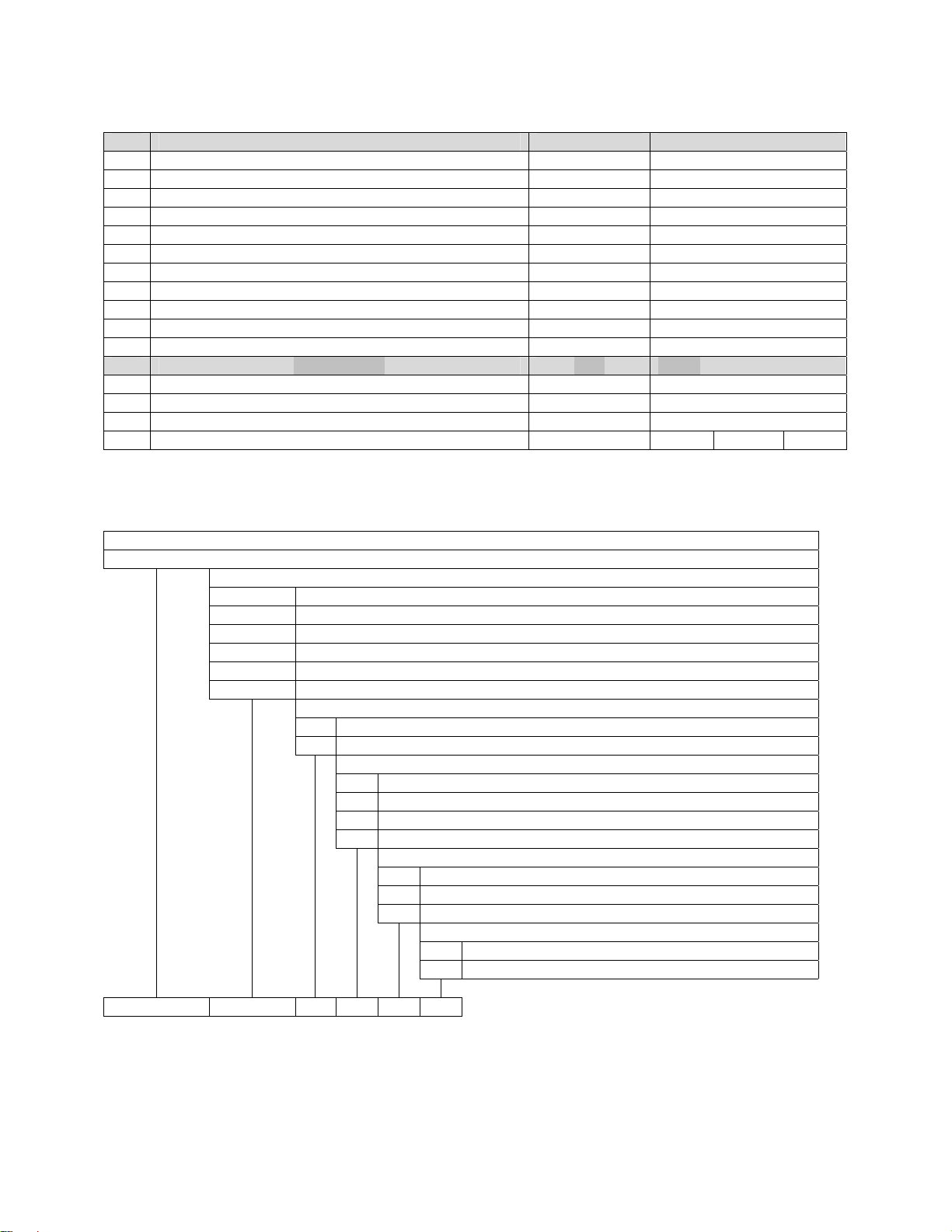

4.0 VERSIONS AND ORDER OPTIONS

LXT 980 Accuracy 0.2%

LXT 981 Accuracy 0.1%

5 0 Nm

1 0 0 Nm

2 5 0 Nm

5 0 0 Nm

1 0 0 0 Nm

2 0 0 0 Nm

0 without angle sensor

1 with angle sensor 360 P / Rev. (optical)

A analog voltage output

S additional current output 4-20mA

P additional PWM output

F additional Frequency output 20-100kHz

0 Standard round shaft ends with key stone

1 Square shaft ends

2 Hexagon shaft ends

0 IP50

1 IP64 (without angle sensor)

5) Only the analog voltage output is calibrated by default. All other output signals are adjusted according

to the analog voltage output.

6) The square and hexagon shaft ends are not in stock. They must be ordered separately first and their

lead time could be 6 – 8 weeks.

Option 1: Measurement range

Option 2: Angle sensor

Option 3: Output signal

Option 4: Shaft ends

Option 5: Protection class

CF 189 5 Rev. E; Dec. 12, 2011

Page 6

5.0 A V AILABLE OPTIONS

5.1 Optional Signal Outputs

In addition to the analog output signal the LXT 980 and LXT 981 can also be delivered with another

option output signal as listed below.

Frequency Output

Description Unit Value

Basic frequency kHz 60

Measurement range kHz 20… 100

Calibration parameter kHz/Nm 40 / measurement range

Current output

Description Unit Unit

Signal at torque = zero mA 12

Measurement range mA 4… 20

Calibration parameter mA/Nm 8 / measurement range

PWM signal output

Description Unit Unit

Carrier frequency Hz 980

Signal at torque = zero % 50

Measurement Range % 10… 90

Error indication % 95

Calibration parameter %Nm 40 / measurement range

5.2 Optical angle sensor

CF 189 6 Rev. E; Dec. 12, 2011

Page 7

7)

2

2

7)

2

2

x

2

2

7)

2

2

Cycles (optical) n 360

1

Cycle error ΔC Degree

2

Pulse width error ΔP Degree

3

State width error Δs

4

Phase error Δφ Degree

5

Index pulse width P

6

Ch I rises after Ch B or Ch A falls t

7

Ch I rises after Ch A or Ch B rises t

8

Rise-time t

9

Fall-time t

10

Symbol Unit Regular Min. Max.

0.8x10

1.9x10

Degree7) 1.4x10

0.6x10

Degree7) 0.25 0.17 0.33

0

ns 100 10 1000

1

ns 300 10 1000

2

ns 180

r

ns 50

f

-

4.2x10

-

8.3x10

-

8.3x10

-

4.2x10

7) Degree is with respect to the rotation.

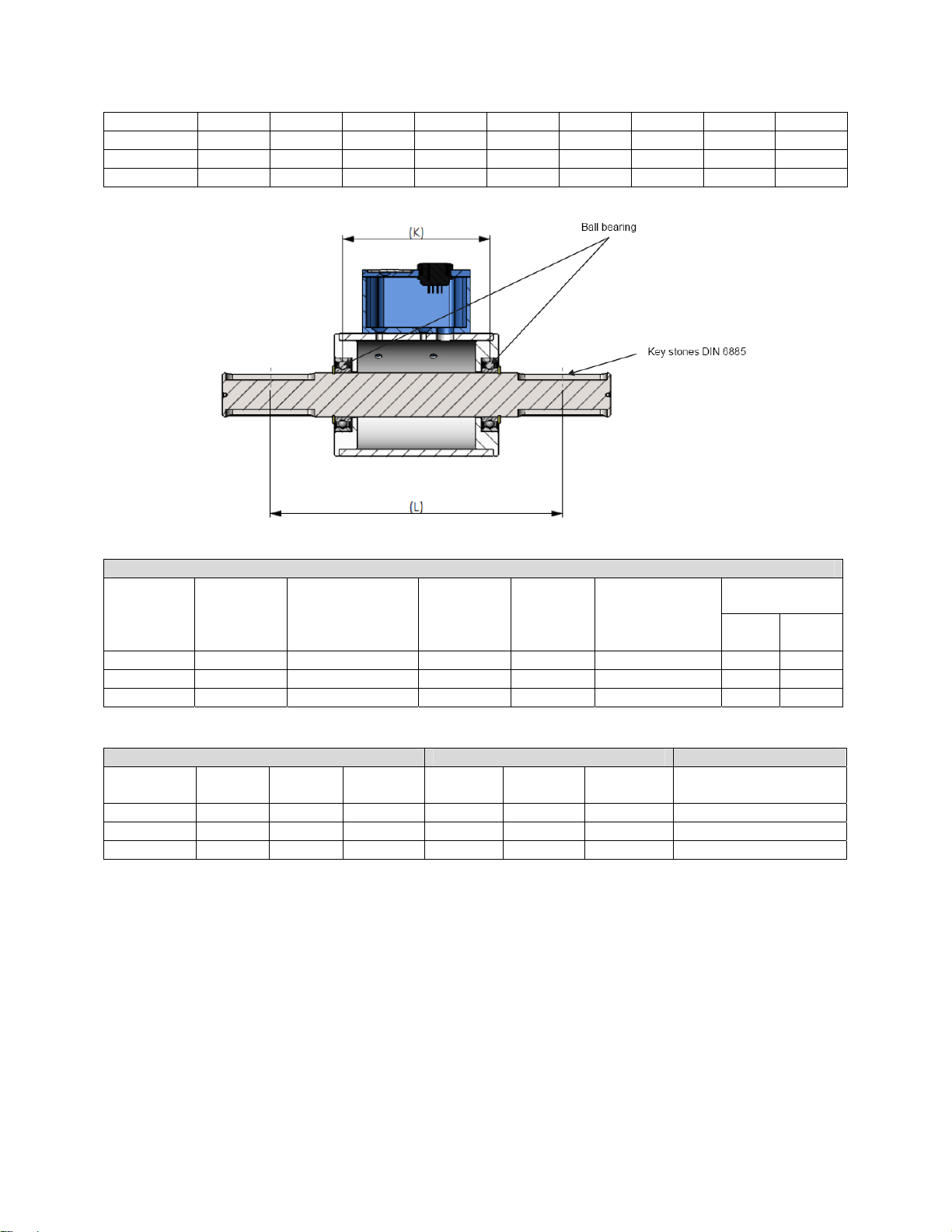

6.0 DIMENSIONS

-

-

-

-

Dimensions (in mm):

50 Nm

100 Nm

CF 189 7 Rev. E; Dec. 12, 2011

A B C D E F G H I

160 93 33,5 15g6 96 60 61 40 57

160 93 33,5 15g6 96 60 61 40 57

Page 8

250 Nm

500 Nm

1000 Nm

2000 Nm

220 93 63,5 25g6 106 70 61 40 67

220 93 63,5 25g6 106 70 61 40 67

350 130 110 40g6 126 90 80 60 87

350 130 110 40g6 126 90 80 60 87

Ball bearing

Load rating

[kN]

Dyn. C Stat.

C

0

Shaft

ending

Ø 15 mm

Ø 25 mm

Ø 40 mm

Distance

K [mm]

Description

Outer

diameter

[mm]

Inner

diameter

[mm]

Max. rotation

of bearing

[rpm]

82.0 E2.6202-2Z/C3 35 15 25,000 7.8 3.75

83.4 61905-2Z 42 25 18,000 7.02 4.3

114.6 6008-2Z 68 40 11,000 17.8 11.6

Dimensions of key stone groove (mm) Key stone DIN 6885 Key stone-position

Shaft

Width Depth Length Height Length Number Distance L

ending

Ø 15 mm

Ø 25 mm

Ø 40 mm

5N9 3 25,5 5 25 1 130,5

8N9 4 50,5 7 50 2 165,5

12N9 5 90,5 8 90 2 252,0

It is recommended to tolerate the hub diameter with H7-clearance. In the situation of dynamic

loads the shaft should be supported with a friction grip, a form lock or a coupling.

CF 189 8 Rev. E; Dec. 12, 2011

Page 9

7.0 CONNECTION PLAN

Pin assignment at Sensor.

Presentation: Top view

Connection example

Model Binder Series 423/723/425

Item number: 09-0132-90-12

Color code according to DIN 47100

Pin Color Description Value

A White Supply voltage

V

CC

B Brown Ground GND

C Green Analog Out 0V…10V

D Yellow Analog GND

E Grey PWM / Frequency /

4-20mA

F Pink Angle Ch A / 0V…5V

G Blue Angle Ch I 0V…5V

H Red Angle Ch B 0V…5V

I Black -

K Violet For internal use only Do not connect

L Grey-Pink For internal use only Do not connect

M Red-Blue Digital GND

11V…28V

8.0 OPERA TING INSTRUCTIONS

8.1 Field of Application

The torque sensor is intended for the use in industrial applications. (e.g. test bench).

8.2 Scope of Delivery

The torque sensor set consists of the sensor itself (signal pick-up and signal processing integrated into

sensor housing), one connecting cable with a soldered plug, key stones and the instruction manual.

CF 189 9 Rev. E; Dec. 12, 2011

Page 10

8.3 Installation and Removal

Make sure to install the sensor shafts exactly with the proper aligned connecting shafts. The key stone

adapter / square endings of the connecting shafts are to be attached forceless to the corresponding ones

of the sensor. The sensor is not designed as a step bearing. No external axial or radial force should be on

the housing of the sensor by fixing it. In case that the bending or radial forces could not avoided the ball

bearing of the sensor must be double-checked. The allowed bearing forces are listed in (Chapter 6.

Dimensions). The M4-screw threads on the side are only for fixing the sensor housing and keeping it from

distortion. A maximum cable length of 3m must not be exceeded. Using a cable or connector other than

supplied by NCTE, or a similar cable that is of a different length may affect the overall performance of the

sensor.

DO NOT REMOVE THE SHAFT WITH TORQUE APPLIED TO THE SENSOR.

8.4 Offset Adjustment

If required the zero point output signal (5V) can be adjusted by pressing the Tare-button. By factory

default the sensor is set to 5V at Null torque.

8.5 Interface Description

Mechanical connection:

The key stone adapters on both ends of the measurement shaft are intended for torque transmission.

Electrical connector:

On the sensor housing there is a 12-pin socket for the power supply and the signal output.(see Chapter 7.

Connection Plan).

8.6 Operation (in regular case or in optimal case)

Optimal measurement parameters may be achieved when the sensor is applied in accordance to the

specification. Use the sensor only for short periods of time at the maximum rotational speed. By

compliance with the specification the sensor works generally trouble-free and maintenance-free.

8.7 Irregular Operation, Measures against Disturbance

The presence of external electromagnetic or magnetic fields can lead to irregular measurement results.

The mechanical overload on the sensor (e.g. exceeding of maximum allowed torque or severe vibrations)

may cause damage to the sensor and in consequence the incorrect signal output. In such cases the

sensor must be reset (see Point 8.4 Offset Adjustment). If this does not help, do not open the sensor but

contact Cooper Instruments directly for assistance.

8.8 Commissioning

After sensor installation pay attention to the followings:

• Switch on the power supply unit and check the supply voltage. Peak voltage to the sensor must

be avoided! Be sure to verify the power supply voltage before connecting the sensor!

• Connect the sensor to the power supply unit by using the delivered cable.

• Connect the sensor output to a high-resistance device such as an A/D converter, oscilloscope,

PC measurement board. The sensor should be in mechanical unloaded state while connecting it.

CF 189 10 Rev. E; Dec. 12, 2011

Page 11

Tare function and error indication:

The LXT 980/981 contains a LED button on the housing surface. Pressing the button will set the signal

output to 5V. The illumination of the button serves as a function / malfunction indicator.

Functional indicator:

LED off: Missing power supply or sensor is damaged.

LED on: Sensor is ready.

Error indicator:

LED flashes: The sensor is not ready.

Flashing of LED can have several possible causes. Various causes are interpreted through a flash code.

After each flash code the LED makes a short pause before repeating the code.

2x flashing: Magnet field sensors defective.

4x flashing: Electronics defective.

8.9 Service / Maintenance

Service-contact:

Tel.: 800-344-3921

Fax: 540-347-4755

8.10 Disposal

For purposes of disposal please send the device back to Cooper Instruments.

8.11 Handling and Transport

While handling, storing and transporting keep sensor away from magnetic and electromagnetic fields

which may exceed the allowed maximum range of EMC listed in Section 3.0, “Technical Characteristics of

the Sensor.”

8.12 Precautions

• Do not open the sensor under any circumstances.

• Do not remove or loosen the locking rings on the shaft ends.

• The mounting nut of the socket as well as the fixing screws should not be loosened or tightened.

• Use only a separate power supply for the sensor

• Use the sensor only according to the specification (Section 3.0 - Technical Characteristics of the

Sensor).

• Keep the sensor away from magnetic and electromagnetic fields which may exceed the allowed

maximum range of EMC (Section 3.0 - Technical Characteristics of the Sensor)

• The sensor is not designed as a step bearing. The existing fixing possibilities serve exclusively for

preventing the sensor from distortion.

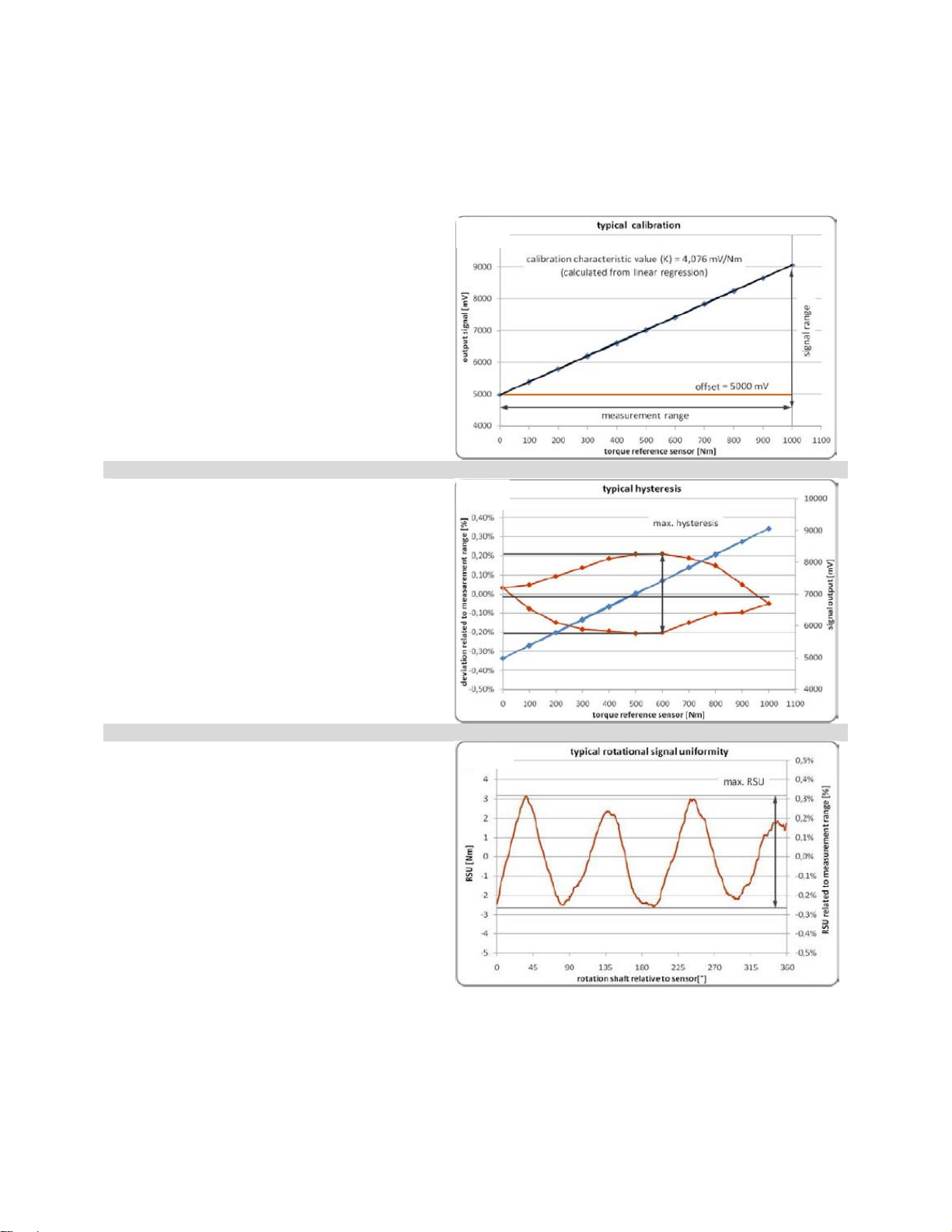

9.0 CALIBRATION AND ACCURACY CLASS

The exact data about the sensor is given in the enclosed factory calibration certificate. Except the sensor

type this certificate also contains the exact calibration data. Each sensor has its own calibration value

CF 189 11 Rev. E; Dec. 12, 2011

Page 12

which is listed in the calibration certificate as well as on the label of the sensor. The calibration certificate

also shows the accuracy of each sensor. The accuracy class of a Cooper Instruments torque sensor

means that the largest single deviation of all values represented in percentage is either smaller than or

equal to the value listed in the accuracy class.

Calibration value:

The calibration characteristic value shows how

much the output signal changes per torque.

There is no difference whether the torque is

directed to the left or to the right.

Hysteresis:

Hysteresis expresses the biggest difference

between upwards and downwards branches at

one torque level in percentage.

Rotational Signal Uniformity (RSU):

RSU is a signal variation created during 360°

rotation of the sensor shaft without torque. The

modulation is the difference between minimal

and maximal values during this single rotation.

RSU is generated by small homogeneities in

the magnetic field and depends mostly on the

property of the sensor shaft.

CF 189 12 Rev. E; Dec. 12, 2011

Page 13

10.0 WARRANTY REPAIR POLICY

Limited Warranty on Products

Any Cooper Instruments product which, under normal operating conditions, proves defective in material

or in workmanship within one year of the date of shipment by Cooper will be repaired or replaced free of

charge provided that a return material authorization is obtained from Cooper and the defective product is

sent, transportation charges prepaid, with notice of the defect, and it is established that the product has

been properly installed, maintained, and operated within the limits of rated and normal usage.

Replacement or repaired product will be shipped F.O.B. from our plant. The terms of this warranty do not

extend to any product or part thereof which, under normal usage, has an inherently shorter useful life than

one year. The replacement warranty detailed here is the buyer’s exclusive remedy, and will satisfy all

obligations of Cooper whether based on contract, negligence, or otherwise. Cooper is not responsible for

any incidental or consequential loss or damage which might result from a failure of any and all other

warranties, express or implied, including implied warranty of merchantability or fitness for particular

purpose. Any unauthorized disassembly or attempt to repair voids this warranty.

Obtaining Service under Warranty

Advance authorization is required prior to the return to Cooper Instruments. Before returning the item,

contact the Repair Department c/o Cooper Instruments at (540) 349-4746 for a Return Material

Authorization number. Shipment to Cooper shall be at buyer’s expense and repaired or replacement

items will be shipped F.O.B. from our plant in Warrenton, Virginia. Non-verified problems or defects may

be subject to a $150 evaluation charge. Please return the original calibration data with the unit.

Repair Warranty

All repairs of Cooper products are warranted for a period of 90 days from date of shipment. This warranty

applies only to those items that were found defective and repaired; it does not apply to products in which

no defect was found and returned as is or merely recalibrated. It may be possible for out-of-warranty

products to be returned to the exact original specifications or dimensions.

* Technical description of the defect: In order to properly repair a product, it is absolutely necessary for

Cooper to receive information specifying the reason the product is being returned. Specific test data,

written observations on the failure and the specific corrective action you require are needed.

CF 189 13 Rev. E; Dec. 12, 2011

Loading...

Loading...